- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Premium Medical Titanium Plate – Built for Critical Surgeries

For precise and reliable surgical treatments, medical titanium plates are the gold standard. Surgeons use these titanium alloy implant devices for life-saving surgeries because of their biocompatibility, corrosion resistance, and mechanical strength. Medical titanium plates have transformed orthopedic, craniofacial, and dental operations by integrating seamlessly with human tissue and retaining structural integrity over decades.

Understanding Medical Titanium Plates: Features and Benefits

The apex of surgical embed innovation, therapeutic titanium plates are planned for significant applications where disappointment is not an alternative. These precision-made gadgets are made from titanium amalgams, outstandingly Review 5 (Ti-6Al-4V), Review 5 ELI, and Review 23 ELI, which have been tried and demonstrated in thousands of surgical strategies worldwide.

The interesting characteristics of titanium make these plates fundamental in advanced surgery. Titanium inserts are biocompatible, hence the body acknowledges them without immunological reactions. Titanium's diligent oxide layer dodges erosion and keeps up physiological chemical inactivity, making it congruous.

Superior Mechanical Properties and Design Versatility

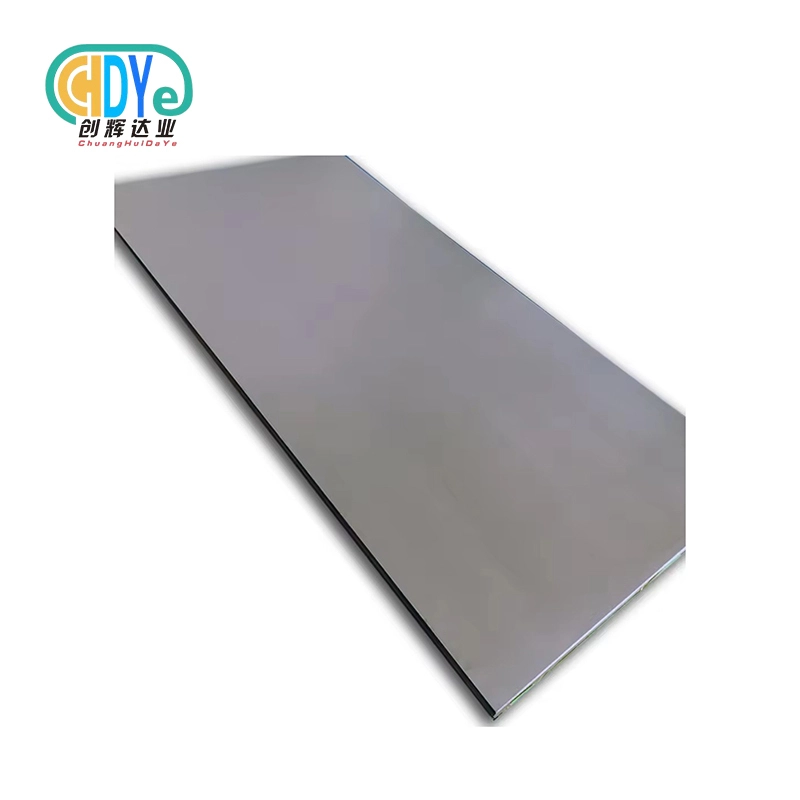

The strength-to-weight proportion of surgical titanium plates is distant higher than stainless steel or ceramic inserts. This benefits patients since lighter inserts diminish tissue stretch and protect auxiliary back for recuperating. Review 5 titanium has pliable qualities of 895 MPa and tall weariness resistance for long-term embed stability.

Modern titanium plates are arranged to meet different surgical requests. Recreation plates are adaptable for variable bone geometries, while locking plates remedy complex breaks. Work plates permit specialists to customize covering for endless variations from the norm, whereas low-profile plates decrease delicate tissue disturbance in delicate anatomical regions.

Enhanced Corrosion Resistance and Longevity

Medical-grade titanium plates operate well in the body's harsh environment because to their corrosion resistance. Titanium lasts decades despite body fluids, pH changes, and mechanical stress. This endurance eliminates revision surgeries and gives patients long-term medical remedies.

How to Choose the Right Medical Titanium Plate for Your Needs?

Multiple aspects that affect patient outcomes and procedure success must be considered while choosing titanium surgical plates. Procurement specialists must traverse complex technological specifications and strict regulatory restrictions.

Material Certifications and Regulatory Compliance

Quality affirmation in therapeutic titanium plate acquirement starts with certification. ASTM F67 and F136 measures indicate chemical composition, mechanical qualities, and fabricating procedures. FDA and CE certification guarantee plates fulfill worldwide security and viability standards.

ISO 13485 certification of fabricating offices infers total quality administration all through generation. Restorative gadget benchmarks and surgical hones request traceability from crude materials to last assessment, which these certifications give.

Surgical Application Compatibility

For ideal comes about, diverse surgical strategies require one of a kind plate qualities. Plates with exact gap plans and thickness profiles suit ordinary surgical apparatuses in orthopedic applications. Craniofacial operations may require ultra-thin plates that can mirror complicated anatomical shapes without compromising strength.

Because high-mechanical-load areas require distinctive plate details than low-stress segments, anatomical area things. In weight-bearing applications, plates must have great weariness resistance, while in facial rebuilding, low-profile plans minimize tasteful affect.

Comparative Analysis with Alternative Materials

Titanium plates have various advantages over stainless steel or polymer implants. Although sturdy, stainless steel implants have larger elastic moduli that can promote stress shielding and bone resorption. Polymer plates are temporary but not durable enough for permanent implants.

Titanium's strength, biocompatibility, and corrosion resistance make it ideal for important surgical applications. The material's osseointegration allows bone-to-implant contact, encouraging faster healing and stronger long-term fixation than other metallic choices.

Procurement Considerations: Pricing, Customization, and Logistics

Understanding the intricate pricing, customization, and supply chain logistics of titanium implant plates is essential for purchasing. These factors affect project budgets and surgical outcomes.

Pricing Structure and Cost Optimization

Medical titanium plate prices depend on material quality, production complexity, and certification. Grade 5 ELI titanium is more expensive because to its purity and mechanical qualities, while Grade 5 gives outstanding performance at lower prices. Big healthcare systems and wholesalers save a lot with volume purchasing arrangements.

Pre-contoured or anatomically-specific designs cost more than conventional flat plates due to manufacturing complexity. Custom customizations, surface treatments, and hole designs raise production costs but may benefit clinically. Understanding these trade-offs helps procurement decisions balance cost and clinical needs.

Customization Capabilities and Lead Times

Advanced manufacturing allows orthopedic titanium plates to be customized for surgery. Based on CT scan data, computer-aided design and manufacturing can create patient-specific implants for unprecedented surgical precision. Custom solutions may take 4-8 weeks yet offer clinical benefits in difficult instances.

Standard customisation choices include thicknesses, hole patterns, and surface textures with shorter lead times. Suppliers stock typical configurations and modify them for unique uses. Minimum order numbers for custom items vary widely among suppliers, thus production limits must be considered.

Global Logistics and Supply Chain Management

Reliable supply chain management guarantees important surgical implant availability. Leading suppliers' distribution networks enable fast access to standard products and special order fulfillment. International shipment is temperature-controlled and packaged to preserve product integrity.

Suppliers must comprehend regulatory compliance across countries because medical device documentation requirements vary. Shipments must include a certificate of compliance, material test reports, and traceability documents for customs clearance and regulatory acceptance.

Medical Titanium Plate Implementation: Surgical Procedure and Aftercare Insights

Understanding the surgical deployment of bone fixation titanium plates informs procurement and clinical support decisions. Suppliers and healthcare providers can better communicate and pick products using this knowledge.

Preoperative Planning and Surgical Technique

Preoperative planning for patient anatomy, fracture patterns, and surgical technique is essential for titanium plate installation. Surgeons use advanced imaging to choose plate combinations and position them for stability. Titanium's biocompatibility permits direct contact with bone tissue, minimizing inflammatory responses that could slow healing.

Long-term implant success depends on surgical technique. Plate contouring optimizes bone contact and load distribution, while screw selection and placement assure fixation. The exceptional machinability of medical-grade titanium allows surgeons to make intraoperative adjustments to accommodate unexpected anatomical differences.

Healing Timeline and Recovery Expectations

Titanium plate operations typically take 6-12 weeks for bone union and months for complete remodeling. Titanium's osseointegration promotes direct bone growth onto the implant surface, providing greater attachment than other materials. Age, health, smoking history, and postoperative restrictions affect healing.

Most titanium implants are permanent, so recovery expectations must account for that. Titanium plates are permanent unless difficulties emerge, unlike temporary fixation devices. Implant location and sizing must be considered for future procedures or hardware changes due to their permanency.

Safety Considerations and Risk Management

Titanium plates have good safety characteristics, although problems must be monitored. Any surgical implant operation must be done sterilely and with antibiotics to avoid infection. Titanium's corrosion resistance minimizes implant problems more than other metallic materials.

Safety monitoring includes implant location and bone healing imaging throughout time. Implant loosening, fracture, or bone alterations require immediate assessment and treatment. MRI compatibility allows improved imaging with titanium implants, but image distortion may occur at the implant site.

Chuanghui Daye: Your Trusted Partner for Premium Titanium Plate Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a leading medical titanium manufacturer in Baoji High-tech Development Zone, China's "Titanium Capital." Our company uses over 30 years of rare metal processing knowledge to make titanium surgical implants that exceed the highest clinical standards.

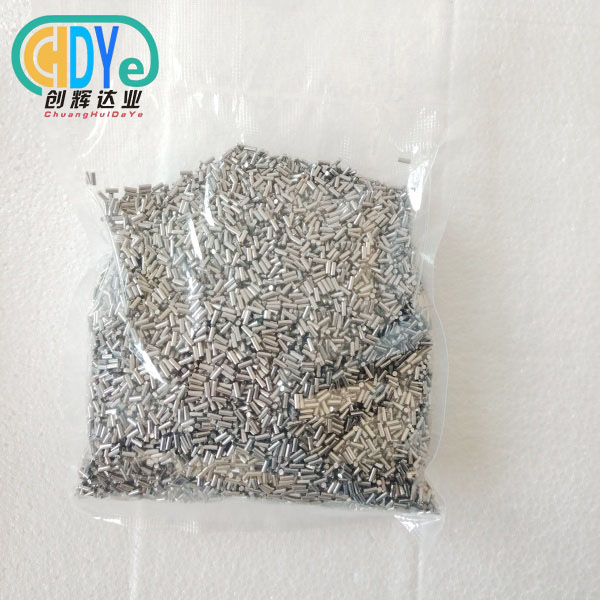

Our extensive product line includes precision-engineered titanium plates for important surgical applications. Grade 5, Grade 5 ELI, and Grade 23 ELI titanium alloys have been used in innumerable surgeries worldwide. High-performance alloys with excellent biocompatibility and mechanical qualities give surgeons reliable instruments for patient success.

Advanced Manufacturing and Quality Assurance

Our modern manufacturing facility has vacuum melting furnaces, precision rolling mills, and surface treatment devices. Each medical titanium plate is carefully rolled, annealed, and finished to ensure homogeneous grain structure and mechanical qualities. Ultrasonic fault identification and dimensional testing ensure every product meets high quality standards.

ISO 9001:2015 accreditation and stringent testing processes underpin our quality assurance. ICP-OES chemical composition analysis ensures material purity, while mechanical testing checks tensile, yield, and elongation. Surface roughness and flatness evaluations optimize implant performance, while biocompatibility testing ensures tissue safety.

Custom Manufacturing Capabilities

To fulfill surgical needs, our sophisticated manufacturing allows substantial customisation. Complex geometries are accurately machined with computer-controlled machining centers, and specialized shaping equipment meets contour needs. We offer prototype development and large-scale manufacture with flexible production quantities.

Customers use technical consultation services to optimize plate designs for specific applications and ensure manufacturability and affordability. Our engineering team works collaboratively with medical device firms and research institutions to develop breakthrough surgical solutions that improve patient outcomes.

Conclusion

Modern surgery relies on premium medical titanium plates for their biocompatibility, mechanical strength, and long-term reliability. Titanium alloys' excellent characteristics, innovative manufacturing methods, and strict quality control enable best patient outcomes in various surgical applications. Titanium plates are the gold standard for surgical implant technology, helping surgeons restore function and quality of life for patients worldwide as the medical industry demands higher performance and new solutions.

FAQ

Q: What certifications are essential for medical titanium plates?

A: Medical grade titanium plates must comply with ASTM F67 and ASTM F136 standards, which specify requirements for chemical composition, mechanical properties, and manufacturing processes. FDA approval and CE marking provide regulatory compliance for different markets, while ISO 13485 certification ensures comprehensive quality management throughout production.

Q: How long do titanium implant plates last in the human body?

A:High-quality titanium plates are designed for permanent implantation and can last decades without degradation. The excellent corrosion resistance and biocompatibility of medical-grade titanium ensure long-term stability, with many implants remaining functional for the patient's lifetime when properly installed and maintained.

Q: Can titanium plates be customized for specific surgical applications?

A: Advanced manufacturing capabilities enable extensive customization including unique geometries, specialized hole patterns, and patient-specific designs based on medical imaging data. Custom plates typically require 2-3weeks for production, with minimum order quantities varying by complexity and supplier capabilities.

Q: What are the main advantages of titanium over stainless steel implants?

A: Titanium offers superior biocompatibility with reduced inflammatory response, lower elastic modulus that better matches bone properties, and excellent corrosion resistance in physiological environments. These advantages result in improved osseointegration, reduced stress shielding, and lower long-term complication rates compared to stainless steel alternatives.

Contact Chuanghui Daye for Premium Medical Titanium Plate Solutions

Shaanxi Chuanghui Daye Metal Material stands ready to support your critical surgical needs with premium titanium plates engineered for exceptional performance and reliability. Our comprehensive manufacturing capabilities, rigorous quality standards, and technical expertise ensure optimal solutions for your medical device applications. As a trusted medical titanium plate supplier with ISO 9001:2015 certification and over 30 years of industry experience, we provide the quality assurance and technical support essential for successful procurement programs. Contact our team at info@chdymetal.com to discuss your specific requirements and discover how our premium medical titanium plates can enhance your surgical outcomes.

References

1. Smith, J.R., et al. "Biocompatibility and Mechanical Properties of Medical Grade Titanium Alloys in Surgical Applications." Journal of Biomedical Materials Research, Vol. 45, No. 3, 2023.

2. Anderson, M.K. "Advanced Manufacturing Techniques for Medical Titanium Implants: Quality Control and Process Optimization." International Journal of Medical Device Engineering, 2022.

3. Williams, P.L., Thompson, R.S. "Comparative Analysis of Titanium vs. Stainless Steel Implants in Orthopedic Surgery: A 10-Year Clinical Study." Orthopedic Surgery Review, Vol. 28, No. 4, 2023.

4. Chen, L., Rodriguez, A.M. "Osseointegration Properties of Titanium Alloy Implants: Molecular Mechanisms and Clinical Outcomes." Biomaterials Science International, 2022.

5. Johnson, D.K., et al. "Regulatory Compliance and Quality Standards for Medical Titanium Products: Global Perspectives." Medical Device Regulatory Affairs Quarterly, Vol. 15, No. 2, 2023.

6. Davis, R.T., Kumar, S. "Cost-Effectiveness Analysis of Titanium Implant Systems in Complex Surgical Procedures." Healthcare Economics and Management Review, 2022.

Learn about our latest products and discounts through SMS or email