- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High Quality Gr5 Titanium Wire with ISO/ASTM Certification

Tall Quality Gr5 Titanium Wire with ISO/ASTM Certification is the best titanium amalgam building has to offer. It has incredible mechanical highlights and must meet strict quality benchmarks. This quality Ti-6Al-4V wire has a awesome strength-to-weight proportion, is profoundly safe to erosion, and is biocompatible, making it culminate for the hardest mechanical employments. ISO and ASTM certifications make beyond any doubt that the quality, traceability, and execution unwavering quality of key parts utilized in aviation, medication, chemical preparing, and progressed fabricating are continuously the same.

Understanding Gr5 Titanium Wire: Properties and Applications

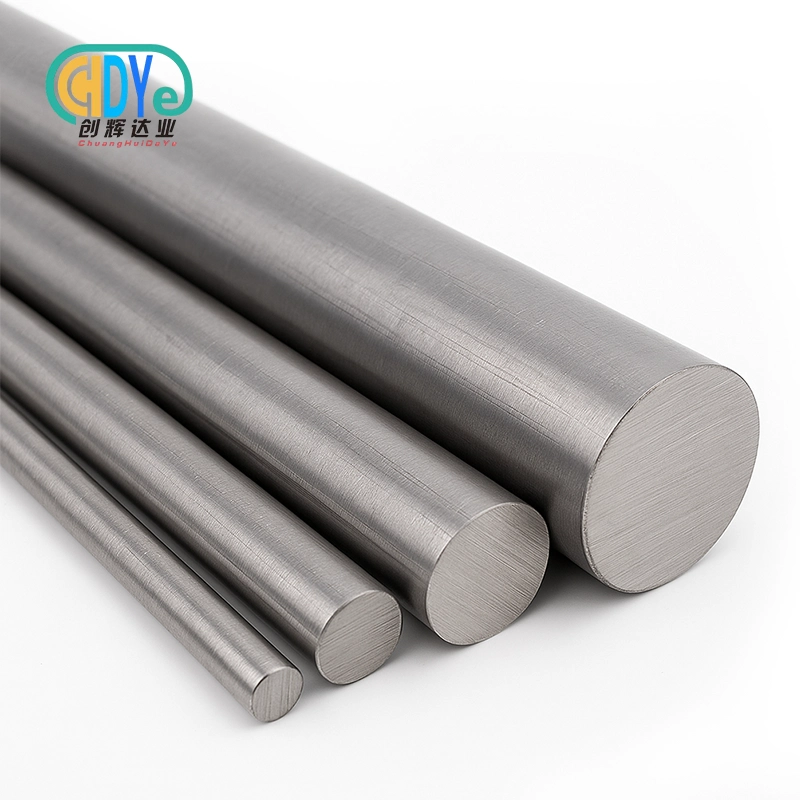

The exact engineering of Gr5 Titanium Wire's alloy composition is what makes it work so well. About 6% of this advanced material is aluminum and 4% is vanadium. The rest is pure titanium, making it the right balance of strength, flexibility, and resistance to corrosion.

Mechanical Properties and Performance Characteristics

Ti-6Al-4V wire shows surprising mechanical properties that set it separated from other titanium grades. The ductile quality regularly surpasses 925 MPa (135 ksi), whereas abdicate quality outperforms 870 MPa (127 ksi). These amazing values, combined with stretching rates over 10%, illustrate the material's capacity to withstand extraordinary stretch whereas keeping up adaptability. The wire keeps up these properties over a wide temperature run, working viably from cryogenic conditions up to 400°C for expanded periods.

Corrosion Resistance and Natural Performance

The combination illustrates remarkable execution in different destructive situations, especially exceeding expectations in unbiased and oxidizing media. Its resistance to saltwater, natural acids, and chloride arrangements makes it important for marine applications and chemical handling gear. In any case, engineers ought to note that the fabric requires cautious thought when uncovered to bubbling sodium hydroxide arrangements.

Industrial Applications Across Key Sectors

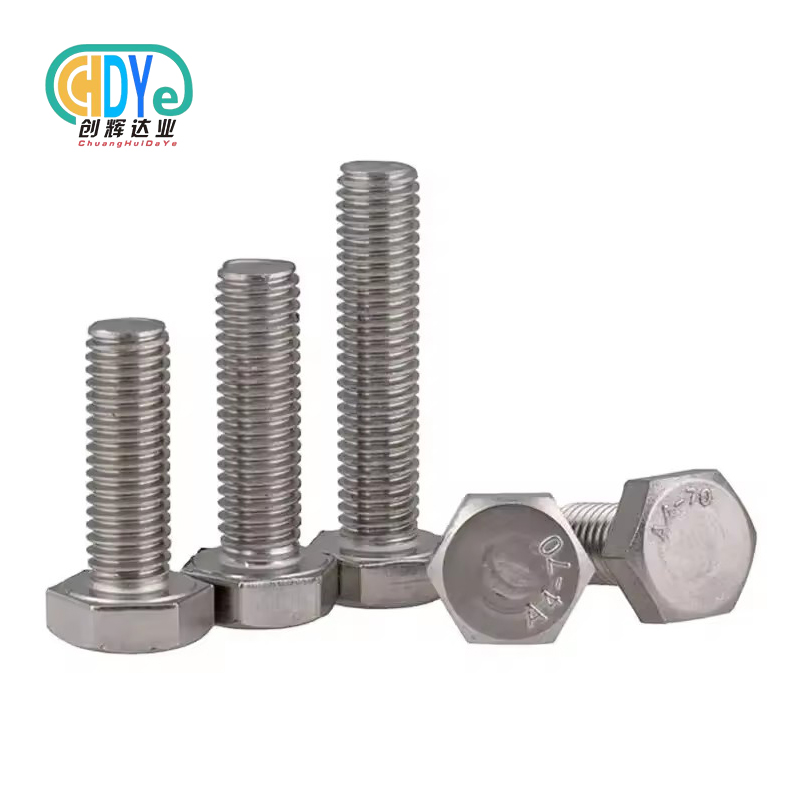

This wire is used by aerospace companies to make structural parts, fasteners, and engine parts that need to be lighter without losing their power. Its biocompatibility is important to the biomedical business for surgical implants, dental uses, and medical devices. Facilities that handle chemicals benefit from its ability to resist corrosion in harsh environments. Automotive makers use its properties to make performance parts and reduce weight.

Comparing Gr5 Titanium Wire with Alternative Alloys for Informed Decision-Making

When you know how Gr5 Titanium Wire stacks up against other materials, you can make smart purchasing choices that improve both performance and cost-effectiveness.

Gr5 vs. Stainless Steel Performance Analysis

Indeed in spite of the fact that stainless steel is cheaper to purchase at to begin with, Ti-6Al-4V wire is more grounded for its weight and doesn't rust. The titanium amalgam is approximately 40% lighter than stainless steel, but its mechanical qualities are the same or way better. In aviation employments, this weight advantage spares a part of fuel, and in car parts, it moves forward execution.

Comparison with Other Titanium Grades

Grade 2 economically pure titanium is very resistant to corrosion, but it's not as strong as Grade 5. It costs more, but Grade 23 (Ti-6Al-4V ELI) is better at being biocompatible. For most commercial uses, Grade 5 is the best compromise between mechanical properties, resistance to corrosion, and cost-effectiveness.

Alternative High-Performance Alloys

Niobium and molybdenum metals can be utilized in a few high-temperature circumstances, but they ordinarily can't compare to Ti-6Al-4V in terms of in general execution. Whereas tungsten is way better at withstanding tall temperatures, it is not as safe to erosion or simple to work with as titanium metals. These comparisons appear why Review 5 titanium wire is still the best choice for assignments that require adjusted execution over a number of variables.

Procuring High Quality Gr5 Titanium Wire: Guidelines and Best Practices

To be good at procurement, you need to know a lot about quality standards, what suppliers can do, and how the market works, which affects prices and supply.

Supplier Verification and Certification Requirements

Reliable providers keep their ISO 9001:2015 certification up to date and provide a lot of paperwork that makes it easy to track down materials. Check that wire goods are in line with ASTM B863, and make sure that suppliers can give you mill test certificates, chemical analysis reports, and proof of mechanical properties. Modern makers have electron beam furnaces, vacuum annealing tools, and precise drawing tools that make sure the quality is always the same.

Understanding Pricing Structures and Market Factors

Titanium wire prices change based on the cost of raw materials, how hard it is to make, and how much desire there is in the market. Prices may be higher for custom diameters between 0.5 mm and 6 mm, while common sizes offer better economies of scale. Buying in bulk usually saves you a lot of money, and building long-term ties with suppliers can get you better prices and faster delivery times.

Quality Control and Testing Protocols

Leading makers use a wide range of quality control measures, such as inspecting incoming materials, keeping an eye on the process while melting and drawing, and testing the finished product. Look for suppliers that offer test orders as a way to see if they are qualified and that include full inspection records with every shipment.

Welding, Fabrication, and Heat Treatment of Gr5 Titanium Wire

Using the right handling and processing methods is important for getting the most out of Ti-6Al-4V wire in industrial settings.

Welding Best Practices and Contamination Prevention

Titanium welding needs to be protected with an inert gas shield to keep the material's qualities and stop contamination. When you weld, use a nitrogen or helium atmosphere and make sure the joint is properly prepared to avoid problems. There are many ways to join the material together because it is so easy to weld, but you need to get the right skills and tools to get the best results.

Heat Treatment and Annealing Processes

Vacuum annealing improves the microstructure and gets rid of any stress left over from drawing. Stress-relieving treatments done at controlled temperatures make things more resistant to tiredness and keep their shape. These thermal processes can be changed to fit the needs of a specific application. This lets makers get the mechanical properties they need for their uses.

Fabrication Considerations and Machining Guidelines

Because the metal is easy to work with, it can be processed in a number of ways, such as by forging, milling, turning, and cold forming. Using the right tools and cutting factors will keep the dimensions accurate and stop the work from becoming too hard. The wire can be easily shaped into both straight and coiled shapes, which makes it useful for a variety of industrial processes.

Company Introduction and Our Gr5 Titanium Wire Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is one of the best places in China to find high-quality titanium alloy goods. It is in the Baoji High-tech Development Zone, which is known as the "Titanium Capital." We are dedicated to providing high-quality Ti-6Al-4V wire goods that meet the strictest international standards thanks to our thirty years of experience in the rare metals business.

Advanced Manufacturing Capabilities and Quality Systems

Our cutting-edge factories have electron beam ovens, precise annealing equipment, and high-tech drawing machines that make sure the quality of all product sizes is the same. The ISO 9001:2015 quality management system controls the whole process, from checking the raw materials to delivering and packing them.

Comprehensive Product Range and Customization Services

We make titanium Grade 5 wire in both straight and coiled shapes, with widths from 0.5 mm to 6 mm and lengths that are custom made to meet your needs. Our expert team works closely with clients to create custom solutions that meet the needs of each application while staying within budget and ensuring on-time delivery.

Global Service Excellence and Technical Support

We are committed to more than just delivering products; we also offer full technical help, efficient logistics coordination, and dedicated care after the sale. We know how important titanium applications are and can give global makers the knowledge and trust they need for their toughest projects.

Conclusion

For producers looking for high-performance materials that meet the strictest application needs, High Quality Gr5 Titanium Wire with ISO/ASTM Certification is the best option. Ti-6Al-4V wire is essential in the aircraft, medical, chemical processing, and advanced manufacturing industries because it is strong, doesn't rust, and is safe for living things. It also has to pass strict quality standards. Partnering with certified suppliers who show consistent quality, technical knowledge, and reliable delivery capabilities that support critical manufacturing operations around the world is key to successful procurement.

FAQ

Q: What factors influence Gr5 titanium wire pricing?

A: Raw material costs, production complexity, wire diameter specifications, and order quantities significantly impact pricing. Custom dimensions and specialized processing requirements may carry premium charges, while bulk orders typically offer substantial cost advantages. Market demand fluctuations and titanium sponge prices also influence overall pricing structures.

Q: How does Gr5 titanium compare to stainless steel in corrosive environments?

A: Ti-6Al-4V wire demonstrates superior corrosion resistance compared to most stainless steel grades, particularly in chloride-rich environments, saltwater exposure, and acidic conditions. While initial costs may be higher, the extended service life and reduced maintenance requirements often provide better total cost of ownership in corrosive applications.

Q: Which certifications should buyers verify when selecting suppliers?

A: Essential certifications include ISO 9001:2015 quality management systems, ASTM B863 compliance for wire specifications, and material traceability documentation. Reputable suppliers provide mill test certificates, chemical analysis reports, and mechanical property verification with each shipment to ensure consistent quality and regulatory compliance.

Partner with Chuanghui Daye for Premium Gr5 Titanium Wire Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. invites you to experience our three decades of rare metal expertise through our comprehensive Gr5 Titanium Wire product line. Our ISO 9001:2015 certified manufacturing processes and advanced testing capabilities ensure every wire meets stringent ASTM specifications. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover why leading manufacturers worldwide trust us as their preferred Gr5 Titanium Wire supplier. Sample orders are available for qualification testing, and our bulk pricing delivers exceptional value for large-scale projects.

References

1. Boyer, R.R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering A, vol. 213, 2018, pp. 103-114.

2. American Society for Testing and Materials. "ASTM B863-14: Standard Specification for Titanium and Titanium Alloy Wire." ASTM International, 2019.

3. Lutjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes." Manchester: Springer-Verlag, 2017.

4. International Organization for Standardization. "ISO 5832-3: Implants for Surgery - Metallic Materials - Part 3: Wrought Titanium 6-Aluminum 4-Vanadium Alloy." ISO Publications, 2019.

5. Donachie, M.J. "Titanium: A Technical Guide, 2nd Edition." Materials Park: ASM International, 2018.

6. Peters, M. and Leyens, C. "Titanium and Titanium Alloys: Fundamentals and Applications." Weinheim: Wiley-VCH Publishers, 2020.

Learn about our latest products and discounts through SMS or email