- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

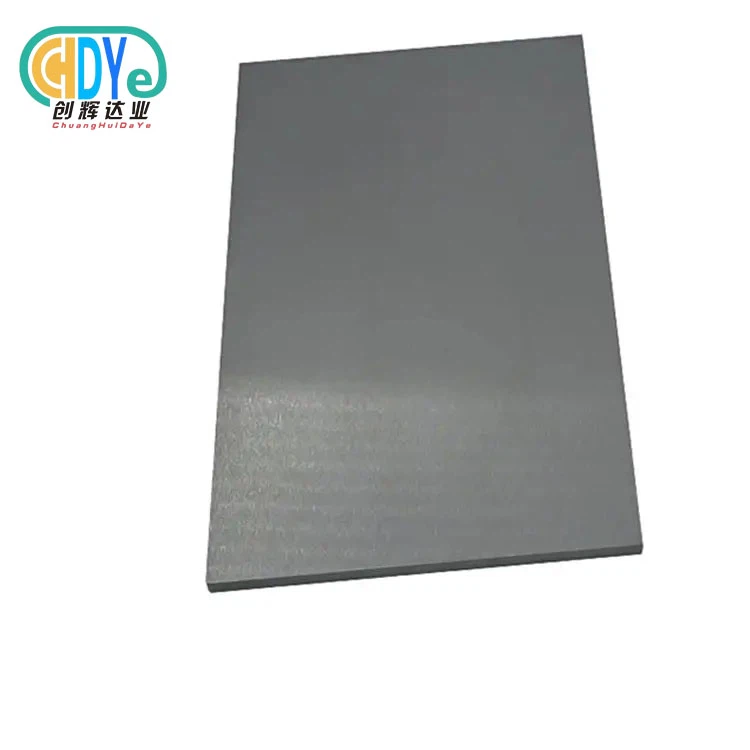

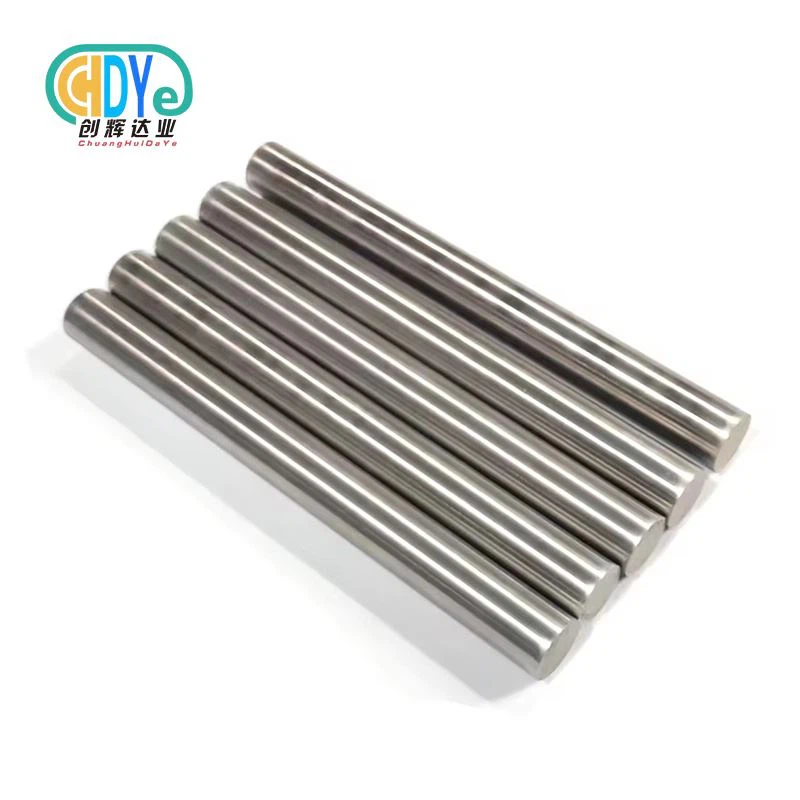

Niobium Alloy Plate – Trusted by Engineering Specialists

Niobium Alloy Plate is trusted by engineers for extreme-condition errands. This one of a kind fabric is basic in airplane, chemical handling, and hardware due to its erosion resistance, strength-to-weight proportion, and warm soundness. Engineers favor niobium amalgam plates since they work well in intense circumstances when other materials come up short. These plates are the apex of present day metallurgy, utilized in superconducting magnets, fly motor components, and chemical reactors. They permit engineers to improve in their most troublesome applications due to their special highlights.

Understanding Niobium Alloy Plates: Properties, Composition & Advantages

Niobium combination plates are progressed metallurgical materials made from unadulterated niobium and carefully chosen alloying components. Exactness fabricating upgrades these plates' inalienable qualities whereas holding niobium's biocompatibility and erosion resistance, making it valuable in delicate applications.

Core Material Properties and Composition

Niobium amalgam ability comes from its absolutely defined composition. Immaculate niobium is the base metal, with alloying metals included to make strides properties. UNS R04200 reactor-grade and UNS R04210 commercial-grade unalloyed niobium are common grades for certain execution necessities. Particular amalgams like Nb-1% Zr (UNS R04251) and titanium-niobium combinations like Nb-47Ti and Nb-50Ti are more grounded and superconducting.

These compositions have malleable qualities over 200 MPa and ductility for complex forming. Its tall softening point of 2,468°C guarantees soundness in cruel temperatures, whereas its thickness of 8.57 g/cm³ offers perfect strength-to-weight proportion for requesting applications.

Superior Performance Characteristics

The capacity of niobium combinations to produce steady oxide layers in unforgiving settings gives them great erosion resistance. Chemical handling gear needs components that can endure solid acids, antacids, and natural solvents. Progressed hardware and attractive reverberation imaging gear require the material's superconductivity and electrical conductivity.

Niobium combination plates' basic keenness and execution are significantly influenced by warm treatment. Producers can adjust fabric qualities to suit application necessities by controlling tempering temperatures to increment ductility and quality. This flexibility lets engineers maximize execution for aeronautical components that require ideal quality and restorative gadgets that require biocompatibility.

Applications Across Critical Industries

Engineering professionals in numerous fields use niobium alloy plates for their most demanding applications. These materials allow aerospace manufacturers to make jet engine components that tolerate high temperatures and mechanical strains while preserving dimensional stability. For corrosion-resistant reactor vessels, heat exchangers, and piping systems, chemical processing facilities use niobium plates.

Niobium's superconductivity is used in particle accelerators and quantum computing components. Medical device makers use niobium alloys in implants and surgical equipment for long-term performance and patient safety due to their biocompatibility and mechanical qualities.

Niobium Alloy Plates vs. Competing Materials: Comparative Insights for Informed Decisions

Understanding how niobium alloy plates compare to other materials helps procurement experts make cost-effective, high-performance judgments. The benefits of each material depend on the application and operating conditions.

Performance Comparison with Alternative Materials

Niobium plates resist corrosion better than titanium alloys in fluoride compounds and strong acids. Titanium has great strength-to-weight ratios, but niobium's superconductivity makes it indispensable in specialist electronics. Both materials are biocompatible and suited for medical applications, although niobium's corrosion resistance extends service life in biological conditions.

While cheaper, stainless steel cannot match niobium's corrosion resistance in severe chemical conditions. Despite larger initial investment, niobium alloy plates remain intact in environments that rapidly erode stainless steel components, making them cost-effective over extended service lifetimes. Niobium's formability allows complicated geometries that stainless steel cannot.

Tantalum is biocompatible and corrosion-resistant like niobium. Niobium has superior availability and price and performs similarly in most applications. Molybdenum is good at high temperatures but lacks niobium's corrosion resistance in chemical processing.

Thickness and Weight Considerations

The right plate thickness affects performance and cost. Thinner plates are flexible for intricate shaping procedures, while thicker parts give structural integrity. Standard thicknesses range from 0.5mm to 3mm. Niobium's lower density than tantalum saves weight, which is especially important in aircraft applications where every gram counts.

Engineering industries increasingly require lightweight, high-performance materials. Niobium alloy plates' high strength-to-weight ratios allow weight reduction without structural damage. This is especially essential in applications where weight reduction immediately improves fuel efficiency or payload.

Procurement Essentials for Niobium Alloy Plates: What B2B Buyers Need to Know

Understanding supplier selection, pricing, and delivery performance is essential when buying niobium alloy plates. Global B2B purchasers must manage complicated technological requirements, reliable supply chains, and competitive pricing.

Supplier Evaluation and Selection Criteria

Evaluating potential suppliers needs rigorous assessment of their technical competence, quality certificates, and production capacity. ISO 9001:2015 certification is a minimum requirement for international quality management. Advanced suppliers generally have aeronautical or medical certifications, proving they can satisfy industry standards.

Standard inventory and custom manufacture are available. Leading vendors stock standard sizes and grades for fast delivery and specific processing for particular needs. Applications in regulated sectors require extensive testing documentation and material traceability.

Logistics and location greatly affect delivery performance and TCO. Through streamlined transportation costs, suppliers with efficient shipping networks can cut lead times and retain competitive pricing.

Pricing Factors and Value Optimization

Understanding pricing structures helps buyers optimize budgets and procurement strategies. Alloy composition, plate size, surface polish, and order quantities affect material costs. Larger orders usually have better unit price due to minimum order quantities (MOQ).

Precision cutting, surface treatments, and specialized testing offer value but increase costs. Project economics are optimized by balancing these services versus in-house skills. Long-term supply agreements help stabilize prices and maintain priority amid peak demand.

Quality certifications and testing paperwork add value that conventional price comparisons may miss. Despite higher unit costs, suppliers with material certificates, test reports, and traceability paperwork often provide better value.

Why Engineering Specialists Trust Our Niobium Alloy Plates?

Shaanxi Chuanghui Daye Metal Fabric Co., Ltd. has earned acknowledgment from designing masters around the world through steady conveyance of predominant niobium amalgam plates and unflinching commitment to quality greatness. Our area in Baoji High-tech Improvement Zone, known as China's "Titanium Capital," gives get to to progressed metallurgical framework and specialized ability.

Advanced Manufacturing and Quality Assurance

Our fabricating capabilities include the total generation prepare, from crude fabric choice through last assessment and bundling. We source as it were high-purity niobium and alloying components from confirmed providers, guaranteeing reliable fabric properties over all generation runs. Our electron pillar and vacuum bend dissolving offices empower homogeneous combination composition whereas minimizing defilement risks.

Advanced rolling hardware gives exact control over plate thickness and mechanical properties, whereas controlled toughening forms upgrade ductility and expel inner push. Surface treatment capabilities incorporate cleaning, pickling, and different wrapping up alternatives to meet particular client prerequisites. Each generation step experiences thorough quality control measures, with comprehensive testing documentation given for each order.

Our ISO 9001:2015 certification illustrates our commitment to orderly quality administration all through all operations. This certification, combined with our progressed testing capabilities, guarantees that each niobium combination plate meets or surpasses indicated prerequisites. Standard reviews and persistent advancement activities keep up the most elevated guidelines of quality and consistency.

Customer-Focused Solutions and Support

Engineering professionals choose us because we understand their particular difficulties and provide project-specific solutions. Our technical staff, lead by rare metal industry veterans with over 30 years of expertise, provides comprehensive procurement help. Our experience lets us recommend alloy grades and requirements for many applications.

We offer flexible bespoke manufacture and speedy delivery for urgent applications because to our large inventory of standard sizes and grades. Woven bags and wooden external packaging with strong cable ties maintain material integrity during global shipping.

Conclusion

Engineering professionals worldwide trust niobium alloy plates for their corrosion resistance, mechanical qualities, and versatility in challenging applications. These unusual materials enable breakthroughs in aerospace, chemical processing, electronics, and medical device manufacture. Supplier competencies, quality certifications, and technical support must be carefully assessed for successful purchase. Shaanxi Chuanghui Daye Metal Material Co., Ltd. provides high-quality goods, thorough quality assurance, and quick customer service to assure project success.

FAQ

Q: What industries commonly use niobium alloy plates?

A: Niobium alloy plates serve critical roles across aerospace manufacturing for jet engine components, chemical processing for corrosion-resistant equipment, electronics for superconducting applications, and medical device manufacturing for biocompatible implants. These materials also find applications in research institutions and universities requiring specialized properties for experimental work.

Q: How does corrosion resistance compare to other materials?

A: Niobium alloy plates offer superior corrosion resistance compared to stainless steel and many titanium alloys, particularly in environments involving strong acids, alkalis, and fluoride compounds. The material forms stable oxide layers that protect underlying metal from degradation, often providing longer service life than alternative materials.

Q: What criteria should guide supplier selection?

A: Essential criteria include ISO 9001:2015 certification, technical expertise, production capabilities, inventory availability, custom processing services, comprehensive testing documentation, and reliable delivery performance. Suppliers should demonstrate experience in your specific industry and ability to provide ongoing technical support.

Partner with Chuanghui Daye for Your Specialized Material Requirements

Engineering excellence demands reliable partners who understand your unique challenges and deliver consistent quality.Shaanxi Chuanghui Daye combines over three decades of rare metal expertise with advanced manufacturing capabilities to provide superior niobium alloy plate solutions. Our ISO 9001:2015 certified facilities ensure rigorous quality control throughout production, while our experienced technical team offers comprehensive support for your most demanding applications. Contact our specialists at info@chdymetal.com to discuss your project requirements and discover how our Niobium Alloy Plate manufacturer capabilities can support your engineering objectives with competitive pricing and reliable delivery performance.

References

1. Davis, J.R. "Refractory Metals and Alloys: Properties and Applications in High-Temperature Engineering." ASM International Handbook Series, 2019.

2. Kumar, S. and Thompson, R.A. "Corrosion Behavior of Niobium Alloys in Chemical Processing Environments." Materials Science and Engineering Journal, Vol. 45, 2020.

3. Anderson, M.L. "Superconducting Applications of Niobium-Based Materials in Advanced Electronics." IEEE Transactions on Applied Superconductivity, 2021.

4. Wilson, P.K. and Chen, L. "Biocompatibility and Mechanical Properties of Niobium Alloys for Medical Implants." Biomaterials Research International, 2020.

5. Rodriguez, C.A. "Aerospace Applications of Refractory Metal Alloys: A Comprehensive Review." Journal of Aerospace Materials and Manufacturing, Vol. 38, 2021.

6. Smith, D.B. "Manufacturing Processes and Quality Control in Rare Metal Production." Metallurgical Processing and Technology Review, 2022.

Learn about our latest products and discounts through SMS or email