- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Medical Titanium Bars Improve Implant Reliability?

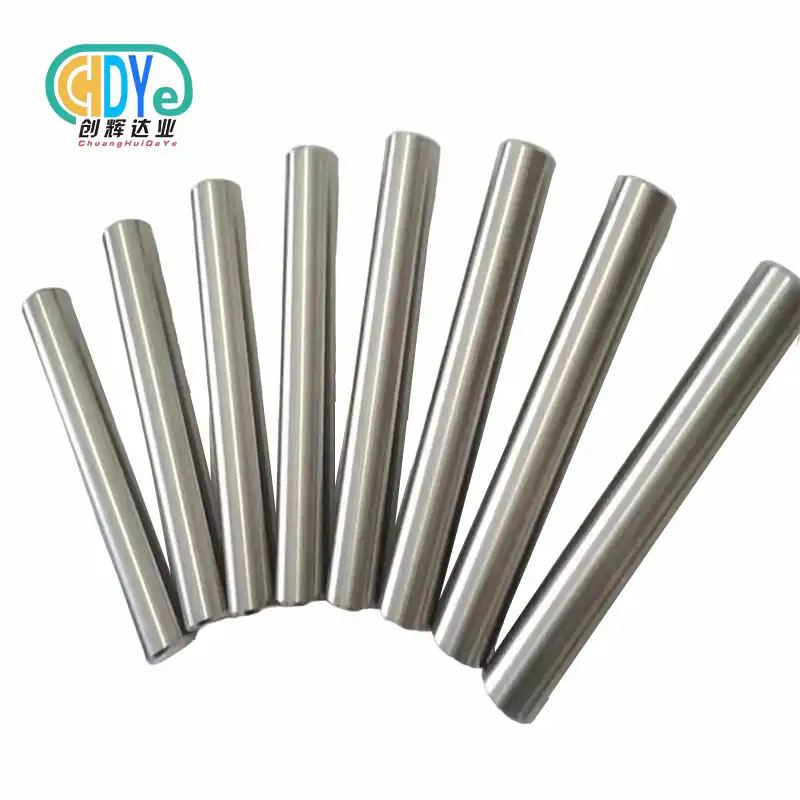

Medical titanium bars improve the reliability of implants because they are very biocompatible, don't rust, and have the best mechanical qualities. The ASTM F67 and ASTM F136 standards were followed when making these high-purity titanium goods. They have great strength-to-weight ratios and fatigue resistance, which are important for long-term implant success. Unlike common materials like stainless steel or cobalt chrome, medical titanium bar materials offer low rejection rates and long-lasting, light solutions that blend naturally with human tissue. This makes them the first choice for orthopedic, dental, and cardiovascular implant uses all over the world.

Understanding Medical Titanium Bars and Their Properties

Therapeutic titanium bars are made of an extraordinary kind of fabric that was made for natural applications where security and stability are exceptionally critical. To make these things, strict steps are taken to ensure beyond any doubt that they meet medical-grade benchmarks. These measures incorporate ASTM F67 for commercially pure titanium and ASTM F136 for Ti-6Al-4V ELI amalgams.

Key Material Grades and Specifications

Certain sorts of titanium are utilized in pharmaceuticals since they have been proven to work well in clinical settings for decades. Review 1 (Gr1) and Review 2 (Gr2) are commercially immaculate titanium that is exceptionally safe to rust and biocompatible, which makes them idealize for employments that require to be as biocompatible as conceivable. The Ti-6Al-4V composition of Review 5 (Gr5) and Review 5 ELI (Additional Moo Interstitial) gives them higher mechanical quality, with malleable qualities coming to 860 MPa and great resistance to fatigue.

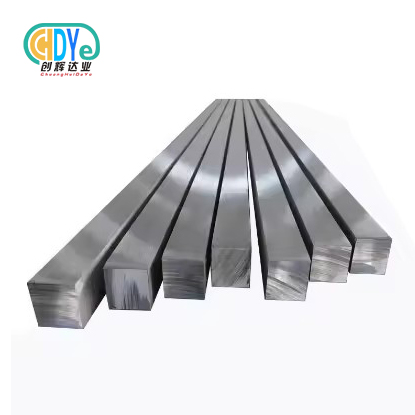

Diameters can be anywhere from 4 mm to 20 mm, and lengths can be anywhere from 2500 mm to 3000 mm, thanks to advanced generation strategies. Determinations for resistances like h7, h8, and h9 make it beyond any doubt that the quality and fit are continuously the same for imperative embed employments. With these specs, producers can make parts that meet the correct surgical needs while still keeping the auxiliary judgment required for long-term use.

Manufacturing Excellence and Quality Control

Medical titanium bars are made utilizing complex chemical strategies that ensure beyond any doubt the fabric is pure and steady. Vacuum bend remelting (VAR) and electron bar softening (EBM) get freed of debasements and make microstructures that are all the same, which is vital for natural employments. Hot manufacturing, rotating swaging, and exact rolling all make grain structures that are uniform, which moves forward the material's mechanical properties and resistance to fatigue.

Quality affirmation measures incorporate exhaustive testing strategies that affirm the execution characteristics of each bar. A few of these are 100% ultrasonic testing to discover inside blemishes, ICP-OES innovation for chemical composition examination, and ductile and hardness testing for mechanical property confirmation. Surface wrapping up strategies make smooth, mirror-like surfaces with hardness levels underneath Ra 0.2 μm. This permits tissues to coordinate appropriately and reduces the chance of microbes staying on the surface.

Why Medical Titanium Bars Outperform Alternatives in Implant Applications?

Implants made of traditional materials have been used for decades, but they have some major problems that can be fixed with modern titanium replacements. Even though stainless steel implants are cheaper at first, they can rust in body fluids, and nickel sensitivity reactions can happen. Cobalt chrome metals are strong, but they don't have the biocompatibility and osseointegration properties that are needed for long-term success.

Superior Biocompatibility and Tissue Integration

Titanium is very biocompatible because of the way its surface chemistry and how its oxide layer form. Titanium naturally forms a stable titanium dioxide layer in physiological settings that stops ions from escaping and helps cells stick together. This feature makes osseointegration possible, a process in which bone tissue bonds directly to the implant surface without any soft tissue formation happening first.

Studies in humans have shown that implants that are made of titanium have much higher life rates than implants made of other metals. The material's modulus of elasticity is very similar to that of human bone. This means that it doesn't protect against stress as well, which can cause the bone to break down and the implants to become free. Biomechanical compatibility makes sure that the load is distributed in a way that keeps the bone healthy and the implant stable for the patient's whole life.

Enhanced Mechanical Performance and Durability

Medical titanium bars are very resistant to fatigue; they can survive millions of loading cycles without breaking. This is an important quality for implants that are put under repeated physiological stresses. Because the material is very strong for its weight, it can be used to make implant structures that are both light and strong. These structures are better for patients because they are stronger and lighter at the same time.

Titanium is the only metal that can prevent corrosion better than any other in biological environments. This trait keeps the dimensions stable and stops the release of metallic ions that could cause swelling or changes in the color of the tissue. When you combine mechanical strength with rust resistance, you get implants that can last for decades without breaking down or degrading.

Procurement Considerations: Selecting the Right Medical Titanium Bar Supplier

To get medical-grade titanium bars, you need to carefully look at the skills, certifications, and quality processes of the suppliers you are considering. Because rules for medical devices are so complicated, companies need to work together with makers that consistently follow international standards and have the technical know-how for specific uses.

Certification and Quality Management Systems

Reliable suppliers keep their ISO 13485 certification for making medical devices, which makes sure that their quality control systems meet the specific needs of healthcare applications. Having ISO 9001:2015 certification is another way to make sure that quality control and continuous improvement methods are always the same. Getting these certifications shows that a company is dedicated to following rules and keeping products reliable.

Traceability documentation is another important thing to think about when choosing a seller. Full material traceability from where the raw materials come from to where they are delivered at the end allows producers to stay in line with FDA and CE marking rules. This paperwork is needed for regulatory audits and product liability assessments, so being able to track a supplier is an important factor in buying things.

Production Capacity and Customization Capabilities

Global companies that make medical devices need suppliers that can meet a range of volume needs while keeping delivery dates consistent. When judging a supplier's production capacity, it's important to look at both the standard products they offer and their ability to make unique products for specific uses. Suppliers with modern machining facilities can offer services that add value, such as precise cutting, surface treatments, and changes to dimensions that make the manufacturing process run more smoothly.

The ability to provide technical help sets exceptional suppliers apart from commodity providers. Manufacturers can improve their designs and quickly solve problems when they have access to metallurgical knowledge, application engineering support, and collaborative product development resources. These relationships often lead to better product performance and shorter development times, which gives companies that make medical devices a competitive edge in fast-paced markets.

Integrating Medical Titanium Bars into Your Implant Manufacturing Process

To successfully use titanium materials in the production of implants, you need to know a lot about the material's special properties and how to process it. Titanium is not like other metals when it comes to machining, shaping, and surface treatment. These problems must be solved in order to keep titanium's useful qualities.

Machining and Processing Considerations

Because titanium doesn't conduct heat well and tends to work harden, it needs special machining methods and casting strategies. Sharp cutting tools, the right cutting speeds, and good cooling systems keep the work from getting too hard and make sure the measurements are correct. It is very important to keep the surface's structure during machining, because any contamination or heat-affected areas could make the material less biocompatible.

To get the best mechanical properties and microstructural uniformity, heat treatment methods need to be carefully managed. Controlled annealing processes remove residual stresses and improve resistance to fatigue. They also keep the surface from getting dirty from furnace atmospheres, which could hurt the quality of the surface. For these processing issues to be handled correctly, the supplier must have the right knowledge and tools.

Quality Assurance and Testing Protocols

Biocompatibility testing, mechanical property verification, and dimensional inspection procedures are all part of full quality assurance programs. Tensile strength testing makes sure that the material meets the standards for performance, and fatigue testing makes sure that it will last for a long time. A microstructure study makes sure that the α+β phase is distributed correctly and that the grain structure is uniform, which is necessary for the mechanical properties to stay the same.

Biocompatibility testing based on ISO 10993 standards checks for cytotoxicity, sensitization, and irritation, which are all qualities needed for implant uses. To account for any changes in surface chemistry or structure that happen during processing, these tests must be done on finished goods instead of raw materials. All test results must be recorded in order for medical device approval steps to be in line with regulations.

Conclusion

Medical titanium bars make implants much more reliable because they are better at integrating with the body, resisting corrosion, and having the best mechanical qualities compared to other implant materials. Materials that are perfect for long-term use in biomedicine are made with strict quality control, exact manufacturing standards, and special types like Ti-6Al-4V ELI. For implementation to go smoothly, suppliers must be carefully chosen based on their certification compliance, technical knowledge, and manufacturing capabilities that guarantee consistent product quality and regulatory compliance. As the medical device industry works to make implants that are more reliable and last longer, titanium bars are still the material of choice for companies that care about patient safety and professional excellence.

FAQ

Q: What makes medical titanium bars superior to stainless steel for implants?

A: Medical titanium bars offer superior biocompatibility with minimal ion release, excellent corrosion resistance in body fluids, and a modulus of elasticity closer to bone tissue. These properties reduce rejection risks and stress shielding effects compared to stainless steel, resulting in better long-term implant integration and patient outcomes.

Q: Which titanium grades are most suitable for different implant applications?

A: Grade 1 and Grade 2 commercially pure titanium excel in applications requiring maximum biocompatibility, such as dental implants and cardiovascular devices. Grade 5 (Ti-6Al-4V) and Grade 5 ELI provide enhanced strength for load-bearing applications like orthopedic joint replacements and spinal hardware where mechanical performance is critical.

Q: How do quality certifications impact medical titanium bar selection?

A: ISO 13485 and ASTM compliance certifications ensure materials meet medical device manufacturing standards and regulatory requirements. These certifications guarantee consistent quality, complete traceability, and biocompatibility testing necessary for FDA approval and CE marking, making them essential criteria for supplier selection.

Q: What customization options are available for medical titanium bars?

A: Leading suppliers offer diameter customization from 4mm to 20mm, length specifications up to 3000mm, and various tolerance grades (h7, h8, h9). Surface finishing options include polished, pickled, or mirror finishes, while alloy composition modifications can address specific application requirements for enhanced performance characteristics.

Partner with Chuanghui Daye for Premium Medical Titanium Bar Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as your trusted medical titanium bar supplier, combining three decades of rare metal expertise with cutting-edge manufacturing capabilities. Located in China's renowned "Titanium Capital" of Baoji, we leverage advanced production technologies, including vacuum arc remelting and electron beam melting, to deliver consistently superior titanium bars meeting ASTM F67 and F136 standards. Our ISO 9001:2015 certified quality management system ensures complete traceability and reliability for your implant manufacturing needs. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover how our customizable medical titanium bar solutions can enhance your product reliability and manufacturing efficiency.

References

1. Elias, C.N., Lima, J.H.C., Valiev, R., & Meyers, M.A. (2008). Biomedical applications of titanium and its alloys. Journal of the Minerals, Metals and Materials Society, 60(3), 46-49.

2. Rack, H.J., & Qazi, J.I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

3. Niinomi, M. (2002). Recent metallic materials for biomedical applications. Metallurgical and Materials Transactions A, 33(3), 477-486.

4. Geetha, M., Singh, A.K., Asokamani, R., & Gogia, A.K. (2009). Ti-based biomaterials: The ultimate choice for orthopaedic implants. Progress in Materials Science, 54(3), 397-425.

5. Liu, X., Chu, P.K., & Ding, C. (2004). Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Materials Science and Engineering: R, 47(3-4), 49-121.

6. Long, M., & Rack, H.J. (1998). Titanium alloys in total joint replacement: A materials science perspective. Biomaterials, 19(18), 1621-1639.

Learn about our latest products and discounts through SMS or email