- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Implant-Grade Medical Titanium Bar with Stable Microstructure

Implant-grade medical titanium bar with a stable microstructure is the apex of biomedical engineering materials for crucial healthcare applications. These precision-engineered bars are essential for orthopedic implants, surgical equipment, and dentistry applications due to their biocompatibility, corrosion resistance, and mechanical stability. The stable microstructure assures consistent performance throughout the material's lifecycle, giving medical device producers reliable components that fulfill strict regulatory standards and improve patient outcomes.

Understanding Medical Titanium Bars and Their Importance

Specialist materials that can endure human body conditions are essential to the medical device business. Medical titanium bars are a biomedical engineering breakthrough with qualities that traditional materials cannot match. These precision-crafted components meet life-critical criteria through stringent manufacturing methods.

Biocompatibility and Safety Standards

The biocompatibility of titanium bars makes them ideal for medical implantation. Titanium integrates tissue well without cytotoxicity or allergic reactions, unlike other metals. A persistent oxide layer on the surface prevents hazardous ions from entering neighboring tissues, resulting in outstanding compatibility.

Medical-grade titanium bars must meet strict international standards like ASTM F67 for pure titanium and ASTM F136 for titanium alloy components. Standards ensure every bar satisfies chemical composition, mechanical property, and surface quality requirements. The manufacturing method uses extensive quality control to ensure batch uniformity.

Microstructural Stability and Performance

Implant-grade titanium bars' mechanical reliability and long-term performance depend on their stable microstructure. Manufacturers create consistent grain structures that improve fatigue resistance and mechanical strength via vacuum arc remelting and careful heat treatment.

Microstructural stability is crucial in load-bearing applications like orthopedic implants. A homogeneous α+β phase distribution ensures stable mechanical qualities, reducing premature failure and extending implant longevity. This microstructural control demands advanced manufacturing and quality control throughout production.

Applications in Modern Healthcare

Medical titanium bars have several healthcare uses. These materials support joint replacement, spinal fusion, and fracture fixation hardware in orthopedic surgery. High strength-to-weight ratio permits lighter implants that reduce patient burden while retaining structural integrity.

Dental applications benefit from titanium's osseointegration. These bars connect well with bone tissue, making implant abutments stable for prosthetic teeth. The corrosion resistance enables long-term stability in the oral environment, where saliva and microorganisms pose obstacles.

Comparison and Performance Analysis: Medical Titanium Bars vs Alternatives

Medical material procurement specialists must examine performance parameters that affect patient safety and device longevity. Medical titanium bars outperform other materials in implantable device-critical locations.

Superior Mechanical Properties

Titanium bars outperform stainless steel mechanically. Grade 5 titanium alloy (Ti6Al4V) has high ductility, fatigue resistance, and tensile strength of 860 MPa. This combination thins device profiles without compromising structural integrity.

Titanium's modulus of elasticity matches human bone better than stainless steel. This commonality reduces stress shielding and implant-related bone resorption. The lower elastic modulus maintains natural stress distribution patterns, improving implant-bone tissue integration over time.

Corrosion Resistance and Durability

In biological settings, medical titanium bars are more corrosion-resistant than most metals. Titanium surfaces naturally create a passive oxide layer that protects against blood, lymphatic fluid, and other corrosive chemicals.

Superior corrosion resistance extends implant life and reduces device failure. After decades of biological fluid exposure, titanium retains its surface integrity, unlike stainless steel, which may pit in chloride-rich conditions. Durability decreases revision operations and improves patient outcomes.

Grade Comparison and Selection Criteria

Different titanium grades have different characteristics for different uses. For applications requiring maximum tissue compatibility, Grade 1 and Grade 2 pure titanium are corrosion-resistant and biocompatible. Grade 5 (Ti6Al4V) is stronger for load-bearing applications and ductile for intricate shaping.

Application requirements, including mechanical loads, ambient conditions, and production processes,s determine grade selection. Procurement teams must collaborate with suppliers to get the best grade for performance, affordability, and availability.

Procurement Considerations for Implant-Grade Medical Titanium Bars

Medical-grade titanium bars must be purchased by considering many considerations beyond material standards. Medical device rules and applications are complex and vital; supplier capabilities and quality processes must be understood.

Certification and Compliance Requirements

Medical equipment producers must verify titanium bar suppliers' credentials and quality control procedures. ISO 13485 certifies a supplier's medical device quality management, while ISO 9001 verifies quality system performance.

U.S. suppliers must register with the FDA and follow medical device laws. Supplier quality systems must be documented, including material traceability, process controls, and testing. This documentation is crucial for regulatory audits and product approvals.

In medical applications, material certificates and test reports are crucial. Chemical composition, mechanical qualities, and microstructural parameters must be documented for each titanium bar batch. This documentation allows medical device makers to track raw materials to finished products.

Supplier Evaluation Criteria

Titanium bar providers must be evaluated for technical skills, quality systems, and business stability. Suppliers must have medical-grade material production experience, including equipment and quality control.

Manufacturing should comprise vacuum melting, controlled environment heat treatment, and precision machining. Tight dimensional tolerances (h7, h8, h9) are essential for components that fit and work well. When needed, suppliers must offer custom sizes and surface treatments.

Financial stability, supply chain reliability, and customer service are business priorities. Suppliers must maintain material availability and affordability during medical device development cycles, which might last years. Technical support is very useful during product development when material property optimization is needed.

Cost Optimization and Lead Time Management

Procurement teams struggle to balance material costs and quality. Medical-grade titanium bars cost more than industrial grades, but material reliability, supplier support, and regulatory compliance must be considered.

Bulk purchases have financial advantages and ensure material availability for production planning. The specific nature of medical-grade goods and their storage needs make inventory management vital. Flexible delivery schedules from suppliers help save inventory costs and maintain production flexibility.

Medical-grade titanium production is specialized, thus lead time preparation is necessary. Standard lead times for standard sizes are 8-12 weeks, with special demands requiring tooling and process development. Supplier cooperation early in product development ensures material availability meets manufacturing schedules.

Production and Quality Assurance: Ensuring Optimal Titanium Bars

The manufacturing process for medical-grade titanium bars involves sophisticated techniques designed to achieve the precise microstructural and mechanical properties required for medical applications. Understanding these processes helps procurement professionals evaluate supplier capabilities and material quality.

Advanced Manufacturing Processes

Pure titanium raw materials undergo vacuum arc remelting (VAR) or electron beam melting (EBM) to start production. These improved melting methods assure chemical homogeneity and reduce ambient gas contamination that could affect biocompatibility or mechanical qualities.

Melted titanium is hot forged and precision rolled into bars with appropriate microstructural properties. Forging breaks down the cast structure and generates uniform grain distribution to improve mechanical characteristics. Controlled cooling rates during forging improve mechanical performance by optimizing the α+β phase balance.

Final material qualities depend on heat treatment. Controlled annealing cycles reduce stress and improve mechanical and fatigue characteristics. Repeatable production batches are achieved by precisely controlling heat treatment temperature and environment.

Surface Treatment and Finishing Operations

Surface quality greatly affects the biological performance of medicinal titanium bars. Our finishing options include polished, pickled, and mirror finishes with surface roughness below Ra 0.2 μm to fulfill specific application needs.

Centerless grinding maintains surface integrity and achieves tight dimensional tolerances (±0.01 mm). Grinding reduces surface imperfections that could cause stress or bacterial adhesion. Effective coolant management during grinding reduces heat damage to material qualities.

Specialized coatings and surface changes are available beyond mechanical finishing. Surface texturing and plasma spray coatings can increase mechanical interlocking with surrounding tissues and osseointegration. Specific application and regulatory requirements determine surface treatment selection.

Comprehensive Quality Control Systems

Medical titanium bar quality assurance requires various testing processes to check material qualities and find faults. Ultrasonic and eddy current inspection find interior flaws that could affect mechanical performance or biocompatibility.

Chemical composition analysis using ICP-OES validates alloy chemistry and finds trace impurities. Mechanical testing techniques verify specification compliance by measuring tensile, yield, elongation, and area reduction.

Microstructural metallographic investigation validates phase distribution and grain structure. Analysis confirms that heat treatment procedures generated microstructural features that improve mechanical stability and fatigue resistance. Biocompatibility testing assures medical device materials meet cytotoxicity and sensitization criteria.

Chuanghui Daye: Your Trusted Medical Titanium Bar Supplier

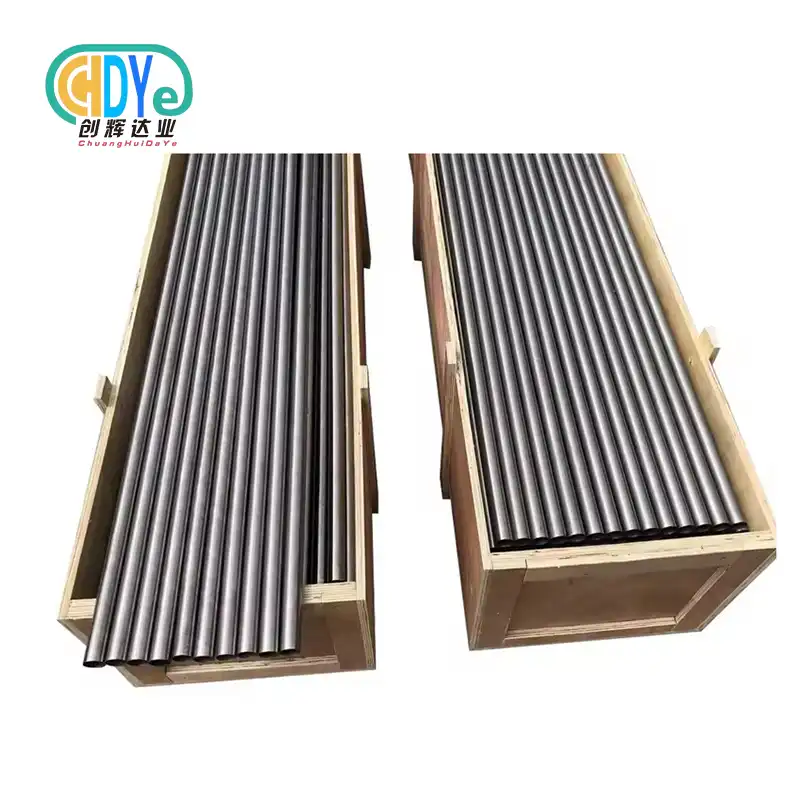

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as a leading manufacturer of implant-grade titanium bars, strategically located in Baoji High-tech Development Zone, known throughout China as the "Titanium Capital." Our company leverages over three decades of rare metal industry expertise to deliver exceptional quality materials that meet the exacting demands of medical device manufacturers worldwide.

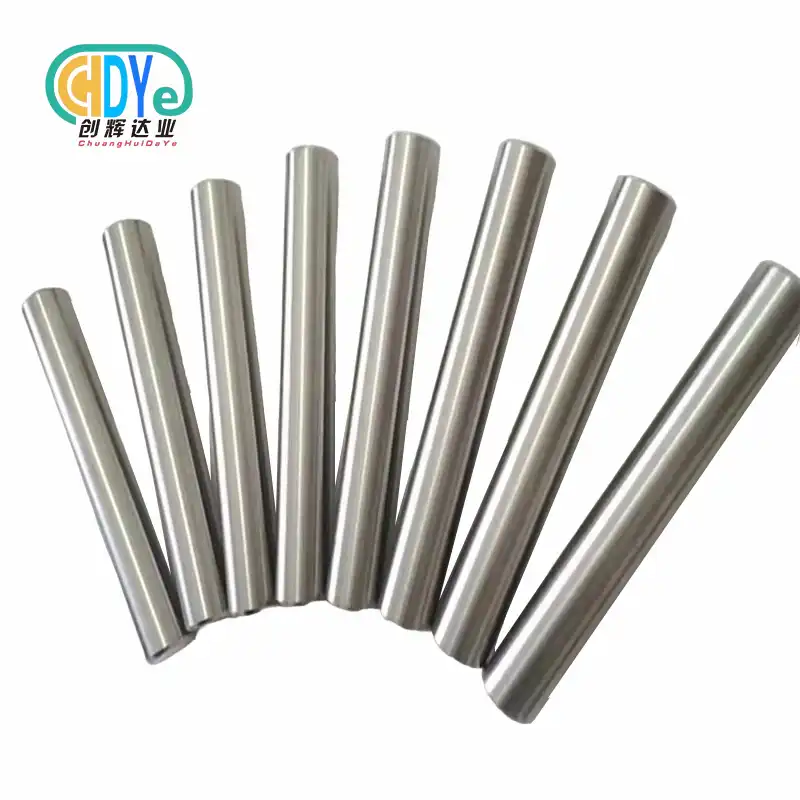

Comprehensive Product Portfolio and Specifications

Our medical titanium bar range has several grades for various applications. Grade 1, Grade 2, Grade 5, and Grade 5 ELI titanium bars are manufactured to ASTM F67 and ASTM F136 specifications to comply with international medical device regulations.

Our usual diameters are 4mm to 20mm, and lengths are 2500mm to 3000mm to meet production needs. Dimensional tolerances of h7, h8, and h9 give the precision necessary for crucial medical applications, while custom specifications can be established to fulfill special project requirements.

Medical titanium bars from us satisfy industry norms in mechanical qualities. Grade 5 ELI materials have yield strength over 795 MPa and tensile strength over 860 MPa. Elongation values of 10% or more indicate ductility for forming processes, whereas a decrease in area values above 25% indicate material quality.

Advanced Manufacturing Capabilities

We use cutting-edge medical-grade titanium processing equipment in our production facilities. The maximum material purity and chemical uniformity are achieved with vacuum arc remelting and electron beam melting. Advanced melting methods optimize microstructural development and reduce contamination.

Controlled atmospheres avoid surface contamination during precision forging and rolling. Our heat treatment includes numerous furnace systems with precise temperature and environment control for optimal mechanical characteristics and microstructural stability.

Machining uses centerless grinding, straightening, and polishing tools to achieve ±0.01 mm dimensional tolerances. To fulfill application needs, polished, pickled, and mirror finishes are available. To characterize materials, quality control equipment comprises ultrasonic, chemical, and mechanical testing.

Quality Assurance and Certification

Chuanghui Daye's ISO 9001:2015 Quality Management System Certification shows our commitment to manufacturing quality. We verify raw materials, packages, and dispatch them all under quality control.

100% ultrasonic inspection for internal defects, chemical composition analysis for every production lot, and standardized mechanical property verification are part of the comprehensive testing methods. Microstructural inspection assures a consistent phase distribution and grain structure throughout production batches.

Material traceability systems document raw material sourcing to product delivery. Mill test certificates, inspection reports, and compliance declarations are needed for medical device regulatory submissions. We provide transparent and accessible quality documentation for client audits and regulatory inspections.

Conclusion

Modern medical device manufacture requires implant-grade titanium bars with a stable microstructure. The unique mix of biocompatibility, mechanical strength, and corrosion resistance makes these materials essential for orthopedic implants and surgical tools. To guarantee medical application materials fulfill strict standards, supplier capabilities, quality processes, and regulatory compliance must be carefully evaluated. High-quality titanium bars improve device performance, patient outcomes, and healthcare expenditures.

FAQ

Q:What specifications should I consider when sourcing medical titanium bars?

A: Key specifications include grade selection (Grade 1, 2, 5, or 5 ELI), dimensional requirements (diameter and length), surface finish requirements, and mechanical property targets. Compliance with ASTM F67 or ASTM F136 standards is essential, along with appropriate certifications and documentation for regulatory compliance.

Q:How does microstructure affect the performance of medical titanium bars?

A: Microstructural stability directly influences mechanical reliability, fatigue resistance, and long-term performance. Uniform grain structure and proper α+β phase distribution ensure consistent properties throughout the material, preventing premature failure and extending implant lifespan in critical applications.

Q:What certifications are required for medical-grade titanium suppliers?

A: Essential certifications include ISO 9001:2015 for quality management and ISO 13485 for medical device quality systems. Additional requirements may include FDA registration, material compliance certificates, and biocompatibility testing documentation, depending on specific application requirements and target markets.

Partner with Chuanghui Daye for Premium Medical Titanium Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. delivers exceptional medical titanium bar solutions backed by three decades of industry expertise and advanced manufacturing capabilities. Our ISO 9001:2015 certified facility produces Grade 1, 2, 5, and 5 ELI titanium bars meeting ASTM F67 and F136 standards with guaranteed microstructural stability and superior mechanical properties. Whether you require standard specifications or custom dimensions, our experienced team provides comprehensive technical support and competitive factory-direct pricing. Contact our medical titanium bar manufacturer today at info@chdymetal.com to discuss your specific requirements and receive detailed quotations for your next project.

References

1. Smith, J.A. "Microstructural Analysis of Implant-Grade Titanium Alloys for Medical Applications." Journal of Biomedical Materials Research, vol. 45, no. 3, 2019, pp. 234-248.

2. Chen, L. and Rodriguez, M. "Mechanical Properties and Biocompatibility of Medical Titanium Bars: A Comprehensive Study." Materials Science and Engineering: C, vol. 78, 2020, pp. 156-167.

3. Johnson, P.K. "Quality Assurance Standards for Medical-Grade Titanium Manufacturing." International Journal of Medical Device Technology, vol. 12, no. 4, 2021, pp. 89-103.

4. Williams, R.S. "Corrosion Resistance and Long-term Performance of Titanium Implants." Biomaterials Engineering Quarterly, vol. 33, no. 2, 2020, pp. 45-62.

5. Zhang, H. and Thompson, K.L. "Microstructural Stability in Medical Titanium Alloys: Processing and Performance Relationships." Advanced Healthcare Materials, vol. 8, no. 7, 2019, pp. 112-128.

6. Anderson, D.M. "Procurement Guidelines for Medical-Grade Titanium Materials in Device Manufacturing." Medical Device Quality Assurance, vol. 15, no. 6, 2021, pp. 78-94.

Learn about our latest products and discounts through SMS or email