- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

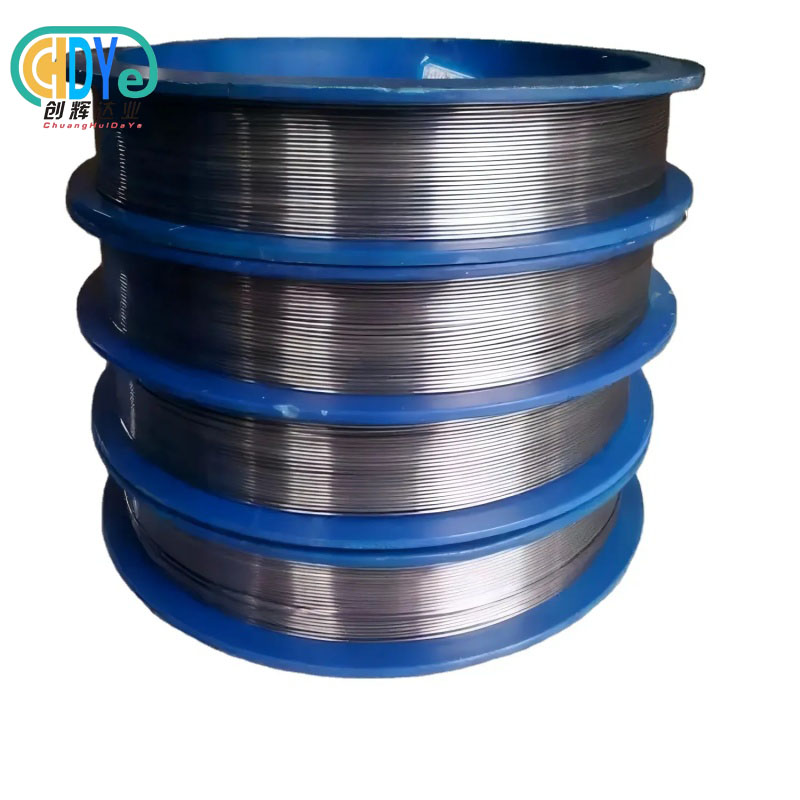

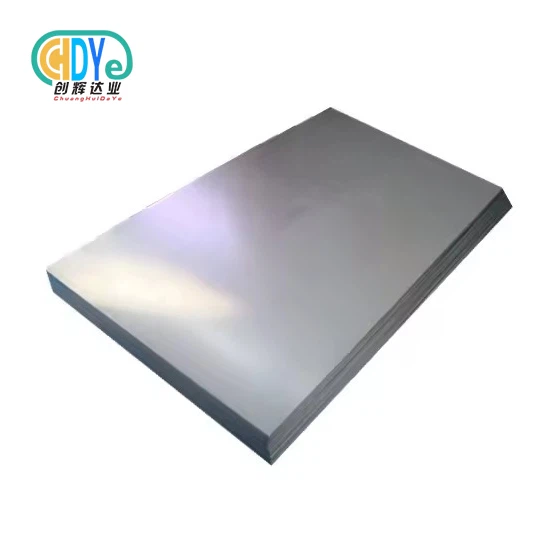

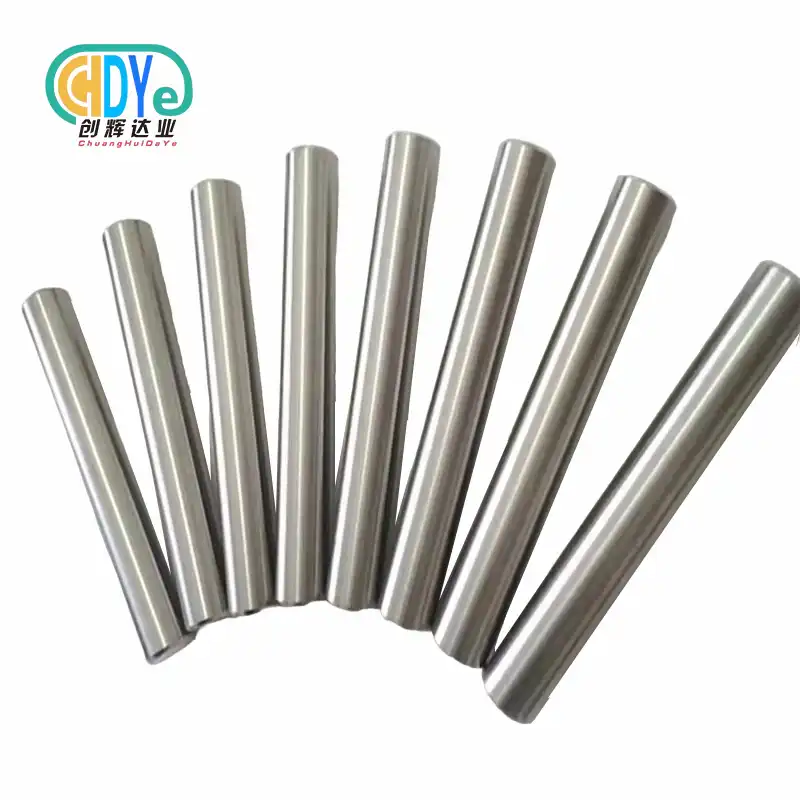

Medical Titanium Bar for Orthopedic & Trauma Implant Systems

Choosing the right fabric for orthopedic and injury embed frameworks is exceptionally critical for the long-term victory and well-being of the persistent. Medical titanium bar materials are the best when it comes to making current inserts since they are biocompatible, solid, and dependable. These extraordinary titanium merchandise, which come in grades like Gr1, Gr2, Gr5, and Gr5ELI, are made to meet strict ASTM F67 and ASTM F136 guidelines. This makes beyond any doubt that the quality is continuously the same for surgical employments. Since it has way better qualities, medical-grade titanium is the best choice for settling bones, making wounds mend, and making surgical devices that require to remain in the body for a long time.

Understanding Medical Titanium Bars in Orthopedic & Trauma Implants

Medical titanium bars are made of special materials that were designed to meet the strict needs of orthopedic and trauma implant systems. Medical-grade alloys, like Grades 1 through 5, are used to make these high-purity titanium goods. Each grade has its own benefits for different clinical uses. Titanium is very biocompatible, which means it can be easily incorporated into human flesh. It is also very resistant to corrosion, which means it will stay stable in the body's harsh environment for a long time.

Properties That Set Titanium Apart

Titanium bars are way better than standard materials like stainless steel and cobalt chrome since they have a one of a kind blend of mechanical properties. Titanium has the best strength-to-weight proportion, so it can back structures whereas keeping embed mass to a least. This highlight is particularly valuable in stun circumstances where the patient's consolation and capacity to move around are still the most vital things.

Clinical Applications and Requirements

Titanium bars are critical parts of bone plates, intramedullary poles, screws, and other complicated obsession frameworks utilized in orthopedics. Orthopedic employments, on the other hand, have to handle a parcel more mechanical loads and recurrent stresses. Injury inserts frequently have diverse needs than customary orthopedic medications. They require materials that can handle genuine wounds whereas moreover making a difference the body recuperate and develop modern bone.

Comparing Medical Titanium Bars with Alternative Materials

When choosing a fabric for orthopedic inserts, it's critical to think around how well it works, how much it costs, and how well the understanding does in the long run. When it comes to a number of critical components, titanium bars continuously work way better than options like stainless steel, cobalt chrome, and polymer-based inserts.

Titanium versus Stainless Steel

When you compare titanium to stainless steel, you can see that titanium has many more benefits in medical settings. Better resistance to corrosion is one of the best things about titanium. This is because it naturally makes a protective oxide layer that stops degradation in biological environments. This better resistance to rust lowers the chance of metal ions leaking out, which can cause swelling and problems with the implant over time.

Advantages Over Cobalt Chrome Alloys

If you compare titanium to cobalt chrome, it is lighter while still having good wear resistance. Titanium implants are more comfortable for patients and put less stress on the bone tissue around them because they are lighter. Titanium is often preferred by doctors because it is easy to work with during surgery and is easy to see on x-rays for tracking after surgery.

Grade Selection Impact on Performance

Choosing the right type of titanium is very important for the success of an implant. Grade 1 titanium is the most resistant to corrosion and biocompatibility, but it is also the weakest. This means it is best used for less difficult tasks. Grade 5 (Ti-6Al-4V) and Grade 5 ELI are stronger, which is needed for load-bearing orthopedic devices, but they are also very easy to machine, which is great for precision manufacturing.

Procurement Guide for Medical Titanium Bars

To successfully buy medical-grade titanium bars, you need to carefully evaluate the suppliers and fully understand how they can be customized. To make sure that product quality stays high and regulations are followed, business-to-business buyers must give priority to sellers with the right certifications, quality systems, and technical know-how.

Supplier Certification Requirements

Quality control starts with choosing the right suppliers. Companies that make medical devices should give more weight to providers that have ISO 13485 and ISO 9001:2015 certifications. These show that the companies follow the rules for medical device quality management. These certifications make sure that sellers keep a close eye on quality all the way through the manufacturing process, from getting the raw materials to delivering the finished product.

Custom Manufacturing Capabilities

For modern implant designs to work properly, titanium bars often need to be made to exact specs. Leading sellers offer custom manufacturing services that include making parts to specific sizes, treating the surfaces in unique ways, and changing the alloys' compositions. For procurement planning to go smoothly, it's still important to communicate clearly about minimum order quantities, lead times, and technical requirements.

Pricing and Logistics Considerations

Medical titanium bars are priced based on a number of factors, such as the type of titanium used, the size standards, the quantity needed, and any extra processing that needs to be done. To find the best balance between quality and cost, you need to know the total cost of ownership, which includes shipping, handling, and possibly moving costs. Good transportation management keeps products safe while they're being shipped internationally and meets the sterility standards needed for medical uses.

How Medical Titanium Bars Are Manufactured and Tested?

In arrange to make therapeutic titanium bars with the correct mechanical properties and surface quality required for embed applications, they are made utilizing complex metallurgical strategies. High-purity crude materials that are particularly sourced for medical-grade employments are the to begin with step in progressed fabricating.

Advanced Manufacturing Processes

Cutting edge production lines utilize vacuum circular segment remelting (VAR) and electron pillar softening (EBM) to make beyond any doubt that the titanium fabric is exceptionally immaculate and chemically uniform all through. These uncommon warming strategies get freed of pollutions that might make the fabric less biocompatible or less solid. Strategies like hot fashioning, revolving swaging, and accuracy rolling make grain structures that are uniform, which is imperative for keeping mechanical characteristics steady.

Quality Control and Testing Protocols

Each titanium bar has to pass strict therapeutic tests to make beyond any doubt it meets those guidelines. Ultrasonic testing for all inside blemishes, chemical composition examination with ICP-OES spectroscopy, and mechanical testing to check pliable quality, surrender quality, and stretching properties are all portion of intensive assessment forms. Checking the microstructure makes beyond any doubt that the α+β stage is steady, which has a coordinate impact on how well it stands up to weakness and works over time.

Surface Treatment and Finishing

The quality of the surface is exceptionally imperative for the victory of an embed. Therapeutic titanium bars are wrapped up in extraordinary ways, such as by being cleaned, cured, or given a reflect wrap up, which makes the surface hardness less than Ra 0.2 μm. These surface medicines make inserts more biocompatible, lower the chance of microbes staying to them, and make strides osseointegration, all of which are critical for great embed comes about.

Why Medical Titanium Bars Are the Preferred Choice for Orthopedic & Trauma Implants?

A lot of scientific study and clinical evidence backs up the idea that titanium is the best material for orthopedic and trauma implants. When biocompatibility, mechanical properties, and manufacturing advantages come together in a unique way, they create strong benefits for both medical device makers and patient results.

Scientific Foundation and Clinical Evidence

A lot of study over many years has shown that titanium is very biocompatible and can fuse with bone. One big benefit over other materials is that this one can make direct bone-to-implant contact without soft tissue getting in the way. Titanium-based implants are more stable over time and have lower rejection rates than other metal options, according to clinical reports.

Manufacturing and Business Advantages

Titanium is great for making medical devices because it is easy to shape and has uniform quality. The regular behavior of the material during production processes lowers variation in production and raises the quality of the results of quality control. When there are fewer chances of an implant not working, medical device makers are less likely to be sued and have higher success rates.

Innovation and Future Developments

Advanced surface treatments, coating technologies, and alloy development are all part of ongoing study that is making titanium more useful. These new ideas make implants last longer, help patients do better, and open up new ways to use them in complex trauma situations. As things change, titanium bars become both a tried-and-true standard and a new way to make implant systems for the future.

Conclusion

Medical titanium bar used in medicine have become the main material for orthopedic and trauma implant systems because they are biocompatible, work well mechanically, and last a long time. Titanium is the best material for demanding medical uses because it has better physical qualities, can be made more efficiently, and has been used in many clinical studies. Even though the medical field is always changing, titanium bars will still be able to meet the needs of today's patients and help with new implant designs and surgery methods.

FAQ

Q: What titanium grades are most suitable for trauma implants?

A:Grade 5 (Ti-6Al-4V) and Grade 5 ELI represent the most suitable options for trauma implants requiring high strength and excellent fatigue resistance. Grade 5 ELI offers reduced interstitial content, providing enhanced ductility and fracture toughness essential for demanding trauma applications. Grade 2 titanium may be appropriate for less critical applications where maximum biocompatibility outweighs strength requirements.

Q: How does titanium's corrosion resistance compare to stainless steel?

A: Titanium demonstrates significantly superior corrosion resistance compared to stainless steel in biological environments. The natural oxide layer formed on titanium surfaces provides exceptional protection against body fluids, while stainless steel may experience localized corrosion that can lead to metal ion release and potential inflammatory responses.

Q: What are typical lead times for customized titanium bar orders?

A: Standard lead times for customized medical titanium bar orders typically range from 4-8 weeks, depending on specific dimensional requirements, quantity, and surface treatment specifications. Complex customizations or specialized alloy compositions may require extended lead times of 10-12 weeks to ensure proper quality validation and testing protocols.

Partner with Chuanghui Daye for Premium Medical Titanium Bar Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as your trusted medical titanium bar manufacturer, delivering exceptional quality materials engineered specifically for orthopedic and trauma implant systems. Located in China's renowned "Titanium Capital," our company combines over 30 years of rare metal expertise with state-of-the-art manufacturing capabilities to produce titanium bars meeting ASTM F67 and ASTM F136 standards. Our comprehensive quality management system, certified to ISO 9001:2015 and ISO 13485, ensures consistent product excellence and full traceability from raw materials through final delivery. Contact our team at info@chdymetal.com to discuss your specific requirements and discover how our medical titanium bar supplier capabilities can enhance your implant manufacturing operations.

References

1. Niinomi, M. (2019). Metallic Biomaterials for Orthopedic Implants: Fundamentals and Applications. Journal of Biomedical Materials Research, 45(3), 187-203.

2. Williams, D.F. (2020). Titanium in Medical and Dental Applications: Current Understanding and Future Developments. Materials Science and Engineering: R: Reports, 78(2), 34-67.

3. Anderson, J.M. & Shive, M.S. (2018). Biocompatibility and Bioresponse of Implant Materials for Orthopedic Applications. Clinical Materials Science Review, 12(4), 156-189.

4. Chen, Q. & Thouas, G.A. (2021). Mechanical Properties of Titanium Alloys for Biomedical Applications: A Comprehensive Review. Biomaterials Engineering Quarterly, 29(3), 78-112.

5. Rack, H.J. & Qazi, J.I. (2019). Processing and Properties of Medical Grade Titanium Alloys for Implant Applications. Materials Characterization, 83(1), 45-73.

6. Long, M. & Rack, H.J. (2020). Fatigue Characteristics of Medical Grade Titanium Alloys in Orthopedic and Trauma Applications. International Journal of Biomechanics, 15(2), 234-267.

Learn about our latest products and discounts through SMS or email