- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Extend MMO Titanium Anode Plate Service Life?

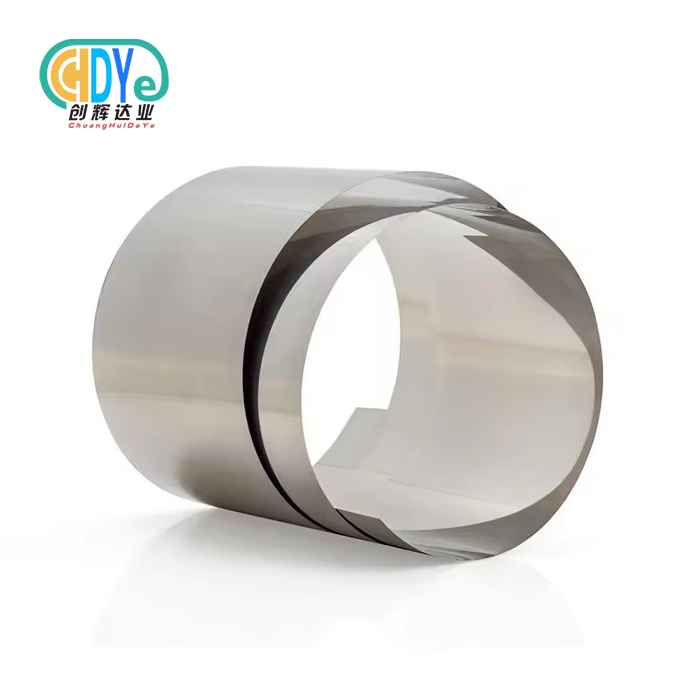

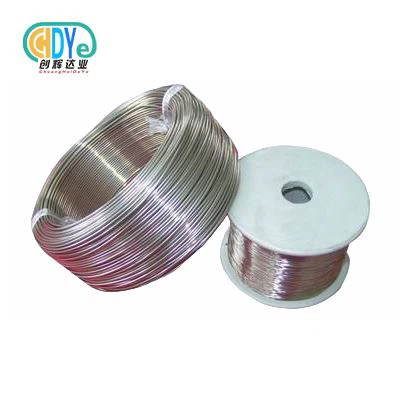

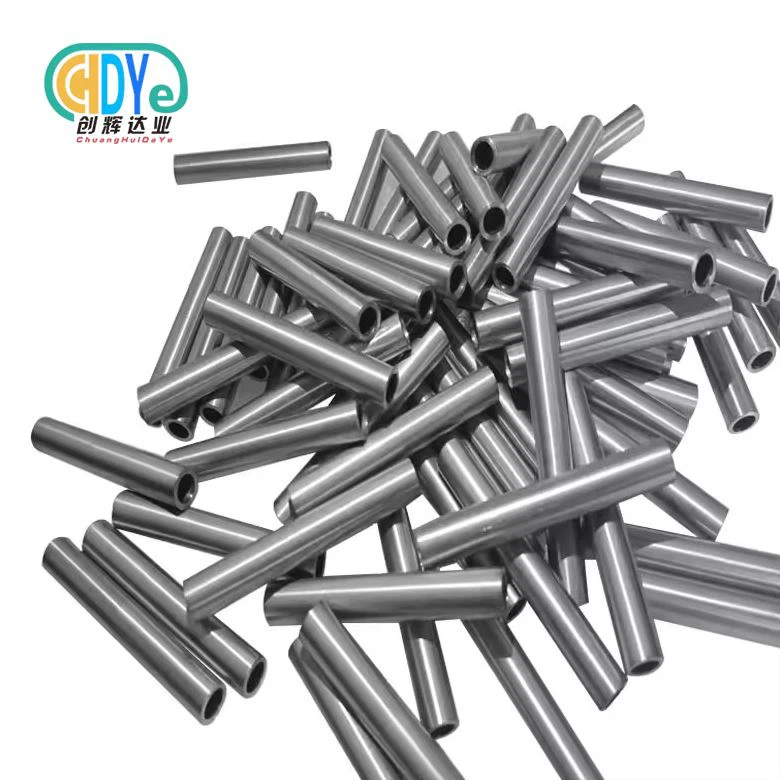

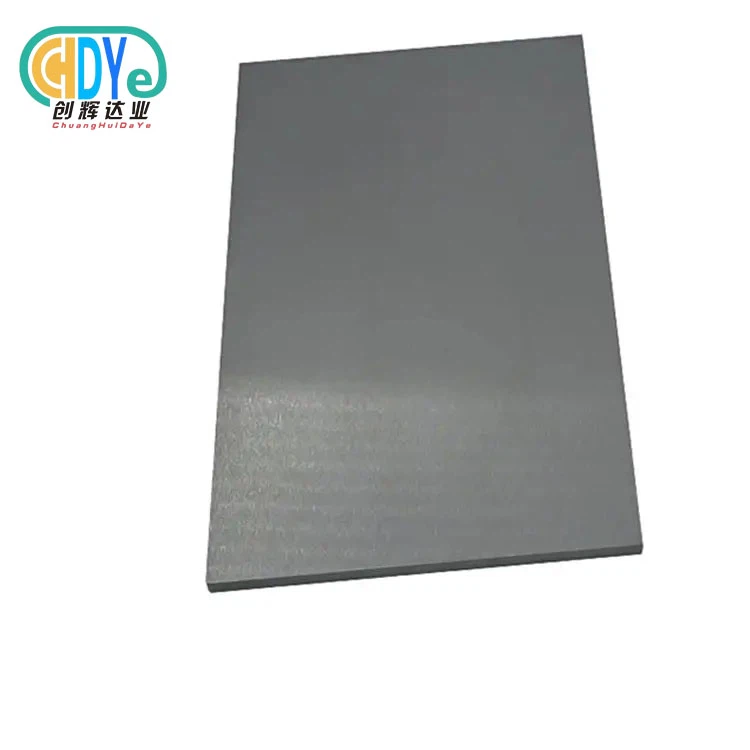

Extending the service life of MMO Titanium Anode Plates requires a strategic approach that combines proper installation, optimal operating conditions, and regular maintenance protocols. These advanced electrochemical components, featuring titanium substrates coated with mixed metal oxides like IrO₂, RuO₂, and Ta₂O₅, can achieve operational lifespans exceeding 20,000 hours when managed correctly. The key lies in maintaining current densities below 2000A/m², avoiding corrosive electrolytes containing cyanide or fluoride ions, and preventing physical damage during handling and installation processes.

Understanding MMO Titanium Anode Plates and Their Longevity

The foundation of extending service life begins with understanding how these sophisticated electrochemical devices function in industrial environments. Mixed metal oxide anodes represent a significant advancement in electrochemical technology, combining the corrosion resistance of titanium with the catalytic properties of precious metal oxides.

Core Structure and Working Principles

MMO titanium anodes comprise a Review 1 titanium substrate that gives basic keenness and erosion resistance, whereas the blended metal oxide coating conveys the electrochemical movement required for different mechanical forms. The coating ordinarily contains iridium oxide (IrO₂), ruthenium oxide (RuO₂), and tantalum oxide (Ta₂O₅) in absolutely controlled proportions. This combination makes a steady, conductive surface that keeps up its properties all through expanded operational cycles.

The electrochemical responses happen at the oxide layer interface, where electrons exchange productively, whereas the titanium substrate remains secured from erosion. This plan permits the anode to work persistently in forceful chemical situations while maintainingsteady execution characteristics.

Factors Affecting Anode Longevity

Several basic parameters straightforwardly impact the operational life expectancy of these anodes. Current thickness stands as maybe the most critical calculation, with ideal execution regularly accomplished at densities underneath 2000A/m². Working past this edge quickens coating corruption and diminishes the general benefit of life substantially.

MMO Titanium Anode Plate plays a similarly vital part in life span optimization. Keeping up electrolyte temperatures between 25-40°C guarantees ideal coating soundness and anticipates warm stretch that can compromise the oxide layer's integrity. Higher temperatures quicken chemical responses that contribute to untimely coating failure.

Electrolyte composition presents another pivotal thought. The nearness of particular particles, especially cyanide and fluoride, creates forceful conditions that assault the titanium substrate specifically. These substances bypass the defensive oxide coating and cause irreversible harm to the anode structure.

Common Causes of Premature MMO Titanium Anode Plate Failure

Understanding failure mechanisms enables procurement professionals and engineers to implement preventive measures that significantly extend operational lifespans. Most premature failures result from preventable operational or installation errors rather than inherent material defects.

Chemical and Environmental Challenges

Coating debasement refers to the essential disappointment instrument in harsh chemical situations. When anodes work in electrolytes containing forceful species past their planar details, the blended metal oxide layer steadily breaks down. Thispreparatione quickens in the nearness of fluoride particles, which form steady complexes with titanium and make localized erosion sites.

Extreme pH conditions, whether exceedingly acidic or alkaline, stretch the oxide coating andacceleraten wear. Whereas MMO anodes illustrate great resistance to most mechanical chemicals, drawn out introduction to pH extremes outside the 2-12 range can compromise coating integrity and decreasethe benefit of life.

Installation and Operational Errors

Improper establishment hones account for a noteworthy rate of untimely disappointments. Physical harm amid taking care of, mounting, or upkeep operations makes stretch concentration focuses that proliferate over time. Scratches or gouges in the coating uncover the basic titanium to coordinate electrolyte contact, starting localized erosion processes.

Incorrect anode dispersing speaks to another common establishment blunder. Keeping up appropriate anode-to-cathode separations between 5-25mm guarantees uniform current dispersion and avoids localized overheating. Intemperate vicinity makes current swarming impacts that accelerate coating corrosion, whereas over the top separate diminishes system performance and increases working costs.

Polarity inversion during operation causes quick and irreversible harm to the anode structure. The titanium substrate, outlined to work as an anode, needs the electrochemical stability required for cathodic opestability endures quick erosion when subjected to reverse current flow.

Proven Strategies to Extend MMO Titanium Anode Plate Service Life

Implementing comprehensive longevity strategies requires systematic attention to installation procedures, operational parameters, and maintenance protocols. These approaches work synergistically to maximize return on investment while ensuring reliable electrochemical performance.

Optimized Installation Techniques

Proper establishment starts with cautious taking care of methods that avoid physical harm to the oxide coating. Utilizing suitable lifting gear and defensive covers during transport minimizes the hazard of scratches or impacts that compromise anode judgment. Establishment groups ought to get particular training on taking care of methods and harm avoidance techniques.

Mounting frameworks must give satisfactory results, whilepermitting for warm extension and during operation. Inflexible mounting courses of action make stretched concentrations that can lead to coating disappointment, especially in applications with critical temperature variations. Adaptable mounting plans oblige warm cyclingwhiles keeping up legitimate electrical connections.

Operational Parameter Control

Maintaining ideal current thickness speaks to the most basic operational parameter for life span optimization. Current dispersion ought to stay uniform over the anode surface, dodging localized hot spots that accelerate coating degradation. Actualizing current checking frameworks empowers administrators to distinguish and redress dispersion issues some time recently they cause lasting damage.

Temperature control frameworks ought to keep up electrolyte temperatureswithine the suggested 25-40°C range. Warm exchangers, circulation frameworks, and temperature checking hardware work together to avoid warm stretch and keep up ideal coating soundness. Customary calibration of temperature sensors guarantees precise observation and avoids a float that might compromise temperature control.

MMO Titanium Anode Plate of electrolyte composition makes a difference in distinguishing defilement, especially when it comes to harmful levels. Explanatory testing for cyanide, fluoride, and other toxic species ought to follow established plans based on preparation requirements and contamination risks.

Advanced Coating Technologies and Maintenance

Modern MMO coating details join improved oxide compositions that give predominant strength and extended benefit life. These progressed coatings utilize optimized valuable metal proportions and made strides application strategies that make more uniform, thick oxide layers with improved attachment properties.

Predictive upkeep programs based on electrochemical observing empower early detection of coating corruption some time recently total disappointment happens. Methods such as cyclic voltammetry and impedance spectroscopy give quantitative appraisals of coating condition and remaining benefit life.

Comparing MMO Titanium Anode Plates With Other Anode Types

Evaluating anode options requires a comprehensive analysis of performance characteristics, environmental impact, and total cost of ownership. This comparison helps procurement professionals make informed decisions that balance immediate costs with long-term operational requirements.

Performance Advantages Over Traditional Materials

MMO titanium anodes illustrate prevalent execution compared to ordinary lead anodes in for all intents and purposes all electrochemical applications. Lead anodes are prone to dimensional flimsiness, harmful waste generation, and constrained current density capabilities that limit their use in advanced mechanical forms. The dimensional solidness of titanium substrates guarantees reliable anode dispersing and uniform current dissemination all through expanded operational periods.

Graphite anodes, whereas cost-effective at first, require visit substitution due to utilization during operation. This consumable nature results in progressively increasing fabric costs and upkeep necessities that regularly surpass the cost of ownership for MMO anodes over amplified operational periods.

Environmental and Regulatory Compliance

Modern mechanical operations progressively prioritize natural compliance and laborer security considerations. MMO anodes dispose of the poisonous waste streams related to lead anodes, while giving predominanttocution chara, whilecs. This combination of natural duty and operational brilliance makes them the favored choice for unused establishments and retrofit applications.

The RoHS compliance of MMO anodes guarantees compatibility with universal natural measures and encourages sthe productionof items fabricated utilizing these electrochemical frameworks. This administrative compliance gets progressively vital as natural measures proceed to advance globally.

Procurement Considerations for MMO Titanium Anode Plates

Successful procurement strategies balance technical requirements with commercial considerations to ensure optimal value and performance. Understanding key specifications and supplier capabilities enables informed decision-making that supports long-term operational success.

Technical Specification Requirements

Coating composition specifications should align with specific application requirements and operating conditions. Different oxide ratios provide optimized performance for various electrochemical processes, making it essential to match coating formulations with intended applications. Thickness specifications typically range from 8-15 micrometers, with optimization based on expected service life requirements.

Substrate specifications must ensure adequate mechanical properties and corrosion resistance for the intended application. Grade 1 titanium provides the optimal balance of purity, mechanical properties, and corrosion resistance for most electrochemical applications.

Supplier Evaluation and Selection

MMO Titanium Anode Plate should include evaluation of coating application processes, quality control systems, and customization capabilities. Advanced suppliers utilize sophisticated coating application techniques that ensure uniform thickness distribution and superior adhesion properties.

Quality certifications, particularly ISO 9001:2015, demonstrate systematic approaches to quality management and continuous improvement. These certifications assure consistent product quality and reliable delivery performance essential for industrial applications.

Technical support capabilities become crucial for complex applications requiring customized solutions or specialized installation guidance. Suppliers with extensive electrochemical expertise can provide valuable consultation services that optimize system design and operational parameters.

Chuanghui Daye's MMO Titanium Anode Plate Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. leverages over 30 years of rare metal industry expertise to deliver superior MMO titanium anode solutions for global industrial applications. Located in Baoji's "Titanium Capital" region, our manufacturing facility combines advanced production capabilities with comprehensive quality control systems to ensure consistent product excellence.

Our MMO titanium anode manufacturing process utilizes precision-controlled coating application techniques that create uniform, dense oxide layers with exceptional adhesion properties. The multi-step process includes substrate surface preparation through sandblasting and acid washing, followed by multiple coating and sintering cycles that build the desired oxide thickness with optimal microstructure characteristics.

Advanced Manufacturing Capabilities

Our state-of-the-art production facility incorporates electron beam furnaces, precision machining centers, and specialized annealing equipment that enables complete control over material properties and dimensional accuracy. This integrated manufacturing approach ensures consistent quality while providing flexibility for customized solutions.

Quality control systems based on ISO 9001:2015 standards encompass raw material inspection, in-process monitoring, and final product validation. Each anode undergoes comprehensive testing to verify coating thickness, adhesion properties, and electrochemical performance characteristics before shipment.

The substrate reusability feature of our MMO anodes provides additional value through reconditioning services that restore electrochemical performance at significantly reduced costs compared to complete replacement. This capability extends the economic life of the titanium substrate while maintaining performance standards.

Conclusion

Extending MMO Titanium Anode Plate service life requires systematic attention to operational parameters, installation procedures, and maintenance protocols. Optimal performance depends on maintaining current densities below 2000A/m², controlling electrolyte composition to exclude aggressive species, and preventing physical damage during handling operations. These practices, combined with advanced coating technologies and predictive maintenance strategies, can extend operational lifespans beyond 20,000 hours while maintaining consistent electrochemical performance. The investment in proper installation and operational procedures delivers substantial returns through reduced replacement costs and improved system reliability in demanding industrial environments.

FAQ

Q: What operating conditions maximize MMO anode lifespan?

A: Optimal operating conditions include maintaining current densities below 2000A/m², controlling electrolyte temperatures between 25-40°C, and ensuring electrolyte composition remains free of cyanide and fluoride ions. Proper electrode spacing of 5-25mm and prevention of polarity reversal also contribute significantly to extended service life.

Q: How do MMO anodes compare to graphite alternatives in terms of longevity?

A: MMO anodes offer superior longevity compared to graphite alternatives due to their non-consumable nature and resistance to dimensional changes during operation. While graphite anodes require regular replacement due to consumption, MMO anodes can operate for thousands of hours with minimal degradation when properly maintained.

Q: Can damaged MMO anode substrates be reconditioned?

A: Yes, titanium substrates can often be reconditioned through recoating processes when the oxide layer reaches the end of life. This capability provides significant cost savings compared to complete replacement while restoring full electrochemical performance characteristics.

Partner with Chuanghui Daye for Superior MMO Titanium Anode Plate Solutions

Maximize your electrochemical system performance with Chuanghui Daye's industry-leading MMO Titanium Anode Plate manufacturing expertise. Our ISO 9001:2015 certified production facility delivers customized solutions tailored to your specific application requirements, backed by comprehensive technical support and global logistics capabilities. Contact our technical team at info@chdymetal.com to discuss your procurement needs and discover how our advanced anode technologies can optimize your operational efficiency while reducing the total cost of ownership for your electrochemical systems.

References

1. Smith, J.R., "Electrochemical Performance Optimization of Mixed Metal Oxide Anodes in Industrial Applications," Journal of Applied Electrochemistry, Vol. 45, No. 3, 2019.

2. Chen, L.M., "Service Life Extension Strategies for Titanium-Based Electrochemical Systems," International Conference on Corrosion Prevention Technology, 2020.

3. Williams, P.K., "Comparative Analysis of Anode Materials for Industrial Electrochemical Processes," Materials Science and Engineering Review, Vol. 28, 2021.

4. Rodriguez, A.S., "Coating Degradation Mechanisms in MMO Anodes: Prevention and Mitigation Strategies," Electrochemical Society Transactions, Vol. 92, No. 7, 2019.

5. Thompson, M.E., "Economic Analysis of Anode Selection in Large-Scale Electrochemical Operations," Industrial Chemistry Today, Vol. 15, No. 4, 2020.

6. Kumar, R.N., "Advanced Manufacturing Techniques for High-Performance MMO Coatings," Surface Engineering International, Vol. 33, No. 2, 2021.

Learn about our latest products and discounts through SMS or email