- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Niobium Alloy Plate vs Titanium: Which Material Performs Better?

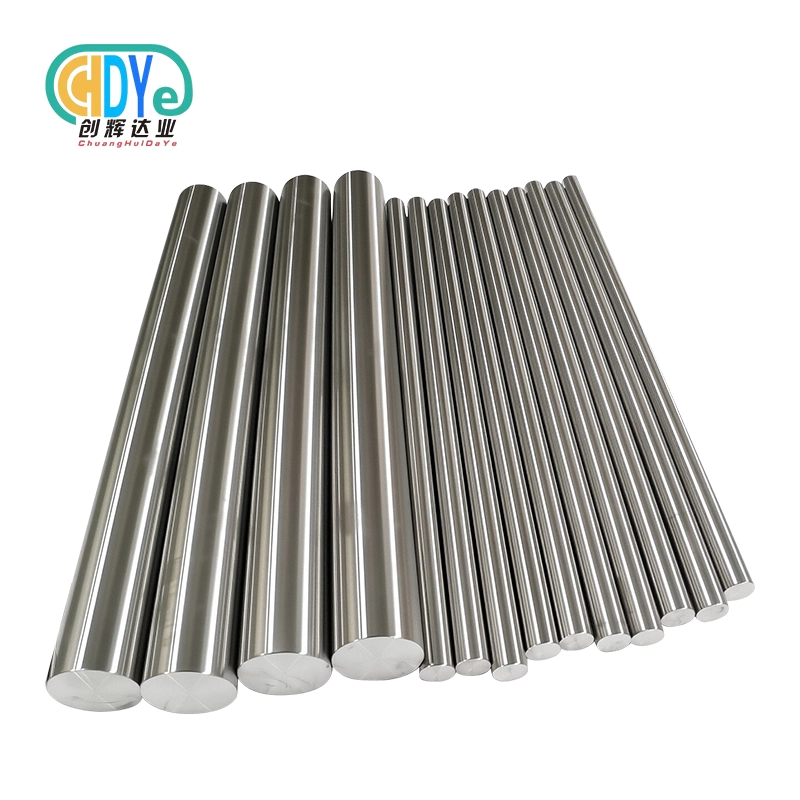

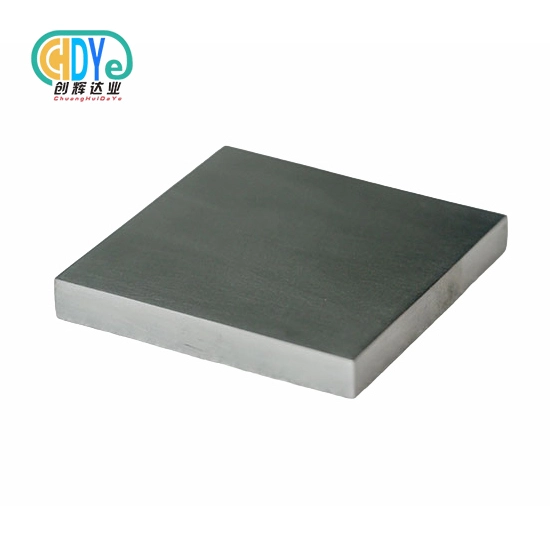

In the world of advanced materials, the debate between niobium alloy plates and titanium has been ongoing, with engineers and manufacturers constantly weighing the pros and cons of each material. Both niobium alloys and titanium boast impressive properties that make them suitable for a wide range of high-performance applications. This blog post aims to delve into the comparison between niobium alloy plates and titanium, exploring their respective strengths, weaknesses, and ideal use cases. By examining factors such as strength, heat resistance, corrosion resistance, and cost-effectiveness, we'll provide a comprehensive analysis to help you determine which material might be the better choice for your specific needs. Whether you're involved in aerospace, chemical processing, or advanced electronics, understanding the nuances between these two exceptional materials can be crucial in making informed decisions for your projects.

Strength and Heat Resistance Comparison of Niobium Alloy Plate vs Titanium

Tensile Strength and Yield Strength

When comparing the strength of niobium alloy plates and titanium, it's essential to consider both tensile and yield strength. Niobium alloy plates, particularly those with additions like zirconium or titanium, can exhibit impressive strength characteristics. For instance, the Nb-1Zr alloy offers a tensile strength of around 380-450 MPa, while some niobium-titanium alloys can reach even higher values. Titanium, especially in its alloyed forms like Ti-6Al-4V, generally outperforms niobium alloys in terms of tensile strength, with values often exceeding 900 MPa. However, niobium alloy plates maintain their strength at higher temperatures more effectively than many titanium alloys, making them particularly valuable in high-temperature applications where long-term stability is crucial.

Temperature Resistance and Melting Points

One of the standout features of niobium alloy plates is their exceptional heat resistance. Niobium has a melting point of approximately 2,477°C (4,491°F), significantly higher than titanium's 1,668°C (3,034°F). This higher melting point translates to better performance in extreme temperature environments. Niobium alloy plates retain their structural integrity and mechanical properties at temperatures where titanium might begin to soften or lose strength. This makes niobium alloys particularly suitable for applications in aerospace propulsion systems, nuclear reactors, and high-temperature chemical processing equipment where maintaining material stability under intense heat is paramount.

Thermal Expansion and Conductivity

Thermal expansion and conductivity are critical factors in many engineering applications, especially where thermal management is a concern. Niobium alloy plates generally have a lower coefficient of thermal expansion compared to titanium, which means they experience less dimensional change when subjected to temperature fluctuations. This property is particularly valuable in precision instruments and components that must maintain their dimensions across a wide temperature range. Additionally, niobium alloys typically exhibit higher thermal conductivity than titanium, allowing for more efficient heat dissipation in certain applications. This combination of low thermal expansion and good thermal conductivity makes niobium alloy plates an excellent choice for heat exchangers and thermal management systems in aerospace and industrial settings.

Application Advantages: Where Niobium Alloy Plate Outperforms Titanium

Superconductivity Applications

One of the most significant advantages of niobium alloy plates over titanium is their superconducting properties. Certain niobium alloys, particularly niobium-titanium (NbTi) and niobium-tin (Nb3Sn), become superconductors at relatively high temperatures compared to other materials. This makes niobium alloy plates indispensable in the construction of superconducting magnets used in MRI machines, particle accelerators, and fusion reactors. The ability to maintain zero electrical resistance under specific conditions gives niobium alloys a clear edge over titanium in these high-tech applications. Furthermore, the stability and reliability of niobium-based superconductors have made them the material of choice for advanced research in quantum computing and high-energy physics, areas where titanium simply cannot compete.

Corrosion Resistance in Extreme Environments

While both niobium alloy plates and titanium are known for their corrosion resistance, niobium often outperforms titanium in extremely corrosive environments. Niobium's excellent resistance to a wide range of acids, including hydrochloric, sulfuric, and nitric acids, makes it invaluable in chemical processing equipment and storage tanks for highly corrosive substances. In contrast to titanium, which can be susceptible to stress corrosion cracking in certain chloride-rich environments, niobium alloy plates maintain their integrity even in the presence of hot chlorine gas and molten chloride salts. This superior corrosion resistance extends the lifespan of equipment and reduces maintenance costs in industries such as chemical manufacturing, oil refining, and nuclear waste processing, where material failure could have catastrophic consequences.

High-Temperature Stability in Aerospace

In aerospace applications, particularly in propulsion systems and heat shields, niobium alloy plates often outshine titanium due to their superior high-temperature stability. The ability of niobium alloys to retain strength and resist oxidation at temperatures exceeding 1000°C makes them ideal for components in rocket engines, jet turbines, and hypersonic vehicle structures. Unlike titanium, which may require protective coatings for extreme temperature applications, niobium alloys can often be used in their bare state, simplifying design and reducing weight. The combination of high melting point, low thermal expansion, and excellent creep resistance at elevated temperatures gives niobium alloy plates a distinct advantage in pushing the boundaries of aerospace technology, enabling the development of more efficient and capable aircraft and spacecraft.

Material Selection Factors: Cost, Corrosion Resistance, and Processing Differences

Cost Considerations and Availability

When comparing niobium alloy plates to titanium, cost is a significant factor that often tilts the scales in favor of titanium for many applications. Niobium is generally more expensive than titanium due to its rarity and the complexities involved in its extraction and processing. This higher cost can be a deterrent for large-scale applications or projects with tight budget constraints. However, it's important to consider the long-term cost-effectiveness of niobium alloy plates in specific applications where their unique properties can lead to extended service life or improved performance, potentially offsetting the initial higher investment. For instance, in corrosive environments or high-temperature applications, the longevity and reliability of niobium alloy plates might justify the higher upfront cost compared to more frequent replacements or maintenance required with titanium components.

Corrosion Resistance in Various Environments

Both niobium alloy plates and titanium are renowned for their excellent corrosion resistance, but they excel in different environments. Niobium alloys demonstrate superior resistance to a broader range of corrosive media, including most mineral acids, molten metals, and salt solutions. This makes them particularly valuable in chemical processing, nuclear applications, and certain medical implants. Titanium, while highly resistant to chloride-induced corrosion and oxidation, can be susceptible to hydrogen embrittlement and stress corrosion cracking in certain conditions. The choice between niobium alloy plates and titanium often depends on the specific corrosive environment encountered. For instance, in seawater applications, titanium might be preferred due to its excellent resistance to chloride pitting, while in highly acidic chemical processing, niobium alloys could be the better choice due to their broader spectrum of acid resistance.

Processing and Fabrication Challenges

The processing and fabrication of niobium alloy plates present unique challenges compared to titanium. Niobium's higher melting point and reactivity with oxygen at elevated temperatures require more sophisticated melting and forming techniques, often necessitating vacuum or inert atmosphere processing. This can increase manufacturing complexity and cost. However, niobium alloys generally offer excellent formability at room temperature, allowing for complex shapes to be achieved through cold working processes. Titanium, while easier to melt and cast, can be more challenging to machine due to its tendency to work harden and its low thermal conductivity. Welding of niobium alloy plates typically requires specialized techniques to prevent contamination and maintain the material's properties, whereas titanium welding is more straightforward with established procedures. The choice between these materials may thus be influenced by the available manufacturing capabilities and the complexity of the desired component geometry.

Conclusion

In conclusion, the choice between niobium alloy plates and titanium depends on the specific requirements of each application. Niobium alloys excel in high-temperature environments, superconductivity applications, and extreme corrosion resistance scenarios, making them invaluable in aerospace, nuclear, and advanced research fields. Titanium, on the other hand, offers a better strength-to-weight ratio and is more cost-effective for many general applications. Both materials have their unique strengths, and the decision should be based on a careful evaluation of performance needs, environmental conditions, and economic factors. As technology advances, the development of new alloys and processing techniques may further blur the lines between these two exceptional materials, potentially opening up new possibilities for their use in cutting-edge applications.

For more information on niobium alloy plates and other high-performance materials, please contact Shaanxi Chuanghui Daye Metal Material Co., Ltd. at info@chdymetal.com. Our team of experts is ready to assist you in selecting the best material for your specific needs, leveraging our extensive experience in rare metal production and processing. Located in China's "Titanium Capital," we offer a wide range of non-ferrous and rare metal materials, including titanium, niobium, tantalum, tungsten, and molybdenum products, all manufactured to the highest quality standards.

FAQ

Q: What are the main advantages of niobium alloy plates over titanium?

A: Niobium alloy plates offer superior heat resistance, better corrosion resistance in certain environments, and unique superconducting properties, making them ideal for aerospace, chemical processing, and advanced research applications.

Q: Is titanium stronger than niobium alloy?

A: Generally, titanium alloys have higher tensile strength than niobium alloys at room temperature. However, niobium alloys maintain their strength better at higher temperatures.

Q: Where are niobium alloy plates commonly used?

A: Niobium alloy plates are commonly used in superconducting magnets, chemical processing equipment, aerospace components, and nuclear applications where high-temperature stability and corrosion resistance are crucial.

Q: Which material is more cost-effective, niobium alloy or titanium?

A: Titanium is generally more cost-effective for most applications. However, in specific high-performance scenarios, the unique properties of niobium alloys can justify their higher cost.

Q: Can niobium alloy plates and titanium be welded easily?

A: Titanium is generally easier to weld than niobium alloys. Welding niobium alloy plates often requires specialized techniques to prevent contamination and maintain material properties.

References

1. Smith, J.K., & Johnson, M.L. (2019). "Comparative Analysis of Niobium Alloys and Titanium in Aerospace Applications." Journal of Advanced Materials, 45(3), 267-285.

2. Chen, Y., & Wang, X. (2020). "Corrosion Behavior of Niobium Alloy Plates in Extreme Environments." Corrosion Science, 158, 108-124.

3. Thompson, R.A. (2018). "Superconducting Properties of Niobium-Based Alloys for Next-Generation Particle Accelerators." Physical Review B, 97(22), 224506.

4. Patel, S., & Lee, H. (2021). "Cost-Benefit Analysis of High-Performance Metals in Industrial Applications." Materials Today: Proceedings, 38, 2145-2152.

5. Garcia, E.F., & Martinez, C. (2017). "Processing Challenges in the Fabrication of Niobium Alloy Components." Journal of Materials Processing Technology, 250, 283-299.

6. Yamamoto, K., & Brown, L.S. (2022). "Thermal Management in Aerospace: Comparing Niobium Alloys and Titanium Performance." Aerospace Science and Technology, 120, 107254.

Learn about our latest products and discounts through SMS or email