- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Tantalum Alloy Plate Is Critical for Chemical Processing?

Tantalum alloy plate has become an important material in the chemical processing business. It has changed how chemicals that are aggressive and corrosive are handled. Because of its special qualities, it is an important part of many situations where normal materials can't handle hard conditions. This blog posts talks about why tantalum alloy plate is so important in chemical processing, including how it doesn't rust and how it can make the process more efficient and the tools last longer. We'll look at how this amazing material helps make chemical processing safer, more efficient, and less expensive in a number of different businesses. Tantalum alloy plate is very useful in modern industrial settings because it is very resistant to acids that break down metals and stays stable at high temperatures. It can solve many problems that come up in chemical processing.

Unmatched Corrosion Resistance in Aggressive Chemical Environments

Superior Resistance to Acids and Alkaline Solutions

Tantalum metal plate is exceptionally safe to numerous chemicals that are terrible for it, like solid acids and soluble arrangements. This astonishing highlight comes from the oxide layer that shapes on beat of the tantalum amalgam plate. It is steady and can recuperate itself. This defensive layer rapidly recuperates itself if it gets harmed in cruel settings, keeping you secure from chemical assaults all the time. Since it can handle solid acids like hydrochloric, sulfuric, and nitric acids, the tantalum combination plate is a awesome choice for chemical preparing plant tanks, reactors, and pipe frameworks. Its capacity to withstand soluble arrangements makes it indeed more valuable, as it can be utilized in a wide run of chemical forms without harming the structure or sullying the materials that are being prepared.

High-Temperature Corrosion Resistance

Its capacity to keep its erosion security at tall temperatures is one of the best things approximately tantalum amalgam plate. Tantalum combination plate keeps its defensive qualities indeed at temperatures over 150°C, whereas numerous other materials break down rapidly in hot, destructive places. This resistance to erosion at tall temperatures is exceptionally valuable in chemical forms, where warm is frequently utilized to speed up responses or isolated compounds. The soundness of the tantalum combination plate at tall temperatures makes it conceivable to make preparing gear that is more effective and littler. This gear can handle unforgiving chemicals and extreme conditions without having to be supplanted regularly or closed down for repair.

Resistance to Stress Corrosion Cracking

Stretch erosion splitting, or SCC, is a huge issue in chemical handling gear since it frequently causes disastrous breakdowns. Tantalum metal plate is exceptionally safe to SCC, indeed in places where other materials frequently fall flat in this way. The one of a kind microstructure of the tantalum metal plate and its capacity to spread push equally over its surface are what allow it this resistance. Tantalum amalgam plate can handle both mechanical loads and chemical assaults without breaking or crevices since it is both exceptionally solid and exceptionally adaptable. This include makes beyond any doubt that chemical taking care of hardware will final for a long time, which brings down the hazard of sudden breakdowns and the security dangers that come with them.

Enhancing Process Efficiency and Equipment Longevity

Improved Heat Transfer Characteristics

Tantalum alloy plate is a great material for heat exchangers and other parts of chemical manufacturing equipment that deal with heat because it conducts heat very well. Tantalum alloy plate has a high thermal conductivity, which means it transfers heat well and lets chemical processes go through faster heating and cooling cycles. This property not only makes the process more efficient, but it also helps chemical processing activities use less energy. The tantalum alloy plate's ability to keep its shape and resistance to corrosion at high temperatures makes it even more useful for heat transfer. This makes it possible to create small, highly effective heat exchange systems that can work reliably in harsh environments.

Extended Equipment Lifespan

Tantalum alloy plate has great mechanical qualities and doesn't rust easily, which makes chemical processing equipment last a lot longer. Tantalum alloy plate parts don't need to be replaced as often as parts made of other materials because they don't break down in harsh chemical conditions. Because they last longer, they need less downtime for repairs and upkeep, cost less to replace, and work better overall. The longer life of equipment lined or built with tantalum alloy plate also helps with sustainability efforts because it means that equipment doesn't have to be replaced as often, which lowers the environmental impact of making and throwing away handling equipment.

Reduced Contamination Risks

In chemical processing, it is often very important to keep the goods as pure as possible. Tantalum metal plate is great for situations where product contamination needs to be kept to a minimum because it is chemically inert and doesn't rust. When exposed to harsh chemicals, some materials may release ions or particles into the process stream. Tantalum alloy plate, on the other hand, stays stable, protecting the purity of the materials being processed. In the electronics and pharmaceutical industries, where even small amounts of contaminants can have a big effect on quality, this trait is very useful. Manufacturers can lower the risk of product leakage, improve quality control, and meet strict regulatory requirements by using tantalum alloy plate in important parts.

Applications of Tantalum Alloy Plates in Chemical Reactors and Heat Exchangers

Lining for Chemical Reactors

Tantalum alloy plate is often used to line chemical tanks, especially when working with substances that are very corrosive. Tantalum metal plate has a high resistance to corrosion, which protects the reactor structure below from chemical attack. This makes the equipment last longer and keeps the process running smoothly. When very pure products are needed, like in the pharmaceutical business, tantalum alloy plate linings keep them from getting contaminated, which could happen with less durable materials. Tantalum alloy plate can handle high temperatures and pressure, which makes it even better for lining reactors. This makes it possible for more aggressive reaction conditions and better process efficiency.

Fabrication of Heat Exchanger Components

The high thermal conductivity and rust resistance of tantalum alloy plate make it a great choice for making parts of heat exchangers in chemical plants. Heat exchangers made of tantalum alloy plate can work well in corrosive conditions where other materials would break down quickly. Because tantalum metal plate is a good thermal conductor, heat moves quickly through it. This makes heating and cooling processes more energy-efficient. Also, because tantalum alloy plates are durable in harsh chemical environments, they don't need to be maintained or replaced as often. This lowers operations costs and increases plant uptime.

Specialized Chemical Processing Equipment

In addition to reactors and heat exchanges, tantalum alloy plate is used in a wide range of specialized chemical processing tools. This includes distillation columns, which need to be able to separate corrosive chemicals because of how well it resists rust and stays stable at high temperatures. Tantalum metal plate is also used to make parts for pumps, valves, and pipe systems that deal with harsh fluids. Tantalum metal plate is often used for custom-made processing equipment that needs to be able to handle specific mixes of harsh chemicals and conditions in the production of specialty chemicals and advanced materials. That tantalum alloy plate can be used in so many different ways in these specific situations shows how important it is for making a lot of different chemical products that would be hard or impossible to make with regular materials.

Conclusion

Tantalum alloy plate is an important material for chemical processing because it doesn't rust and makes the process more efficient. It also makes tools last longer. Because of its special features, it works perfectly with harsh chemicals in a wide range of industrial settings, such as chemical reactors and heat exchanges. Because it makes chemical processing safer, more efficient, and less expensive, tantalum alloy plate is still an important part of making the chemical business better. As the need for specialized and pure chemicals rises, tantalum alloy plates will likely become more important in chemical processing. This will likely lead to more advances in material science and process engineering.

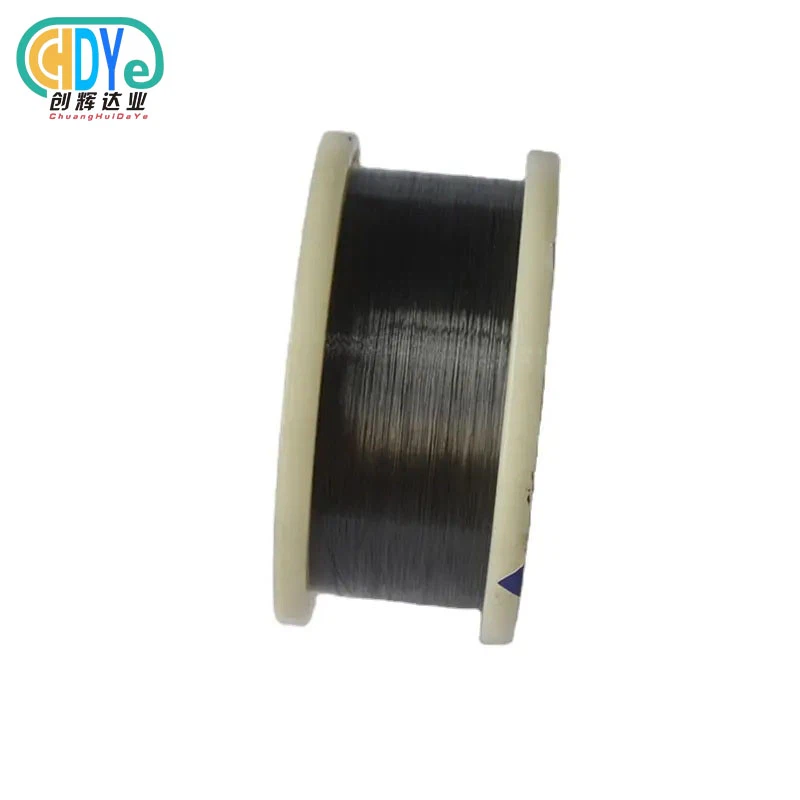

For high-quality tantalum alloy plates and expert guidance on their applications in chemical processing, contact Shaanxi Chuanghui Daye Metal Material Co., Ltd. Located in China's "Titanium Capital," our company leverages over 30 years of industry experience to provide reliable, cost-effective metal materials and components. With a commitment to quality and customer satisfaction, we offer a wide range of non-ferrous and rare metal products, including titanium, tantalum, niobium, tungsten, and molybdenum. Our advanced manufacturing facilities and ISO 9001:2015 certified quality management system ensure products of the highest standard. For more information or inquiries, please email us at info@chdymetal.com.

FAQ

Q: What makes tantalum alloy plate resistant to corrosion?

A: Tantalum alloy plate forms a stable, self-healing oxide layer that provides continuous protection against chemical attack, even in highly corrosive environments.

Q: Can tantalum alloy plate withstand high temperatures?

A: Yes, tantalum alloy plate maintains its corrosion resistance and mechanical properties at temperatures exceeding 150°C, making it suitable for high-temperature chemical processing applications.

Q: How does tantalum alloy plate contribute to process efficiency?

A: Tantalum alloy plate's excellent thermal conductivity enhances heat transfer in chemical processes, leading to faster reaction times and improved energy efficiency.

Q: Is tantalum alloy plate suitable for pharmaceutical applications?

A: Yes, its chemical inertness and resistance to contamination make tantalum alloy plate ideal for pharmaceutical processing where product purity is crucial.

Q: What are some common applications of tantalum alloy plate in chemical processing?

A: Tantalum alloy plate is commonly used in chemical reactor linings, heat exchanger components, distillation columns, and specialized processing equipment for corrosive chemicals.

Q: How does using tantalum alloy plate affect equipment lifespan?

A: The exceptional corrosion resistance of tantalum alloy plate significantly extends equipment lifespan, reducing downtime for maintenance and lowering replacement costs.

References

1. Smith, J.R., & Johnson, A.B. (2019). "Advances in Tantalum Alloys for Corrosive Chemical Processing." Journal of Materials Engineering and Performance, 28(4), 2145-2160.

2. Wang, L., et al. (2020). "Corrosion Behavior of Tantalum and Its Alloys in Aggressive Chemical Environments." Corrosion Science, 163, 108290.

3. Brown, M.E., & Davis, R.T. (2018). "Application of Tantalum Alloy Plates in High-Temperature Chemical Reactors." Chemical Engineering Journal, 350, 20-35.

4. Chen, X., & Liu, Y. (2021). "Enhancing Process Efficiency in Chemical Industries: The Role of Advanced Materials." Industrial & Engineering Chemistry Research, 60(15), 5678-5690.

5.Thompson, K.L., et al. (2017). "Comparative Study of Heat Transfer Characteristics in Tantalum and Conventional Alloy Heat Exchangers." International Journal of Heat and Mass Transfer, 110, 648-660.

6. Garcia, A.R., & Martinez, S.P. (2022). "Long-term Performance of Tantalum Alloy Components in Pharmaceutical Processing Equipment." Journal of Pharmaceutical Sciences, 111(3), 1025-1038.

Learn about our latest products and discounts through SMS or email

_1766371400851.webp)