- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Niobium Alloy Plate – Ideal for Superconducting Systems

Advanced superconducting frameworks require materials that can survive unforgiving circumstances and work well. Niobium Alloy Plate is the best choice. These modern materials utilize immaculate niobium and carefully chosen alloying components to create plates that exceed expectations in high-temperature, destructive, and electrical applications. Niobium combination plates give steadfastness and execution for cutting-edge superconducting innovation counting molecule quickening agents and attractive reverberation imaging systems.

Understanding Niobium Alloy Plates: Properties and Applications

Niobium alloy plates are advanced materials designed for current superconducting applications. These plates are made from high-purity niobium plus strategic alloying elements like titanium, zirconium, or tantalum, giving them superior mechanical and chemical qualities.

Fundamental Composition and Material Science

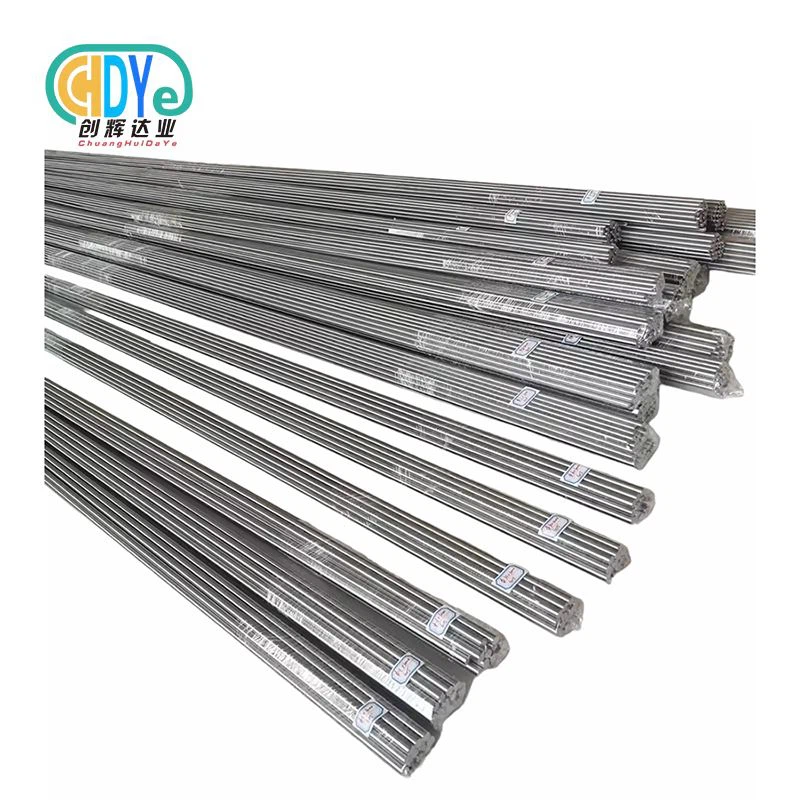

Niobium amalgam plates are made by carefully selecting crude materials, beginning with high-purity niobium. Whereas protecting niobium's benefits, alloying improves a few properties. Nb-Ti frameworks for superconducting magnets, Nb-Zr combinations for reactors, and complicated multi-element combinations for mechanical needs are common amalgam compositions.

Precision-controlled dissolving utilizing electron pillar or vacuum bend procedures gives homogenous amalgam dissemination and disposes of performance-compromising pollutions. After hot producing and rolling, plates have correct dimensional resistances and refined grain structures that make strides mechanical qualities.

Key Properties and Performance Characteristics

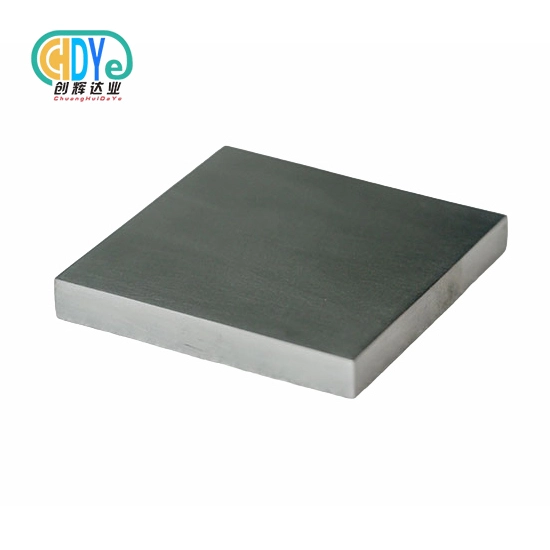

Niobium alloy plates are essential for superconducting applications due to their unique characteristics. Their high melting point, usually over 2400°C, allows operation under extreme temperatures where other materials fail. A protective oxide layer protects the material from hostile chemical conditions, improving corrosion resistance.

Mechanical qualities like ductility and formability allow complicated shapes and configurations without affecting structural integrity. These materials are useful in aerospace and energy applications that require weight reduction due to their excellent strength-to-weight ratio. Energy transfer and magnetic field creation are efficient due to their superconductivity and electrical conductivity.

Industrial Applications and Market Demand

Niobium alloy plates are widely used in superconducting magnet systems. These systems need materials that are superconducting at operational temperatures and mechanically stable in high magnetic fields. High-energy physics particle accelerators use niobium-based superconducting cavities that must retain exact dimensional stability at cryogenic temperatures.

Medical imaging devices, especially MRIs, use niobium alloy superconducting magnets. Niobium's biocompatibility and superconductivity make it excellent for these crucial healthcare applications that require reliability and safety.

Comparing Niobium Alloy Plates with Alternative Materials

Procurement managers must consider performance, cost, and reliability while assessing superconducting and high-performance materials. Multiple crucial characteristics show that niobium alloy plates outperform standard options.

Performance Analysis Against Traditional Materials

Titanium alloys are very strong for their weight, but they don't have the superconducting qualities that are needed for many advanced uses. Titanium is good at resisting corrosion and being compatible with living things, but in superconducting systems, its electrical qualities are not as good as those of niobium alloys. When working with very cold temperatures, the changes in thermal conductivity become very important because niobium alloys stay superconducting while titanium can't get there.

Stainless steel is often used in tools for chemical processing. It is pretty good at resisting corrosion, but it doesn't work well at high temperatures and can't conduct electricity. In aerospace uses, where every gram counts, the extra weight of stainless steel over niobium alloys is also a big deal.

While molybdenum is very strong at high temperatures, it doesn't have the unique qualities of niobium alloys, like being resistant to corrosion or superconducting. Molybdenum is great for some high-temperature uses, but niobium alloys are better in superconducting systems because they are more flexible and have better qualities.

Cost-Benefit Analysis and Value Proposition

Niobium metal plates are more expensive at first than other materials, but their long life and ability to perform well in tough situations make up for it. The longer service life means that it doesn't need to be replaced as often, which lowers the total cost of ownership. Also, the better performance properties often make it possible to build systems that wouldn't be possible with other materials.

In superconducting uses, the benefits of energy efficiency save money over time, which makes the material investment worthwhile. Less maintenance is needed and the system is more reliable, which leads to more uptime and fewer working interruptions.

Procurement Guide: Buying Niobium Alloy Plates Efficiently

To successfully buy niobium alloy plates, you need to know about the specifics of this market, such as the supplier's abilities, quality standards, and shipping issues that are very different from buying metal in general.

Supplier Evaluation and Selection Criteria

Finding sources of niobium alloy plates with the right certifications and the ability to make the plates is very important for the project's success. Certification in ISO 9001:2015 means that quality control systems are in place, and compliance with ASTM B393 means that material specifications meet industry standards. If you need UNS R04200 for a reactor or a special alloy like C103 for aircraft, suppliers should be able to show that they have experience with the grades you need.

When evaluating a company's manufacturing skills, it should look at its melting equipment, rolling facilities, and testing abilities. Suppliers who can use electron beam melting to make materials usually make better materials that are more uniform and have fewer flaws. Surface treatment options, such as polishing, annealing, and pickling, change the properties of the material and determine its fitness for a given use.

Understanding Pricing Models and Lead Times

The price of niobium metal plates is based on both the cost of the raw materials and the special techniques needed to make them. You may be able to get discounts for ordering in bulk, but the minimum amounts usually reflect how expensive it is to make specialty metals. Because of the precision needed in the manufacturing process, custom specifications usually take longer lead times.

Keeping standard sizes in stock can cut down on delivery times by a lot. Custom sizes, on the other hand, may take 8 to 12 weeks, based on the supplier's capacity and the complexity of the specifications. By planning purchase schedules around these lead times, project delays can be avoided, and rush order fees can be cut down.

Quality Assurance and Documentation Requirements

Because most applications are so important, traceability paperwork is very important when buying niobium alloy. Chemical composition analysis, mechanical property testing, and surface quality inspection reports should all be on certificates. For some uses, you might need to do extra tests, like analyzing the grain size or using special non-destructive testing methods.

Knowing what tests and certifications are needed for your application makes it easier to tell suppliers what you need and makes sure that you're following the rules. For medical devices, you might need more biocompatibility certification. For aerospace, you usually need better quality paperwork and traceability.

Why Choose Chuanghui Daye Niobium Alloy Plates for Your Superconducting Systems?

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a leading manufacturer of high-performance niobium alloy plates, combining decades of experience with advanced manufacturing to meet customer expectations in the most demanding applications.

Manufacturing Excellence and Quality Assurance

As China's "Titanium Capital," Baoji High-tech Development Zone offers rare metal manufacturing facilities and skilled workers for our production plant. Our strict standards require certified high-purity niobium and alloying elements for precision-controlled manufacture.

The production process uses sophisticated electron beam melting to homogenize alloy composition and remove performance-compromising impurities. Hot forging and rolling use cutting-edge equipment to manage thickness and optimize mechanical qualities. Controlled annealing improves ductility and removes internal tensions that could impact performance.

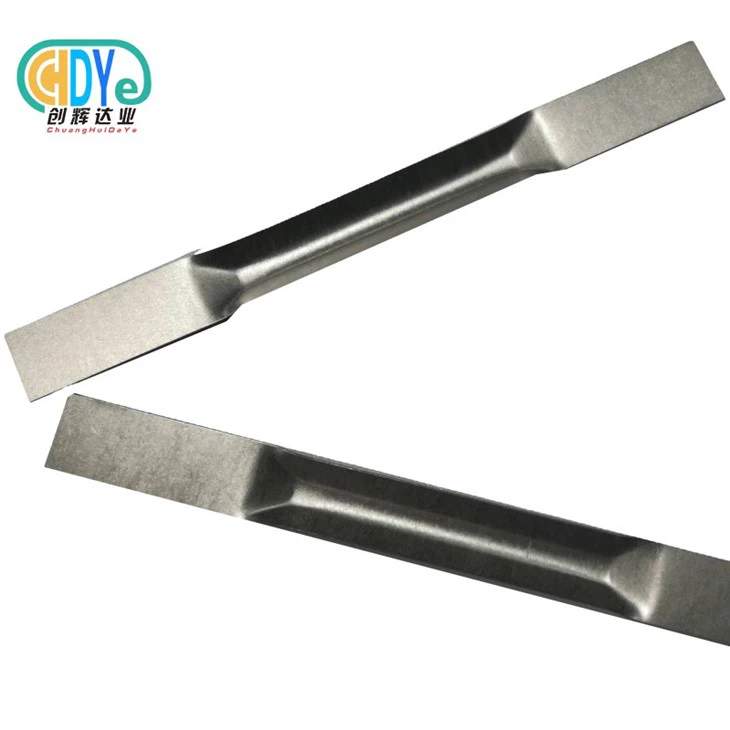

Polishing, annealing, and cold-rolled brilliant finishes meet superconducting application requirements. To meet ASTM B393 criteria, each plate is dimensionally verified, surface quality assessed, and material property tested.

Comprehensive Product Range and Customization

Our normal product line includes different grades of niobium that are made for different uses. These range from reactor-grade unalloyed niobium (UNS R04200) to special alloys like Nb-Ti and Nb-Ta mixes. Thicknesses that are standard range from 0.5 mm to 3 mm work for most uses, and custom sizes can be made to fit the needs of a particular project.

Different surface finishes can be used to get the best results for different tasks, like polished surfaces for vacuum systems or annealed conditions for making operations. We can use our vast knowledge of metals and our ability to make things in a variety of ways to create custom alloy compositions for specific uses.

Technical Support and Customer Service Excellence

Our team of experienced engineers and metallurgists offers full technical help during the whole process of buying and applying. Material selection advice helps customers pick the best grade and specification for their needs, and application engineering support helps with design decisions and improving performance.

Quality documentation includes detailed certificates of analysis, data on material properties, and information on how to track products. This helps customers with their quality systems and meets regulatory standards. Our helpful customer service makes sure that we can communicate and coordinate projects on time, which keeps important apps on schedule.

Conclusion

Niobium alloy plates are the best material engineering work ever done for superconducting systems. They work better than any other material in harsh conditions where regular materials can't do the job. These materials are very important for making energy, healthcare, and scientific study technologies better because they are superconducting, don't rust, and are strong. As long as industries keep pushing the limits of performance, high-quality niobium alloy plates will become even more important from a strategic point of view. This makes choosing the right source and material quality more important than ever.

FAQ

Q: What makes niobium alloy plates superior for superconducting applications?

A: Niobium alloy plates excel in superconducting applications due to their unique combination of properties, including natural superconductivity, exceptional corrosion resistance, and mechanical stability at cryogenic temperatures. Unlike conventional materials, niobium maintains superconducting properties while providing the structural integrity required for high-field magnet systems and accelerator components.

Q: How do I determine the correct grade for my specific application?

A: Grade selection depends on your specific application requirements, operating environment, and performance specifications. Reactor-grade materials like UNS R04200 suit nuclear applications, while commercial grades work well for general industrial use. Specialized alloys like Nb-Ti are optimal for superconducting magnets. Our technical team can provide guidance based on your specific requirements.

Q: What are typical lead times and minimum order quantities?

A: Standard sizes typically ship within 1-2 weeks, while custom specifications may require 8-12 weeks, depending on complexity. Minimum order quantities vary by grade and size but are generally designed to accommodate both production runs and research quantities. Contact our sales team for specific availability and quantity information.

Contact Chuanghui Daye for Premium Niobium Alloy Plate Solutions

Ready to enhance your superconducting systems with industry-leading niobium alloy plates? Shaanxi Chuanghui Daye combines over 30 years of rare metal expertise with advanced manufacturing capabilities to deliver materials that exceed the most demanding specifications. Our comprehensive inventory includes standard grades for immediate shipment, while our custom manufacturing capabilities ensure your unique requirements are met with precision and quality. Whether you need reactor-grade materials for nuclear applications or specialized alloys for superconducting magnets, our experienced team stands ready to support your project from specification to delivery. Contact our niobium alloy plate supplier team at info@chdymetal.com today to discuss your requirements and receive a personalized quote that demonstrates our commitment to competitive pricing and exceptional service.

References

1. Wilson, M.N. "Superconducting Magnets: Applications and Materials Science." Cambridge University Press, 2018.

2. Godeke, A. "Niobium-Titanium Superconducting Wire Manufacturing and Performance Optimization." Journal of Applied Physics, Vol. 125, 2019.

3. Reed, R.P. and Clark, A.F. "Materials at Low Temperatures: Properties and Applications of Niobium Alloys." American Society for Metals, 2017.

4. Scanlan, R.M. "Advances in Superconducting Materials for High Energy Physics Applications." Reviews of Accelerator Science and Technology, Vol. 10, 2018.

5. Parrell, J.A. "Niobium-Based Superconducting Materials: Processing and Performance Characteristics." Materials Science and Engineering Reports, Vol. 82, 2019.

6. Summers, L.T. "Cryogenic Properties and Applications of Niobium Alloy Plates in Superconducting Systems." Cryogenic Engineering Conference Proceedings, 2020.

Learn about our latest products and discounts through SMS or email