- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Wire for Anodizing – Excellent Surface Finish

Titanium wire for anodizing revolutionizes industrial surface treatment, producing excellent results in challenging manufacturing situations. The durable titanium dioxide coating created by this process improves corrosion resistance and aesthetics, making anodized titanium wire the best choice for high-performance applications. An anodizing process changes the wire's molecular characteristics, protecting it from harsh chemical conditions while retaining its strength-to-weight. Quality anodized titanium wire guarantees long-term cost effectiveness, decreased maintenance, and constant performance, according to procurement decision-makers. Anodized titanium wire meets crucial industrial applications where failure is not an option, from aerospace components to medical devices.

Understanding Titanium Wire for Anodizing

Physical and Chemical Properties

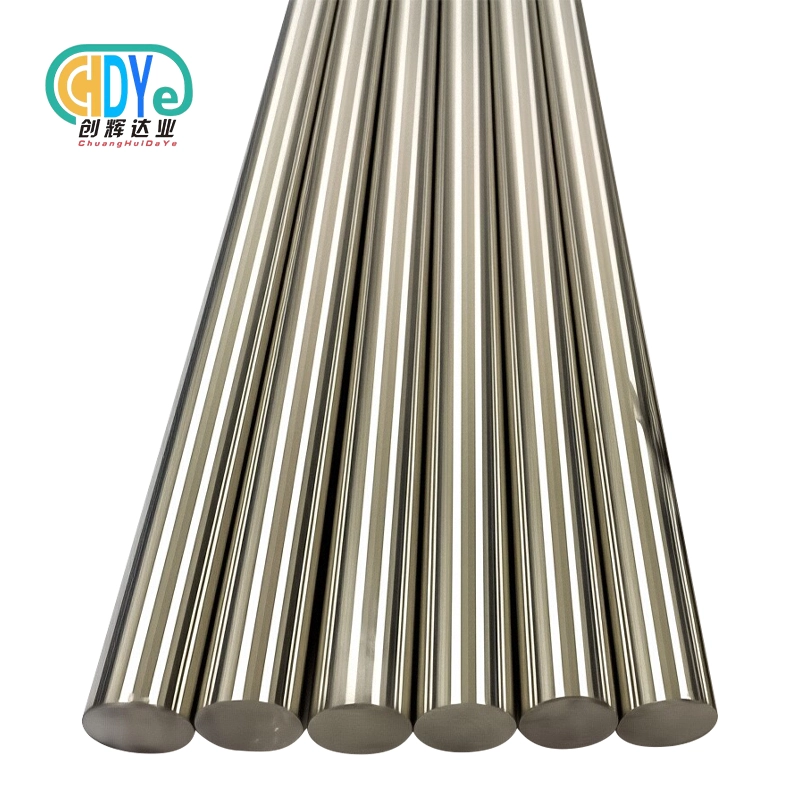

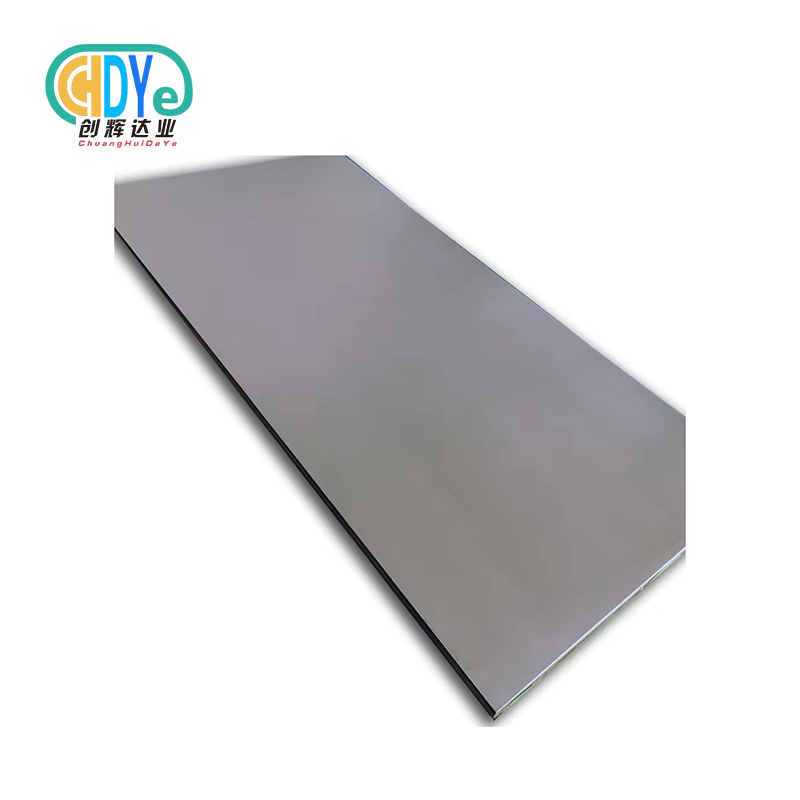

Titanium wire for anodizing applications has interesting characteristics that recognize it from routine materials. The base fabric shows an uncommon strength-to-weight proportion, roughly 40% lighter than steel, while keeping up comparable mechanical properties. This inalienable erosion resistance stems from titanium's normal capacity to form a defensive oxide layer when exposed to oxygen, making an impermeable boundary against natural degradation.

The anodizing handle improves these characteristic properties by making a controlled, uniform oxide layer with exact thickness details. Amid electrochemical treatment, the wire surface experiences controlled oxidation in an electrolytic arrangement, regularly containing phosphoric or sulfuric acid. Connected voltage ranges between 20 and 120 volts, depending on wanted oxide thickness and coloration requirements. This change happens at the infinitesimal level, where titanium molecules bond with oxygen particles to frame a crystalline titanium dioxide structure.

Available Grades and Specifications

Fabricating applications regularly utilize two essential titanium grades for anodizing operations. Review 2 commercially immaculate titanium offers great formability and erosion resistance, making it perfect for common anodizing applications requiring an ideal balance between quality and ductility. Review 5 (Ti-6Al-4V) gives upgraded mechanical properties through its aluminum and vanadium alloying components, conveying prevalent execution in high-stress environments.

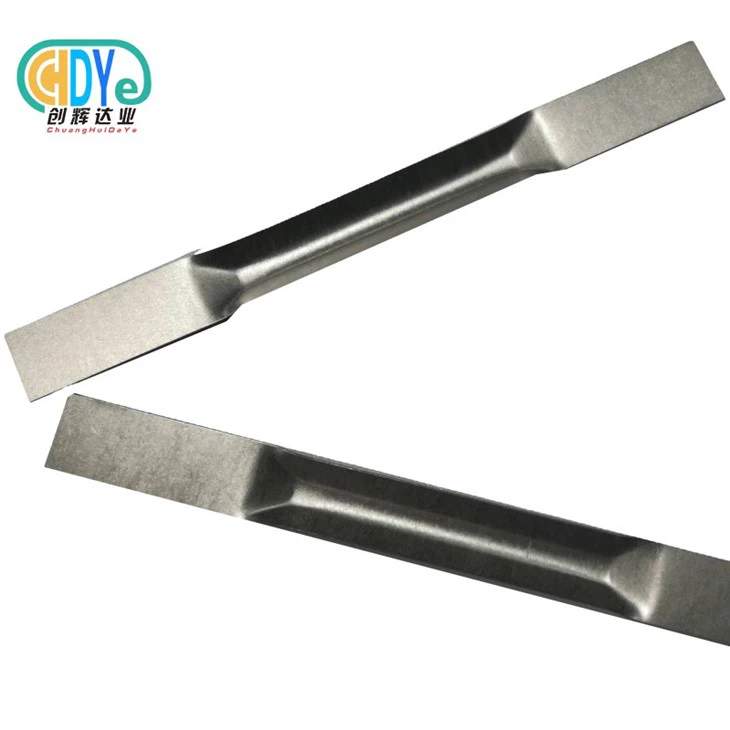

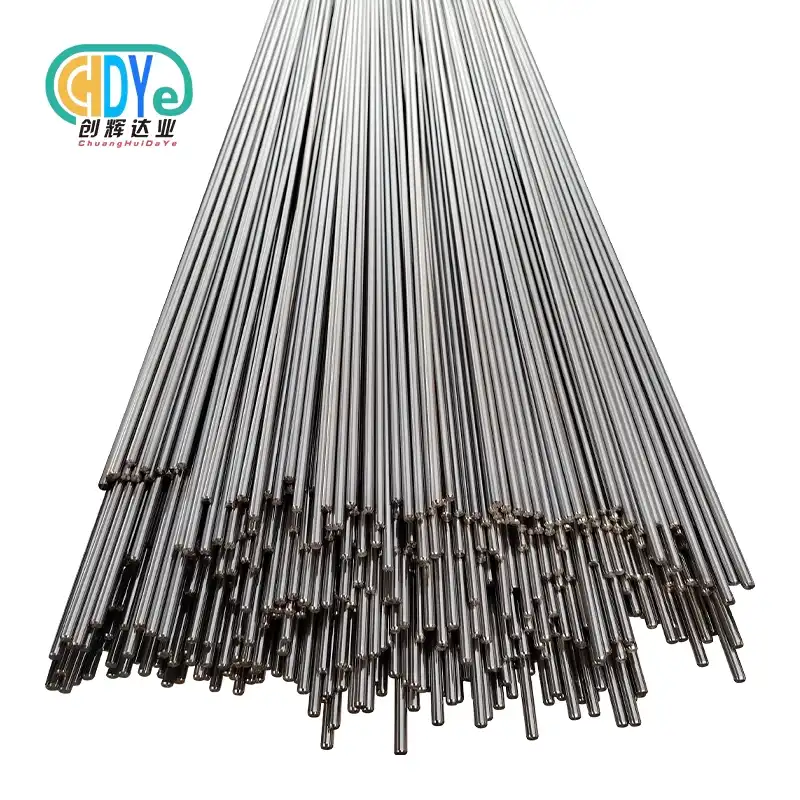

Wire distance across determinations runs from 0.2mm to 7mm, accommodating differing application prerequisites from exact electronic components to vigorous mechanical assemblies. Surface arrangement measures guarantee oxide-free conditions earlier to anodizing, killing contamination that seems to compromise coating consistency. Temperature solidness characteristics permit reliable execution over working ranges from -200°C to 400°C, fundamental for aviation and chemical processing applications.

Titanium Wire Anodizing Process – Step-by-Step Guide

Surface Preparation and Cleaning Methods

Consistent anodised finishes require careful surface preparation. Alkaline cleaning methods degrease the wire, then acid etching removes oxide layers and surface impurities. This cleaning sequence optimizes electrolyte contact throughout the wire surface, eliminating uneven oxide buildup that could affect performance or appearance.

Ultrasonic cleaning removes microscopic particles and residues from wire surfaces, which is critical for small-diameter applications with high surface area-to-volume ratios. Quality control includes visual examination under magnification and surface roughness assessments to ensure anodizing preparation standards.

Electrolyte Selection and Process Parameters

The oxide layer and surface qualities depend on the anodizing bath composition. For precision applications, phosphoric acid solutions are concentrated between 10-15% to control oxidation. Sulfuric acid alternatives process faster but require temperature control to avoid localized heating.

Voltage application begins at low levels and ramps up to goal values over time. Current density calculations take wire diameter and surface area into consideration, ensuring consistent oxide formation over the length. The process takes 15 minutes for thin decorative coatings and several hours for thick protective layers over 10 micrometers.

Temperature Control and Quality Assurance

For consistent results, bath temperature should be 18-25°C. Higher temperatures can induce uneven oxide production or surface etching. Processing cycles are stable thanks to cooling and temperature monitoring systems. Gentle solution circulation using agitation systems prevents concentration gradients that impair coating uniformity.

Quality verification involves eddy current or magnetic induction coating thickness measurements, surface hardness testing, and adhesion evaluations. For accurate aesthetic criteria, spectrophotometric color consistency tests are used.

Comparative Insights for Procurement Decisions

Material Form Factor Analysis

Anodized titanium wire has advantages over other titanium products in certain applications. Wire designs have higher surface area-to-volume ratios than titanium sheets or plates, enhancing anodizing treatment benefits while reducing material costs. The cylindrical design allows regular current delivery during electrochemical processing, resulting in consistent oxide layer thickness around the circle.

To obtain desired specifications, rod and bar alternatives may require additional machining, raising processing costs and material waste. Wire forms can be directly integrated into production assemblies or end-use configurations, eliminating secondary activities.

Alternative Material Comparisons

Despite their lower initial prices, stainless steel wire alternatives lack titanium's corrosion resistance and biocompatibility. Stainless steel needs additional protection in marine or chemical processing applications, which anodized titanium wire provides. Every gram of titanium improves fuel efficiency and payload in aircraft applications.

Aluminum wire is lightweight and anodizable, although it has lower mechanical strength and temperature limits than titanium. Anodized titanium wire's strength-to-weight advantage is useful in structural applications that need durability and mass optimization.

Procurement Guide for Titanium Wire Anodizing

Global Supplier Landscape

Titanium suppliers specialize in anodizing-grade wire manufacture. ATI (Allegheny Technologies) has titanium processing facilities with wire drawing and aerospace industry quality certifications. They offer commercially pure and alloyed titanium grades for various anodizing applications.

Kennametal subsidiary Wah Chang makes titanium wire and other refractory and reactive metals. Their production expertise includes precision medical and heavy industrial wire diameters. ISO 9001:2015-compliant quality management systems provide product requirements and traceability.

Pricing Structures and Order Planning

Titanium wire prices reflect commodity market changes and production complexity. Minimum order quantities vary by diameter and grade, but are usually 50–500 kilos. Volume savings apply to annual contracts over 1,000 kg, which benefits OEM firms with known consumption patterns.

Custom diameter tolerances, length cutting, and surface preparation are available for anodizing. Standard grades take 4-12 weeks, whereas specialty alloy compositions or non-standard dimensions take 16-20 weeks.

Logistics and Quality Considerations

Titanium wire for anodizing is a reactive metal; international shipping standards require proper packaging and paperwork. Transportable protective atmospheres prevent oxidation, sustaining anodizing surface conditions. Shipments include quality certificates for chemical composition, mechanical qualities, and dimensions.

Critical supplier evaluation factors should include production capacity, quality management, and technical support. ISO accreditation shows quality dedication, while aerospace or medical industry approvals show competence to meet strict specifications.

Our Company & Titanium Wire Solutions

Shaanxi Chuanghui Daye's Manufacturing Expertise

Shaanxi Chuanghui Daye Metal Material Co., Ltd. provides quality titanium wire solutions for anodizing using 30 years of rare metal industry experience. Our factory in Baoji, China's "Titanium Capital," has developed supply chains and specialized manufacturing facilities to ensure product quality and a competitive price.

We can manufacture wire from melting to packing. Precision wire drawing machines with diamond dies, electron beam furnaces for high-purity melting, and controlled environment annealing systems optimize mechanical qualities are advanced equipment. This integrated strategy eliminates multi-supplier manufacturing chain quality discrepancies.

Quality Assurance and Certification Standards

ISO 9001:2015 accreditation shows our production quality management dedication. Raw material inspection techniques check chemical composition and purity before processing. At regular intervals, in-process monitoring comprises dimensions inspections, surface quality assessments, and mechanical property testing.

Final inspection tests chemical composition, mechanical qualities, surface condition, and dimensional accuracy. In aerospace, medical, and chemical processes, certificate packages give complete traceability documentation for quality assurance. Before delivery, our quality control systems verify that every cargo satisfies the criteria.

Product Range and Customization Capabilities

Our titanium wire comes in Grade 2 commercially pure and Grade 5 (Ti-6Al-4V) alloy compositions in 0.2mm to 7mm diameters. Anodizing requirements determine surface preparation: pickled, polished, or as-drawn. Special diameter tolerances and length parameters meet application needs.

Technical support includes anodizing process consultation to improve surface treatment parameters. Grade selection, diameter optimization, and surface treatment are advised by our technical staff based on end-use applications. This collaborative approach reduces development time and costs and ensures project success.

Conclusion

Titanium wire for anodizing offers great corrosion resistance and surface polish in various industrial applications. Anodizing generates protective oxide coatings that improve functional and aesthetic qualities, making this material appropriate for aerospace, medical, and chemical processing settings. Understand grade parameters, supplier capabilities, and quality standards to achieve consistent results in procurement. Chuanghui Daye's ISO 9001:2015 accreditation and decades of titanium wire manufacturing experience ensure reliable and technical support for anodizing projects. Anodized titanium wire provides long-term value through decreased maintenance, improved performance, and excellent surface qualities that exceed the most demanding application requirements.

FAQ

Q: What factors affect anodized titanium wire coloration?

A: Anodizing voltage and electrolyte composition primarily determine color characteristics in anodized titanium wire. Voltage levels between 20-40V produce interference colors ranging from gold to blue, while higher voltages create purple, green, and pink variations. Electrolyte pH and concentration affect color intensity and uniformity across the wire surface.

Processing time influences color depth and consistency, with longer exposure times generally producing more saturated colors. Temperature control remains critical, as variations can cause color shifts or uneven appearance. Surface preparation quality also impacts final coloration, with any remaining contaminants potentially causing discolored areas.

Q: Which titanium grades work best for anodizing applications?

A: Grade 2 commercially pure titanium provides excellent anodizing characteristics due to its high purity and consistent surface properties. The absence of alloying elements ensures uniform oxide formation and predictable color development. This grade offers optimal formability for wire drawing operations while maintaining excellent corrosion resistance.

Grade 5 (Ti-6Al-4V) also anodizes successfully, though alloying elements may cause slight color variations compared to commercially pure grades. The enhanced mechanical properties make this grade suitable for high-stress applications where both strength and anodized surface protection are required.

Q: How should anodized titanium wire be stored and transported?

A: Proper storage requires dry, clean environments with stable temperature conditions to prevent surface contamination or oxide layer damage. Protective packaging using foam wrapping and moisture-barrier materials maintains surface integrity during transport. Avoid contact with dissimilar metals that could cause galvanic reactions or surface staining.

Handling procedures should minimize surface contact and use clean gloves to prevent fingerprint contamination. Storage areas must remain free from chemical vapors or corrosive atmospheres that could affect the anodized surface. Regular inspection during long-term storage helps identify any surface changes before use.

Partner with Chuanghui Daye for Premium Titanium Wire Solutions

Shaanxi Chuanghui Daye stands ready to fulfill your anodizing-grade titanium wire requirements with unmatched quality and reliability. Our comprehensive product range includes diameters from 0.2mm to 7mm in both Grade 2 and Grade 5 compositions, all manufactured under ISO 9001:2015 certified quality systems. Located in China's Titanium Capital, we offer competitive pricing without compromising quality standards. Contact our technical team at info@chdymetal.com to discuss your specific requirements and receive customized quotations for titanium wire for anodizing supplier partnerships that deliver consistent results.

References

1. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Wire." ASTM B863-20. West Conshohocken: ASTM International, 2020.

2. Boyer, R.R., and Briggs, R.D. "The Use of β Titanium Alloys in the Aerospace Industry." Journal of Materials Engineering and Performance, vol. 14, no. 6, 2005, pp. 681-685.

3. Lutjering, G., and Williams, J.C. "Titanium: Engineering Materials and Processes." 2nd edition. Berlin: Springer-Verlag, 2007.

4. Rack, H.J., and Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering C, vol. 26, no. 8, 2006, pp. 1269-1277.

5. Sul, Y.T. "The Significance of the Surface Properties of Oxidized Titanium to the Bone Response: Special Emphasis on Potential Biochemical Bonding of Oxidized Titanium Implant." Biomaterials, vol. 24, no. 22, 2003, pp. 3893-3907.

6. Veiga, C., Davim, J.P., and Loureiro, A.J.R. "Properties and Applications of Titanium Alloys: A Brief Review." Reviews on Advanced Materials Science, vol. 32, no. 2, 2012, pp. 133-148.

Learn about our latest products and discounts through SMS or email