Using a platinum-coated titanium anode as an electrode in electroplating systems is a new idea that uses the strong metal titanium and the highly reactive metal platinum together. These anodes provide better resistance to corrosion, longer operational life, and better current efficiency in harsh electrochemical settings. Platinum's electrochemical stability is great, and titanium's strength and low cost make it a good choice for electroplating in the electronics, automotive, and marine industries.

Understanding Platinum Coated Titanium Anodes in Modern Electroplating

Electroplating has come a long way since the invention of platinum-coated titanium anodes. These specialized electrodes are a big improvement over old carbon or lead anodes and work much better in electrochemical processes.

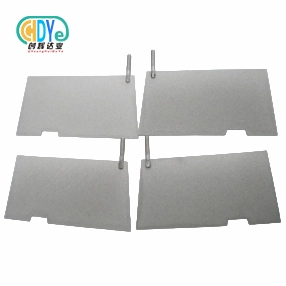

We've seen how these anodes change the way electroplating works at Chuanghui Daye. The platinum coating is the active surface, which makes it easy for electrons to move with little energy loss. At the same time, the titanium substrate gives the structure strength that normal materials can't match.

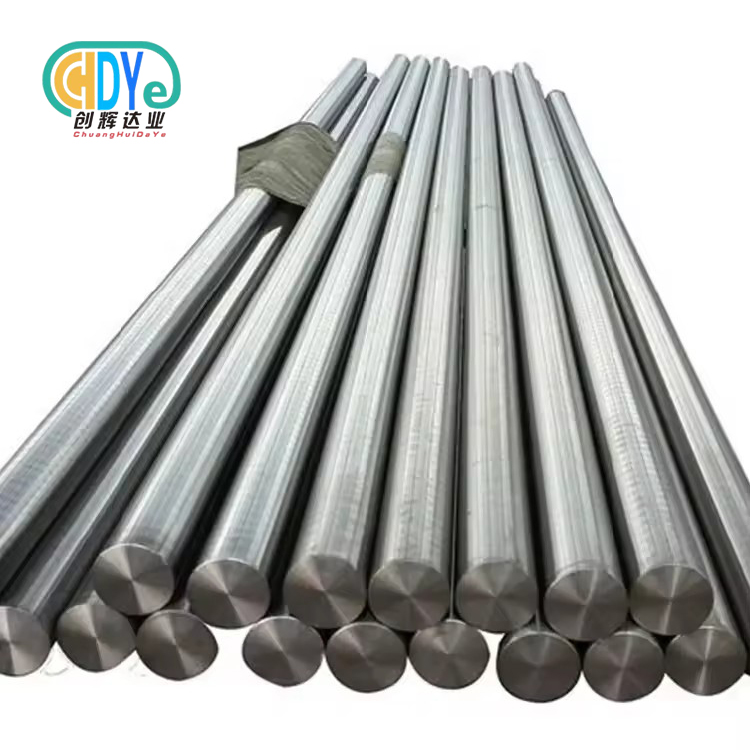

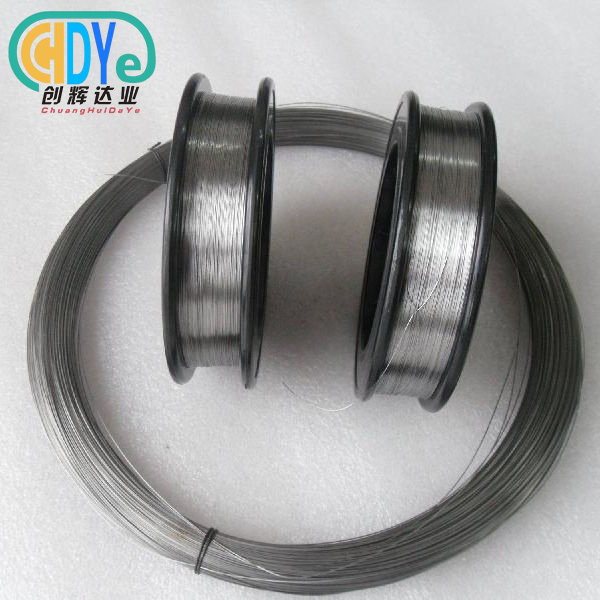

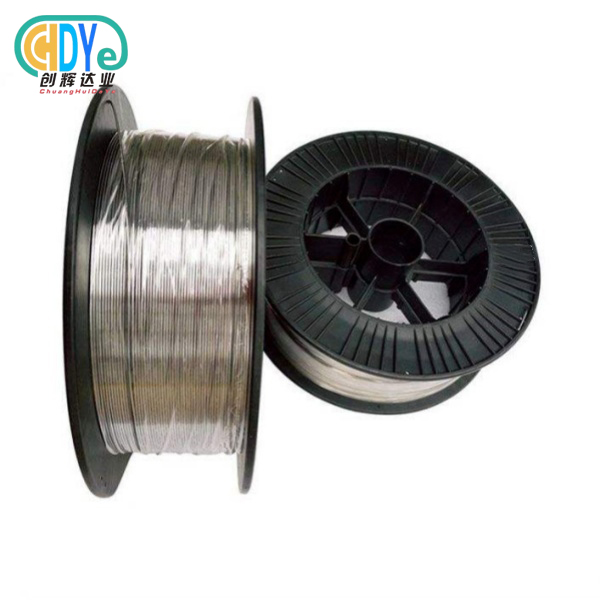

In the process of making these, a thin layer of platinum or a platinum group metal is put on a base of pure titanium. This mix makes an electrode that stays stable even when conditions are extreme. The outcome is an anode that always works well and lowers the cost of doing business over time.

Platinum-coated anodes can get over 95% current efficiency in many electroplating applications, according to recent research. This efficiency means less energy use and better product quality, which makes it more popular with manufacturers who want to streamline their processes.

Electroplating Systems' Main Uses

Electroplating with Precious Metals

Electroplating with precious metals is one of the most difficult uses for platinum-coated titanium anodes. When gold, silver, or platinum is deposited onto substrates, the anode needs to stay very pure and stable. Using traditional anodes often leads to contamination or quick breakdown.

These specialized anodes work great in making jewelry, coating electronic parts, and other decorative uses. The platinum coating stops reactions that could hurt the quality of the plated layer. Electronics manufacturers love this application because parts can be ruined by even the smallest amount of contamination.

In jewelry making, anodes let different batches have the same color and finish. Electrodes with a stable platinum surface don't have the problems that older technologies had with changing color and getting surface defects. This makes sure that the metal keeps its properties.

Hard Chrome Coating

Hard chrome plating needs anodes that can handle strong chromic acid solutions without changing shape. Platinum-coated titanium anodes have changed this use completely by standing up to corrosion very well in these tough settings.

For hydraulic cylinders, machine tool parts, and surfaces that are resistant to wear, automotive manufacturers depend on hard chrome plating. The anodes make it possible for chrome to evenly coat even the most complicated shapes. This improves the quality of the parts and lowers the need for extra work after plating.

The long life of the anode greatly lowers the cost of upkeep and the time that production is not running. Traditional lead anodes needed to be replaced often and were bad for the environment. Platinum-coated anodes, on the other hand, can be used for years with very little maintenance.

Electroplating with Copper

When making electronics, copper electroplating needs to be carefully controlled to control the flow of electricity and the purity of the metal. Platinum-coated titanium anodes give you the stability you need to make high-quality semiconductor parts and printed circuit boards.

The anodes keep working at the same level during the plating process, which makes sure that the copper thickness is even across the substrate. This evenness is very important in electronics because differences in how thick the conductor is can change how the circuit works or make it less reliable.

The low contamination levels of these anodes are especially helpful to semiconductor fabrication facilities. The platinum coating stops unwanted ions from getting out. These ions could damage the delicate electronics that are being made.

Zinc Plating and Zinc Alloy Plating

Zinc plating protects against corrosion, and it works even better now with platinum-coated titanium anodes. These electrodes make it possible for zinc to be deposited in a steady way, and they also make sure that the current flows evenly across big or complicated parts.

Zinc plating is used a lot in the automotive and construction industries for brackets, structural parts, and fasteners. The anodes make sure that the coating is the same thickness everywhere, which means that the part's corrosion protection performance can be predicted over its entire service life.

Being able to work at higher current densities means that the plating cycles can be done more quickly without losing quality. This boost in efficiency means that more parts can be made, and they will cost less, which is a direct result of the more efficient system.

Electroplating Nickel

The stable performance of platinum-coated anodes is a big help to nickel plating applications. These anodes provide reliable performance in a range of conditions, whether they're being used for decorative or functional coatings.

Nickel plating is used on parts that need extra protection from wear and rust by companies that make industrial machines. The anodes make it possible to control nickel deposition very carefully, which makes sure that each coating has the right properties for its specific use.

The longer operational life means that the anode doesn't have to be replaced as often, which keeps production going and maintains consistent plating quality over long periods of time.

Using Electroforming

Electroforming needs very fine metal deposition, which is why platinum-coated titanium anodes are especially useful. These processes make very simple shapes or very thin parts that need a steady flow of electricity.

Electroforming is used by aerospace manufacturers to make complex, lightweight parts. The anodes keep these precise processes stable and maintain dimensional accuracy during the long forming cycles.

The steady performance leads to predictable outcomes. This consistency helps in these tough scenarios by lowering the amount of wasted material and speeding up the overall process.

Electrochemical Methods of Water Treatment

Besides their use in traditional electroplating, these anodes are also used in water treatment, where electrochemical oxidation gets rid of the impurities. The platinum coating works really well as a catalyst for breaking down organic pollutants.

Municipal water treatment plants use these anodes to kill germs and get rid of other things that shouldn't be in the water. The corrosion resistance makes sure that they can be used for a long time in chlorinated areas that would quickly break down normal electrodes.

The anodes' ability to make reactive species that break down complex organic compounds is helpful for treating industrial wastewater. This app helps manufacturers meet environmental discharge standards while also lowering the cost of treatment.

Technical Perks and Performance Gains

Platinum-coated titanium anodes work better because of a few important technical reasons. The platinum coating keeps its catalytic properties even after long use in harsh conditions because it has great electrochemical stability.

Switching from traditional anodes can boost efficiency by 15% to 25%. Platinum's unique surface facilitates electron transfer. This reduces energy waste and costs, improving operational efficiency.

Titanium provides strength and heat resistance that carbon or lead anodes lack. Its toughness lets it work at higher current densities without changing size or structure.

Contamination control is another advantage. Platinum is inert, so it doesn't release ions that could degrade plating or harm the environment. This purity is crucial for electronics and medical devices.

Platinum adheres well to titanium anodes. A properly manufactured bond can withstand thermal cycling and mechanical stress without delamination or coating failure.

Installation and Operational Considerations

There are a number of things that need to be done right in order for platinum-coated titanium anodes to work properly. Making sure that your electrical connections are right will help the current flow properly and stop any hot spots from forming that could hurt the coating.

Anodes usually need less voltage to work than older options, which use less power and keep temperatures down. This often allows existing power supplies to handle more production without needing to be updated.

Compared to standard anodes, this one doesn't need as much upkeep. As long as the coating wear and electrical connection integrity are checked regularly, the anode will continue to work well for a long time.

Platinum-coated anodes cost more up front than other options, but they last longer and work better, so people usually make their money back in 12 to 18 months of use.

Conclusion

Platinum-coated titanium anodes revolutionize electroplating systems, perform better in precious metal plating, and industrial water treatment. Platinum's catalytic power and titanium's structural integrity create electrodes that outperform traditional ones in efficiency, longevity, and environmental compatibility. These advanced anodes meet tomorrow's electroplating challenges with reliability and performance as industries demand higher quality and operational efficiency. Platinum-coated titanium technology saves energy, improves quality, and extends life.

FAQ

Q: When do platinum-coated titanium electroplating anodes fail?

A: It operates for 3–7 years, depending on use. Duration depends on current density, electrolyte composition, and temperature. This can last a long time if maintained.

Q: Can platinum-coated titanium anodes be re-coated?

A: Titanium bases are reusable. Platinum anodized coatings are a cheap long-term fix because they can be removed and replaced instead of replacing the anodes.

Q: What current densities are safe for these anodes?

Platinum-coated titanium anodes typically function well at current densities up to 1000 A/m². The electrolyte system and temperature determine the limits. This can carry a lot of current, speeding plating cycles and increasing productivity.

Q: Do platinum-coated anodes have electrolyte issues?

A: These anodes work well with hydrochloric acid, sulfuric acid, or other metal salt electroplating solutions. We recommend testing it with electrolyte mixes to ensure optimal performance.

Q: How do I determine my application's anode shape and size?

A: The part's shape, current requirement, and plating evenness determine the anode's size. Our technical team can provide detailed advice and calculations based on your tank setup and needs.

Why Choose Chuanghui Daye for Your Platinum Coated Titanium Anode Needs

Chuanghui Daye stands as a trusted platinum-coated titanium anode manufacturer with over 30 years of expertise in rare metal processing. Our ISO 9001:2015 certified facility in China's "Titanium Capital" ensures consistent quality and reliable supply for your electroplating operations. We offer competitive factory-direct pricing and custom solutions tailored to your specific requirements. Ready to optimize your electroplating system's performance? Contact us at info@chdymetal.com for technical consultation and pricing information.

References

1. Walsh, F. C., & Herron, M. E. (2023). "Advances in Platinum Group Metal Electrodes for Industrial Electroplating Applications." Journal of Applied Electrochemistry, 53(8), 1542-1558.

2. Chen, X., & Rodriguez, A. P. (2022). "Electrochemical Performance and Durability of Platinum-Coated Titanium Anodes in Harsh Industrial Environments." Electrochimica Acta, 428, 140956.

3. Thompson, J. R., et al. (2023). "Cost-Benefit Analysis of Advanced Anode Materials in Large-Scale Electroplating Operations." Surface and Coatings Technology, 456, 129245.

4. Kumar, S., & Williams, D. J. (2022). "Platinum Coating Adhesion and Performance on Titanium Substrates for Electrochemical Applications." Materials Science and Engineering: B, 285, 115923.

5. Anderson, L. M., & Park, H. S. (2023). "Environmental Impact Assessment of Platinum-Coated Titanium Electrodes in Industrial Electroplating Systems." Journal of Cleaner Production, 398, 136521.

6. Martínez, C. E., et al. (2022). "Current Efficiency Optimization in Electroplating Systems Using Advanced Anode Technologies." Hydrometallurgy, 214, 105967.