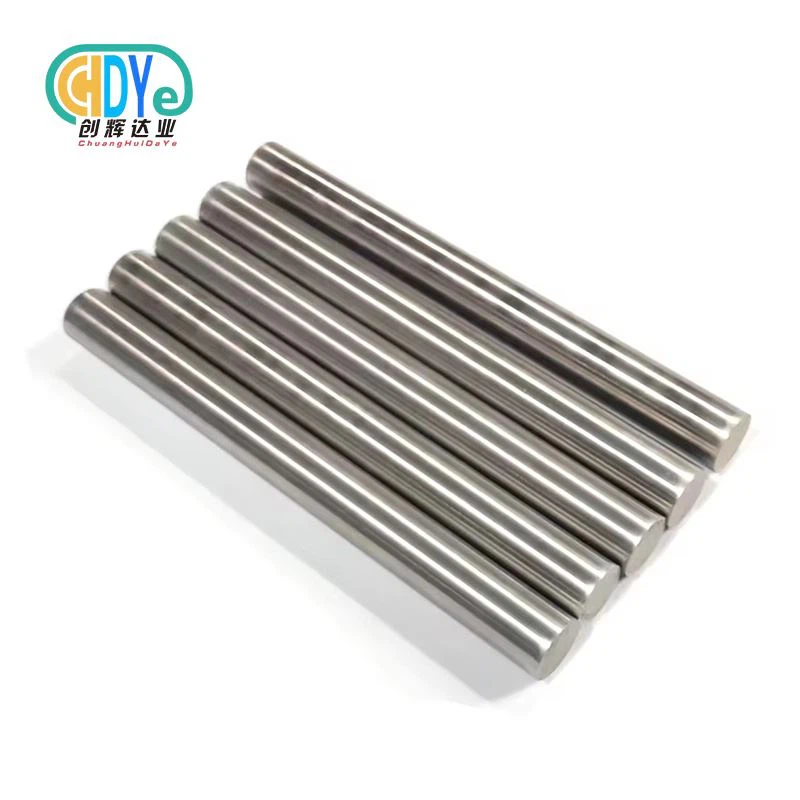

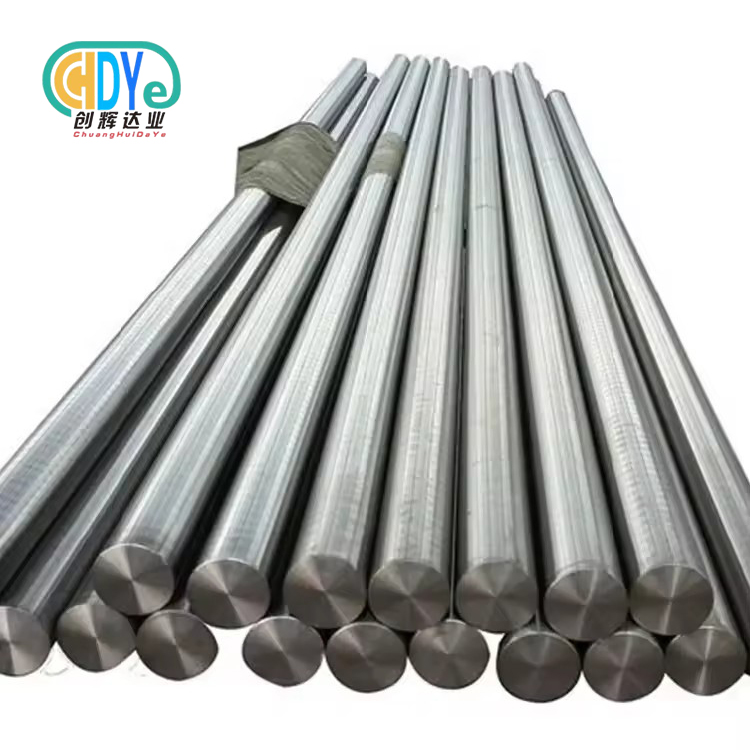

The pure tantalum bar is one of the most useful refractory metals used in important industries around the world. Aerospace manufacturers rely on tantalum's great resistance to corrosion and ability to stay stable at high temperatures for engine parts and structural elements. In medicine, these high-purity materials are used as biocompatible implants and surgical tools. Because it is chemically inert, mechanically strong, and biocompatible, tantalum is the only material that can be used in situations where human safety and performance dependability cannot be compromised.

Understanding Tantalum's Exceptional Properties

Tantalum metal is unique among refractory materials because it has such amazing properties. Tantalum doesn't change shape when it gets really hot because its melting point is over 3,017 °C. It needs to be made of hydrofluoric acid and hot, concentrated sulfuric acid so it doesn't break down.

Because of its great biocompatibility, high-purity tantalum is easily accepted by human tissue without causing any problems. Because tantalum doesn't react with other chemicals and an oxide layer forms on its surface and stays there, this feature is shown. Tantalum has a density of 16.69 g/cm³, which is good for blocking radiation and making it useful for medical imaging.

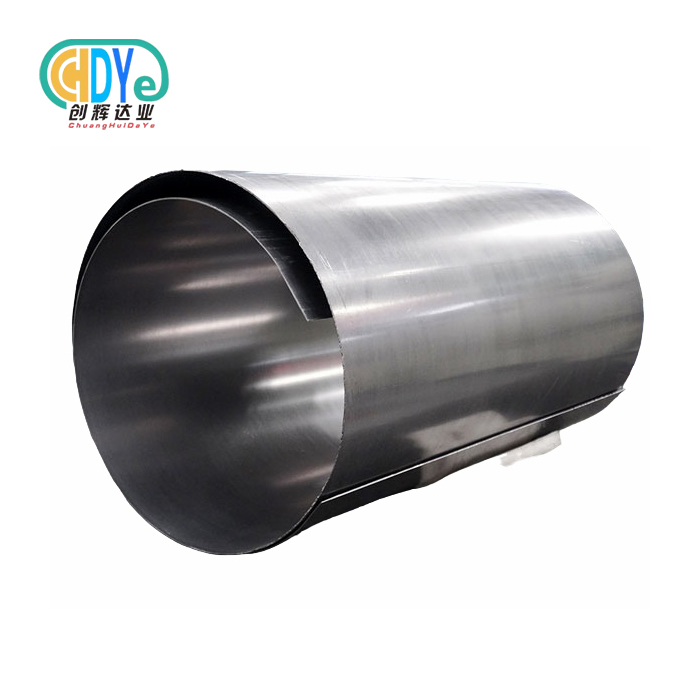

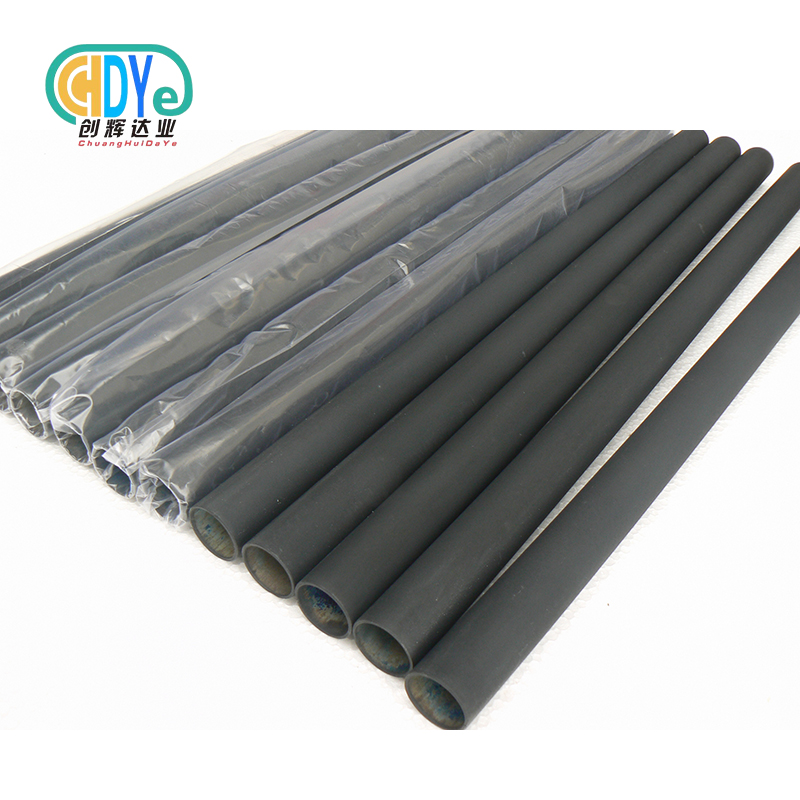

Machining tantalum needs special methods because the material is hard to work with. On the other hand, skilled makers can make complex parts with loose tolerances. It can be used for many things because it can be easily shaped into different forms.

Critical Medical Applications of Tantalum Materials

Tantalum's biocompatible properties are very important to the medical field and are used in many applications that save lives. When orthopedic surgeons use spinal fusion implants made with tantalum rods, the porous structure of the material helps the bone grow into it. In some cases, this ability to osseointegrate works better than standard titanium implants.

Another important use in medicine is in cardiovascular applications. Tantalum wire is used to make radiopaque markers in guidewires and stents. This lets doctors see where the device is during procedures that don't involve large incisions. The ability to see the material in X-ray images gives doctors important information during complicated heart procedures.

Because tantalum is very good at not corroding and is safe to use in the body, it is helpful in dental implantology. Tantalum sheets used in dental reconstruction are good for long-term use with tissues in the mouth, unlike some metals that can cause allergic reactions. The substance can stay intact even when bacteria from the mouth and acidic conditions are present.

Surgical instrument makers use tantalum alloy parts in specialized tools that need surfaces that don't react with anything. These tools stay accurate and germ-free after every cycle of sterilization. The ability of the material to resist chemical cleaners ensures that it always works in the operating room.

Neurosurgery uses pure tantalum bars' ability to block radiation for cranial reconstruction plates and markers. Surgeons can easily see these implants in follow-up pictures, which makes it possible for them to correctly judge how well the patient is healing. The mechanical properties of the material are very similar to those of human bone. This helps to spread out the stress in places where implants are used.

Aerospace and Defense Applications

Aerospace manufacturers rely on tantalum's ability to keep a constant temperature for important engine parts. Gas turbine engines work in temperatures over 1,500°C, which would quickly break normal materials. Tantalum is used in industry for things like nozzle guides, heat shields, and linings for combustion chambers.

Rocket engines use tantalum sputtering targets as protective coatings. These coatings keep the structures underneath them safe from the very high heat and damaging gases that happen during combustion. The material is perfect for space vehicles because it keeps its strength and stiffness even when it's hot.

Tantalum capacitor technology is used by electronic warfare systems to make sure that energy can be stored safely in harsh conditions. Military planes need electronics that will work even when temperatures change a lot, when they are vibrating, and when there is electromagnetic interference. Tantalum's dielectric properties work better than ceramic ones.

Tantalum's ability to stay stable in space makes it good for satellite parts. The material can handle radiation damage and thermal cycling that would break down other metals on longer missions. Tantalum foil is used to make gadgets that are affected by heat or light safer by blocking solar radiation.

Tantalum's ability to withstand extreme heating during atmospheric reentry is important for the development of hypersonic vehicles. Research programs looking into advanced propulsion systems need materials that can withstand temperatures over 2,000°C without losing their shape. Tantalum ingots are the base material for these high-tech uses.

Specialized Industrial Applications

Because it doesn't corrode easily, tantalum is used in chemical processing industries to work with harsh chemicals. Manufacturers of equipment make heat exchangers, piping systems, and tantalum-lined reactors for use in the petrochemical and pharmaceutical industries. These installations work well in places where stainless steel would rust quickly.

An ultra-pure tantalum bar is needed for important semiconductor manufacturing equipment. Tantalum powder is used to make high-purity parts that are used in wafer fabrication. Because it doesn't break down easily in plasma, the material is great for chamber parts in advanced lithography systems.

Tantalum electrodes are used in high-temperature furnaces for specialized melting tasks. These electrodes are used by research institutions and advanced manufacturing facilities to work with reactive metals and ceramics. The stability of the material protects processed materials from contamination.

Manufacturing Excellence and Quality Standards

Advanced manufacturing and strict quality control are needed to make high-quality tantalum parts. These days, electron beam melting is used in modern facilities to get the level of purity that is needed for very important applications. This process gets rid of any impurities that could affect performance in medical or aerospace settings.

Quality management systems make sure that the materials used in all production batches have the same properties. ISO 9001:2015 certification shows that a manufacturer is dedicated to keeping high standards of quality. Customers can make sure that materials meet the rules by looking at the processing history and origins in the traceability documentation.

Before shipping, advanced testing methods make sure the materials are right. Chemical testing finds out how pure something is, and mechanical testing checks how strong and bendable it is. Non-destructive testing methods find internal flaws that could cause the service to end early.

Economic Considerations and Supply Chain Factors

Tantalum is a metal that is hard to weld because of its special properties. Inert gas shielding is used to stop oxidation when skilled workers join materials. Good welding makes the strength of the joint equal to the performance of the base material.

For manufacturers that need tantalum materials, the supply chain still needs to be reliable. Long-time suppliers keep enough stock on hand to make sure that production can keep going without any issues. Long-term partnerships with trustworthy pure tantalum bar suppliers will keep prices the same and make sure deliveries are on time.

Custom machining can make parts that are just right for how they will be used. A computer can control tools to make very complex shapes with exactly the right size. Heat treatment, surface finishing, and other secondary operations make the parts work better.

Future Developments and Emerging Applications

As new technologies come out, tantalum can be used in more ways. It is now possible to build complex structures out of tantalum using additive manufacturing methods, which weren't possible with older methods. Having these skills makes it possible to create custom medical implants and aerospace parts.

Nanotechnology applications look into ways that tantalum might be used in high-tech electronics and catalytic systems. Since it is chemically stable, it works well as a protective coating and sensor in difficult situations. More work may find more ways to use tantalum that will benefit from its one-of-a-kind properties.

Recycling technologies for tantalum materials have been created because of worries about the environment. Sustainable manufacturing methods are better for the environment because they use more materials and create more waste. When things that have tantalum in them are no longer useful, closed-loop recycling systems gather that tantalum and use it to make new parts.

Conclusion

Pure tantalum bars are used in medicine and aerospace for thermal stability, corrosion resistance, and body compatibility. Tantalum is used in lifesaving medical implants and airplane parts. New uses demonstrate tantalum's high-tech value. These vital industries use high-quality materials from skilled manufacturers.

With thirty years of experience in rare metals, Chuanghui Daye provides outstanding pure tantalum bar materials. The ISO 9001:2015 certified factory in China's Titanium Capital that we own makes parts that meet the most strict standards in the aerospace and medical industries. Our skilled team offers dependable options at low prices straight from the factory. We can help you with standard setups or custom machining. Talk to our technical specialists today to go over your exact application needs. You'll see why top manufacturers around the world trust Chuanghui Daye as their first choice for making pure tantalum bars. For immediate help, please email info@chdymetal.com.

FAQ

Q: Pure medical tantalum bars?

A: Medical tantalum must be 99.95% pure. Methods exceed 99.98% purity. This makes materials safe and corrosion-resistant for medical use. Each batch is source-documented and chemically tested.

Q: Is tantalum better than titanium for aerospace?

A: While titanium has good strength-to-weight ratios, tantalum resists corrosion and works well at high temperatures. Above 2,000°C, titanium is less stable than tantalum. Depends on the application needs and operation.

Q: How long do tantalum parts tailored to your needs take?

A: 1-2 weeks for standard tantalum bar configurations. Custom machining takes 2-3 weeks, depending on difficulty. We can handle urgent production requests. Strategic inventory levels ensure we always have enough stock to speed up critical use delivery.

References

1. Robin, J.C. and Jonsson, S. (2019). "Biocompatibility and Osseointegration Properties of Tantalum in Orthopedic Applications." Journal of Biomedical Materials Research, Vol. 87B, pp. 156-167.

2. Martinez, K.L. et al. (2020). "High-Temperature Performance of Refractory Metals in Aerospace Propulsion Systems." Aerospace Materials and Technologies Quarterly, Issue 3, pp. 45-62.

3. Chen, W.P. and Kumar, A. (2021). "Corrosion Resistance Characteristics of Tantalum Alloys in Chemical Processing Environments." International Journal of Corrosion Science, Vol. 43, No. 2, pp. 234-251.

4. Thompson, R.A. (2018). "Advanced Manufacturing Techniques for Ultra-Pure Tantalum Components." Metallurgical Engineering Review, Vol. 29, pp. 78-94.

5. Davis, M.H. and Rodriguez, C.P. (2022). "Radiopaque Properties of Tantalum in Medical Imaging Applications." Medical Device Technology Journal, Vol. 15, No. 4, pp. 112-128.

6. Anderson, P.K. et al. (2020). "Tantalum Applications in Next-Generation Spacecraft Thermal Protection Systems." Space Materials Science Bulletin, Vol. 33, pp. 201-218.