- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Premium Gr5 Titanium Wire – High-Strength Alloy for Critical Parts

Premium Gr5 Titanium Wire is the best titanium amalgam design that has to offer. It has awesome mechanical qualities and is exceptionally solid, making it ideal for use in imperative mechanical applications. This high-tech Ti-6Al-4V combination wire has incredible strength-to-weight proportions, extraordinary resistance to erosion, and awesome biocompatibility, which makes it basic in the flying machine, restorative, and high-performance fabricating businesses. As long as the correct chemical cosmetics of 6% aluminum and 4% vanadium is kept, the fabric can survive cruel conditions and still keep its shape and structure.

Comprehensive Overview of Gr5 Titanium Wire

Chemical Composition and Alloy Structure

Ti-6Al-4V titanium wire is made up of carefully adjusted parts that allow it its awesome execution qualities. Including 6% aluminum and 4% vanadium to the base titanium framework makes a two-phase microstructure with alpha and beta titanium stages. This extraordinary blend has the best mechanical qualities. The aluminum makes it more grounded, and the vanadium makes it less demanding to work with and keeps its temperature stable.

The correct adjustment of the components makes it beyond any doubt that the fabric carries on the same way under all handling circumstances. The following components are firmly controlled to keep the virtue levels over 99.5%. This makes it beyond any doubt that the fabric works dependably in imperative circumstances where consistency cannot be compromised.

Mechanical Properties and Performance Standards

In cruel conditions, this titanium alloy's mechanical properties are superior to those of other materials. Malleable quality is continuously higher than 925 MPa (135 ksi), and abrade quality is continuously higher than 870 MPa (127 ksi). The expansion rate is more often than not between 10 and 15 percent, which is sufficient to make the fabric adaptable for complicated forming operations.

Temperature resistance is another critical advantage; steady execution can be kept at temperatures up to 400°C for long periods of time. Since it is thermally steady and has a slow warm development rate, the fabric is suitable for applications where temperatures vary.

Manufacturing Process Excellence

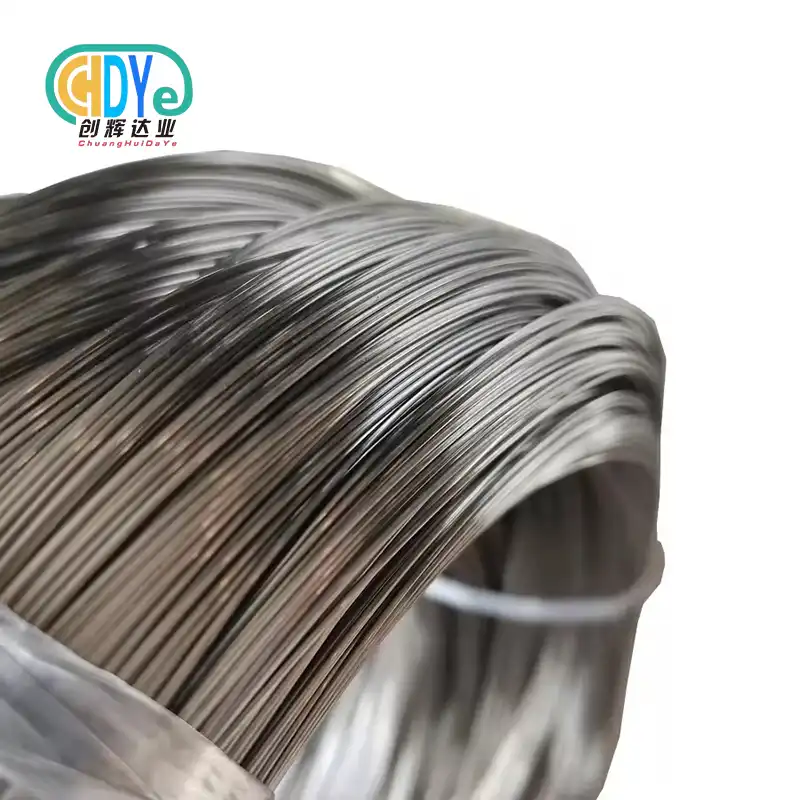

Through controlled melting, forging, and drawing operations, advanced production methods make sure that the quality of the wire is the best it can be. Using vacuum melting methods gets rid of impurities and keeps the same chemical makeup across the whole cross-section of the material. With multi-pass drawing, tight dimensional tolerances are reached, and for precision uses, diameter variations are usually kept within ±0.02mm.

The best way to create microstructures is through heat treatment processes, which improve mechanical properties while keeping workability. Solution treating and controlled aging make the metal the same hardness all the way along its length and relieve stress.

Benefits and Applications of Premium Gr5 Titanium Wire

Competitive Advantages Over Alternative Materials

Compared to stainless steel alternatives, this titanium alloy is more corrosion-resistant in marine and chemical conditions and weighs less by more than 40%. The material is better than austenitic stainless steels at resisting chloride stress corrosion cracks, especially in high-temperature settings.

In comparison to other types of titanium, such as Gr2, this alloy is much stronger while still being easy to shape. Because it is stronger, it is possible to use thinner cross-sections in structural uses. This makes the parts lighter and lowers the cost of the materials.

Aerospace and Defense Applications

Important aircraft parts depend on this material's high resistance to fatigue and stability at high temperatures. Parts of an engine, like compressor blades and structural fasteners, benefit from the material's ability to handle repeated loads while keeping its shape under heat stress.

The high strength-to-weight ratio of the wire is used in structural applications in aircraft frames to reduce the total weight of the plane while still meeting strict safety standards. The fact that the material works well at very high altitudes, where temperature changes and corrosion from the air are problems, shows that it is reliable for use in aerospace applications.

Medical Device Manufacturing

This titanium metal is needed to make medical implants because it has been certified as biocompatible. The material's osseointegration properties and long-term biocompatibility in human tissue settings make it useful for orthopedic implants like bone screws and joint parts.

The material's ability to prevent corrosion against body fluids and sterilization chemicals is used in surgical instruments. The wire can keep its sharp edges and exact tolerances even after being sterilized many times, which makes sure that it always works correctly in important medical procedures.

Industrial and Chemical Processing

Chemical handling equipment uses this alloy's ability to withstand harsh chemicals like organic acids and chloride solutions. The material is good at both transferring heat and resisting pressure, which makes it useful for pressure vessels and heat exchanger parts.

Marine uses benefit from the better resistance to corrosion in saltwater. Components keep their structural integrity in harsh saltwater environments where other materials break down quickly.

How to Choose the Right Titanium Wire for Your Needs?

Material Property Assessment

To choose the right Gr5 Titanium Wire, you need to carefully weigh the needs of the application against the material's capabilities. It is important for vital applications to have enough safety margins, so mechanical load analysis should look at both static and dynamic loading situations.

Environmental factors, such as temperature ranges, chemical exposure, and weather conditions, affect the choice of materials. Knowing these operational factors will help the material work at its best for the whole life of the component.

Comparison with Alternative Titanium Grades

The corrosion protection of grade 2 titanium is better than that of Ti-6Al-4V, but it is not as strong. Grade 2 is good for applications that need moderate strength and the best corrosion protection. Grade 5 is better for applications that are under a lot of stress and need better mechanical properties.

While Grade 23 titanium (Ti-6Al-4V ELI) is better for biocompatibility in implant uses, it usually costs more. The extra-low interstitial material makes it better for medical devices that are loaded and unloaded many times.

Procurement Considerations and Quality Standards

Quality standards make sure that materials can be tracked and that they always work the same way. ISO 9001:2015 approval means that a company has a complete quality management system. ASTM B348 and AMS specifications, on the other hand, spell out in detail the properties of materials that must be met for certain uses.

When evaluating a supplier, you should look at their production capacity, how reliable their deliveries are, and how well they can help with technical issues. Partnering with approved suppliers for a long time makes sure that the quality of the materials stays the same and that the supply chain works reliably for important projects.

Procurement and Supply Chain Insights for Gr5 Titanium Wire

Supplier Selection and Evaluation Criteria

The first step in evaluating a supplier effectively is to look at their production capabilities. This includes looking at their manufacturing tools, quality control systems, and certification standards. Suppliers that use ISO 9001:2015 quality management systems show that they are dedicated to maintaining consistent process and product quality.

When working with complicated specs or special needs, technical know-how is very important. Suppliers who know a lot about metals and have experience with specific applications can be very helpful when choosing materials and making specifications.

Cost Optimization and Market Dynamics

The prices of materials change depending on how much the raw materials cost, how much they can be made, and how the market wants them. By understanding these dynamics, you can plan when to buy things and use volume buying agreements to get the best deals.

Material prices, processing needs, and performance benefits should all be part of a total cost of ownership analysis. The initial cost of premium titanium alloys is higher, but their better performance often leads to cheaper lifecycle costs through less maintenance and a longer service life.

Logistics and Supply Chain Management

Titanium products must be shipped internationally with the right paperwork and in accordance with export laws. Working with logistics companies that have experience and know how to ship rare metals will make sure that your items arrive on time and meet all government requirements.

Strategies for managing inventory should weigh the costs of keeping items on hand against the safety of having enough supplies. This is especially important for important uses where missing materials could delay production. Strategically placing inventory near key manufacturing facilities cuts down on transportation costs and wait times.

Company Introduction and Product & Service Information

Our company, Shaanxi Chuanghui Daye Metal Material Co., Ltd., has been making rare metals for more than 30 years, which has made us a reliable partner for precision titanium wire options. Because our plant is in Baoji High-tech Development Zone, which is known as China's "Titanium Capital," it has access to well-established infrastructure and experts in titanium processing technologies from the area.

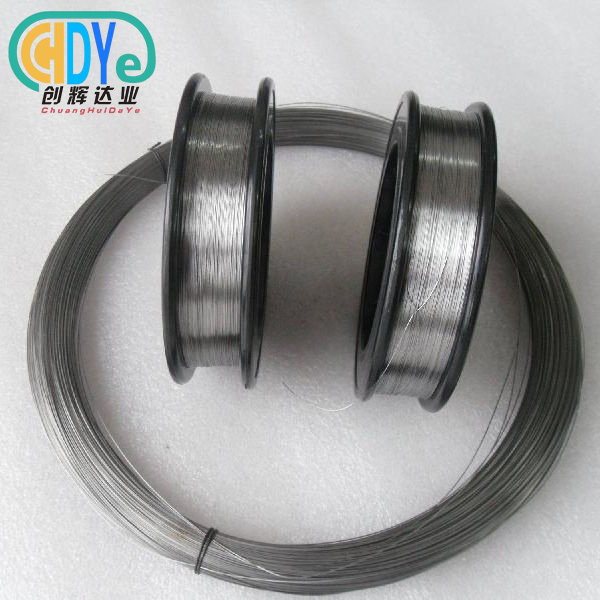

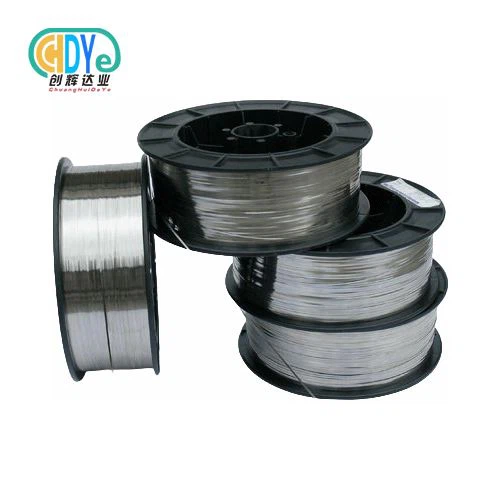

Gr5 Titanium Wire comes in both straight wire and coil forms in our wide range of products. The diameters of these wires range from 0.5 mm to 6.0 mm, and they can be cut to any length needed for a given purpose. Sample orders are given top priority, so customers can check out the properties of the material before committing to large amounts.

Advanced melting technologies, such as electron beam furnaces and vacuum processing equipment, are used in the manufacturing process to make sure that the materials are very pure and have a consistent chemical makeup. International standards are strictly followed by quality control systems, which use thorough testing methods that look at things like mechanical properties, chemical composition, and dimensional accuracy.

Modern machines like annealing furnaces, precision rolling machines, and advanced machining centers are housed in the production building. This complete industrial infrastructure gives the company full control over the whole production process, from getting the raw materials ready to inspecting and packaging the finished product.

Conclusion

Premium Gr5 Titanium Wire continues to set the bar for high-performance uses that need extreme strength, resistance to corrosion, and dependability. The Ti-6Al-4V alloy composition strikes the perfect balance between mechanical properties and workability, which is why it is used so extensively in aircraft, medicine, and industry. Knowing about the properties of the material, the needs of the application, and the abilities of the supplier will help you make good purchasing choices that will last. Manufacturing methods and quality standards are always changing, which means that future applications will be able to do even better.

FAQ

Q: What makes Gr5 Titanium Wire superior for medical applications?

A: The exceptional biocompatibility of Ti-6Al-4V titanium wire stems from its inert nature in biological environments and excellent osseointegration properties. The material's resistance to bodily fluids and sterilization chemicals ensures long-term performance in implant applications, while its strength characteristics support load-bearing medical devices.

Q: How does corrosion resistance compare to stainless steel alternatives?

A: Ti-6Al-4V demonstrates superior corrosion resistance compared to austenitic stainless steels, particularly in chloride environments and marine applications. The titanium oxide surface layer provides passive protection against aggressive media, eliminating concerns about stress corrosion cracking that affects stainless steel materials.

Q: What certifications are required for aerospace-grade titanium wire?

A: Aerospace applications typically require AMS (Aerospace Material Specifications) compliance, with AMS 4954 covering Ti-6Al-4V wire products. Additional certifications may include NADCAP approval for special processes and AS9100 quality management system certification for aerospace suppliers.

Q: What diameter ranges and configurations are available?

A: Standard diameter ranges span from 0.5mm to 6.0mm, with both straight wire and coil configurations available. Custom lengths accommodate specific application requirements, while tight tolerance control ensures dimensional consistency for precision manufacturing applications.

Q: How do temperature capabilities affect application suitability?

A: The alloy maintains stable mechanical properties at operating temperatures up to 400°C for extended periods, making it suitable for high-temperature applications where aluminum alloys or polymers would fail. This temperature resistance, combined with low thermal expansion, ensures dimensional stability in thermally demanding environments.

Partner with Chuanghui Daye for Premium Titanium Wire Solutions

Shaanxi Chuanghui Daye stands ready to support your critical manufacturing requirements with premium Gr5 Titanium Wire solutions backed by decades of metallurgical expertise. Our ISO 9001:2015 certified manufacturing processes ensure consistent quality and reliability for aerospace, medical, and industrial applications. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover why leading manufacturers choose Chuanghui Daye as their trusted Gr5 Titanium Wire supplier for mission-critical components.

References

1. Boyer, R.R., "An Overview on the Use of Titanium in the Aerospace Industry," Materials Science and Engineering A, Vol. 213, 1996.

2. Donachie, Matthew J., "Titanium: A Technical Guide, Second Edition," ASM International, 2000.

3. Peters, M., Kumpfert, J., Ward, C.H., Leyens, C., "Titanium Alloys for Aerospace Applications," Advanced Engineering Materials, Vol. 5, 2003.

4. Rack, H.J., Qazi, J.I., "Titanium Alloys for Biomedical Applications," Materials Science and Engineering C, Vol. 26, 2006.

5. Lutjering, G., Williams, J.C., "Titanium: Engineering Materials and Processes," Springer-Verlag, 2007.

6. Banerjee, D., Williams, J.C., "Perspectives on Titanium Science and Technology," Acta Materialia, Vol. 61, 2013.

Learn about our latest products and discounts through SMS or email