- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Premium Titanium Square Bar Solutions for Engineering

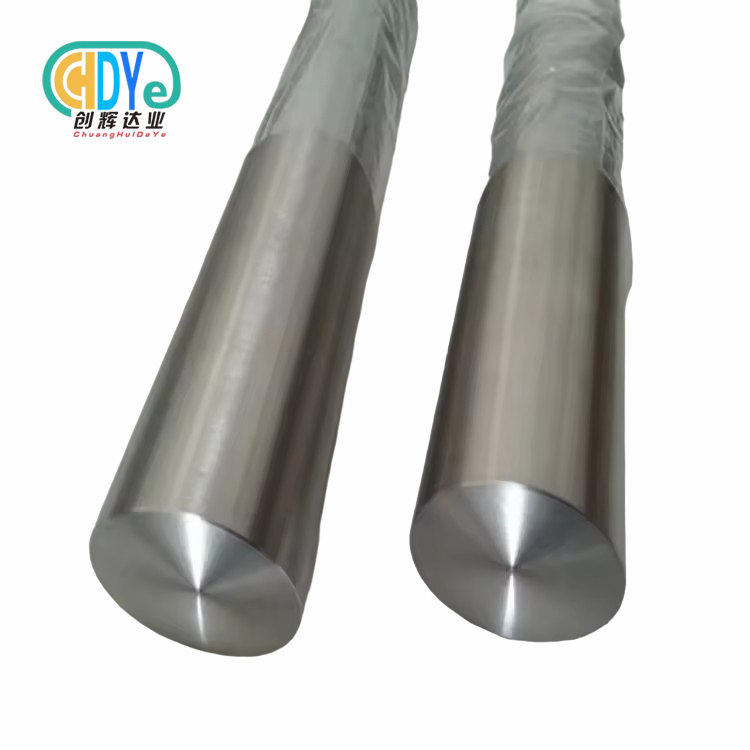

Premium Titanium Square Bar solutions underpin innovative production applications when engineering excellence requires outstanding materials. These precision-engineered components are essential in aerospace, medical device, and chemical processing due to their high strength-to-weight ratios and corrosion resistance. Premium titanium square bars offer unrivaled dimensional stability and mechanical qualities, helping engineers succeed under the toughest conditions.

Understanding Titanium Square Bars: Properties and Applications

Titanium square bars are designed to meet strict industrial criteria for precision, durability, and performance. These rectangular cross-section bars outperform round bars and sheet materials in applications that need precision fitting, load distribution, and structural integrity.

Fundamental Properties of Titanium Square Bars

Their unusual metallurgical qualities provide titanium square bars with outstanding properties. Due to their low density of 4.51 g/cm³, these components outperform traditional metals in strength-to-weight ratio. Titanium square bars are ideal for weight-critical applications due to their lightweight nature and tensile strengths of 240 MPa for commercially pure grades and above 900 MPa for high-strength alloys.

Another trait is corrosion resistance. Titanium surfaces' natural oxide layer protects against chloride, saltwater, and acidic conditions. When destroyed, this passive layer regenerates autonomously, assuring long-term durability in demanding working situations.

Industrial Applications Across Multiple Sectors

Titanium square bars are versatile throughout industries. These components are structural supports, mounting brackets, and precise fixtures in aircraft production. Weight reduction improves fuel efficiency and cargo capacity. Automotive manufacturers use their qualities for high-performance exhaust systems, racing parts, and specific fasteners.

Medical device producers use biocompatible titanium for surgical tools, implant components, and precision tooling. The non-magnetic characteristics make these materials perfect for MRI and other delicate medical applications. For reactor supports, valve components, and corrosive structural parts, chemical processing plants use titanium square bars.

Geometric Advantages in Engineering Design

The square cross-section geometry has engineering advantages over round bars. Flat surfaces permit precise machining and assembly, while enhanced corner strength improves bolted connection load transfer. Titanium square bars are useful for keying and anti-rotation systems because their shape inhibits rotation in square holes or slots.

Comparing Titanium Square Bars with Other Metals: Making the Best Choice

Selecting the best engineering material needs careful consideration of performance, cost, and long-term value. Titanium square bars outperform stainless steel and aluminum in applications that require many performance requirements.

Performance Comparison with Stainless Steel

Titanium square bars are lighter than high-grade stainless steel and have similar or better mechanical characteristics. Titanium weighs 4.51 g/cm³, while stainless steel grade 316L, used in corrosive settings, weighs around 8.0 g/cm³. Aerospace and automotive operations benefit from this 44% weight reduction.

Titanium's corrosion resistance is better in chloride and high temperatures. Titanium's natural oxide layer resists pitting and crevice corrosion better than stainless steel's chromium. Titanium maintains mechanical qualities at temperatures where stainless steel begins to lose strength.

Advantages Over Aluminum Alloys

Aluminum alloys are lightweight, while titanium square bars are stronger and more temperature-resistant. Titanium Grade 5 (Ti-6Al-4V) normally reaches 900 MPa, whereas high-strength aluminum alloys reach 400-500 MPa. Titanium can keep its qualities at temperatures of 400°C, unlike aluminum, which is limited to 150-200°C.

Titanium fatigue resistance exceeds that of aluminum, making it vital for cyclic loading. This high fatigue life and fracture toughness allow reliable operation in important structural applications with severe failure consequences.

Grade Selection for Specific Applications

Specific performance requirements determine the choice between commercially pure titanium grades (Gr1, Gr2, Gr4) and titanium alloys (Gr5, Gr9, Gr23). Grade 2 titanium is formable and corrosion-resistant for chemical processing, whereas Grade 5 is strong for aerospace and high-stress structural components.

For medical implants, Grade 23 (Ti-6Al-4V ELI) is best due to its biocompatibility and strength. Understanding these differences helps procurement experts choose materials based on application needs rather than general specs.

Procurement Guide: Buying Premium Titanium Square Bars Online

Selecting excellent titanium square bars demands a thorough review of supplier capabilities, quality processes, and services. Titanium manufacture requires suppliers with established experience, advanced processing capabilities, and unshakable quality standards.

Supplier Evaluation Criteria

Supplier evaluation is key to titanium procurement. ISO 9001:2015 accreditation represents systematic quality management and process control. Titanium-specific certifications like AS9100 for aerospace or ISO 13485 for medical products add to the confidence of specialist capabilities.

Manufacturing skills are also important. Integrated suppliers from vacuum melting to final machining provide better quality control and traceability. Premium titanium square bar production requires advanced equipment like vacuum arc remelting (VAR) furnaces, precision forging presses, and CNC machining centers.

Customer references and case studies reveal supplier performance under pressure. Established vendors should be able to demonstrate successful projects in similar applications to prove they can meet strict specifications and delivery criteria.

Customization and Technical Specifications

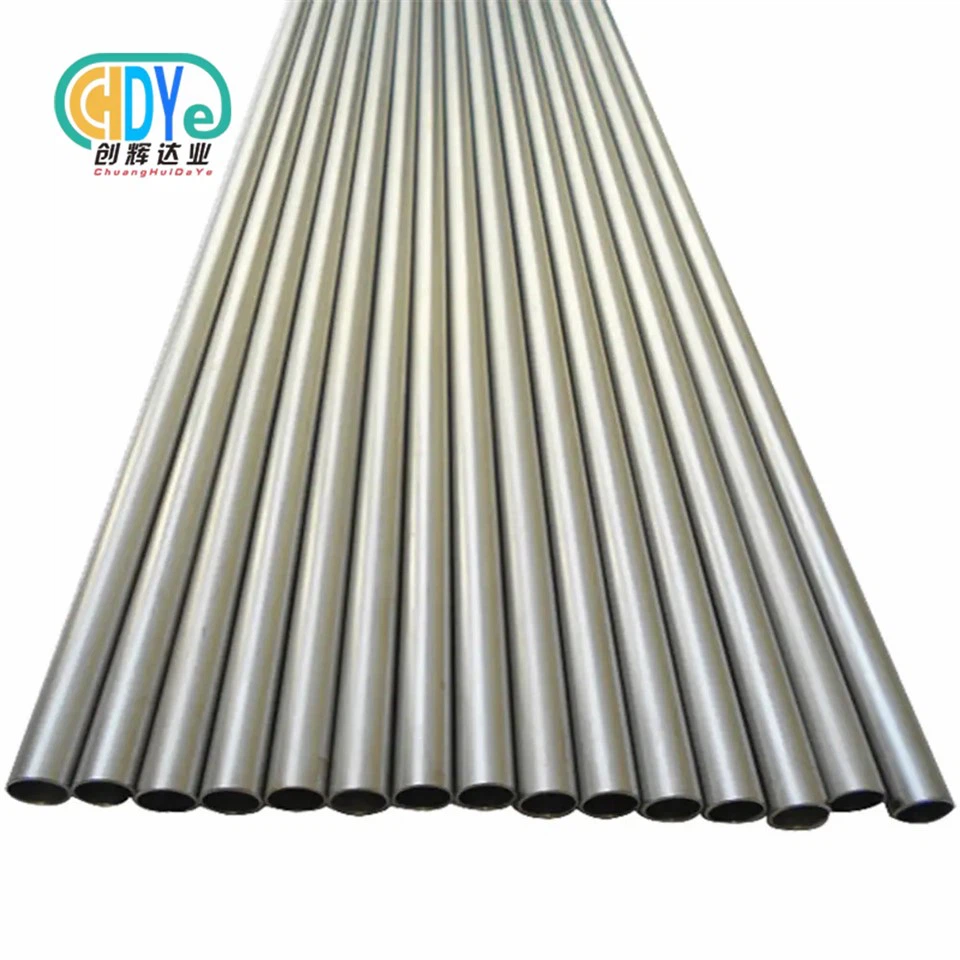

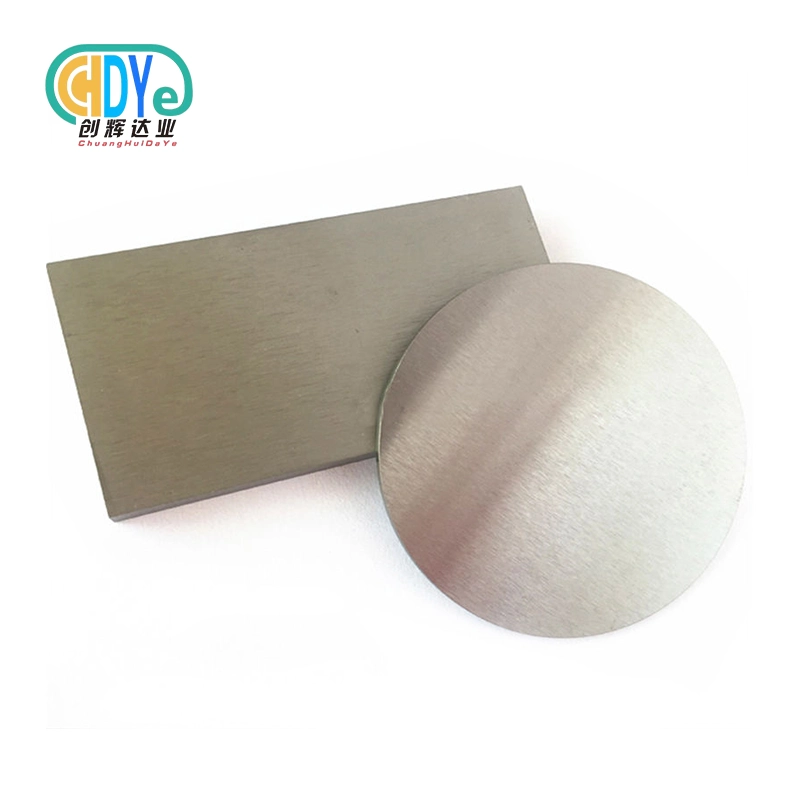

To suit project needs, premium titanium square bar suppliers should offer extensive customization. Typical parameters include 8x8 to 200x200 mm cross-sections and lengths up to 6000 mm. But custom cutting, precise machining, and specific surface treatments are valuable for complex applications.

All shipments must include chemical composition analysis, mechanical property testing, and dimensional inspection reports. Aerospace and medical applications require full documentation linking completed products to raw material sources for traceability.

Lead times vary greatly by grade, size, and quantity. Specialized alloys or unique configurations may take longer to manufacture than standard grades like Grade 2 and Grade 5 in popular sizes.

Cost Optimization Strategies

Complex production procedures and raw material prices affect premium titanium square bar pricing. Understanding price structures improves budgeting and cost management. Volume reductions are significant for orders over 100-500 kg, depending on specifications.

Long-term supplier agreements can guarantee project availability and price stability. These agreements frequently offer attractive pricing for agreed quantities over time. Instead of unit price, procurement decisions should consider the total cost of ownership, including shipping, handling, and expediting.

Enhancing Titanium Square Bar Performance: Processing and Maintenance

Titanium square bars must be handled properly during manufacturing and continuous maintenance to maximize performance and service life. Understanding titanium's specific qualities helps engineers and fabricators optimize processing settings and avoid frequent mistakes that might damage material attributes or dimensional accuracy.

Machining Best Practices

To handle titanium square bars' unusual properties, machining requires specialized procedures and tooling. Titanium's limited thermal conductivity concentrates heat at cutting interfaces, requiring active cooling and optimum cutting conditions. Sharp carbide tools with positive rake angles limit cutting forces and heat generation, while flood coolant application provides proper heat dissipation.

Cutting speeds should be kept within suggested ranges to avoid work hardening, which can hinder following operations. Climb milling often outperforms conventional milling in surface finish and tool life. Consistent feed rates minimize hard patches that damage cutting blades and reduce dimensional accuracy.

Optimization of tool life involves meticulous cutting-edge maintenance and timely replacement when wear occurs. Worn tools generate excessive heat and cause surface flaws that may necessitate additional polishing or material rejection.

Heat Treatment and Property Enhancement

The most frequent heat treatment for titanium square bars is stress relief annealing at 480-650°C, depending on grade and manufacturing history. This treatment retains good mechanical qualities for service applications while eliminating residual stresses from forming operations.

Solution treatment and aging can strengthen titanium alloys, especially Grade 5 and Grade 23. Protective atmospheres and careful temperature control are needed to prevent surface contamination and ensure uniform property development over the cross-section.

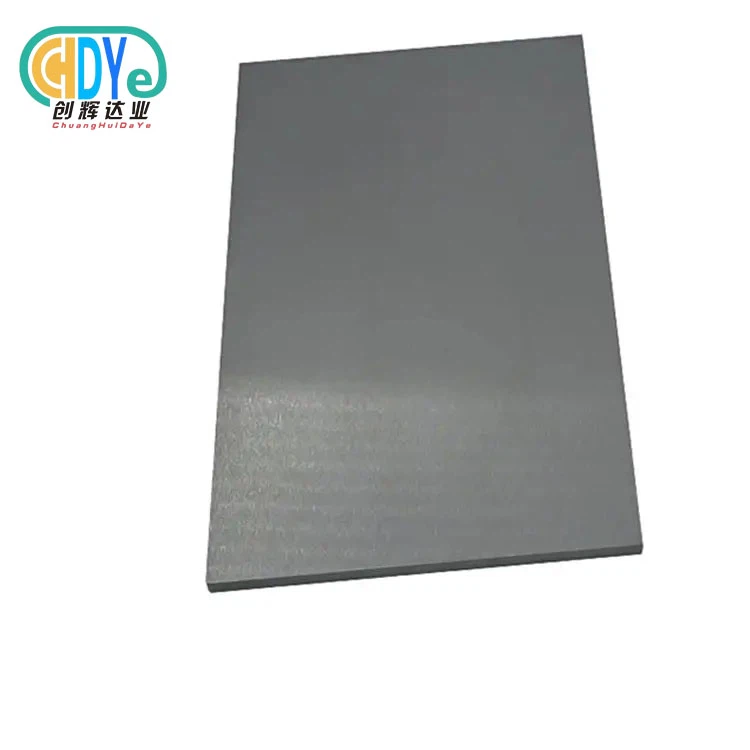

Surface Finishing Options

Titanium square bars' appearance and performance depend on surface condition. For decorative uses and clean environments, bright polished surfaces are mirror-like. By reducing surface imperfections that could initiate corrosion, this finish improves corrosion resistance slightly.

Machining provides tight dimensional tolerances and excellent surface roughness for precise mechanical applications. For coating or bonding applications that need surface preparation, the regulated surface texture is ideal.

Pickled surfaces retain dimensional precision by removing oxide layers and contaminants. This treatment is especially useful for welding, where surface cleanliness affects joint quality and mechanical properties.

Why Choose Our Premium Titanium Square Bars for Your Engineering Projects?

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a renowned titanium square bar producer with decades of experience and a commitment to quality. As China's "Titanium Capital," Baoji High-tech Development Zone provides our organization with superior infrastructure and a competent titanium production staff.

Manufacturing Excellence and Quality Assurance

Our production capabilities include raw material processing, final inspection, and packaging. Advanced vacuum melting furnaces optimize metallurgical structure and chemical composition, while precision forging improves mechanical qualities and dimensional accuracy. Our entire product line has precise tolerances and outstanding surface finishes thanks to hot rolling and cold drawing.

ISO 9001:2015-certified quality management systems provide product quality and traceability throughout manufacturing. Chemical composition, mechanical property, and ultrasonic inspection for internal defects are performed on each production batch. Every shipment includes material test certificates (MTC), dimensional inspection reports, and ultrasonic inspection paperwork for quality assurance.

To ensure product uniformity, our trained specialists monitor temperature, deformation rates, and microstructure development. To verify compliance, the final inspection involves dimensional verification, surface quality assessment, and mechanical property validation.

Product Portfolio and Customization Capabilities

Our ASTM B348, AMS 4928, and ISO 5832-compliant product line includes commercially pure titanium (Gr1, Gr2, Gr4) and high-strength aircraft alloys (Gr5, Gr9, Gr23). Standard cross-sections include precision bars and massive structural components, with bespoke sizes available for specific applications.

To maximize application performance, bright polished, machined, and pickled surfaces are available. Heat treatment includes stress relief annealing, solution treating, and aging cycles to meet mechanical and metallurgical requirements.

For research and development, our manufacturing processes can handle high-volume production runs and small-batch custom orders. Universities and research institutes needing custom settings or experimental program specifications benefit from this capacity.

Technical Support and Customer Service

Our technical staff, driven by rare metal industry veterans, provides application support throughout the project lifetime. Our experts collaborate with customers to optimize results for challenging applications, from material selection to processing advice and quality assurance.

Fast order processing and communication are guaranteed by responsive customer service. To meet global shipping needs, we offer EXW, FOB, and CIF logistics. Certificates of origin, business invoices, and inspection reports streamline customs clearance and receiving.

Conclusion

Premium Titanium Square Bar solutions are the best technical materials for strength-to-weight ratios, corrosion resistance, and dimensional stability. These specialised components excel in aerospace, medical, chemical processing, and precision manufacturing. Effective material selection, processing, and supplier partnerships with titanium production experts are needed for success. Chuanghui Daye's sophisticated production and technical support offer excellent solutions for the most demanding engineering projects.

FAQ

Q: What grades of titanium square bars are best for aerospace applications?

A: Grade 5 (Ti-6Al-4V) titanium square bars represent the optimal choice for aerospace applications requiring maximum strength-to-weight ratios. This alpha-beta alloy achieves tensile strengths exceeding 900 MPa while maintaining excellent fatigue resistance and temperature stability up to 400°C. Grade 23 (Ti-6Al-4V ELI) offers similar strength characteristics with enhanced fracture toughness for critical structural components.

Q:How do titanium square bars compare to steel in corrosion resistance?

A: Titanium square bars demonstrate superior corrosion resistance compared to steel in most environments, particularly chloride and acidic conditions. The natural oxide layer provides passive protection that regenerates automatically when damaged, unlike steel coatings that can fail catastrophically. In seawater applications, titanium maintains structural integrity while steel requires protective coatings or cathodic protection systems.

Q:Can you provide custom sizing and cutting services?

A: Yes, we offer comprehensive customization services, including precision cutting, custom cross-sections, and specialized length requirements. Our advanced machining capabilities enable tight tolerance cutting and specialized surface preparations to meet specific application requirements. Custom sizing typically requires 1-2weeks of additional lead time, depending on specifications.

Q: What surface finishes are available for titanium square bars?

A: We provide three primary surface finishes: bright polished for a mirror-like appearance and enhanced corrosion resistance, machined finish for tight dimensional tolerances, and pickled finish for optimal cleanliness in welding applications. Each finish option can be tailored to specific surface roughness requirements and dimensional tolerances.

Partner with Chuanghui Daye for Superior Titanium Square Bar Solutions

Shaanxi Chuanghui Daye delivers exceptional titanium square bars engineered for demanding applications across aerospace, medical, and chemical processing industries. Our ISO 9001:2015 certified manufacturing processes ensure consistent quality, while our experienced technical team provides comprehensive application support from material selection through final delivery. Contact our specialists at info@chdymetal.com to discuss your specific requirements and discover why leading manufacturers trust Chuanghui Daye as their preferred titanium square bar supplier. Experience the advantages of premium materials backed by three decades of rare metal expertise and unwavering commitment to customer success.

References

1. ASM International Handbook Committee. "Properties and Selection: Nonferrous Alloys and Special-Purpose Materials." ASM Handbook Volume 2, ASM International, 2018.

2. Boyer, Rodney R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering: A, Volume 213, International Journal of Materials Science, 2019.

3. Lutjering, Gerd, and James C. Williams. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, Second Edition, 2017.

4. Peters, Manfred, and Christoph Leyens. "Titanium and Titanium Alloys: Fundamentals and Applications." Wiley-VCH Verlag GmbH, Advanced Materials Research Series, 2018.

5. Rack, Henry J., and John I. Qazi. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering: C, Biomimetic and Supramolecular Systems, Volume 26, 2019.

6. Welsch, Gerhard, Rolf Boyer, and E.W. Collings. "Materials Properties Handbook: Titanium Alloys." ASM International Materials Park, Comprehensive Reference Edition, 2020.

Learn about our latest products and discounts through SMS or email