- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Wire for Anodizing – Superior Corrosion Resistance

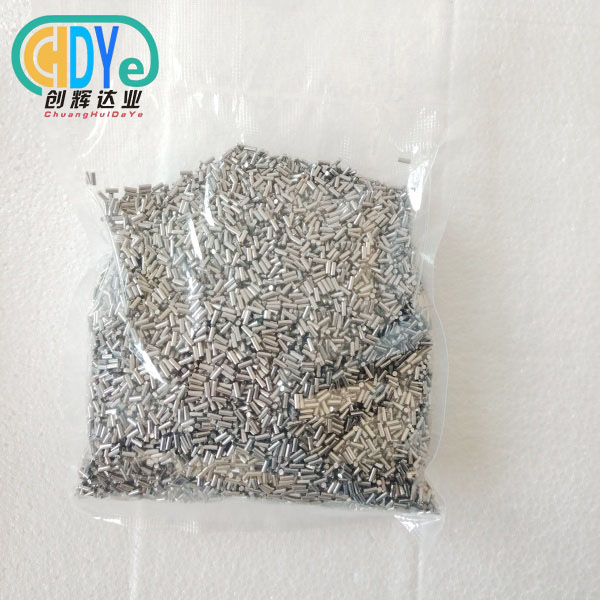

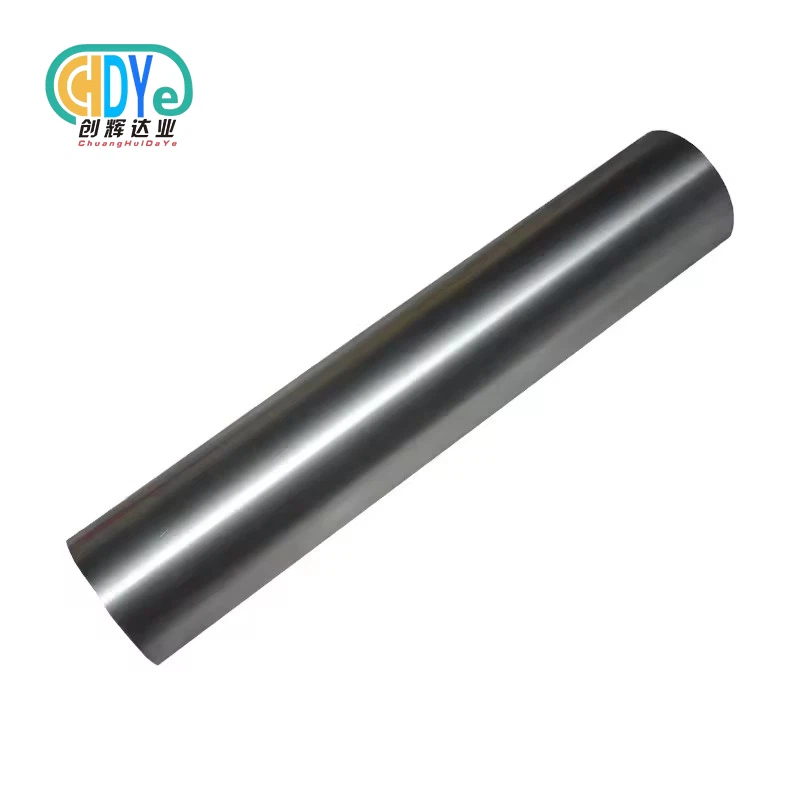

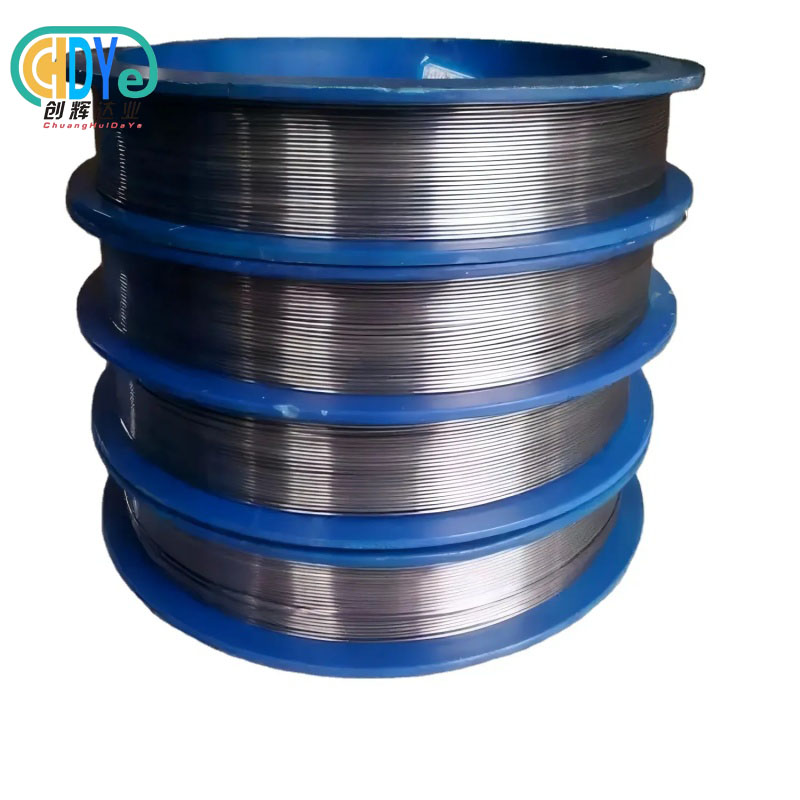

For mechanical settings that require steady electrochemical materials, titanium wire for anodizing is the best choice. Producers require this wire for reliable, long-lasting anodizing because it has uncommon erosion resistance and electrical conductivity. Titanium wire, accessible in 0.2mm to 7mm distances across, is perfect for chemical preparation, device generation, and master coating applications in various segments.

Understanding Titanium Wire for Anodizing

Titanium wire for anodizing, a breakthrough in materials research, has unique features that set it apart from aluminum and steel anodizing. Titanium wire is made of high-purity titanium that resists even the harshest electrochemical conditions.

Material Properties and Composition

Titanium wire performs well due to its fabric properties. Titanium's oxide coating protects it from erosion, making it perfect for anodizing applications with persistent chemical exposure. This defensive layer recovers, actually, when broken, guaranteeing wire execution throughout its life.

Titanium wire sold commercially incorporates 99.2% to 99.7% immaculate titanium with follow oxygen, nitrogen, carbon, and press. Controlled pollutions progress the wire's mechanical qualities without influencing erosion resistance. Ti is lighter than steel and performs way better due to its crystalline structure and tall strength-to-weight proportions.

Grades and Specifications

Two grades rule the titanium wire anodizing industry. Review 2 titanium, moreover named commercially pure titanium, is formable and corrosion-resistant. This review has moo alloying content and equalization quality and ductility, making it suitable for common anodizing with mellow mechanical qualities.

Ti-6Al-4V, review 5 titanium, is more grounded due to 6% aluminum and 4% vanadium. This review examines mechanical qualities and high-stress anodizing execution. Aluminum increments quality and diminishes thickness, whereas vanadium improves durability and warm steadiness.

Advantages and Applications of Titanium Wire Anodizing

Titanium wire for anodizing processes has benefits beyond functionality. These benefits increase product quality, operational efficiency, and long-term cost reductions for producers across industries.

Superior Performance Characteristics

Titanium wire stands up to erosion way better than anodizing materials in unforgiving chemicals. Titanium wire remains basically and electrically intact in acidic, antacid, or oxidizing circumstances. A steady titanium dioxide layer ensures against chemical attack.

Titanium wire's electrical conductivity guarantees effective anodizing current conveyance. Titanium holds electrical characteristics over numerous working cycles, not at all like degradable materials. This solidness guarantees uniform anodizing and spares gear upkeep and wire replacement.

Titanium wire's temperature steadiness is another advantage. Titanium wire holds mechanical and electrical qualities from cold to high handling temperatures. Warm soundness is basic in mechanical anodizing, where temperature varies.

Industrial Applications and Case Studies

Aerospace manufacturers depend on titanium wire anodizing for extreme-environment components. Anodized titanium wire processing improves corrosion resistance in aircraft structural components, fasteners, and connectors. Titanium reduces weight, improving commercial and military aircraft fuel efficiency.

Implantable and surgical device makers use titanium wire anodizing. Titanium is biocompatible, and anodizing improves surface characteristics, creating devices that merge easily with human tissue and last long. Cardiovascular stents, orthopedic implants, and dental applications benefit from anodized titanium wire processing.

For corrosive equipment, chemical processing plants use titanium wire anodizing. Anodized titanium wire heat exchangers, reaction vessels, and pipe systems last longer and require less maintenance.

Titanium Wire Anodizing Process Explained

Titanium wire is anodized using controlled electrochemical processes to improve surface qualities while keeping material attributes. Manufacturers can optimize operations and establish consistency by understanding these processes.

Surface Preparation and Cleaning

Titanium wire anodizing requires comprehensive surface preparation to eliminate impurities and maximize coating adherence. For surface oxides and scale removal, alkaline cleaning solutions are followed by acid pickling. The cleaning process must remove all lubricants, handling oils, and ambient pollution that could affect coating formation.

Mechanical preparation can generate a consistent surface texture with minor abrasion or brushing. Avoid excessive mechanical treatment, which can cause surface tension and compromise coating homogeneity. The goal is a clean, homogeneous surface for electrolyte contact and current distribution.

Electrolyte Selection and Process Control

Electrolytes greatly affect anodized coating characteristics and appearance. Phosphoric acid solutions form thick, corrosion-resistant coatings for severe chemicals. Electronic applications benefit from sulfuric acid electrolytes' thinner coatings and superior electrical characteristics.

Controlling voltage, current density, temperature, and duration is essential for coating quality. Voltage ranges from 20 to 120 volts, depending on coating thickness and electrolyte composition. Process testing and validation determine appropriate current density ranges for coating formation pace and homogeneity.

Temperature control prevents wire damage and coating flaws from high heat. Active cooling devices keep electrolyte temperatures between 18°C and 25°C in most titanium wire anodizing procedures.

Quality Control and Testing

Comprehensive quality control ensures coating consistency and specification compliance. Eddy current or magnetic induction coating thickness tests confirm wire surface uniformity. Cross-sectional microscopy shows the coating structure and reveals flaws.

Simulated service corrosion resistance testing verifies coating performance. Salt spray testing, electrochemical impedance spectroscopy, and chemical solution immersion testing quantify coating durability and protection.

Selecting and Procuring Titanium Wire for Anodizing

Application needs, supplier capabilities, and quality assurance processes must be considered while buying titanium wire. Multiple aspects affecting short-term performance and long-term cost effectiveness are considered during selection.

Technical Specifications and Requirements

Application requirements and current-carrying capacity determine wire diameter. Space-constrained precision electronic applications use 0.2mm to 1mm dimensions. For general industrial applications, 1mm to 3mm sizes are versatile. For heavy-duty anodizing, 3mm to 7mm diameters provide more current.

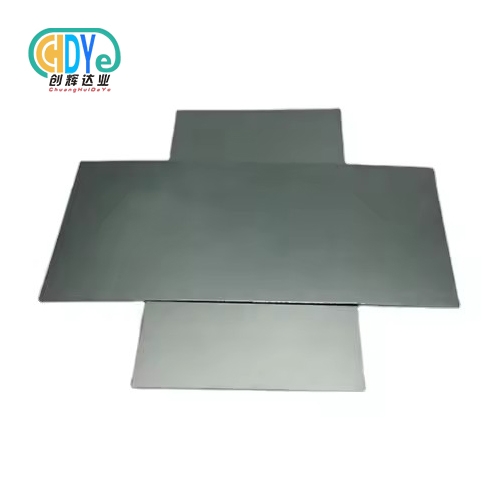

Surface finish depends on use. For most uses, as-drawn surfaces work well, polished surfaces may be needed for optical or aesthetic applications. Anodizing uniformity and appearance depend on surface condition.

Application stresses and ambient conditions should match mechanical property standards. Tensile strength, elongation, and fatigue resistance define the wire's viability under installation and service loads.

Supplier Evaluation and Certification

Reliable suppliers have robust quality management systems that guarantee product quality and traceability. ISO 9001:2015 certification shows a supplier's quality control and improvement efforts. End-use requirements may require AS9100 for aerospace or ISO 13485 for medical equipment.

It should be possible to manufacture all wire sizes and grades. Suppliers with in-house melting, drawing, and testing facilities offer superior quality control and quicker lead times than wholesalers that source from several manufacturers.

Supplier technical support helps with application-specific recommendations and troubleshooting. Complex or critical applications benefit from metallurgical and process engineering expertise.

Supply Chain Considerations

Titanium wire procurement now prioritizes global supply chain reliability. Diversified raw material sources and flexible production help suppliers weather supply disruptions and market volatility. Transportation costs and lead times can be reduced by closeness to manufacturing plants, boosting communication and technical support.

Inventory management should balance carrying costs and supply security. For established applications with known demand, just-in-time delivery programs perform well, while safety stock solutions protect key applications from supply disruptions.

Chuanghui Daye Metal Material: Your Trusted Partner for Premium Titanium Wire

In Baoji High-tech Development Zone, China's "Titanium Capital," Chuanghui Daye Metal Material Co., Ltd. has 30 years of rare metal experience. From raw material selection to quality testing and packaging, we offer total manufacturing.

Manufacturing Excellence and Quality Assurance

Our modern facilities include electron beam furnaces for high melting quality, precision drawing equipment for uniform wire dimensions, and controlled environment annealing furnaces for optimal mechanical qualities. This integrated approach provides quality and competitive pricing through efficient operations.

We monitor quality throughout every production phase with ISO 9001:2015 certification. Raw material examination checks chemical composition and purity before processing. Dimensional accuracy, surface quality, and mechanical qualities are monitored in-process. Finally, specification compliance is checked before protective packaging and shipment.

We make Grade 2 and Grade 5 titanium wire in sizes from 0.2mm to 7mm. Special alloy compositions and processing can meet application needs. Every package includes technical documentation for key application traceability and certification.

Technical Support and Customer Service

Chuanghui Daye offers technical help throughout procurement and application in addition to manufacturing excellence. For customer application success, our metallurgical engineers help with material selection, process optimization, and troubleshooting.

Customers globally receive reliable delivery from global logistics. Strategic agreements with foreign shipping providers streamline transportation while protective packaging prevents contamination. Flexible order quantities accommodate big manufacturing runs and small-batch prototyping.

Conclusion

Titanium wire for anodizing is best for producers seeking corrosion resistance, endurance, and consistent performance in severe electrochemical applications. Titanium wire is essential in aerospace, medical, chemical processing, and electronics due to its chemical resistance, electrical conductivity, and biocompatibility. After correct selection and procurement, titanium wire provides long-term value through prolonged service life and decreased maintenance. Titanium wire anodizing solutions will lead to materials technology advancement as industrial applications seek higher performance.

FAQ

Q: What makes titanium wire superior for anodizing compared to other materials?

A: Titanium wire offers exceptional corrosion resistance due to its natural oxide layer formation, which regenerates automatically when damaged. This property, combined with excellent electrical conductivity and biocompatibility, makes it superior to aluminum, steel, or other conventional anodizing materials. The lightweight design provides 40% weight reduction compared to steel while maintaining superior strength characteristics.

Q: How do I determine the appropriate wire diameter for my anodizing application?

A: Wire diameter selection depends on current-carrying requirements, space constraints, and mechanical stress factors. Smaller diameters (0.2-1mm) suit precision electronics applications, medium diameters (1-3mm) work well for general industrial use, and larger diameters (3-7mm) provide higher current capacity for heavy-duty operations. Our technical team can assist with specific diameter recommendations based on your application requirements.

Q: What is the typical lead time for custom titanium wire orders?

A: Lead times vary based on wire specifications, quantity requirements, and current production schedules. Standard grades and diameters typically ship within 1-2weeks, while custom compositions or specialized processing may require 2-3weeks. We maintain strategic inventory levels for common specifications to minimize delivery times for urgent requirements.

Q: Can titanium wire be anodized to different colors?

A: Yes, titanium wire anodizing can produce various colors through controlled voltage application during the anodizing process. Different voltages create different oxide thicknesses, resulting in various colors from gold and blue to purple and green. However, color consistency requires precise process control and may affect other coating properties.

Partner with Chuanghui Daye for Superior Titanium Wire Solutions

Shaanxi Chuanghui Daye stands ready to support your anodizing projects with premium-grade titanium wire manufactured to the highest quality standards. Our experienced team combines three decades of industry expertise with cutting-edge manufacturing capabilities to deliver reliable, cost-effective solutions tailored to your specific requirements. Whether you need standard specifications or custom configurations, our titanium wire for anodizing supplier capabilities ensure optimal performance for aerospace, medical, chemical, and electronics applications. Contact us today at info@chdymetal.com to discuss your project requirements and experience the Chuanghui Daye difference in quality, service, and technical support.

References

1. ASM International. "Properties and Selection: Nonferrous Alloys and Special-Purpose Materials." ASM Handbook Volume 2, 2018.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International Materials Park, 2019.

3. Peters, M., Kumpfert, J., Ward, C.H., and Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials Journal, Vol. 5, 2020.

4. Lutjering, Gerd and Williams, James C. "Titanium: Engineering Materials and Processes, 3rd Edition." Springer-Verlag Berlin Heidelberg, 2021.

5. Boyer, Rodney R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering: A, Volume 213, 2019.

6. Rack, Henry J. and Qazi, Jahan N. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering: C, Volume 26, 2020.

Learn about our latest products and discounts through SMS or email