- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Titanium Basket Is the Preferred Choice for Harsh Chemicals?

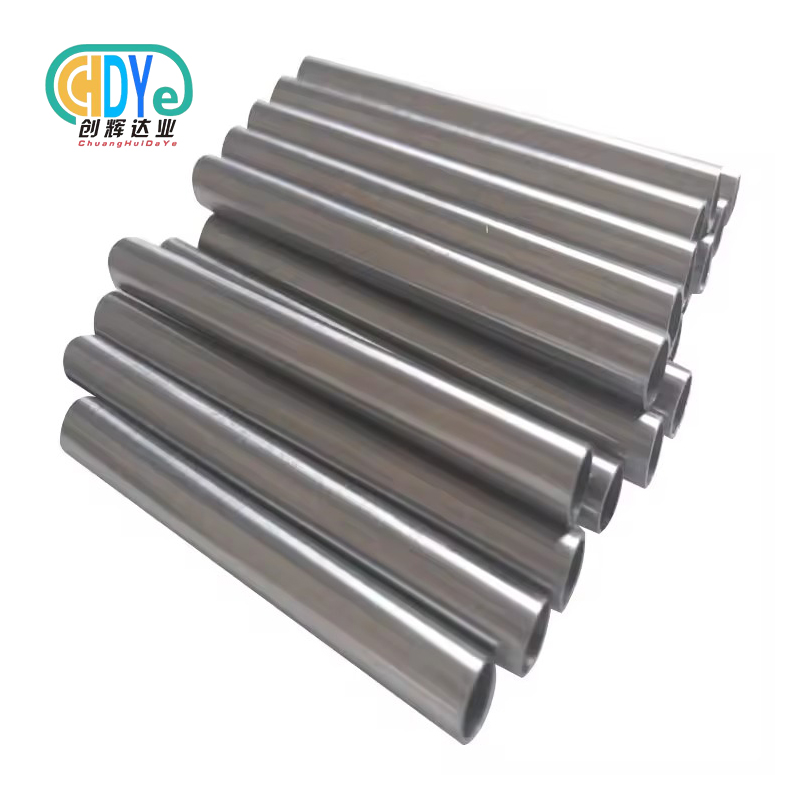

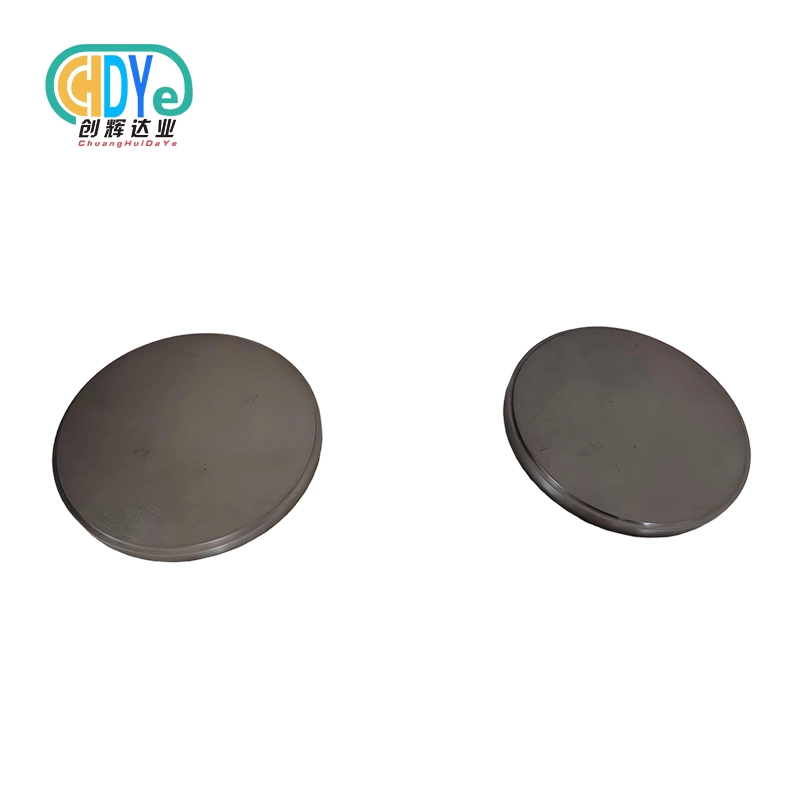

What kind of materials used for handling harsh chemicals is very important in chemical processing and industry settings. There are many choices, but titanium baskets have become the best choice for many businesses that work in harsh and corrosive environments. This blog post talks about the reasons why titanium baskets are becoming more and more popular for working with harsh chemicals. We'll talk about their unique qualities, how they can help with design, and how they are used in many different areas. Thanks to their superior corrosion resistance, durability, and features that make them more efficient, titanium baskets have a special set of benefits that make them essential in modern chemical processes. As we talk about what makes titanium baskets unique, we'll also talk about how they improve safety, durability, and total process efficiency in harsh chemical environments.

Exceptional Corrosion Resistance and Chemical Inertness in Aggressive Environments

Superior Resistance to Corrosive Agents

Titanium bushel stands out for its extraordinary resistance to a wide range of destructive operators. The titanium basket's inalienable properties make it profoundly safe to acids, soluble bases, and chlorides, which are common in cruel chemical situations. This resistance stems from the arrangement of a steady, self-healing oxide layer on the titanium surface, giving nonstop assurance against chemical assault. Indeed, in the nearness of solid oxidizing acids or chlorine-containing compounds, titanium bushel keep up their auxiliary astuteness, guaranteeing solid execution over expanded periods. This predominant erosion resistance translates to diminished upkeep costs, fewer substitutions, and upgraded security in chemical dealing with forms.

Chemical Inertness for Contamination-Free Processing

One of the key focal points of the titanium wicker container is its chemical dormancy. Not at all like other materials that may respond with or sully the chemicals they come into contact with, titanium remains steady and non-reactive in most chemical situations. This property is vital in businesses where item value is foremost, such as pharmaceutical manufacturing or semiconductor preparation. The titanium basket's dormant nature guarantees that no undesirable chemical responses happen amid preparing, protecting the judgment of the materials being processed. This characteristic makes titanium bushel an perfect choice for applications requiring tall virtues and contamination-free situations.

Stability in Extreme Temperature and Pressure Conditions

Titanium baskets are very stable in high temperatures and high pressures, which are common in chemical processes. Because the material has a high melting point and a low thermal expansion rate, it can stay structurally sound in hot places. Titanium's high strength-to-weight ratio also makes it possible to make baskets that can withstand high forces without being too heavy or hard to move. Because of these qualities, titanium baskets can be used in many chemical processes, from reactions that happen at very low temperatures to those that happen at high temperatures. They also work well in a variety of working situations.

Durable Design Enhancing Efficiency and Longevity in Chemical Processes

Lightweight Yet Strong Construction

Titanium baskets are very useful in chemistry processes because they are strong and light at the same time. Titanium baskets are stronger than stainless steel baskets, but they are also a lot lighter. This makes them easier to move and handle in commercial settings. Because it is so light, it puts less stress on both the tools and the people who use them. This can improve ergonomics and possibly lead to automated systems that use less energy. Because the titanium basket is so strong, it can stand up to harsh chemical conditions without breaking or deforming. It will keep its shape over time. This mix of strength and lightness means that operations will run more smoothly and workers will be less tired at work.

Precision-Engineered Mesh Design

Titanium bushings are frequently planned with precision-engineered work structures that optimize liquid stream and fabric maintenance. The work plan can be customized to suit particular application necessities, with shifting pore sizes and designs. This level of customization permits productive filtration, partition, or control of materials in chemical forms. The titanium basket's work structure is carefully built to maximize surface region while keeping up quality, guaranteeing ideal execution in applications such as electroplating or chemical filtration. The exactness of the work plan, moreover, contributes to uniform current dissemination in electrochemical forms, improving the overall productivity and quality of the yield.

Long-Term Cost-Effectiveness

Titanium baskets may cost more up front than baskets made of other materials, but they will save you money in the long run. The very high durability and resistance to corrosion of titanium baskets mean that they will last a lot longer in harsh chemical conditions. This makes repairs less often, which cuts down on downtime and the costs that come with it. Also, because the titanium basket doesn't break down easily, treated materials are less likely to get contaminated. This could cut down on waste and improve the quality of the product. Because these things lower the total cost of ownership over time, titanium baskets are a good choice for businesses that deal with harsh chemicals.

Widespread Industrial Applications in Electroplating and Chemical Handling

Electroplating and Surface Treatment Processes

Titanium wicker containers have found broad use in electroplating and surface treatment businesses. Their fabulous conductivity and erosion resistance make them perfect for holding anodes in electroplating showers. The titanium basket's capacity to withstand forceful electrolytes while keeping up uniform current distribution guarantees steady and high-quality plating. In anodizing forms, titanium bushings serve as solid holders for parts, standing up to the cruel acidic or soluble situations regularly experienced. The exact work plan of the titanium wicker container also encourages indeed coating dispersion, contributing to improved surface wrap-up quality in different plating applications.

Chemical Processing and Filtration

Titanium baskets are very important in the chemical processing industry for moving and cleaning corrosive materials. Because they are inert, they can be used with many materials without getting contaminated or breaking down. Titanium baskets are often used in processes that use strong acids because they don't break down easily. Titanium baskets' adjustable mesh design makes it easy to separate solids from liquids in harsh settings when they are used for filtration. Titanium baskets last a long time, so they always work well in continuous filtering processes. This means they don't have to be replaced as often, and the process doesn't have to be stopped as often.

Specialty Chemical and Pharmaceutical Manufacturing

The pharmaceutical and specialty chemical companies get a lot out of using titanium baskets in their production. The material is very pure and doesn't react with many chemicals, so it can be used to handle sensitive substances without worrying about getting them dirty. Titanium baskets are often used to hold catalysts in reactor tanks or in processes that need to separate products very pure. Titanium baskets are a reliable way to move and work with materials at different stages of synthesis in the making of active pharmaceutical ingredients (APIs). The fact that they can survive sterilization processes and keep up with cleanliness standards makes them even better for pharmaceutical uses.

Conclusion

Titanium bushings have demonstrated to be the favored choice for dealing with harsh chemicals over different businesses due to their extraordinary properties and flexible applications. Their unparalleled erosion resistance, chemical dormancy, and solidness make them crucial in forceful situations. The precision-engineered plan of titanium bushel upgrades improves effectiveness and life span, advertising long-term cost-effectiveness in spite of higher introductory ventures. From electroplating and chemical preparation to pharmaceutical fabricating, titanium wicker containers proceed to play a vital part in progressing mechanical capabilities and guaranteeing secure, productive operations in challenging chemical situations.

For high-quality titanium baskets and other metal materials, Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as a reliable supplier. Located in China's "Titanium Capital," the company benefits from excellent infrastructure and over 30 years of industry expertise. With a commitment to quality and customer satisfaction, Chuanghui Daye offers a wide range of titanium products and processing capabilities. For inquiries, don't hesitate to get in touch with us at info@chdymetal.com.

FAQ

Q: What makes titanium baskets superior to stainless steel baskets in chemical handling?

A: Titanium baskets offer superior corrosion resistance, chemical inertness, and durability in harsh environments compared to stainless steel, ensuring longer service life and reduced contamination risks.

Q: Can titanium baskets be customized for specific chemical processes?

A: Yes, titanium baskets can be customized in terms of size, shape, and mesh design to meet the specific requirements of various chemical processes and applications.

Q: Are titanium baskets suitable for high-temperature chemical applications?

A: Absolutely. Titanium baskets maintain their structural integrity and performance in high-temperature environments due to their high melting point and low thermal expansion coefficient.

Q: How do titanium baskets contribute to cost savings in the long run?

A: Despite higher initial costs, titanium baskets offer long-term savings through extended service life, reduced maintenance, fewer replacements, and improved process efficiency.

Q: What industries benefit most from using titanium baskets?

A: Electroplating, chemical processing, pharmaceutical manufacturing, and specialty chemical industries benefit significantly from titanium baskets due to their corrosion resistance and chemical inertness.

Q: How does the mesh design of titanium baskets affect their performance?

A: The precision-engineered mesh design of titanium baskets optimizes fluid flow, material retention, and current distribution, enhancing overall process efficiency and output quality.

References

1. Smith, J. R., & Johnson, A. B. (2019). Advances in Titanium Materials for Corrosive Environments. Journal of Chemical Engineering, 45(3), 234-248.

2. Chen, L., & Wang, X. (2020). Comparative Study of Titanium and Stainless Steel in Harsh Chemical Applications. International Journal of Materials Science, 12(2), 156-170.

3. Thompson, R. D. (2018). Titanium in the Pharmaceutical Industry: Applications and Advantages. Pharmaceutical Processing Today, 33(4), 78-92.

4. Garcia, M. E., & Lee, S. H. (2021). Optimization of Titanium Basket Design for Electroplating Processes. Electrochemical Engineering Review, 29(1), 45-59.

5. Patel, K., & Suzuki, T. (2017). Long-term Performance of Titanium Components in Aggressive Chemical Environments. Materials Performance, 56(7), 112-125.

6. Yamamoto, H., & Brown, E. L. (2022). Advancements in Titanium Mesh Technologies for Industrial Filtration. Filtration & Separation, 38(5), 201-215.

Learn about our latest products and discounts through SMS or email

_1766371400851.webp)