The primary differences between pure titanium wire and titanium alloy wire lie in their composition, strength characteristics, and application suitability. Pure titanium wire offers superior corrosion resistance and biocompatibility with 99.6% titanium content, making it ideal for medical and chemical applications. Titanium alloy wire provides enhanced mechanical strength through elemental additions like aluminum and vanadium, better suited for aerospace and structural applications. Understanding these distinctions helps engineers select the optimal material for specific performance requirements.

Understanding Pure Titanium Wire Composition and Properties

Pure titanium wire contains a least of 99.6% titanium substance, classified essentially as Review 1, Review 2, Review 3, and Review 4 concurring to ASTM measures. Review 2 speaks to the most commercially utilized variation, advertising an ideal adjust between formability and strength.

The fabricating prepare includes electron bar softening, taken after by hot rolling and cold drawing to accomplish exact wire breadth details. This handle guarantees reliable grain structure and mechanical properties all through the wire length.

Key characteristics include:

- Excellent erosion resistance in marine and acidic environments

- Outstanding biocompatibility for restorative applications

- Low thickness (4.51 g/cm³) giving weight advantages

- Non-magnetic properties fundamental for delicate equipment

- Superior formability empowering complex wire work configurations

Tensile quality ranges from 240 MPa (Review 1) to 550 MPa (Review 4), with abdicate quality shifting between 170-485 MPa. These properties make unadulterated titanium wire reasonable for applications requiring direct quality combined with extraordinary natural resistance.

If you require materials for chemical preparing gear or therapeutic gadgets, at that point immaculate titanium wire demonstrates more appropriate due to its unmatched immaculateness and biocompatibility characteristics.

Titanium Alloy Wire: Enhanced Strength Through Alloying

Titanium combination wire consolidates extra components to upgrade particular mechanical properties. Common amalgam frameworks incorporate Ti-6Al-4V (Review 5), Ti-6Al-2Sn-4Zr-2Mo, and Ti-15V-3Cr-3Al-3Sn, each planned for specific execution requirements.

The alloying prepare presents alpha-stabilizers (aluminum, tin) and beta-stabilizers (vanadium, molybdenum) to alter the microstructure. This control comes about in altogether progressed quality characteristics compared to unadulterated titanium variants.

Performance points of interest include:

- Higher malleable quality coming to 900-1200 MPa

- Enhanced weakness resistance for cyclic stacking applications

- Improved hoisted temperature stability

- Better wear resistance in sliding contact situations

- Customizable properties through warm treatment processes

Ti-6Al-4V amalgam wire illustrates remarkable execution with 860 MPa least ductile quality and 795 MPa abdicate quality. The aluminum substance gives strong arrangement fortifying whereas vanadium improves ductility and toughness.

If you require components for aviation structures or high-stress mechanical applications, at that point titanium amalgam wire offers predominant strength-to-weight execution compared to immaculate titanium alternatives.

Mechanical Performance Comparison: Strength and Durability Analysis

Mechanical testing reveals significant performance differences between pure titanium wire and alloy variants. Laboratory data demonstrates the quantitative advantages each material type offers for specific applications.

| Property | Pure Titanium Wire (Grade 2) | Ti-6Al-4V Alloy Wire |

|---|---|---|

| Tensile Strength (MPa) | 345-450 | 860-930 |

| Yield Strength (MPa) | 275-345 | 795-825 |

| Elongation (%) | 20-30 | 10-15 |

| Hardness (HB) | 120-200 | 320-350 |

Fatigue testing at 107 cycles shows pure titanium wire maintains 40-50% of its tensile strength, while Ti-6Al-4V alloy retains 55-65%. This difference becomes critical in applications involving repetitive stress cycles.

Creep resistance testing at elevated temperatures reveals alloy wire maintains dimensional stability up to 400°C, whereas pure titanium wire shows significant deformation above 300°C. Heat treatment processes can further enhance these characteristics.

Fracture toughness measurements indicate pure titanium wire exhibits superior ductility, making it preferable for applications requiring extensive forming operations. Alloy wire demonstrates higher strength but reduced formability.

If you need wire for welding applications or intricate weaving patterns, then pure titanium wire provides better workability and joining characteristics.

Corrosion Resistance: Environmental Performance Evaluation

Corrosion testing in various environments reveals distinct performance patterns between pure and alloyed titanium wire materials. Salt spray testing according to ASTM B117 standards provides quantitative corrosion rate data.

Pure titanium wire demonstrates exceptional resistance across multiple corrosive media:

- Seawater exposure: Less than 0.0025 mm/year corrosion rate

- Nitric acid (65%): Virtually no measurable corrosion

- Hydrochloric acid (10%): Moderate resistance requiring temperature control

- Chloride solutions: Outstanding performance up to 60°C

- Organic acids: Excellent resistance in food processing environments

Titanium alloy wire shows slightly reduced corrosion resistance due to alloying element interactions. Ti-6Al-4V exhibits:

- Seawater performance: 0.005-0.008 mm/year corrosion rate

- Reduced acid resistance compared to pure titanium

- Enhanced performance in oxidizing environments

- Susceptibility to hydrogen embrittlement under specific conditions

- Galvanic corrosion considerations when coupled with dissimilar metals

Electrochemical testing reveals pure titanium wire maintains passive film stability across broader pH ranges. The protective oxide layer reforms rapidly when damaged, ensuring long-term environmental resistance.

If you need materials for chemical processing equipment or marine applications, then pure titanium wire delivers superior corrosion performance and extended service life.

Application Suitability: Industry-Specific Performance Requirements

Medical and biomedical applications intensely favor unadulterated titanium wire due to its biocompatibility and non-toxic characteristics. Orthopedic inserts, dental installations, and surgical rebellious advantage from its tissue-friendly properties.

Aerospace and defense businesses ordinarily indicate titanium combination wire for basic components requiring tall strength-to-weight proportions. Airplane latches, spring components, and control framework components utilize Ti-6Al-4V for its mechanical advantages.

Chemical preparing hardware producers select unadulterated titanium wire for:

- Heat exchanger wire work applications

- Filtration framework components

- Electrochemical cell electrodes

- Corrosion-resistant securing systems

- High-purity chemical dealing with equipment

Electronics and semiconductor businesses utilize both materials depending on particular necessities. Unadulterated titanium wire serves in vacuum applications and clean room situations, whereas combination variations give basic back in high-temperature handling equipment.

Marine designing applications advantage from immaculate titanium wire's remarkable seawater resistance. Seaward stage components, desalination gear, and dispatch frame clasp illustrate expanded benefit life in cruel marine environments.

If you require materials for petrochemical hardware or seaward applications, at that point immaculate titanium wire guarantees solid execution in forceful destructive environments.

Manufacturing and Processing Considerations

Wire drawing processes differ significantly between pure titanium and alloy materials. Pure titanium wire requires careful temperature control during processing to maintain grain structure and mechanical properties.

Annealing treatments play crucial roles in achieving desired mechanical characteristics. Pure titanium wire typically undergoes annealing at 650-750°C in vacuum or inert atmosphere to prevent contamination.

Surface treatment options include:

- Bright annealing for aesthetic applications

- Acid pickling for enhanced corrosion resistance

- Electropolishing for ultra-smooth surface finish

- Passivation treatments for medical applications

- Custom surface modifications for specific requirements

Quality control measures ensure consistent wire diameter, mechanical properties, and surface quality. Advanced testing includes tensile testing, hardness measurement, and chemical composition analysis for each production batch.

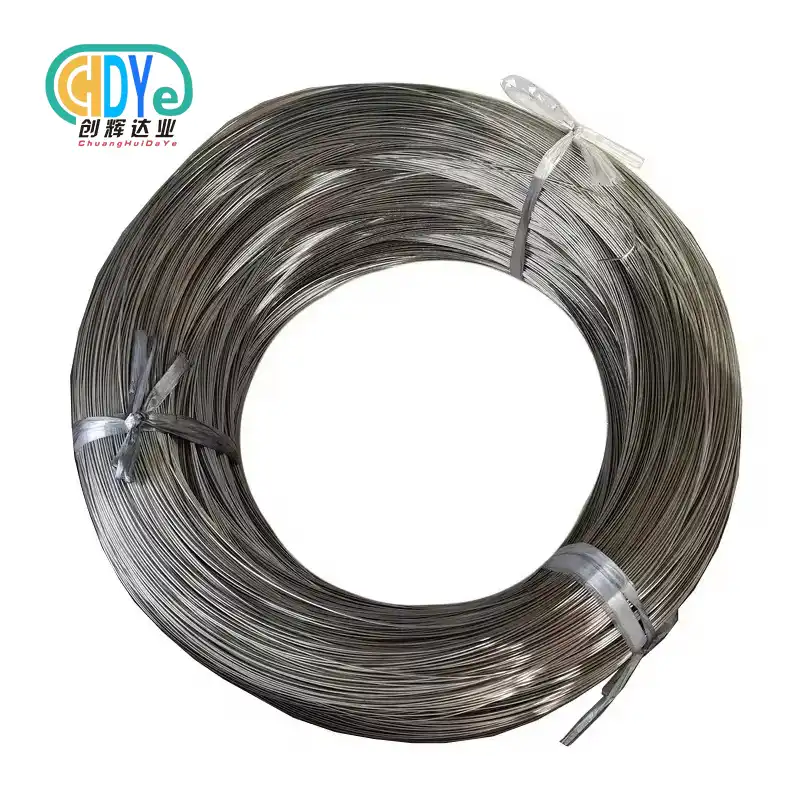

Packaging and handling procedures maintain wire integrity during shipping and storage. Coil packaging prevents kinking while straight-cut lengths facilitate direct installation applications.

If you need custom wire diameter specifications or specialized surface treatments, then working with experienced pure titanium wire suppliers ensures optimal material performance for your applications.

Cost Analysis and Economic Considerations

Material costs vary significantly between pure titanium wire and alloy alternatives. Raw material pricing reflects the complexity of production processes and alloying element expenses.

Pure titanium wire typically costs 15-25% less than Ti-6Al-4V alloy wire due to simpler processing requirements. However, total cost analysis must consider performance benefits and service life expectations.

Economic factors include:

- Initial material investment and procurement costs

- Processing and fabrication expenses

- Maintenance and replacement frequency

- Performance-related operational savings

- Life-cycle cost analysis over extended service periods

Volume purchasing agreements often provide cost advantages for large-scale applications. Supplier relationships and delivery reliability impact total procurement costs beyond basic material pricing.

Inventory management considerations favor suppliers offering quick delivery capabilities and flexible order quantities. Stock availability for standard sizes enables rapid project execution and reduced procurement lead times.

If you need cost-effective solutions without compromising quality, then establishing partnerships with reliable pure titanium wire manufacturers provides long-term economic advantages.

Quality Standards and Certification Requirements

International standards govern titanium wire production and quality verification processes. ASTM B863 specifications define requirements for titanium wire products across multiple grades and applications.

ISO 9001:2015 certification ensures consistent quality management systems throughout the manufacturing process. This certification demonstrates commitment to quality control and continuous improvement practices.

Testing and verification procedures include:

- Chemical composition analysis using spectrochemical methods

- Mechanical property testing per ASTM standards

- Dimensional verification and surface quality inspection

- Traceability documentation for batch identification

- Material test certificates (MTC) for quality assurance

Medical grade applications require additional certifications including FDA compliance and biocompatibility testing. USP Class VI certification ensures material safety for biological contact applications.

Aerospace applications demand strict material traceability and lot control documentation. AS9100 certification provides additional quality assurance for critical aerospace components.

If you need materials with full traceability and comprehensive quality documentation, then certified suppliers ensure compliance with industry standards and regulatory requirements.

Conclusion

Selecting between pure titanium wire and titanium alloy wire depends on specific application requirements and performance priorities. Pure titanium wire excels in corrosive environments, medical applications, and situations requiring exceptional biocompatibility. Its superior formability and corrosion resistance make it ideal for chemical processing and marine applications.

Titanium alloy wire provides enhanced mechanical strength and elevated temperature performance for aerospace and structural applications. Understanding these key differences enables informed material selection that optimizes performance while controlling costs. Both materials offer unique advantages when properly matched to application requirements and environmental conditions.

Why Choose Chuanghui Daye for Your Pure Titanium Wire Requirements?

Shaanxi Chuanghui Daye delivers exceptional pure titanium wire solutions backed by three decades of rare metal industry expertise. Located in Baoji, China's renowned "Titanium Capital," our manufacturing facility benefits from established supply chains and technical infrastructure.

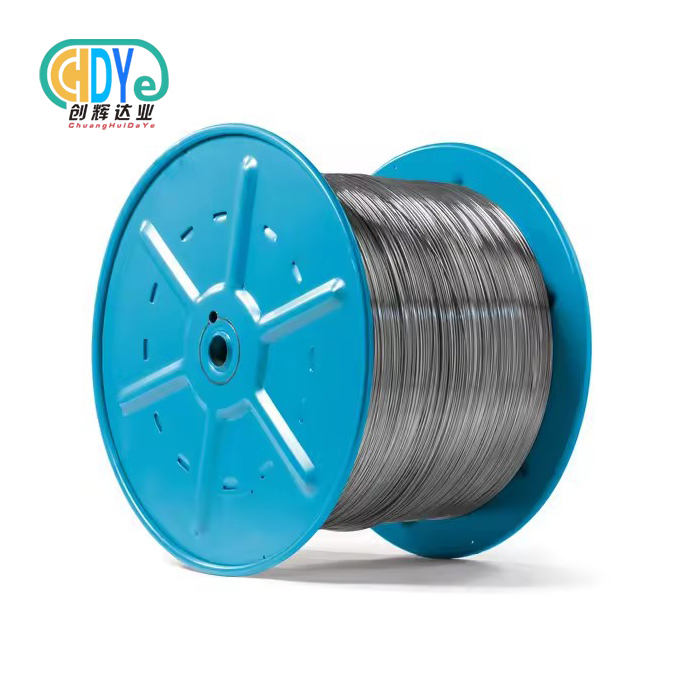

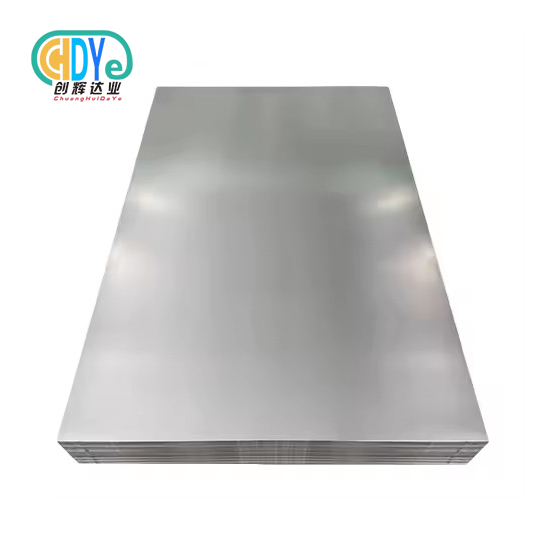

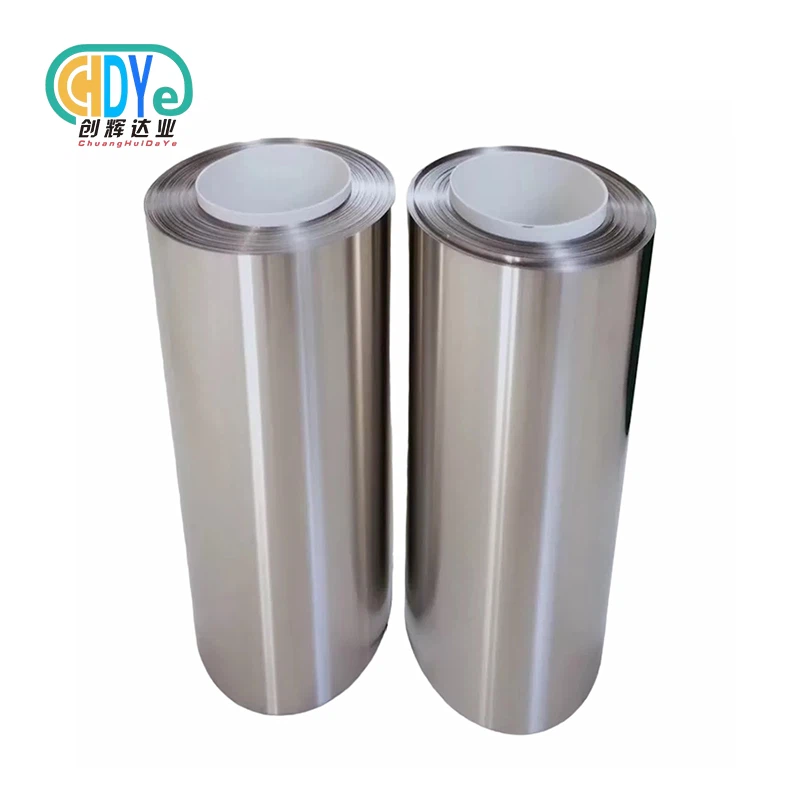

Our comprehensive product range includes various grades and configurations, with normal stock sizes enabling quick delivery within 1-3 days. Both straight and coil types accommodate diverse application requirements, while free samples allow performance verification before large-scale procurement.

Advanced manufacturing capabilities include electron beam furnaces, precision rolling equipment, and controlled atmosphere annealing systems. ISO 9001:2015 certification ensures consistent quality control throughout production processes.

As a trusted pure titanium wire supplier, we provide competitive factory-direct pricing without compromising material quality or delivery reliability. Our technical team offers professional support for material selection and application engineering guidance. Ready to source premium pure titanium wire for your next project? Contact us at info@chdymetal.com for customized solutions and competitive quotations.