Finding reliable sources for ASTM B 265 titanium sheet requires careful consideration of supplier capabilities, quality certifications, and delivery commitments. The global market offers multiple procurement channels, from specialized manufacturers in China's "Titanium Capital" to international distributors worldwide. Direct manufacturer sourcing often provides the most competitive pricing, especially for bulk orders and custom specifications. Quality-certified suppliers with ISO 9001:2015 certification ensure consistent material properties and traceability documentation essential for aerospace, medical, and chemical processing applications.

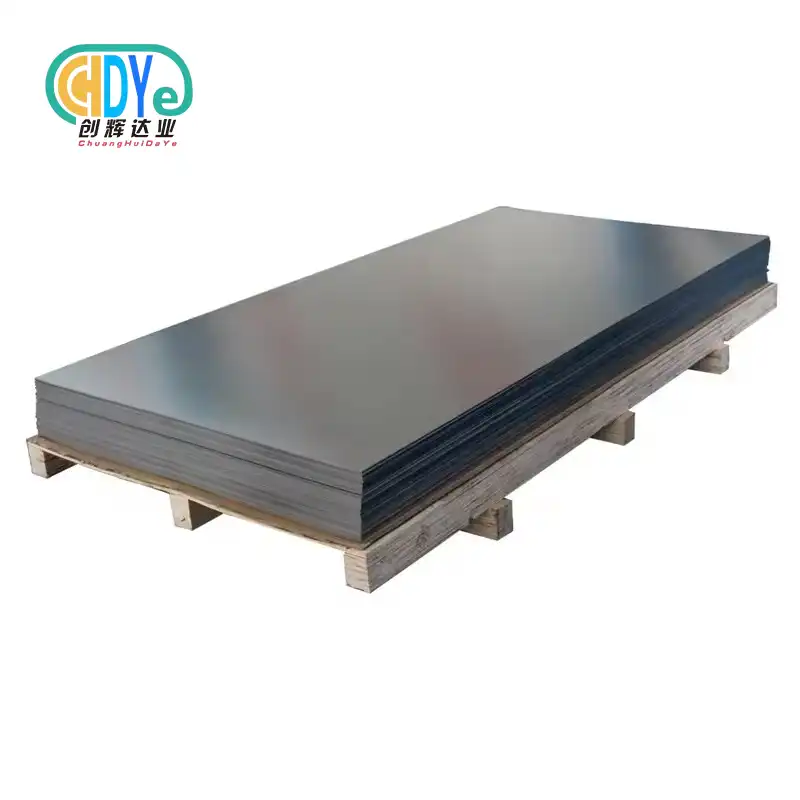

Understanding ASTM B 265 Titanium Sheet Specifications and Market Demand

The titanium amalgam sheet advertise has experienced noteworthy development over numerous businesses, driving request for standardized materials that meet rigid quality prerequisites. ASTM B 265 review 2 speaks to the most commercially immaculate titanium choice, advertising great erosion resistance for chemical preparing hardware. In the mean time, ASTM B 265 review 5 gives prevalent mechanical quality for aviation applications.

Key Technical Properties and Industrial Applications

Titanium sheet mechanical properties change essentially over distinctive grades, with each serving particular mechanical purposes. Review 1 through Review 4 offer expanding quality levels whereas keeping up fabulous erosion resistance. Review 5 (Ti-6Al-4V) conveys the most elevated strength-to-weight proportion among titanium combinations, making it crucial for aviation auxiliary components.

Medical gadget producers especially esteem the biocompatibility of titanium sheet therapeutic review materials. The material's resistance to body liquids and tissue compatibility makes it perfect for surgical inserts and dental applications. Chemical composition prerequisites for restorative applications request amazingly moo oxygen and nitrogen substance to guarantee ideal performance.

Surface Finish and Processing Requirements

Titanium sheet surface finish for ASTM B 265 titanium sheet plays a critical role in final application performance. Cold-rolled sheets regularly offer prevalent surface quality compared to hot-rolled options. The tempering prepare expels work solidifying impacts whereas optimizing mechanical properties for particular applications. Legitimate titanium sheet warm treatment guarantees uniform grain structure and unsurprising fabric behavior.

Global Supply Chain Analysis for Titanium Sheet Procurement

The worldwide titanium sheet market operates through complex supply chains connecting raw material producers, processors, and end users. China dominates global titanium production, with Baoji serving as the primary manufacturing hub for high-quality titanium products. This concentration creates both opportunities and challenges for international buyers seeking reliable suppliers.

Regional Market Dynamics and Pricing Factors

Titanium sheet cost vacillations reflect crude fabric costs, vitality costs, and fabricating capacity utilization. Asian producers for the most part offer competitive estimating due to coordinates supply chains and lower operational costs. European providers frequently center on specialized grades and custom preparing administrations for specialty applications.

Transportation costs altogether affect conveyed estimating, especially for bulk orders. Sea shipping remains the most conservative alternative for expansive amounts, whereas discuss cargo serves pressing necessities in spite of higher costs. Lead times change impressively based on fabric grades, thickness details, and current request levels.

Quality Standards and Certification Requirements

Aerospace applications request thorough fabric traceability and testing documentation. Titanium sheet aviation details require comprehensive chemical examination, mechanical property confirmation, and dimensional assessment records. Providers must keep up point by point bunch following frameworks to bolster client quality requirements.

Chemical handling businesses prioritize erosion resistance execution information. Titanium sheet erosion resistance testing in particular media gives fundamental data for hardware plan and fabric choice. Appropriate certification documentation guarantees compliance with industry guidelines and administrative requirements.

Comparing Procurement Channels: Direct Manufacturers vs. Distributors

Different sourcing strategies offer distinct advantages depending on order quantities, technical requirements, and delivery timelines. Understanding these options helps buyers optimize their procurement approach and achieve better overall value.

Direct Manufacturer Sourcing

Purchasing specifically from producers gives a few key benefits:

- Lower unit costs due to disposed of wholesaler markups

- Custom preparing capabilities for particular measurements

- Specialized bolster from generation engineers

- Adaptable least arrange amounts for expansive buys

- Coordinate quality control oversight and office audits

Challenges for ASTM B 265 titanium sheet include higher minimum order requirements and longer lead times for specialized grades. Dialect boundaries and time zone contrasts may complicate communication, in spite of the fact that numerous producers presently utilize multilingual specialized staff.

Regional Distributor Networks

Local distributors offer advantages for smaller quantities and immediate availability:

- Reduced shipping costs and faster delivery

- Local inventory for common grades and sizes

- Established customer service and technical support

- Simplified payment terms and currency transactions

- Lower minimum order quantities

Distributor pricing typically includes markups ranging from 15% to 40% above manufacturer costs. However, the convenience and reduced logistics complexity often justify these premiums for many buyers.

B2B Platform Procurement

Online B2B stages give get to to different providers through centralized marketplaces. These stages offer cost comparison devices, provider confirmation administrations, and coordinates installment frameworks. Be that as it may, buyers must carefully assess provider accreditations and quality capabilities when utilizing these channels.

Supplier Evaluation and Quality Verification Processes

Selecting dependable titanium sheet providers requires orderly assessment of specialized capabilities, quality frameworks, and trade qualifications. Legitimate provider appraisal diminishes dangers and guarantees reliable fabric performance.

Technical Capability Assessment

Manufacturers ought to illustrate comprehensive preparing capabilities counting softening, producing, rolling, and wrapping up operations. Titanium sheet manufacture requires specialized gear and ability to keep up fabric judgment all through generation. Progressed offices ordinarily incorporate electron pillar heaters, vacuum tempering frameworks, and accuracy rolling mills.

Quality control framework must bolster required testing and assessment exercises. Basic capabilities incorporate chemical investigation hardware, mechanical testing machines, and dimensional estimation frameworks. Providers ought to give nitty gritty quality manuals archiving strategies and review criteria.

Certification and Compliance Verification

ISO 9001:2015 certification gives pattern affirmation of quality administration framework viability. Aviation providers regularly require AS9100 certification for aviation-specific quality necessities. Therapeutic gadget producers regularly request ISO 13485 certification for biocompatible materials.

Financial steadiness appraisal makes a difference guarantee provider reasonability all through amplified supply connections. Credit reports, office visits, and reference checks give bits of knowledge into provider unwavering quality and trade sustainability.

Sample Testing and Qualification Procedures

Material tests ought to experience comprehensive testing some time recently favoring modern providers. Titanium sheet pliable quality confirmation guarantees mechanical properties meet detail necessities. Chemical composition examination affirms amalgam substance and pollution levels.

Corrosion resistance testing in significant media approves fabric execution for particular applications. Microstructural examination uncovers grain structure consistency and preparing consistency. These capability steps set up standard execution desires for generation orders.

Practical Procurement Guidelines and Common Pitfalls

Successful titanium sheet procurement requires attention to technical specifications, commercial terms, and logistics coordination. Understanding common challenges helps buyers avoid costly mistakes and delays.

Minimum Order Quantities and Payment Terms

Manufacturer MOQs for ASTM B 265 titanium sheet typically range from 500 kg to 2000 kg depending on grade and thickness requirements. Custom measurements may require higher least amounts to legitimize tooling and setup costs. Wholesalers frequently acknowledge littler orders but at premium estimating levels.

Payment terms change altogether between providers and locales. Letter of credit courses of action give security for universal exchanges but include costs and complexity. Wire exchange installments frequently get particular estimating but require cautious provider vetting.

Delivery Timeline Management

Standard review materials regularly dispatch inside 2-4 weeks from set up producers. Custom handling may amplify lead times to 6-8 weeks or longer depending on complexity. Precise conveyance planning requires clear communication of necessities and reasonable timeline expectations.

Transportation courses of action ought to consider fabric dealing with prerequisites and traditions methods. Titanium sheets require cautious bundling to avoid surface harm amid shipping. Appropriate documentation guarantees smooth traditions clearance and convenient delivery.

Quality Control and Inspection Points

Pre-shipment assessment gives last confirmation of fabric conformance some time recently conveyance. Third-party review administrations offer free quality evaluation for basic applications. Nitty gritty review reports report fabric properties and dimensional compliance.

Receiving review methods ought to confirm fabric recognizable proof, measurements, and surface quality. Incite notice of any errors empowers fast determination and avoids generation delays. Keeping up review records bolsters traceability necessities and quality framework compliance.

Conclusion

Sourcing ASTM B 265 titanium sheet at competitive prices requires balancing cost considerations with quality requirements and supplier reliability. Direct manufacturer relationships typically offer the best pricing for large volumes, while distributors provide convenience for smaller quantities. Thorough supplier evaluation and quality verification processes ensure consistent material performance and reduce procurement risks. Success depends on clearly defining technical requirements, establishing realistic delivery expectations, and maintaining effective supplier communication throughout the procurement process.

FAQ

Q: What are the typical minimum order quantities for ASTM B 265 titanium sheet?

A: Minimum order quantities vary by supplier and grade. Direct manufacturers typically require 500-2000 kg, while distributors may accept orders as small as 50-100 kg. Custom sizes and specialized grades often have higher MOQs due to processing requirements.

Q: How long does delivery take for titanium sheet orders?

A: Standard grades typically ship within 2-4 weeks from manufacturers, while custom processing may require 6-8 weeks. Distributor stock items can often ship within days, but selection may be limited to common sizes and grades.

Q: What certifications should I look for in titanium sheet suppliers?

A: Essential certifications include ISO 9001:2015 for quality management. Aerospace applications require AS9100, while medical applications need ISO 13485. Material test certificates should accompany each shipment to verify chemical composition and mechanical properties.

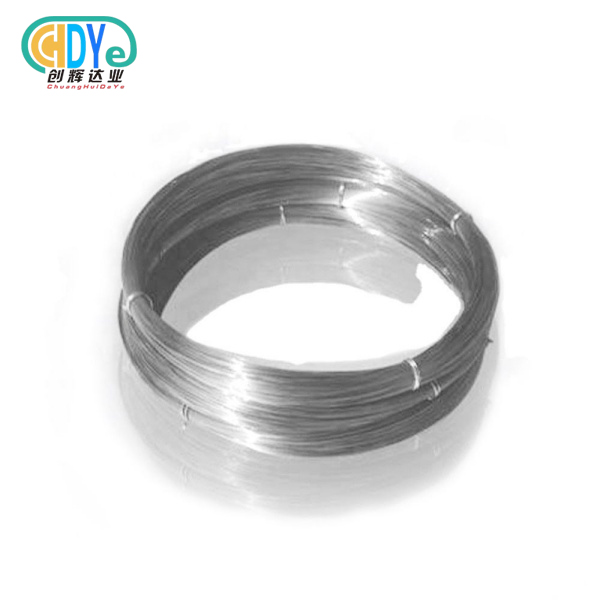

Choose Chuanghui Daye for Premium ASTM B 265 Titanium Sheet Supply

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as your trusted titanium sheet manufacturer, located in China's renowned "Titanium Capital" of Baoji. Our three decades of industry expertise ensures exceptional quality and competitive pricing for all titanium alloy sheet requirements. We maintain ISO 9001:2015 certification and offer comprehensive custom processing services including precision cutting, forming, and heat treatment. Our advanced facilities support both prototype development and large-scale production with complete traceability documentation. Contact us at info@chdymetal.com to discuss your specific ASTM B 265 titanium sheet requirements.

References

1. American Society for Testing and Materials. "ASTM B265 - Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate." ASTM International, 2021.

2. Boyer, R., Welsch, G., and Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, 1994.

3. Lutjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes." Springer-Verlag, 2007.

4. Peters, M., Kumpfert, J., Ward, C.H., and Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, vol. 5, no. 6, 2003.

5. Rack, H.J. and Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering C, vol. 26, no. 8, 2006.

6. Donachie, M.J. "Titanium: A Technical Guide." ASM International, 2000.