- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Rod for Sale – Industrial Grade Titanium Bars Online

When looking for high-quality titanium rods for sale, business buyers need materials that work well in a wide range of tough situations. Industrial-grade titanium bars are one of the most useful and reliable materials used in modern manufacturing. They are very strong for their weight and don't rust. These precision-engineered goods are very important in the semiconductor, chemical processing, medical device manufacturing, and aerospace businesses. Industrial titanium rods are made with advanced metallurgical properties and strong quality control standards. They are used to build mission-critical parts that can't fail.

Understanding Industrial Grade Titanium Rods

Fundamental Properties of Titanium Materials

Titanium bars made for industry are made from very pure titanium and special alloys that are made to meet strict chemical and mechanical requirements. These materials have unique properties that make them stand out from regular metals in tough situations. Titanium is very popular because it doesn't rust and is better than stainless steel at resisting corrosion in saltwater and chemical conditions. Titanium has a higher ratio of strength to weight than aluminum, and it lasts longer even in harsh circumstances.

Biocompatibility is another important trait that makes titanium rods essential in medical settings where materials need to safely bond with human tissue. Because of this one-of-a-kind feature, titanium implants can osseointegrate, which means that natural bone tissue can bond directly to them without the need for extra cellular layers.

Industry Applications Across Sectors

When you look at how industrial titanium bars are used in different fields, you can see how versatile they are. When making things for spacecraft, titanium bars are used to support important structural parts that need to be light and strong at the same time. These materials can handle big changes in temperature and mechanical stress, and they also help make fuel more efficient.

Medical device makers use titanium rods to make surgical tools, dental implants, and bone fixtures. Because it is biocompatible and doesn't rust, titanium is a great material for long-term implants. Some titanium medical devices stay in the body for over twenty years. Titanium bars are used in chemical processing plants for heat exchangers, reactor parts, and pipe systems where harsh chemicals would quickly break down other materials.

Performance Advantages Over Alternative Materials

When it comes to efficiency, titanium rods are better than traditional materials like aluminum and stainless steel. While stainless steel is pretty good at resisting corrosion, titanium is even better at it when it comes to chloride-induced corrosion, which makes it very useful in naval settings. The mass of titanium, which is 4.51 g/cm³, makes it much lighter than steel while keeping the same level of strength.

Due to its lack of magnetic properties, titanium is useful in computer devices and medical imaging. MRIs are safe for people with titanium devices but not for people with ferromagnetic materials. This trait is also useful for making semiconductors, where magnetic interference needs to be kept to a minimum.

How to Choose the Right Titanium Rod Grade for Your Application?

Understanding Titanium Grade Classifications

To choose the right titanium rods for sale grades, you need to know a lot about the material's qualities and how it will be used. The way grades are assigned is based on well-known rules, such as ASTM B348, AMS 4928, and ISO 5832-2. Some types of pure titanium, like Grade 1 and Grade 2, are very resistant to corrosion. Grade 2 is a little stronger than Grade 1. These types are good for uses where maximum corrosion resistance is more important than maximum strength.

Ti-6Al-4V alloy, also called Grade 5, is the most common titanium alloy because it has a great mix of strength, resistance to corrosion, and ability to be welded. This grade is used a lot in medical implants and aerospace applications that need high strength-to-weight ratios. This type of Ti-6Al-4V, called Extra Low Interstitial (ELI), is better at stopping cracks from spreading, which makes it perfect for important medical uses.

Application-Specific Selection Criteria

The operational environment has a big impact on choices about which grades to give. Alloys with aluminum and vanadium are good for high-temperature uses because they stay strong at high temps. Pure titanium types that are better at resisting corrosion in certain media may be needed in places where chemicals are processed. Grade 5 alloys are often used in aerospace applications because they are the strongest and lightest.

Grade choice is also affected by manufacturing factors. Some titanium metals are easier to machine, which lowers the cost of production and improves the quality of the finish on the outside. Weldability standards may favor certain grades that keep the integrity of the joint when temperatures change.

Compliance with International Standards

To make sure they work the same way in all situations, industrial titanium bars have to meet strict quality standards. The ASTM standards spell out the limits for chemical composition, mechanical properties, and testing needs. ISO guidelines make sure that medical applications are used the same way all over the world, which is safe and biocompatible. AS9100 aerospace standards set the rules for how things are made and how quality control systems work for use in flight.

Each shipment of titanium rods comes with certification paperwork that lets you track it from the raw materials to the final review. Customers can use this paperwork to make sure that their unique needs are met and to keep quality control going while the products are being made.

Procuring Titanium Rods – Where and How to Buy Industrial Grade Titanium Bars Online?

Evaluating Supplier Capabilities

Getting titanium rods for sale that work well starts with carefully evaluating suppliers based on their manufacturing skills, quality standards, and technical knowledge. Reliable suppliers keep up with ISO 9001:2015 quality management systems and any other certifications that are needed for their business. Advanced melting technologies, such as vacuum arc remelting (VAR) and precision forging, should be used by manufacturing sites to make sure that the mechanical properties and grain structures are always the same.

When choosing a supplier, geography plays a role, especially for jobs that need to be delivered quickly. Strategically located suppliers with well-established logistics networks can offer faster arrival times and lower shipping costs, giving them a competitive edge. Inventory control tools make sure that standard sizes are always available, and custom manufacturing is available for unique needs.

Understanding Market Dynamics

There are some things that make the titanium market special that affect how people buy things. The prices of finished goods are affected by changes in the costs of raw materials, which depend on the supply of ore and the processing capacity. Bulk purchasing deals often save money and make sure that projects don't run out of supplies. Market demand from the medical and aerospace industries can affect availability, which is why partnerships between suppliers are so important for ensuring stable access.

When thinking about the supply chain, it's not just about the main suppliers; you also need to think about backup sources and different types that meet the needs of the application. Diversified buying strategies keep quality standards high across all channels of procurement while lowering the risks of supply disruptions.

Streamlined Procurement Processes

Technical specification creation, supplier qualification, and delivery coordination should all be part of an effective procurement process. Dimensional tolerances, surface finish standards, and certification requirements should all be part of the initial definition of requirements. Quotes from suppliers must include all technical needs as well as clear terms and schedules for delivery.

Through dimensional inspection and certification review, quality assurance procedures make sure that incoming materials match the specifications for the purchase. As part of the receiving process, there should be proper storage methods that keep the integrity of the materials until production starts. Documentation management helps with quality control and makes sure that everything can be tracked along the supply chain.

Machining and Handling Tips for Industrial Titanium Rods

Optimal Machining Practices

To get the results you want while keeping the tool life and surface quality high, you need to use special techniques and tools when you machine titanium. Positive rake angles on sharp cutting tools lower cutting forces and keep work from hardening, which can make later operations more difficult. Cutting speeds should stay modest so that too much heat doesn't build up and hurt the performance of the tool or the properties of the material.

Keeping the workpiece cool while it's being machined stops heat buildup that could lead to surface rust and changes in size. Flood cooling systems get rid of heat better, and chip evacuation stops the need to re-cut and protects the tool. When compared to traditional milling methods, climb milling techniques lower the cutting forces and improve the quality of the surface finish.

The choice of tool affects both how well the part is machined and how well it turns out. When used correctly, finishes that are right for carbide tools make them last longer. High-speed steel tools can be used on a variety of shapes, but they need to be carefully controlled in terms of speed and feed. Monitoring tool wear stops catastrophic failures that hurt workpieces and put people in danger.

Storage and Handling Protocols

Proper keeping keeps the quality of titanium rods high from the time they are delivered until they are finished being made. Clean, dry places to store things keep them from getting contaminated, which could change the way the material works or make it harder to machine. Separated storage keeps different metals from coming into contact with each other, which could lead to galvanic corrosion in damp conditions.

Surface damage that could lead to stress buildup or lower corrosion resistance should be kept to a minimum during handling. Using the right lifting tools keeps machines from breaking down while moving things. Protecting the surface while it is being stored and moved keeps the finish quality and cuts down on the amount of cleaning that needs to be done before cutting.

Cleaning procedures get rid of manufacturing residues, storage contaminants, and handling marks that could affect how well the end part works. The right solvents and mechanical cleaning methods can restore the surface's state without leaving behind any harmful residues. Keeping records of the cleaning steps helps with quality control and meeting traceability standards.

Company Introduction and Product Services

Shaanxi Chuanghui Daye Metal Material Excellence

As a top producer of industrial-grade titanium bars, Shaanxi Chuanghui Daye Metal Material Co., Ltd. is based in the Baoji High-tech Development Zone, which is in China's famous "Titanium Capital." Our facility is near great transportation systems and well-established industry networks that make global distribution easy. We were started by people who have worked with rare metals for more than 30 years, so we have a lot of technical knowledge and can make things in modern ways.

Our dedication to quality greatness guides every part of our business, from choosing the raw materials to delivering the finished product. Our method of working with clients and making new products is based on the philosophy of "quality first and customer foremost." Because of this dedication, long-term relationships have been formed with chemical processing plants, medical device companies, and aerospace manufacturers around the world.

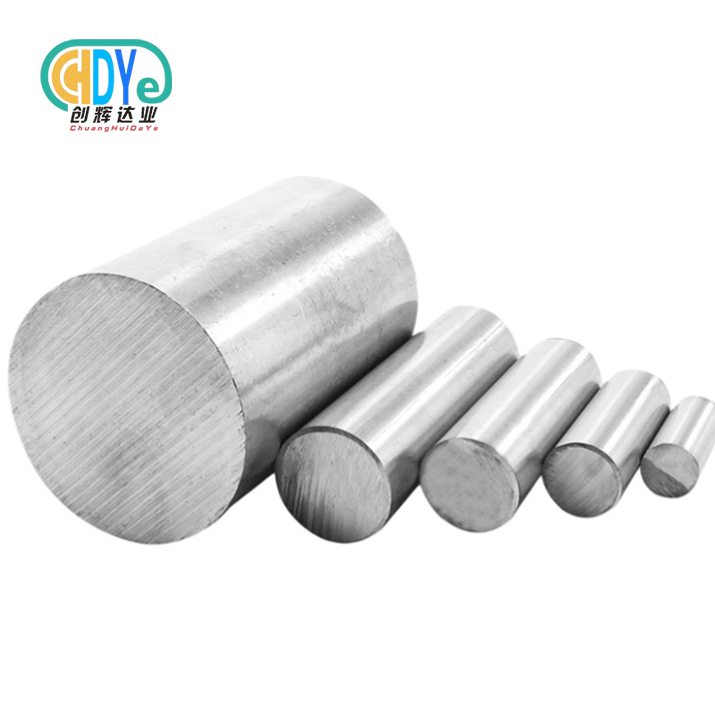

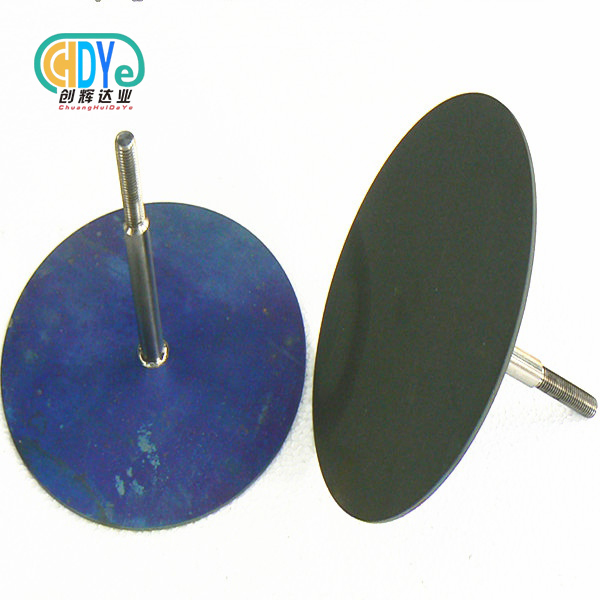

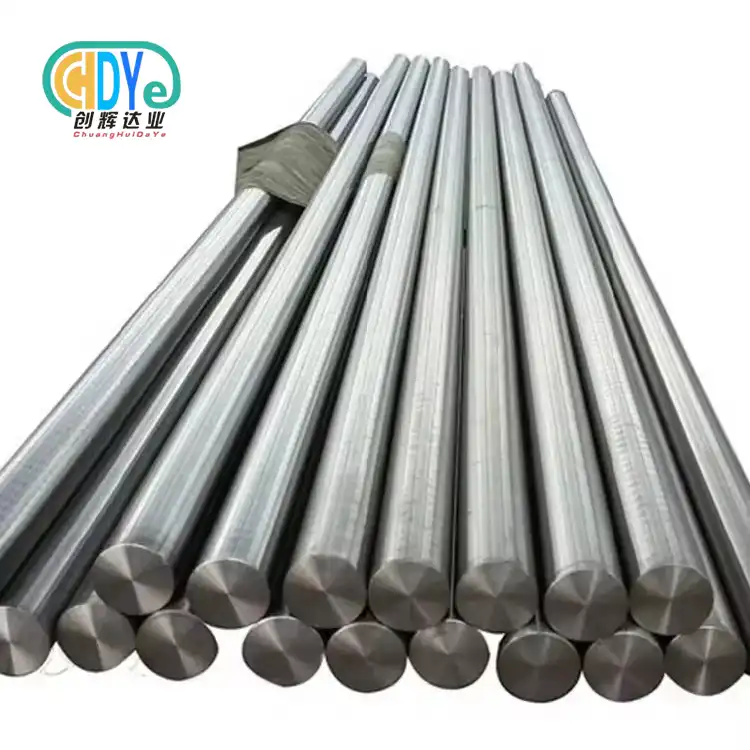

Manufacturing skills cover the full range of making titanium rods using advanced vacuum arc remelting (VAR) technology and precise forging methods. Titanium bars with diameters from 6 mm to 300 mm and lengths up to 6000 mm are made at our site. There are different ways to finish the surface, such as polishing, pickling, or machine-working it to fit the needs of the purpose.

Comprehensive Product Portfolio and Services

The titanium rods for sale we have for sale come in all the main types, from pure titanium to complex alloys made for specific uses. For chemical processing, Grade 1 and Grade 2 pure titanium offer the best corrosion protection. Ti-6Al-4V metals have the best strength-to-weight ratios for use in medicine and spacecraft. Specialized metals, such as Ti-3Al-2.5V and ELI versions, meet certain performance needs.

In competitive areas, our value-added services set our products apart. Custom cutting services give customers exact widths that cut down on waste and the need for extra inventory. With expedited processing, you can meet tight project deadlines without sacrificing quality. Full certification packages come with compliance paperwork for regulated businesses, material test reports, and records of dimensional inspections.

Customers can get help from technical consultation services as they choose materials and build applications. Our engineering team can help you choose the right grade, make suggestions for machining, and find solutions that work for your unique needs. This collaborative method makes sure that the materials work best and that the total cost of the project is kept as low as possible.

Conclusion

Titanium rods for sale made to industrial standards are important materials for tough jobs in the semiconductor, medical, chemical, and aircraft industries. Due to their high strength, resistance to corrosion, and biocompatibility, titanium bars are essential for mission-critical parts. The best performance and highest material value are achieved by choosing the right grade, evaluating the provider, and using the right machining techniques. As global demand keeps growing, building partnerships with trusted suppliers is becoming more and more important for staying ahead of the competition and making sure projects are successful.

FAQ

Q: What are the primary applications for industrial titanium rods?

A: Industrial titanium rods serve diverse applications, including aerospace structural components, medical implants and surgical instruments, chemical processing equipment, semiconductor manufacturing tools, and marine hardware. The material's unique combination of strength, corrosion resistance, and biocompatibility makes it suitable for environments where other metals would fail.

Q: How do I verify titanium rod quality before purchase?

A: Quality verification requires reviewing comprehensive material test reports that document chemical composition, mechanical properties, and dimensional tolerances. Reputable suppliers provide certificates of compliance with relevant standards, including ASTM B348, AMS 4928, and ISO specifications. Third-party testing services can provide independent verification when required.

Q: What factors influence titanium rod pricing in bulk orders?

A:Bulk pricing depends on grade specification, order quantity, delivery timeline, and market conditions. Raw material costs fluctuate based on ore availability and processing capacity. Custom specifications and expedited delivery typically increase costs, while standard grades in large quantities offer better pricing. Long-term agreements often provide price stability and supply security.

Start Your Titanium Rod Procurement Today

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands ready to support your titanium bar procurement needs with premium-quality industrial-grade materials and comprehensive technical expertise. Our extensive inventory includes certified titanium rods for sale across all major grades, backed by ISO 9001:2015 quality certification and global shipping capabilities. Contact our engineering team at info@chdymetal.com for personalized quotations and technical consultation tailored to your specific application requirements. As a trusted titanium rod supplier, we deliver competitive factory-direct pricing with expedited delivery options for urgent projects.

References

1. Boyer, R. R. "An Overview of the Use of Titanium in the Aerospace Industry." Materials Science and Engineering, Vol. 213, 1996.

2. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. "Ti-Based Biomaterials, the Ultimate Choice for Orthopaedic Implants." Progress in Materials Science, Vol. 54, 2009.

3. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Vol. 5, 2003.

4. Donachie, Matthew J. "Titanium: A Technical Guide, Second Edition." ASM International, Materials Park, Ohio, 2000.

5. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Bars and Billets." ASTM B348-13, West Conshohocken, Pennsylvania, 2013.

6. Lutjering, G. & Williams, J. C. "Titanium: Engineering Materials and Processes." Springer-Verlag, Berlin Heidelberg, 2003.

Learn about our latest products and discounts through SMS or email