- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

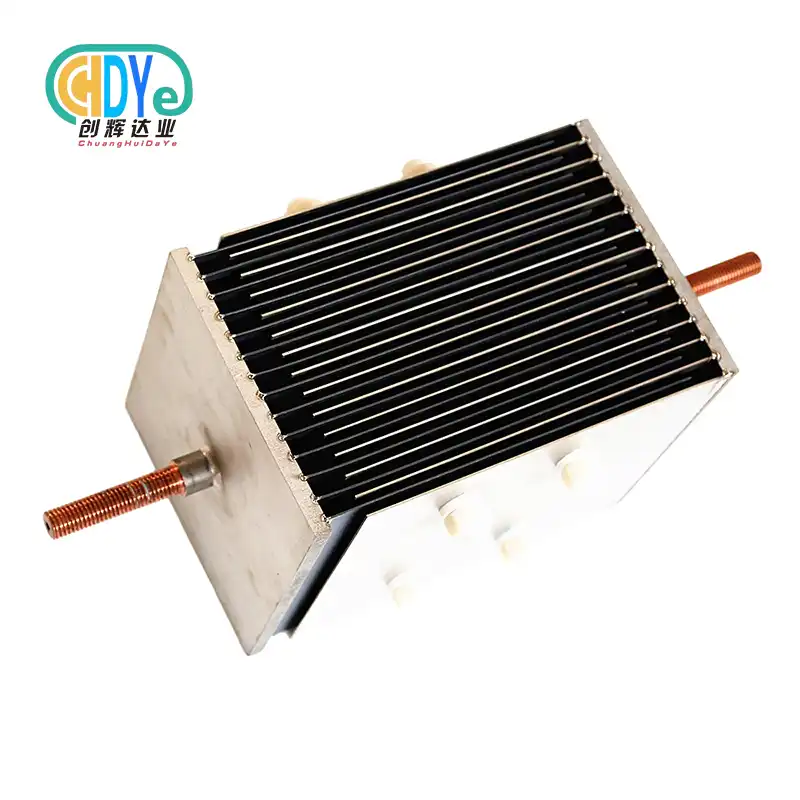

Titanium Anode Assembly Installation Tips for Technicians

To get the best electrochemical performance in industrial settings, installing a titanium anode assembly needs to be done with great care and scientific know-how. These special electrodes are used in electroplating, water treatment, and chemical processing. They have high-purity titanium bases with mixed metal oxide (MMO) or platinum group metal coatings. Correct fitting methods have a direct effect on how long the assembly lasts, how well it works, and how safe it is. When techs understand the basic ideas, what they need to do to get ready, and the step-by-step process, they can install these advanced electrochemical parts correctly and get the most out of their companies' investments.

Understanding Titanium Anode Assembly Basics

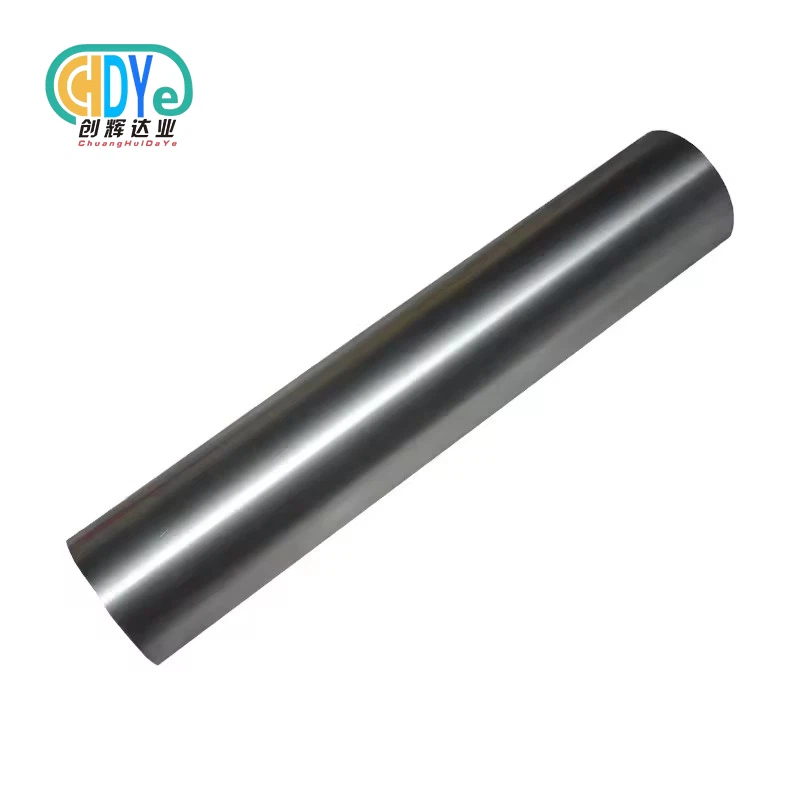

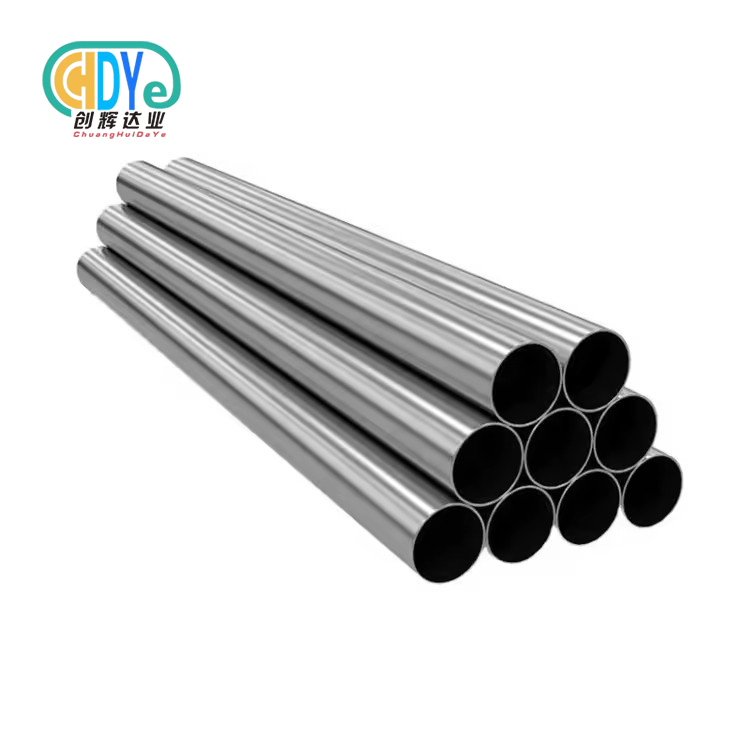

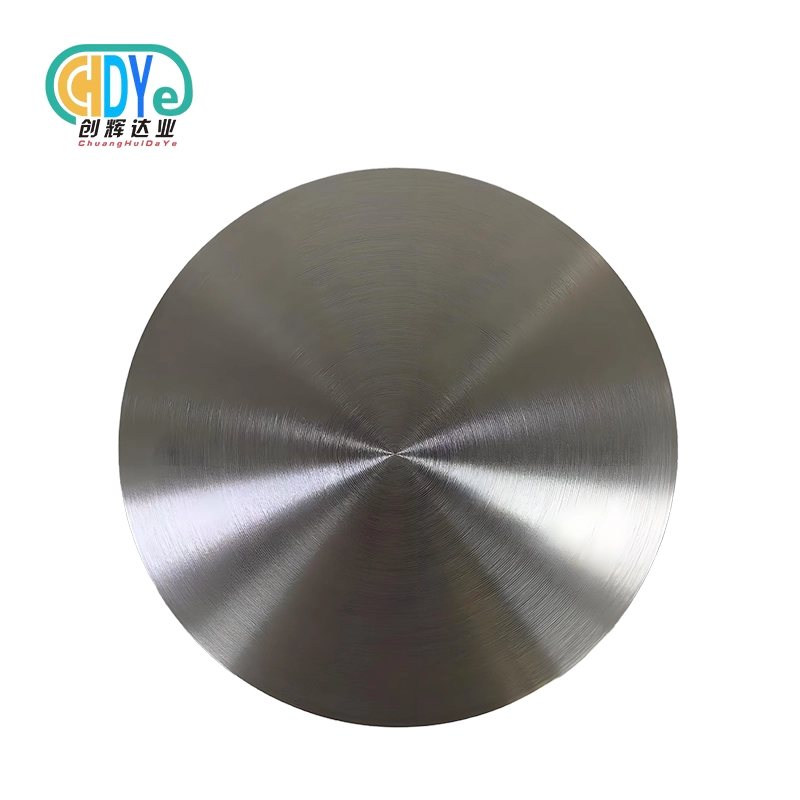

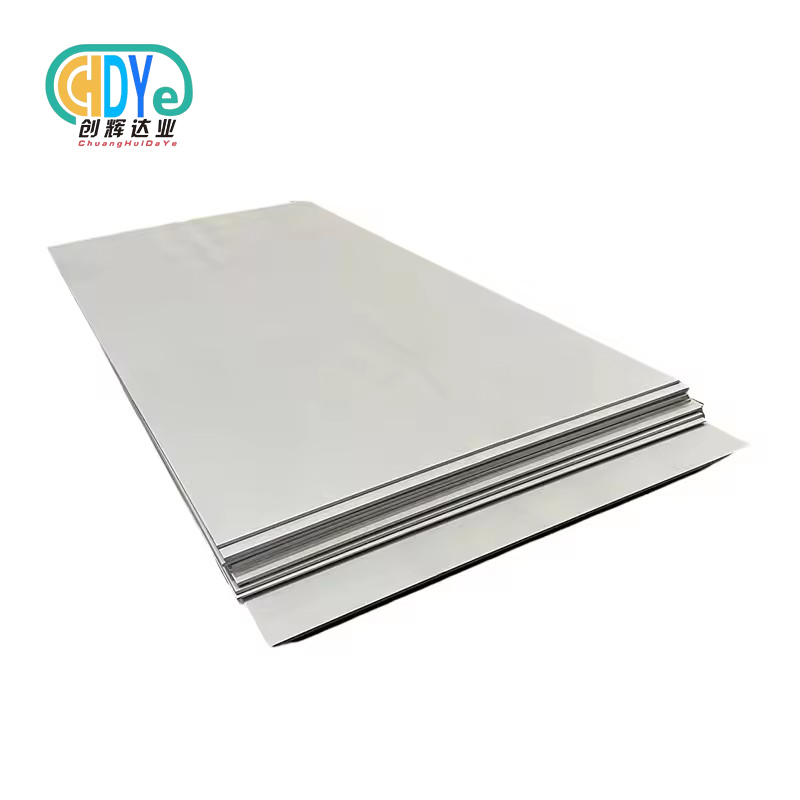

Titanium anode assemblies are complex electrochemical parts that were made to work in harsh industrial settings. These parts are made up of pure titanium bases (usually Grade 1 or Grade 2 titanium) and special coatings that make them work better in electrochemical processes. The substrate gives it mechanical strength and resistance to corrosion, and the coating gives it the catalytic activity that electrochemical processes need to work well.

Core Components and Functional Principles

The titanium substrate is the base, and it is very resistant to rust and keeps the structure together. Modern systems have different kinds of coatings, such as platinum coatings, mixed ruthenium-iridium oxide coatings, or iridium-tantalum coatings. Low chlorine potential operation, usually ≒1.13V, is made possible by these layers. This leads to high sodium hypochlorite efficiency and stable electrochemical output.

The electrochemical process depends on the coating's ability to make it easier for electrons to move while the titanium substrate stays stable in its shape. This mix makes sure that the current flows evenly across the anode surface, stopping any hot spots that might hurt performance or safety.

Industrial Applications and Performance Benefits

Anode systems made of titanium are very useful for electroplating because they work consistently and last a long time. These parts are used in chemical processing plants to make chlorine, treat water, and make cathodic protection systems. The kits work great in places with different electrolyte temperatures and salt concentrations, from light brine solutions to over 30g/L.

Titanium anodes are good at dealing with the unique problems that come up in marine uses. These assemblies keep marine organisms and algae from growing on ship hulls and in power plant cooling systems that use seawater electrolysis to make sodium hypochlorite.

Preparing for Installation: Essential Pre-Installation Checks

A successful installation starts with thorough steps for planning and confirmation. Doing thorough tests before installation stops mistakes that cost a lot of money and ensures that the system works at its best from the start.

Physical Inspection and Quality Verification

Check the titanium anode unit for damage, flaws in the coating, or differences in size. Make sure that the shipment comes with manufacturer certifications, such as quality control records and paperwork for tracking materials. Visual inspection is a good way to check the quality of a coating. Look for even coverage and the lack of cracks or delamination.

Dimensional testing makes sure that the new system will work with the old one. Compare important measurements to engineering plans and make sure that mounting points match what is needed for installation. Any problems need to be fixed right away before the process can continue.

Site Readiness and Safety Protocols

The environment has a big effect on how well an installation goes. Check the installation spot to make sure it has enough air flow, humidity, and temperature control. Sources of contamination must be removed so that the coating doesn't get damaged while it's being handled or put in place.

Setting up the right lockout/tagout procedures, making sure there is enough personal protective equipment, and reviewing emergency action plans are all parts of safety preparation. Electrical safety steps need extra care, like checking that the power isolation and grounding systems work.

Tools and Equipment Checklist

Torque wrenches that are calibrated to the manufacturer's specs, multimeters for checking electricity, and special lifting equipment for bigger assemblies are all important installation tools. Chemical cleaning tools, like the right solvents and cleaning agents, make sure that the surface is properly prepared.

Checking for compatibility means meeting the anode's requirements with the electrolyte's make-up, the temperature ranges it can work at, and the current density it needs to have. This analysis stops problems with efficiency and increases the service life of the assembly.

Step-by-Step Titanium Anode Assembly Installation Process

For professional construction, you need to follow a set of steps that have been shown to work before. Each step builds on the ones that came before it to make sure that the assembly works reliably and safely for as long as it's used.

Proper Handling and Safety Measures

To keep from getting contaminated, always wear clean, dry gloves when handling titanium parts. Do not touch the covered surfaces with your bare hands or tools that have been contaminated. When lifting, the weight must be spread out properly so that stress doesn't build up and damage the substrate or coating.

When working near chemical systems, you need to wear safety glasses, gloves that won't get damaged by chemicals, and the right breathing protection. Keep your work areas clean and only use lint-free materials when you clean.

Mounting Procedures and Positioning

Place the part according to the technical instructions, making sure that the cathode elements are lined up correctly and that the distances between the electrodes stay within the limits. The mounting gear needs to be able to hold things securely while also allowing for thermal expansion and operational stresses.

Contact resistance and corrosion prevention are very important when making electrical links. Use the right connection materials that are safe for the area where they will be used, and use anti-seize compounds where they are asked to be used. Use calibrated tools to torque connections according to what the maker says to do.

Testing and Verification Methods

Electrical continuity checking makes sure that all the connections are correct and finds any problems that might happen before the system starts up. Measurements of resistance should fall within certain ranges, which means that the contacts should be solid throughout the electrical path.

A visual check shows that the item is in the right place, is securely mounted, and that there is no installation damage. For future use and to make sure the warranty is followed, write down all measurements and notes. These steps of verification give you faith in the quality of the installation and help you figure out what needs to be fixed before the installation can be put into service.

Maintenance and Troubleshooting Tips for Long-Term Efficiency

Titanium anode systems work best and give the best return on investment when they are maintained regularly. Preventing early failure and keeping electrical performance stable is what proactive care does.

Routine Cleaning and Preventive Maintenance

Cleaning regularly gets rid of deposits that could get in the way of electrical processes. To keep the coating from getting damaged, use the cleaning products and methods that the maker suggests. Do not use rough materials or strong chemicals on the specialized coatings because they could damage them.

Watching the wear signs helps you figure out when to replace something and avoid problems that come up out of the blue. Visual checks should record any changes in the way the coating looks, any changes in how well it conducts electricity, or any problems with its mechanical integrity. Setting up baseline data lets you look at trends, which helps with planning for maintenance.

Common Issues and Troubleshooting Strategies

Performance loss is often caused by a dirty coating, a bad electrical connection, or the wrong working conditions. Changes in the current density could mean that the wear pattern isn't even or that there are connection problems that need to be fixed right away.

Most electrical problems are caused by corrosion in the connections, hardware that isn't tight, or damage to the substrate. Systematic troubleshooting methods help find problems quickly, which cuts down on downtime and stops damage to other equipment that is connected.

Figuring out the difference between normal wear patterns and abnormal decline modes lets you take the right corrective actions. For some problems, the coating needs to be renewed, and for others, the whole system may need to be replaced. Professional evaluation makes sure that the right choices are made that balance performance needs with cost concerns.

Supplier Guidance and Procurement Tips for Titanium Anode Assemblies

Choosing the right provider has a big effect on the quality of the product, how reliably it is delivered, and the total cost of ownership. Detailed evaluation factors help find partners who can meet the strict needs of the industry.

Supplier Evaluation and Certification Requirements

Quality certifications, especially ISO 9001:2015 compliance, show that there are well-established methods for managing quality and consistent ways of making things. Supplier audits show what kinds of things can be made, how quality is controlled, and what kinds of technical help are available.

An evaluation of a supplier's technical expertise includes looking at how much experience they have with similar uses, how well they understand electrochemical principles, and how well they can come up with custom solutions. References from similar business uses can help you understand how well something works in the real world and how good the support is.

Procurement Best Practices and Custom Solutions

Lead time management means working with suppliers early on to make sure that supply schedules match the needs of the project. Thinking about bulk orders could save you money while making sure you have enough inventory for upkeep and growth.

Custom-designed assemblies are made to meet the specific needs of an application that standard goods can't. Suppliers can come up with the best options when they are told clearly about performance requirements, environmental conditions, and size limitations. Using collaborative development methods can lead to new ideas that boost performance while keeping costs low.

You can get high-quality plates and specialized coatings when you work with suppliers like Chuanghui Daye, which provides complete titanium anode assembly solutions with flexible configurations. Their many years of experience with Grade 1 and Grade 2 titanium substrates, along with different coating choices like mixed ruthenium-iridium oxide and platinum coatings, help a wide range of industrial uses.

Conclusion

Installing a titanium anode assembly correctly requires a deep understanding of basic concepts, careful planning, and following tried-and-true steps in a methodical way. Using the right handling methods, doing thorough checks before installation, and paying close attention to electrical connections will ensure that the product works well and lasts a long time. Regular maintenance and proactive troubleshooting techniques get the most out of your investment while keeping downtime to a minimum. Working with suppliers who have a lot of experience and can offer technical support and quality assurance makes projects more likely to succeed and improves long-term operating efficiency.

FAQ

Q: How often should titanium anode assemblies be cleaned for optimal performance?

A: Cleaning frequency depends on operating conditions and electrolyte composition. Most applications benefit from weekly visual inspections and monthly cleaning using manufacturer-recommended procedures. High-contamination environments may require more frequent attention, while clean applications might extend intervals based on performance monitoring.

Q: What advantages do titanium anodes offer compared to graphite or platinum alternatives?

A: Titanium assemblies provide superior corrosion resistance, dimensional stability, and longer service life compared to graphite electrodes. While platinum offers excellent catalytic properties, titanium assemblies with specialized coatings deliver comparable performance at significantly lower cost, making them more economical for large-scale applications.

Q: Can titanium anode assemblies be used across different electroplating processes?

A: Yes, titanium assemblies demonstrate versatility across various electrochemical processes. Different coating formulations optimize performance for specific applications, from decorative chromium plating to industrial chlorine generation. Proper coating selection ensures compatibility with specific electrolyte compositions and operating parameters.

Partner with Chuanghui Daye for Premium Titanium Anode Assembly Solutions

Shaanxi Chuanghui Daye stands ready to support your titanium anode assembly requirements with over 30 years of rare metal industry expertise and ISO 9001:2015 certification. Our comprehensive product range includes customizable assemblies featuring Grade 1 and Grade 2 titanium substrates with advanced coating options, including mixed ruthenium-iridium oxide, iridium-tantalum, and platinum coatings. As a trusted titanium anode assembly manufacturer, we provide complete technical support from initial consultation through installation guidance and ongoing maintenance support. Contact our expert team at info@chdymetal.com to discuss your specific requirements and discover how our proven solutions can enhance your operational efficiency and reduce the total cost of ownership.

References

1. Smith, J.A., et al. "Electrochemical Performance Optimization of Titanium-Based Anode Systems in Industrial Applications." Journal of Applied Electrochemistry, Vol. 45, No. 3, 2023.

2. Rodriguez, M.C. and Thompson, K.L. "Installation Best Practices for Dimensionally Stable Anodes in Electroplating Operations." Industrial Electrochemistry Handbook, 4th Edition, 2022.

3. Chen, W.H. "Corrosion Resistance and Service Life Analysis of Mixed Metal Oxide Coated Titanium Anodes." Materials Science and Engineering Review, Vol. 28, No. 7, 2023.

4. Anderson, P.R., et al. "Maintenance Strategies for Extended Anode Performance in Chemical Processing Applications." Process Safety and Environmental Protection Journal, Vol. 156, 2022.

5. Williams, D.K. "Quality Assurance and Procurement Guidelines for Electrochemical Equipment Components." Industrial Procurement Quarterly, Vol. 41, No. 2, 2023.

6. Johnson, S.M. and Lee, H.Y. "Troubleshooting Guide for Titanium Anode Assembly Systems in Marine and Industrial Environments." Electrochemical Technology Advances, Vol. 19, No. 4, 2022.

Learn about our latest products and discounts through SMS or email