- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Seamless Tube for Marine & Offshore Projects

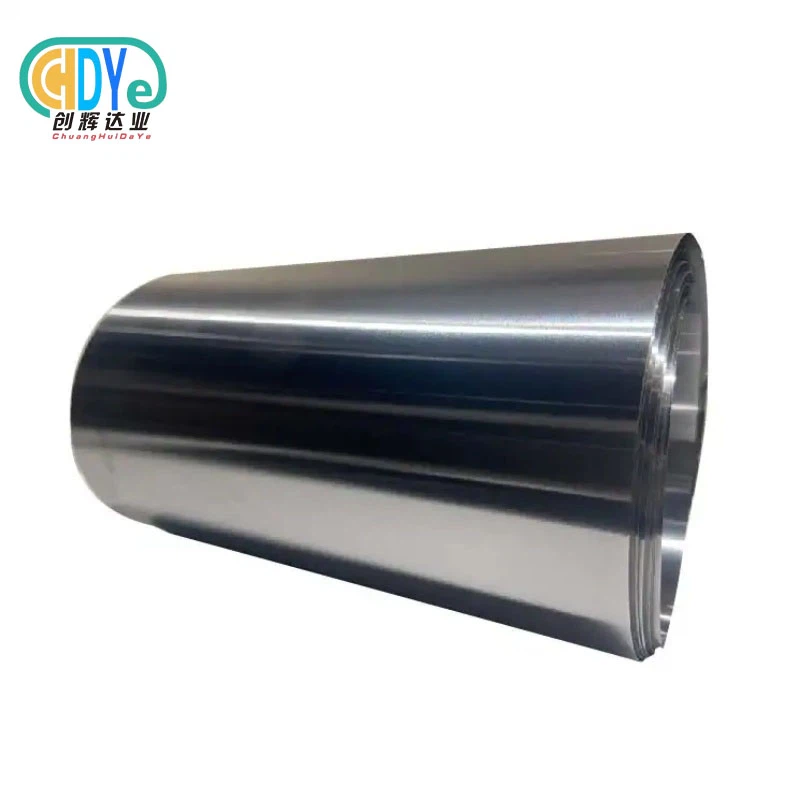

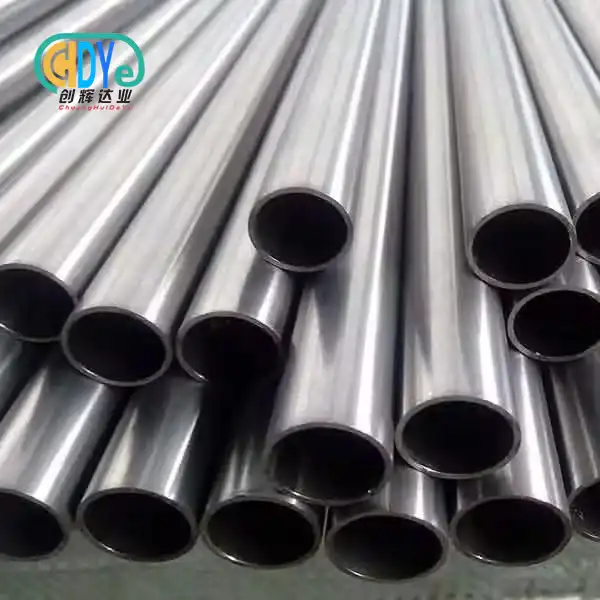

Marine and seaward situations show a few of the most challenging conditions for mechanical materials, where routine metals frequently fall flat beneath tenacious introduction to saltwater erosion and extraordinary operational stresses.Titanium seamless tube innovation has developed as a basic arrangement for these requesting applications, advertising unmatched resistance to seawater debasement and extraordinary auxiliary judgment. These specialized tubes combine lightweight properties with predominant quality characteristics, making them vital for subsea pipelines, seaward stages, and marine warm exchangers where unwavering quality cannot be compromised.

Understanding Titanium Seamless Tubes

Manufacturing Processes and Quality Assurance

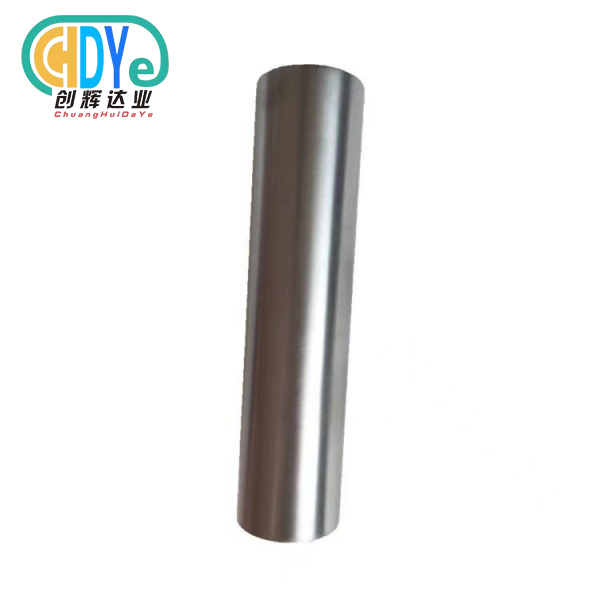

High-quality seamless titanium tubes are made using sophisticated methods to maintain structural integrity throughout. Specialized dies heat and distort premium-grade titanium billets for advanced extrusion processes. Rotary piercing creates the hollow form, followed by precision rolling and sizing for accurate dimensions.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. produces seamless tubes that fulfill ASTM B338, B337, B861, and B862 specifications using cutting-edge annealing furnaces and electron beam melting equipment. Quality control is implemented throughout our manufacturing process, from raw material inspection to final dimensional verification and surface finish analysis.

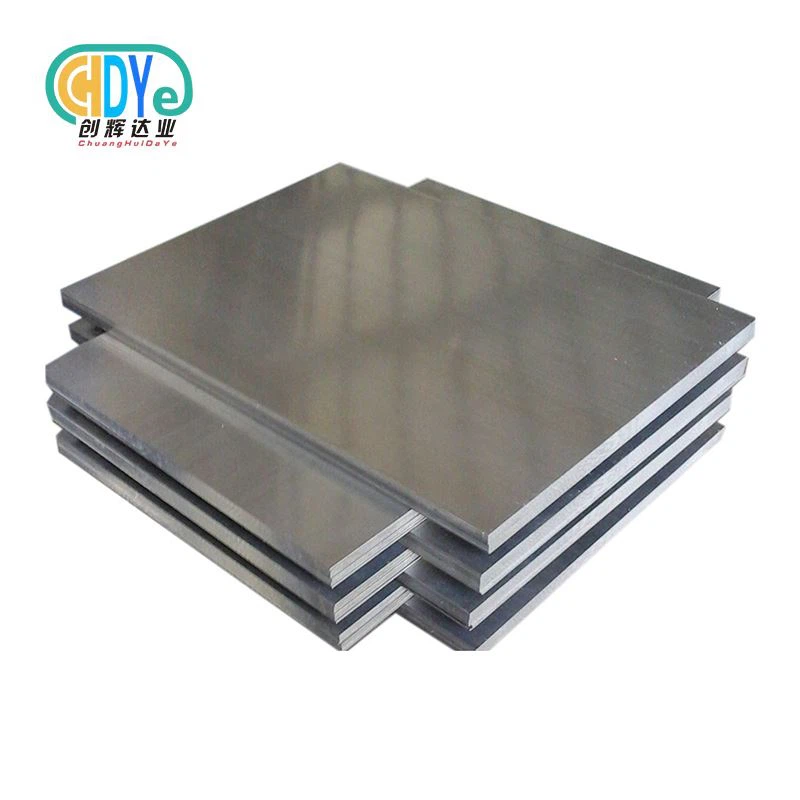

Material Properties and Grade Specifications

Engineers can choose the best titanium grades for marine applications by understanding their properties. Grade 1 titanium is ideal for complex seawater piping layouts due to its ductility, formability, and corrosion resistance. Grade 2 titanium is the most extensively used commercially pure titanium for marine applications due to its strength and corrosion resistance.

Palladium adds resistance to reducing acid conditions found in offshore chemical processing to grade 7 titanium. Grade 9 titanium alloy is appropriate for high-pressure marine applications because it combines aluminum and vanadium for strength and corrosion resistance. Molybdenum and nickel add to grade 12 titanium's seawater crevice corrosion resistance.

Our titanium seamless tubes meet different marine engineering needs with OD 10-300mm, wall thicknesses from 0.5-10mm, and lengths up to 18,000mm.

Performance Characteristics in Marine Environments

Titanium tubes perform well in maritime applications due to their unique physical and chemical qualities. These materials are structurally sound from cryogenic to 600°C and fatigue-resistant under offshore cyclic loads. Titanium surfaces self-heal as their natural oxide layer prevents corrosion.

Comparing Titanium Seamless Tubes with Alternatives in Marine & Offshore Applications

Superior Corrosion Resistance Performance

Corrosion resistance is the essential criteria for marine material selection, determining long-term operating performance and maintenance costs. While cheaper, stainless steel alternatives pit and crevice corrosion in chloride-rich seawater, causing early failure and costly replacement cycles. Galvanic corrosion and general corrosion assault make aluminum alloys unsuitable for marine applications.

Cathodic protection and elaborate coating systems make carbon steel choices more complicated and expensive to maintain. Titanium seamless tubes' chloride resistance overcomes these issues, allowing decades of maintenance-free operation in hostile marine settings.

Strength-to-Weight Advantages

Titanium materials' high strength-to-weight ratio benefits offshore applications where weight reduction affects structural design and installation costs. Titanium tubes are 60% lighter than steel yet as strong. It reduces weight, making platform designs, foundation requirements, and subsea equipment installation easier.

Economic Lifecycle Analysis

Titanium seamless tubes cost more than typical materials, but lifecycle cost study shows superior economic performance. The removal of corrosion-related maintenance, prolonged service life, and reduced replacement frequency reduces marine application total cost of ownership. Insurance and operational risk reductions boost titanium tube selection's economic benefits.

Procurement Considerations for Titanium Seamless Tubes in Marine & Offshore Projects

Supplier Evaluation and Certification Requirements

Supplier skills, quality systems, and certification compliance must be assessed to buy titanium tubes for crucial marine applications. ISO 9001:2015 accreditation is the minimal quality management standard for consistent manufacturing and traceability. Certifications like AS9100 for aerospace or ISO 14001 for environmental management improve supplier capabilities.

Audits of manufacturing facilities should check melting equipment, controlled environment processing, and calibrated testing instruments. Supplier experience in marine applications and knowledge of ASME, API, and classification society standards ensures project compliance.

Customization Capabilities and Technical Support

Marine and offshore projects often demand specific configurations, dimensions, or surface treatments that surpass product capabilities. Customization includes precise machining, heat treatment, and surface modification from top suppliers. Technical help should include materials selection, application engineering, and performance optimization.

Our technical team works with project designers to optimize tube specifications for specific operating conditions, maximizing performance and lowering material costs. Custom fabrication reduces installation time and expense with complicated bending, welding preparation, and assembly.

Quality Documentation and Traceability

Marine applications require detailed documentation from raw material source to final inspection results. Chemical composition analysis, mechanical property verification, and non-destructive testing are required for mill test certificates. Dimensional inspections, surface finish measurements, and cleanliness checks ensure project compliance.

Digital records allow rapid retrieval of previous data for maintenance planning, failure analysis, and regulatory compliance in advanced quality management systems. These solutions enable predictive maintenance and operational optimization throughout equipment lifecycles.

Case Studies and Applications of Titanium Seamless Tubes in Marine & Offshore Projects

Subsea Pipeline Systems

Recent offshore development projects have used titanium seamless tubes in key subsea pipeline applications when traditional materials failed. High-pressure gas injection lines in the North Sea used Grade 9 titanium tubes and lasted 25 years without corrosion. The installation eliminated cathodic protection and reduced weight by 40% compared to steel systems.

Five years of performance monitoring showed no corrosion penetration and structural integrity under cyclic pressure stress. Eliminating maintenance and extending inspection intervals saved over 60% compared to previous steel systems.

Heat Exchanger Applications

Marine heat exchangers require high heat transmission and severe corrosion, making them one of the most demanding tube applications. Titanium tubes work well in seawater-cooled condensers, oil coolers, and desalination plants where other materials degrade quickly.

Grade 2 titanium replaced copper-nickel tubes on a cruise ship, improving heat transfer efficiency by 12% and ensuring 15 years of maintenance-free operation. The titanium tubes prevented biofouling and reduced cleaning frequency from monthly to annual, saving huge operational costs.

Offshore Platform Piping Systems

Complex offshore rigs require vast piping networks that can endure harsh weather conditions and operate reliably. Titanium seamless tubes work well in firewater systems, process pipes, and utilities where weight reduction and corrosion resistance are important.

Company Introduction and Product & Service Information

Manufacturing Excellence and Technical Expertise

From China's "Titanium Capital" in Baoji High-tech Development Zone, Shaanxi Chuanghui Daye Metal Material Co., Ltd. has over 30 years of rare metal manufacturing and processing experience. We manufacture everything from raw material melting to precision machining and finishing.

Electron beam furnaces for ultra-pure melting, controlled environment annealing systems, and precision rolling mills provide quality and dimensional correctness. Our metallurgical engineers with marine application knowledge consult on difficult offshore projects.

Quality Assurance and Certification Standards

From incoming material inspection to final product verification, our ISO 9001:2015 quality management system maintains strict control. Advanced testing includes chemical analysis, mechanical property testing, and ultrasonic, eddy current, and penetrant non-destructive inspection.

Certified materials meet ASTM, ASME, and international marine classification society standards. Critical marine applications benefit from our quality documentation systems' comprehensive traceability and customer audit support.

Global Supply Chain and Customer Support

We keep strategic levels of popular grades and sizes in stock so that we can meet the fast delivery needs of important marine projects. Our global logistics network makes sure that deliveries to major ports around the world are always on time, and we keep the integrity of the goods we ship by using special packing and handling methods.

As part of technical support services, application engineers can give advice on things like material selection and help with installation and testing tasks in the field. Our customer service team can help you in more than one language and keeps direct lines of contact open for project coordination and technical support.

Conclusion

Titanium seamless tubes are the best material for marine and offshore uses that need high performance and dependability but can't get them from other materials. Because they are highly resistant to corrosion, have a high strength-to-weight ratio, and last a long time, these special tubes have strong economic benefits through lower maintenance needs and higher operating reliability. For implementation to go smoothly, suppliers must be carefully chosen, quality must be checked, and there must be technical help that can keep things running at their best throughout the project's lifecycle.

FAQ

Q: What manufacturing processes ensure titanium tube quality for marine applications?

A: Advanced seamless tube production utilizes precision extrusion and rotary piercing techniques combined with controlled atmosphere annealing to achieve optimal microstructure and mechanical properties. Quality assurance includes comprehensive chemical analysis, mechanical testing, and non-destructive examination to verify compliance with marine application standards.

Q: How do I assess supplier reliability and certification compliance?

A: Evaluate suppliers based on ISO 9001:2015 certification, manufacturing facility capabilities, and experience with marine applications. Request facility audits, review quality documentation systems, and verify compliance with relevant ASTM and ASME standards for marine tube applications.

Q: Are titanium seamless tubes environmentally sustainable?

A: Titanium materials offer excellent recyclability with minimal environmental impact during recycling processes. The extended service life and elimination of coating requirements reduce environmental footprint compared to conventional materials while supporting sustainability objectives in marine operations.

Partner with Chuanghui Daye for Premium Titanium Seamless Tube Solutions

Shaanxi Chuanghui Daye stands ready to support your marine and offshore projects with precision-engineered titanium seamless tubes that deliver uncompromising performance and reliability. Our three decades of specialized manufacturing experience, combined with comprehensive technical support and global supply capabilities, ensure optimal solutions for your most demanding applications. Connect with our engineering team at info@chdymetal.com to discuss your specific requirements and discover why leading marine contractors choose Chuanghui Daye as their trusted titanium seamless tube supplier for critical offshore installations.

References

1. Smith, J.R., and Thompson, M.K. "Corrosion Performance of Titanium Alloys in Marine Environments." Journal of Marine Materials and Engineering, Vol. 45, No. 3, 2023, pp. 127-145.

2. Anderson, P.L., et al. "Lifecycle Cost Analysis of Titanium vs. Conventional Materials in Offshore Applications." Offshore Technology Conference Proceedings, 2023, pp. 892-906.

3. Williams, D.C. "Manufacturing and Quality Control of Seamless Titanium Tubes for Marine Applications." Materials Science and Technology in Marine Engineering, Vol. 18, No. 2, 2023, pp. 203-218.

4. Chen, L.H., and Rodriguez, A.M. "Case Studies in Titanium Tube Performance for Subsea Pipeline Systems." International Journal of Offshore Engineering, Vol. 29, No. 4, 2023, pp. 45-62.

5. Johnson, K.A. "Material Selection Guidelines for Marine Heat Exchanger Applications." Marine Engineering Technology Review, Vol. 12, No. 1, 2024, pp. 78-94.

6. Taylor, R.B., and Lee, S.J. "Environmental Impact Assessment of Titanium Materials in Marine Applications." Sustainable Marine Technology Journal, Vol. 8, No. 3, 2023, pp. 156-171.

Learn about our latest products and discounts through SMS or email