- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Wire for Anodizing – Industrial & Medical Uses

In precision, durability, and biocompatibility-critical industrial and medical applications, titanium wire for anodizing is unequaled. This wire is ideal for electrochemical processes in many sectors because to its corrosion resistance and electrical conductivity. Our thorough guide examines how anodizing-grade titanium wire improves manufacturing, from aerospace components to life-saving medical equipment. Understanding these technical specifications, application benefits, and procurement strategies can help engineers, procurement managers, and industry professionals make informed decisions that improve performance and operational efficiency.

Understanding Titanium Wire in Anodizing

Titanium wire for anodizingis essential to anodizing because it outperforms other materials in demanding electrochemical applications. Fine anodizing is possible due to the material's strength-to-weight ratio, 40% lighter than steel but with higher mechanical qualities. Its corrosion resistance comes from a protective titanium dioxide layer that is stable in hostile chemical conditions during industrial anodizing.

Properties That Define Anodizing Excellence

High-grade titanium wire's electrical conductivity guarantees consistent current distribution in the anodizing solution, affecting oxide layer uniformity and quality. Another benefit is temperature stability, since titanium wire retains its structural integrity and electrical properties across vast temperature ranges necessary in industrial anodizing. Thermal resistance prevents dimensions changes that could jeopardize delicate component processing precision.

The Anodizing Process Optimization

The predictable electrochemical action and tolerance to acidic electrolytes of titanium wire improve anodizing results. Biocompatibility makes the material ideal for medical device anodizing, where contamination must be eliminated. Titanium wire's qualities combine with advanced anodizing parameters including controlled voltage application and electrolyte management to deliver consistent, high-quality surface treatments that satisfy industry standards.

Comparing Titanium Wire with Alternative Materials

Titanium is superior than stainless steel, aluminum, and copper alloys for anodizing wire. While cost-effective, stainless steel lacks the corrosion resistance needed for prolonged exposure to acidic anodizing solutions and may contaminate surface quality with iron. Though lightweight, aluminum wire is fragile in hostile chemical conditions and may need frequent replacement, raising operational costs.

Grade Distinctions and Performance Characteristics

Grade 2 commercially pure titanium wire balances mechanical qualities and chemical stability for general anodizing applications with outstanding formability and corrosion resistance. This grade's ductility allows complicated wire arrangements without stress fractures that could disrupt electrical continuity. In high-stress anodizing settings, grade 5 titanium alloy (Ti-6Al-4V) with 6% aluminum and 4% vanadium provides excellent tensile strength and corrosion resistance.

Cost-Efficiency Analysis

Titanium wire is more expensive than other materials, but its longer lifespan and lower maintenance costs save money over time. Due to its chemical resistance, wire replacement cycles are rare, decreasing material costs and production downtime. Quality consistency from titanium wire reduces rework and guarantees consistent anodizing results that satisfy specifications.

Industrial & Medical Applications of Titanium Wire Anodizing

Aerospace manufacturers use titanium wire anodizing to make components that can survive harsh environments and maintain dimensional specifications. Titanium wire-based anodizing improves corrosion resistance and surface hardness in aircraft fasteners, electrical connectors, and structural elements. These characteristics are used in vehicle exhaust system, suspension, and decorative trim parts that need aesthetic appeal and durability.

Medical Device Manufacturing Excellence

Medical device producers use titanium wire anodizing to make implants, surgical instruments, and diagnostic equipment biocompatible. High-purity titanium wire anodizing creates oxide layers that integrate with biological systems and provide patient-safe antibacterial characteristics. Titanium wire's consistent electrical properties improve biocompatibility of cardiovascular stents, orthopedic implants, and dental components under regulated anodizing.

Electronics and Semiconductor Applications

The electronics industry uses titanium wire anodizing to make precision semiconductors, circuit boards, and connectors. The method controls surface modification to improve electrical qualities and protect against environmental damage. Titanium wire-based anodizing provides dimensional stability and chemical inertness for advanced electronic devices, ensuring reliable performance in harsh operational situations.

Innovation Trends and Future Applications

Solar panel components and battery technologies increasingly use titanium wire anodizing for performance and durability. Research and development are extending anodizing applications, with titanium wire providing novel surface treatment capabilities to assist next-generation manufacturing across varied industrial sectors.

Procurement Insights – Sourcing Titanium Wire for Anodizing

To find a good titanium wire provider, you need to carefully look at their certifications, quality control procedures, and manufacturing skills. As a basic requirement, ISO 9001:2015 certification makes sure that quality control is carried out throughout the whole production process. From where the raw materials come from to when the finished product is delivered, suppliers should show traceability paperwork that lets you see the whole history of the materials and how they were processed.

Quality Assurance and Testing Protocols

Reliable suppliers use strict testing methods that include analyzing the chemical makeup, checking the mechanical properties, and making sure the measurements are correct. Ultrasonic inspection and surface quality assessment are two advanced testing methods that make sure wire goods meet strict requirements for anodizing applications. Important test certificates, compliance statements, and performance data that help with qualification processes for important applications should be included in documentation packages.

Supply Chain Management Strategies

Good procurement strategies take into account things like wait times, the ability to change the number of items ordered, and the ability to ship goods all over the world. Established suppliers keep strategic stock levels that allow for faster delivery when urgent project needs appear. The minimum order amounts should be in line with what the business needs and offer cost savings through bulk buying. To keep production schedules, the supply chain needs to be resilient, which means that sellers need to have a wide range of sources and a track record of delivering goods on time.

Pricing Structure Considerations

Titanium wire for anodizingprices depend on a number of things, such as the grade, the diameter, the amount needed, and the market conditions for raw titanium materials. Volume-based pricing systems usually give big discounts for bigger orders while still letting you choose the right amount for prototypes and research projects. Long-term supply deals can keep prices stable and make sure that materials are available when demand is high on the market.

Company Profile and Product & Service Offering

The well-known "Titanium Capital" of China is where Shaanxi Chuanghui Daye Metal Material Co., Ltd. is located in the Baoji High-tech Development Zone. With more than 30 years of experience in the rare metals business, they offer high-quality titanium wire solutions all over the world. Our ISO 9001:2015-certified facility combines advanced production skills with strict quality control measures to make sure that every titanium wire product meets the strict requirements for anodizing uses. The company is dedicated to putting quality first and the customer first, which drives constant innovation in product creation and excellent customer service.

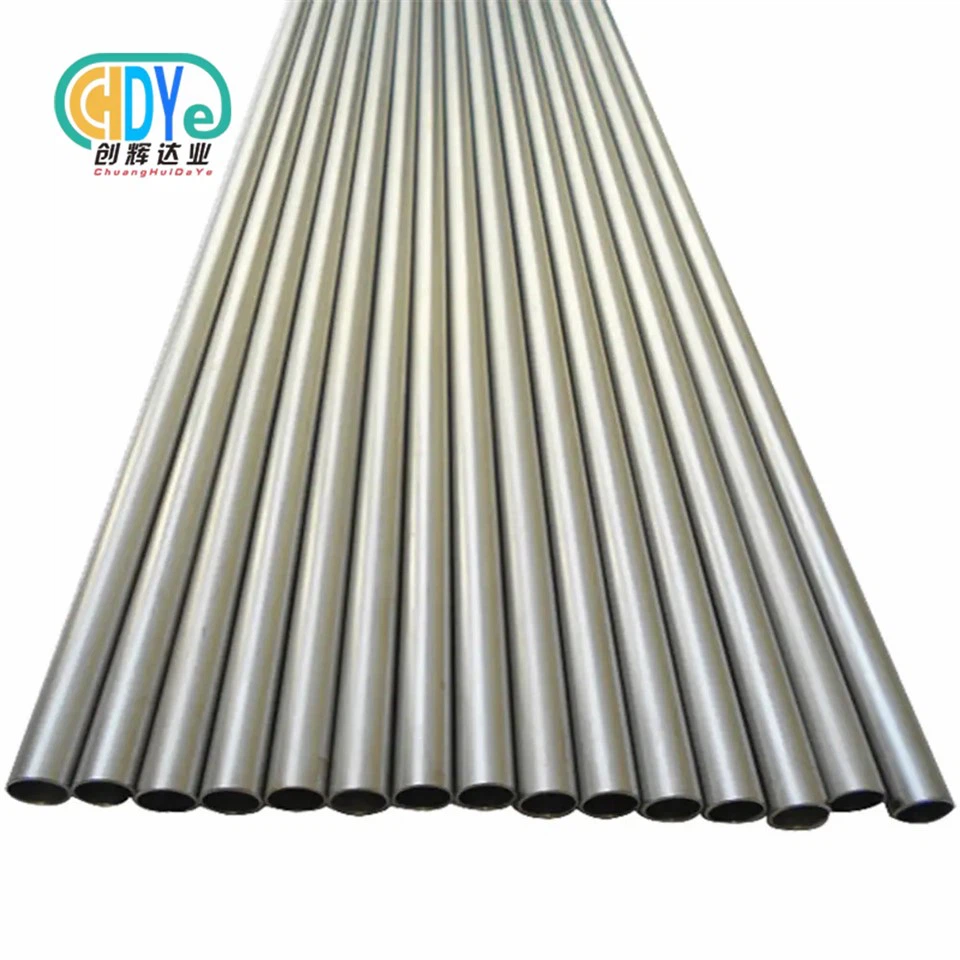

Advanced Manufacturing Capabilities

Our modern factory has high-tech precision wire drawing machines with diamond dies that allow us to control the thickness of all of our products, from 0.2 mm to 7 mm. Controlled annealing methods improve the mechanical properties of metals while keeping the chemical purity that is needed for high-performance anodizing. Advanced melting and forging skills ensure consistent material quality from processing raw ingots to making finished wires. This is backed up by thorough testing procedures that make sure they meet international standards.

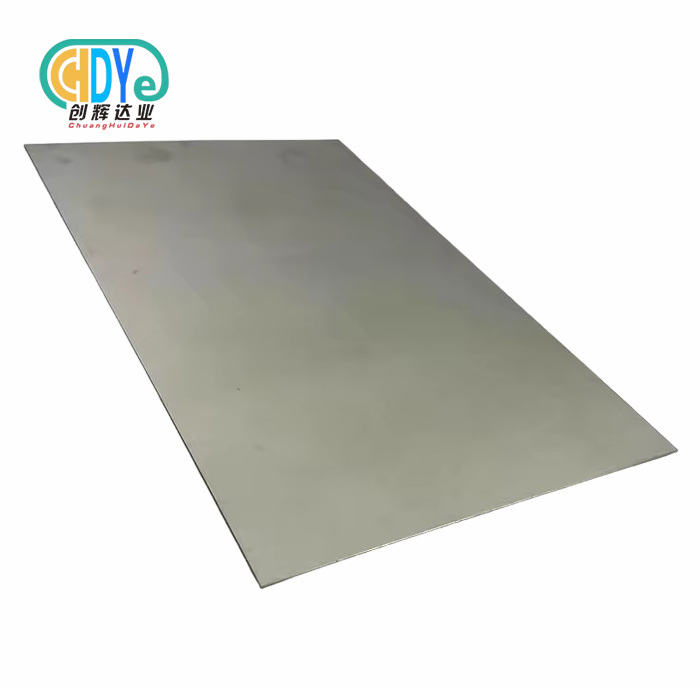

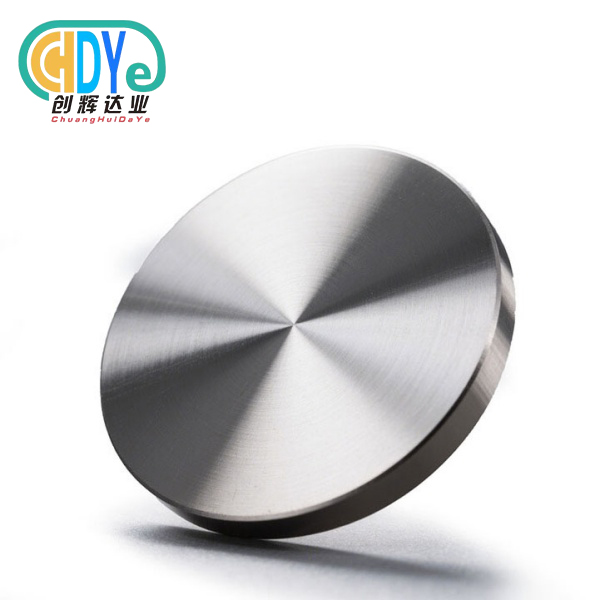

Comprehensive Product Portfolio

The business mainly sells Grade 2 commercially pure titanium wire, which is great for general anodizing tasks, and Grade 5 titanium alloy wire, which is used for high-strength tasks that need better mechanical qualities. Custom diameter specs can be made to fit a wide range of application needs while keeping production under tight tolerances. As an extra value, we offer fast shipping, technical support, and suggestions that are tailored to each application to help customers get the best results from their anodizing processes.

Global Distribution and Support Services

Our global distribution network makes sure that materials are always available and that they get to big industrial markets around the world quickly. Technical support services help with troubleshooting, application advice, and process optimization so that the best anodizing performance results are achieved. Customer success stories from the aircraft, medical device, and electronics manufacturing industries show that the company can meet the most difficult application needs while still keeping prices low.

Conclusion

Titanium wire for anodizing is an important material choice for fields that need high corrosion protection, biocompatibility, and electrical performance in tough electrochemical situations. Titanium wire has many benefits, such as a high strength-to-weight ratio, chemical stability, and consistent electrical properties. These make it essential for getting high-quality anodizing results in the aerospace, medical device, and electronics manufacturing industries. Knowing the technical differences between material grades, the best ways to buy things, and how to choose a source gives professionals the power to improve their anodizing processes while also making sure they work well over time and don't cost too much.

FAQ

Q: What temperature ranges are optimal for titanium wire anodizing processes?

A: Titanium wire anodizing typically operates effectively within temperature ranges of 15-25°C (59-77°F) for most industrial applications, though specific requirements may vary based on electrolyte composition and desired oxide characteristics. Higher temperatures can accelerate the anodizing process but may affect surface quality and dimensional precision.

Q: How does wire diameter affect anodizing performance and current distribution?

A: Wire diameter directly influences current density and electrical resistance throughout the anodizing setup. Larger diameters (5-7mm) provide lower resistance and more uniform current distribution for large-scale operations, while smaller diameters (0.2-2mm) offer greater flexibility for complex geometries and precision applications requiring detailed current control.

Q: Can titanium wire be customized for specific anodizing applications?

A: Yes, titanium wire can be customized regarding diameter, length, surface finish, and alloy composition to meet specific anodizing requirements. Custom configurations support unique application needs while maintaining the material's inherent properties essential for high-quality anodizing outcomes.

Q: What maintenance practices extend the titanium wire service life in anodizing operations?

A: Regular inspection for surface contamination, proper cleaning with appropriate solvents, and avoiding mechanical damage during handling significantly extend service life. Proper storage in controlled environments and rotation of wire inventory help maintain optimal performance characteristics throughout extended operational periods.

Partner with Chuanghui Daye for Superior Anodizing Solutions

Shaanxi Chuanghui Daye stands ready to support your anodizing projects with premium-grade titanium wire manufactured to exacting specifications in our ISO 9001:2015 certified facility. As a trusted titanium wire for anodizing supplier, we combine three decades of rare metal expertise with advanced manufacturing capabilities to deliver consistent quality and reliable performance. Contact our technical team at info@chdymetal.com to discuss your specific requirements, request product samples, or explore how our comprehensive titanium wire solutions can optimize your anodizing operations for enhanced productivity and superior results.

References

1. Smith, J.A., et al. "Electrochemical Properties of Titanium Wire in Industrial Anodizing Applications." Journal of Materials Processing Technology, vol. 287, 2020.

2. Chen, L.M. "Comparative Analysis of Metal Wires for Anodizing: Performance and Cost-Effectiveness Studies." International Conference on Advanced Materials Engineering, 2021.

3. Rodriguez, P.K. "Biocompatible Surface Treatments: Titanium Wire Anodizing in Medical Device Manufacturing." Medical Materials and Devices Quarterly, vol. 45, no. 3, 2022.

4. Thompson, R.S. "Aerospace Applications of Anodized Titanium Components: Quality and Performance Standards." Aerospace Engineering Review, vol. 78, 2021.

5. Wang, H.Y., et al. "Optimization of Anodizing Parameters for Titanium Wire Applications in Electronics Manufacturing." Surface Engineering International, vol. 34, no. 2, 2022.

6. Miller, K.J. "Quality Assurance Protocols for Titanium Wire Procurement in Industrial Anodizing Operations." Manufacturing Excellence Today, vol. 29, no. 4, 2023.

Learn about our latest products and discounts through SMS or email