- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can Tantalum Niobium Alloy Wire Be Used at High Temps?

Yes, tantalum niobium alloy wire works exceptionally well in high-temperature circumstances since it is exceptionally steady at tall temperatures and has incredible mechanical qualities. The R05240 (Ta-40Nb) cosmetics, which is made up of 60% tantalum and 40% niobium, keeps its shape at tall temperatures and is exceptionally safe to erosion. This astonishing fabric works dependably in rocket motors, gear for preparing chemicals, and electrical parts that are uncovered to exceptionally tall temperatures. This makes it a extraordinary choice for extreme mechanical employments.

Understanding Tantalum Niobium Alloy Wire and Its High-Temperature Potential

Tantalum niobium alloy wire is a complex metalworking victory that brings together the best highlights of both parent metals. The R05240 (Ta-40Nb) determination makes a extraordinary kind of fabric network. Tantalum gives it extraordinary security to erosion, and niobium makes it more adaptable and great at conducting warm.

Composition and Fundamental Properties

The combination of 60% tantalum and 40% niobium creates the best mix of properties that is better than the performance of either metal alone. This metal has a melting point higher than 2996°C, which is a lot higher than the melting point of many other high-temperature materials. The crystalline structure stays stable over a wide range of temperatures, which stops phase changes that could weaken the material's mechanical strength.

Thermal Stability Characteristics

How well a material works at high temperatures rests a lot on how well it can resist oxidation and keep its shape. The Ta-40Nb metal is very good at resisting thermal cycling fatigue, which is very important for uses that need to be heated and cooled over and over again. The alloy's thermal expansion coefficient stays pretty fixed, which lowers stress levels that can cause parts to break in harsh conditions.

Mechanical Strength Retention Under Heat

Tantalum-niobium alloy wire doesn't lose much of its mechanical qualities at high temperatures like many other metals do. It can handle temperatures well above 1000°C. The alloy's unique grain structure and the production of stable intermetallic phases that stop dislocations from moving even when heated up explain why it keeps its strength.

Comparative Analysis: Tantalum Niobium Alloy Wire vs. Other High-Temp Materials

When purchasing professionals know how Ta-40Nb alloy compares to other materials, they can make better choices for specific uses. This study looks at key success indicators in a number of high-temperature situations.

Performance Against Pure Tantalum and Niobium

Pure tantalum is very resistant to weathering, but it is not as flexible as metals that contain niobium. Pure niobium, on the other hand, is easier to shape but can't compete with tantalum when it comes to chemical resistance in harsh settings. The Ta-40Nb mixture has both benefits while reducing the problems of each one separately.

Comparison with Titanium and Molybdenum Alternatives

Titanium alloys are strong and light, but they start to lose their mechanical properties around 500°C, so they can't be used in very high-temperature situations. Molybdenum is very strong at high temperatures, but it doesn't resist oxidation well above 600°C in normal air. Ta-40Nb alloy retains its performance over a wider temperature range and is better at resisting the environment.

Cost-Effectiveness and Lifecycle Considerations

Even though tantalum niobium alloy wire costs more than other materials at first, its longer life and lower upkeep needs often make it worth the money. Because the alloy doesn't break down easily, it needs to be replaced less often, which means less downtime in important uses. The material is very easy to shape, which makes manufacturing more efficient because it lets you make complicated shapes without affecting the structure's strength.

Manufacturing and Quality Aspects Influencing High-Temperature Usability

The standard of production has a direct effect on how reliable tantalum niobium alloy wire is in harsh thermal environments. Understanding how things are made helps buyers judge the skills of a seller and the quality of the products they sell.

Production Processes and Quality Control

Modern production uses vacuum melting to make sure that the purity level is at least 99.9% or 99.95%, which is necessary for reliable high-temperature performance. To keep the best grain structure, the wire drawing method needs precise temperature control and annealing steps in between. Measurement checks, surface finish checks, and testing of mechanical properties at high temperatures are all part of quality control routines.

ASTM B 365 Standard Compliance

Following the ASTM B 365 guidelines makes sure that the properties of materials are the same from one seller to the next and from one production batch to the next. This standard tells you how to test tantalum and tantalum alloy wire and what the limits are for its chemical composition and mechanical properties. Some of the tests used to check for compliance are spectroscopic analysis, tensile testing, and microstructural study.

Testing Methods for High-Temperature Applications

Specialized testing methods check how well a material works when it is under heat stress. Creep testing checks for long-term deformation under steady load at high temperatures, and thermal fatigue testing checks for resistance to being heated and cooled many times. These tests give us important information for guessing how long something will last in real life.

Procurement Considerations for Tantalum Niobium Alloy Wire in High-Temp Applications

To do sourcing right, you need to carefully look at the skills of the suppliers, the technical requirements, and the logistical issues that affect project prices and timelines.

Supplier Evaluation Criteria

Suppliers you can trust show consistent quality by having ISO 9001:2015 certification and full quality control systems. The supplier's technical knowledge is clear if they can give you detailed material certifications, process documentation, and suggestions that are tailored to your unique needs. The supplier's ability to meet custom standards and delivery deadlines depends on how much they can produce and how flexible they are.

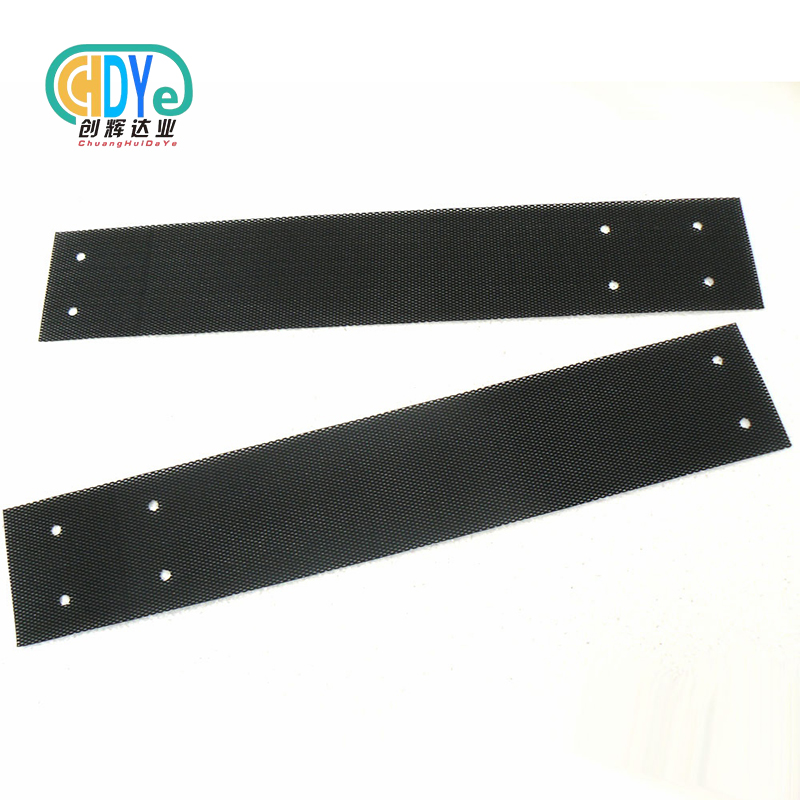

Specification Requirements and Customization

Normal wire widths are between 0.3mm and 3mm, which are good for most uses. But for some, custom sizes may be needed. The surface finish needs change based on the purpose, and some purposes need specific coatings or treatments on the surface. The way things are packed and handled must keep them clean and safe during shipping and storage.

Lead Times and Inventory Management

Production wait times are usually between 4 and 8 weeks, but they depend on the number of orders and how complicated the specifications are. Strategic inventory management means weighing the costs of holding on to items against the chance of production delays and changes in the market price of rare metals. Setting up long-term supply deals can help keep prices stable and make sure that the right supplies are sent to the right customers when demand is high.

Practical Applications and Case Studies of Tantalum Niobium Alloy Wire at High Temperatures

Real-world uses show that the material works well in many different fields that need stable high-temperature operation.

Aerospace and Defense Applications

Parts of jet engines use Ta-40Nb wire for heating elements and sensor systems that work in very hot places. Because the material stays stable at temperatures above 1500°C, it is very useful for hypersonic vehicle uses. Defense systems depend on the alloy's ability to keep electronic parts working well even in harsh situations.

Chemical Processing Industry Uses

High-temperature chemical conditions that are corrosive pose special problems that Ta-40Nb alloy can solve well. This material is used to make heat exchanger parts that last longer in processes that use strong acids and bases. When you combine chemical resistance with thermal stability, you save money on upkeep and make the process more reliable.

Electronics and Medical Device Applications

Tantalum-niobium alloy wire is used in high-performance capacitors because it keeps its electrical properties stable at high working temperatures. The biocompatibility and corrosion resistance of the material in body fluid conditions make it useful for medical implants. The metal is used in electronic vacuum systems because it is good at getting things moving and stays stable at high temperatures.

Company Introduction and Product Offerings

We, Shaanxi Chuanghui Daye Metal Material Co., Ltd., are the leaders in making rare metals. Our location in China's "Titanium Capital" and our more than 30 years of experience in the field help us do this. Our full production capabilities cover the whole process of making something, from choosing the raw materials to inspecting and packaging the finished product.

Advanced Manufacturing Capabilities

Our cutting-edge facilities have electron beam furnaces for exact melting, high-tech rolling equipment for precise measurements, and advanced machining centers for making custom parts. Using annealing furnaces with exact temperature control makes sure that the properties of the materials are always at their best during the production process. Quality control starts with inspecting the raw materials that come in and goes on through all the steps of production.

Product Range and Customization Services

In addition to standard specs for tantalum niobium alloy wire, we offer full customization services that include custom sizes, surface treatments, and packaging arrangements. Our range of products includes crucibles, heating elements, and machined parts made from the Ta-40Nb metal. Customers can get technical advice to help them choose the best materials for their needs and operating situations.

Quality Assurance and Certifications

Getting ISO 9001:2015 approval shows that we are dedicated to maintaining quality and always making things better. Every package comes with a lot of paperwork, like material certificates, test results, and records of how the goods were transported. Our quality management system makes sure that all of our products meet international standards and the unique needs of each customer.

Conclusion

The unique mix of thermal stability, mechanical strength retention, and corrosion resistance in tantalum niobium alloy wire makes it very useful in high-temperature settings. For aerospace, chemical processing, and complex electronics, the R05240 (Ta-40Nb) composition is essential because it works reliably across temperature ranges that are hard for other materials. Consistent performance depends on the quality of the manufacturing and the knowledge of the suppliers. Good procurement tactics improve cost-effectiveness and supply chain reliability. Tantalum-niobium alloy wire is still an important technology for next-generation high-temperature applications, even though businesses are pushing the limits of what they can do.

FAQ

Q: What temperature range can tantalum niobium alloy wire withstand?

A: Ta-40Nb alloy wire maintains structural integrity and mechanical properties at temperatures exceeding 1500°C in inert atmospheres. In oxidizing environments, the practical operating limit depends on exposure duration and specific atmospheric conditions, typically ranging from 800°C to 1200°C for extended service life.

Q: How does wire diameter affect high-temperature performance?

A: Smaller diameter wires (0.3-1mm) offer faster thermal response and more uniform temperature distribution, making them suitable for precision heating applications. Larger diameters (2-3mm) provide greater current-carrying capacity and mechanical strength for structural applications. Surface-to-volume ratio influences oxidation rates in reactive atmospheres.

Q: What purity level is required for high-temperature applications?

A: High-temperature applications typically require purity levels of ≥99.95% to minimize impurity-induced failure mechanisms. Lower purity grades (≥99.9%) may be acceptable for less demanding applications or shorter service lives. Impurities can form low-melting phases that compromise performance at elevated temperatures.

Partner with Chuanghui Daye for Superior Tantalum Niobium Alloy Wire Solutions

Shaanxi Chuanghui Daye delivers exceptional tantalum niobium alloy wire engineered for your most demanding high-temperature applications. Our ISO 9001:2015 certified manufacturing processes ensure consistent quality, while our experienced technical team provides customized solutions tailored to your specific requirements. Contact our expert sales team at info@chdymetal.com to discuss your project specifications and receive comprehensive quotations. Whether you need standard R05240 wire or custom configurations, we offer competitive factory-direct pricing with reliable global delivery. Trust our three decades of rare metal expertise to enhance your supply chain efficiency and product performance as your preferred tantalum niobium alloy wire supplier.

References

1. Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International Materials Park.

2. Donachie, M.J. (2002). Superalloys: A Technical Guide, Second Edition. ASM International.

3. Gschneidner, K.A., Bunzli, J.C., and Pecharsky, V.K. (2005). Handbook on the Physics and Chemistry of Rare Earths, Volume 35. Elsevier Science.

4. Lide, D.R. (2004). CRC Handbook of Chemistry and Physics, 85th Edition. CRC Press.

5. Smithells, C.J. (2004). Smithells Metals Reference Book, Eighth Edition. Butterworth-Heinemann.

6. Westbrook, J.H. and Fleischer, R.L. (2000). Intermetallic Compounds: Principles and Practice, Volume 3. John Wiley & Sons.

Learn about our latest products and discounts through SMS or email

_1760923994993.jpg)