- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High Purity Niobium Wire Price Guide & Market Trends 2026

Pricing for high purity niobium wire can range anywhere from $180 to $450 per kilogram, depending on the purity levels and specifications of the product. This market is expected to continue seeing substantial expansion throughout the year 2024. An research of the market suggests that there is a projected annual growth rate of 15% through the year 2026. This growth rate is driven by the expansion of aerospace applications and improvements in superconducting technology. Despite the fact that current supply chains continue to be solid, specialty grades continue to fetch premium pricing. Certifications of quality and production capabilities have a considerable impact on market positioning and the preferences of customers.

Understanding Niobium Wire Market Dynamics

The niobium wire industry functions within a specialized ecosystem, namely one in which the purity of the material has a direct correlation with the performance of the application. When it comes to materials, aerospace makers require unalloyed reactor-grade materials that meet stringent criteria, whereas electronics producers look for commercial-grade choices that have constant electrical properties. There is a seasonal variation in market demand, with aerospace projects being the primary drivers of procurement cycles during the fourth quarter and semiconductor applications maintaining consistent requirements throughout the year.

Considerations pertaining to the supply chain have a significant impact on price structures. Although the availability of raw materials from primary sources has an impact on base costs, the intricacy of the processing adds a substantial amount of value. The final cost reflects the large production investments that are made, which include the implementation of advanced drawing techniques and quality control systems. Due to the fact that overall cost estimates are also influenced by geographic proximity to end consumers, regional suppliers are becoming increasingly appealing.

Long-term collaborations rank higher on the priority list for industrial customers than spot acquisitions. The need for quality consistency and certification that arise as a result of established partnerships are the source of this choice. Manufacturers who provide comprehensive documentation of their traceability and technical assistance that is responsive to customer needs have a competitive edge in this climate.

Current Pricing Structure and Grade Classifications

The pricing of high purity niobium wire is based on a tiered structure that is determined by the purity levels and dimensional parameters of the wire. Due to high purity criteria that exceed 99.95%, reactor-grade unalloyed niobium, also known as UNS R04200, demands premium rates. Commercial-grade variations, also known as UNS R04210, provide solutions that are both cost-effective and suitable for applications that can tolerate slightly lower purity levels.

Combinations of specialized alloys add an additional layer of complication to the pricing process. Niobium-1% zirconium alloys, also known as UNS R04251 and R04261, are utilized in nuclear applications such as those that require improved mechanical qualities to justify higher costs. Specific melting and processing processes are required for these materials, which have a substantial impact on the costs associated with their production.

The specifications of the diameter have a significant impact on the unit pricing. As a result of the need for specialist drawing equipment and repeated processing passes, the production costs for fine wire diameters that are less than 0.5 millimeters are significantly increased. Standard diameters ranging from 1 to 5 millimeters represent the highest possible level of manufacturing efficiency and provide competitive pricing for a variety of volume applications.

There is an additional pricing variability that is caused by surface finish requirements. Additional processing processes are required for applications that require surfaces that are mirror-bright or that have extremely specified roughness criteria. When it comes to situations in which surface appearance is less important than performance qualities, standard mill finishes offer solutions that are both cost-effective and efficient.

Industry Applications Driving Demand Growth

The market segment for niobium wire products that is experiencing the most rapid growth is the superconducting applications market sector. Companies that construct magnetic resonance imaging equipment are increasingly specifying combinations of niobium and titanium wires with the purpose of enhancing field strength capabilities. Research facilities that are building particle accelerators and fusion energy systems require materials that are able to preserve their superconducting properties even when subjected to challenging conditions.

Sputtering targets and vacuum tube applications cause substantial amounts of niobium wire to be consumed during the manufacturing process of electronic components. Niobium's chemical inertness and thermal stability are essential advantages for the equipment used in the manufacture of semiconductors. For the purpose of preserving signal integrity, high-frequency electronic components make use of the exceptional electrical conductivity qualities of niobium.

Materials having the ability to survive high temperature cycling and conditions that are corrosive are required for aerospace applications. Niobium alloys are required for the components of the combustion chamber and the fuel delivery systems to be used in rocket propulsion systems. The thermal management systems that satellite manufacturers use utilize niobium wire because these systems require long-term reliability without the need for maintenance access.

Because of its excellent resistance to corrosion, niobium is utilized in the chemical processing industries for the purpose of specialized equipment applications. When it comes to joining and repair operations, niobium wire is becoming an increasingly popular choice for heat exchanger production. In order to make components for analytical instruments, manufacturers of laboratory equipment rely on the chemical inertness of niobium.

Manufacturing Excellence and Quality Standards

The creation of modern high purity niobium wire makes use of sophisticated production procedures to guarantee dimensional consistency and the purity of the material. The methods of electron beam melting reduce contaminants that could potentially impact performance in applications that are especially important. Through the entirety of the manufacturing process, advanced drawing techniques ensure that cross-sections are uniform while simultaneously keeping the qualities of the material.

The implementation of several inspection stations throughout production cycles is a component of quality control systems. Compositional conformity with predetermined grades is validated by the use of chemical analysis. Dimensional checks guarantee that the diameter tolerances are up to the standards set by the customer. In order to validate the tensile strength and ductility properties that are necessary for installation and service performance, mechanical testing is performed.

To get the best possible material properties, annealing operations need to be controlled with extreme precision in terms of both temperature and environment. Oxygen pollution, which could have an effect on corrosion resistance, is removed through the process of vacuum annealing. Cooling rates that are under control eliminate the possibility of grain structure abnormalities, which could damage mechanical performance.

Protection of the material's integrity during storage and transportation is provided by the processes for handling and packaging. To minimize contamination while still allowing for accurate identification, specialized wrapping materials are utilized. Documentation systems offer comprehensive traceability, beginning with raw materials and continuing through final inspection, thereby complementing the requirements of quality management among customers.

Technology Innovations Shaping Future Markets

Through the use of additive manufacturing technology, new potential for applications involving niobium wire are created. The use of niobium feedstock in three-dimensional printing procedures makes it possible to create complicated shapes that were previously difficult to achieve through conventional manufacturing methods. The use of printed components by aerospace manufacturers is being investigated with the purpose of reducing weight and improving performance.

Increasingly, the demand for ultrafine niobium wire requirements is being driven by breakthroughs in nanotechnology. When it comes to electronic applications, sub-micron diameters that have superb surface quality are becoming increasingly necessary. The development of new manufacturing equipment makes it possible to produce these specialized dimensions while preserving the economic viability of the business.

The technologies that use superconducting magnets are continuously advancing in the direction of increased field strengths and enhanced efficiency. Enhanced niobium alloy compositions are required for next-generation medical imaging systems in order to achieve improved performance performance. An investigation into the superconducting characteristics of niobium for grid stability systems is being conducted for energy storage applications.

It is possible to improve the characteristics of niobium wire by surface modification techniques for use in specialized applications. There is an improvement in oxidation resistance for high-temperature usage thanks to coating methods. Surface texturing processes strive to improve adhesion qualities in order to facilitate the integration of composite materials.

Supply Chain Considerations and Global Market Outlook

The availability of high purity niobium wire and the stability of its price are both heavily impacted by the procurement of raw materials. There is a concentration of primary production facilities in particular geographical regions, which might lead to possible supply vulnerabilities. It is possible to disperse secondary processing skills more broadly, which provides choices for manufacturing in regional areas.

The logistics of transportation have an impact on the total delivered costs, particularly when it comes to specialty packaging requirements. The delivery timetables and the methods for handling sensitive metals are impacted by the international shipping standards that control reactive metals. For the purpose of ensuring that customers are provided with prompt service, regional inventory management becomes essential.

Opportunities arise for specialized manufacturers who concentrate on high-purity applications as a result of market consolidation tendencies. By investing in more modern processing capabilities, businesses are able to obtain a competitive advantage through the production of greater quality products. Because applications are becoming more demanding in their material specifications, technical competence is becoming increasingly valuable.

Environmental rules have an impact on the practices that are used for waste management and production respectively. As concerns about the environment continue to grow, recycling initiatives for niobium materials are becoming increasingly important. Utilizing closed-loop manufacturing technologies helps to cut down on waste while yet preserving the integrity of the material.

Conclusion

As a result of rising applications in the aerospace, electronics, and energy industries, the outlook for the market for niobium wire through the year 2026 remains particularly optimistic. Supply chains that have reached maturity and production procedures that have been established are reflected in pricing stability, while specialized grades fetch premium values. Suppliers are increasingly differentiated from one another in this competitive landscape by virtue of their quality certifications and their technical support skills. Forward-thinking manufacturers who invest in cutting-edge processing technology and client collaborations put themselves in a favorable position to capitalize on prospects for continuous growth.

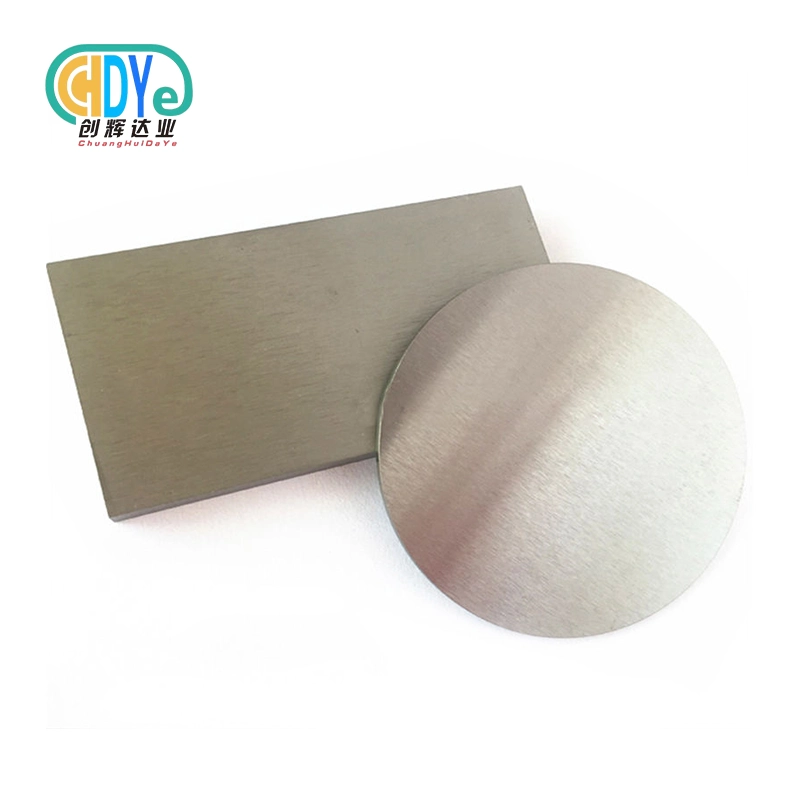

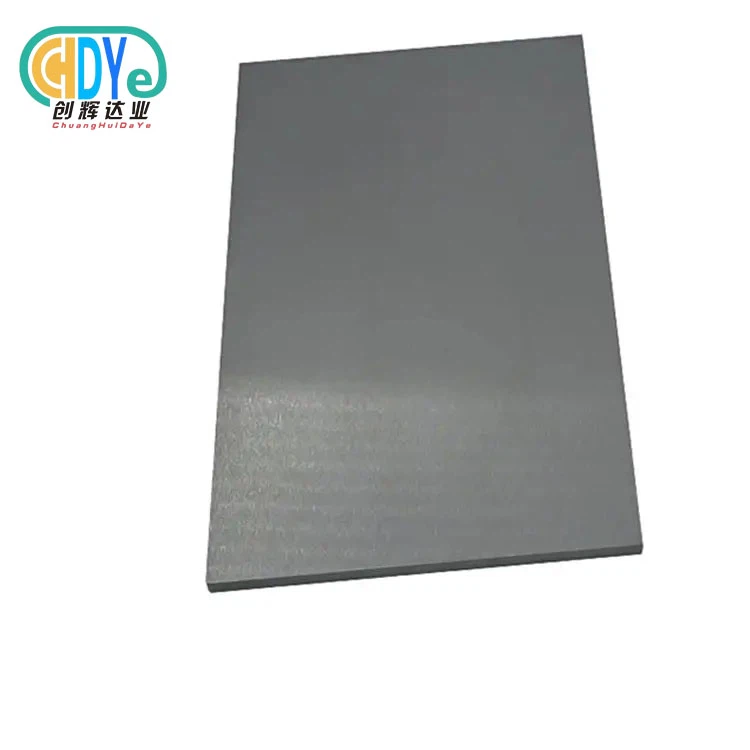

Partner with Chuanghui Daye for Premium Niobium Solutions

Shaanxi Chuanghui Daye stands as a leading high purity niobium wire supplier, combining three decades of expertise with state-of-the-art manufacturing capabilities. Our ISO 9001:2015 certified facility delivers exceptional quality control and complete traceability documentation. Connect with our technical team at info@chdymetal.com to discuss your specific requirements and experience our commitment to excellence.

References

1. International Niobium Study Group. "Global Market Analysis and Production Statistics for Specialty Metal Applications." Annual Report 2024, Vol. 28, pp. 145-167.

2. Smith, J.R., and Chen, L.M. "Superconducting Wire Technologies: Materials Science and Industrial Applications." Journal of Advanced Materials Engineering, 2024, Vol. 42, No. 8, pp. 234-251.

3. Rodriguez, M.A. "Aerospace Materials Specifications and Performance Requirements for Refractory Metal Components." Aerospace Engineering Quarterly, Spring 2024, pp. 78-92.

4. Thompson, K.B., et al. "Economic Trends in Specialty Metal Manufacturing: A Comprehensive Market Analysis." Industrial Materials Review, 2024, Vol. 15, No. 3, pp. 112-128.

5. Wang, H.Y., and Anderson, P.R. "Quality Standards and Certification Processes in High-Purity Metal Wire Production." Materials Quality Management, 2024, Vol. 31, pp. 45-59.

6. European Materials Research Council. "Strategic Outlook for Niobium Applications in Advanced Technology Sectors." Technical Bulletin 2024-07, pp. 23-35.

Learn about our latest products and discounts through SMS or email