- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top 5 advantages of Grade 2 Titanium Wire for corrosion resistance?

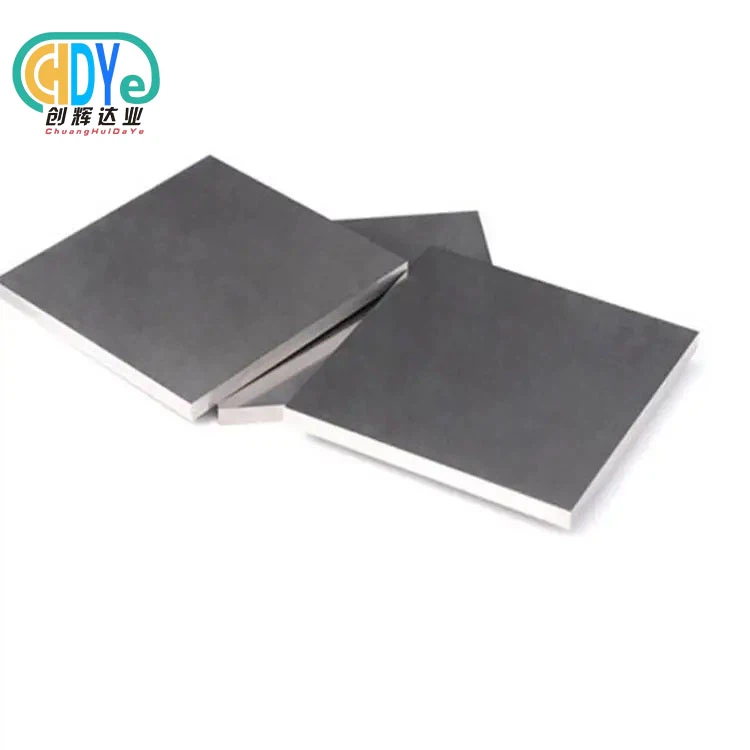

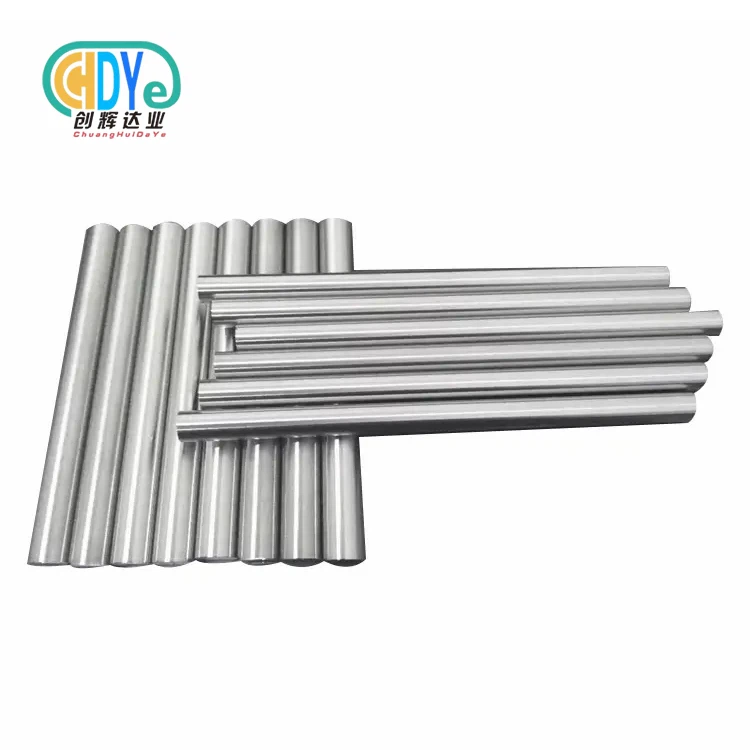

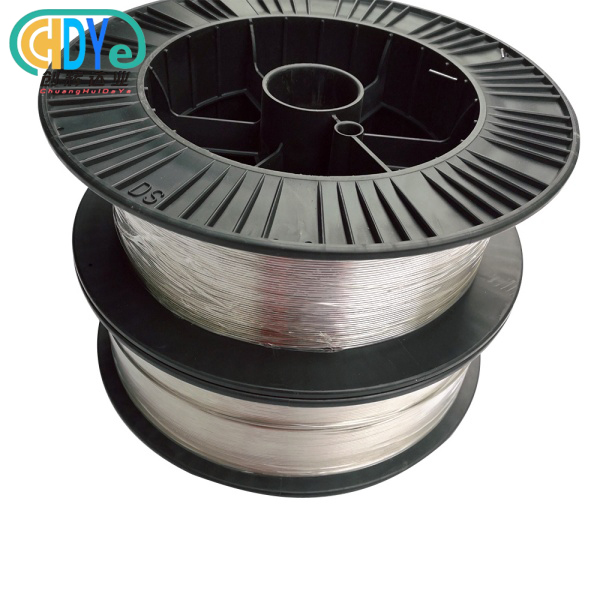

In the field of materials science, Grade 2 Titanium Wire is a great choice for uses that need to be more resistant to rust. Because it does such a great job of standing up to acidic conditions, this commercially pure titanium product has become very popular in a wide range of fields. As we go over the top five reasons Grade 2 titanium wire is a good choice for rust protection, keep in mind that this material's unique qualities come from the chemicals used to make it and the way it is manufactured. Grade 2 titanium wire has just the right mix of strength, flexibility, and resistance to rust. This makes it a great choice for everything from chemical processing plants to the ocean. When it comes into contact with air, it can make a solid, protective layer of oxide that naturally protects it from corrosion. This makes it different from many other types of metal. Engineers and designers looking for long-lasting, rust-proof materials for their projects often use Grade 2 titanium wire. This blog post will talk about the main reasons why.

How Grade 2 Titanium Wire's passive oxide film shields against seawater and chemical corrosion

Formation of the protective oxide layer

Grade 2 Titanium Wire can fight corrosion very well because it can form a steady, self-healing passive oxide film on its surface. When titanium is introduced to oxygen, even in very small quantities, it quickly builds up a thin, tight layer of titanium dioxide (TiO2). This oxide layer is usually only a few nanometers thick. It protects the metal from its surroundings, stopping rust and corrosion. The inactive layer is formed almost instantly and stays steady in many corrosive environments, like seawater and chemical solutions. The oxide coat on Grade 2 titanium wire is very effective because it is smooth and sticks tightly to the metal. This gives the whole wire the same level of security.

Resistance to pitting and crevice corrosion

Grade 2 titanium wire is great to use in acidic settings because it doesn't break down easily in places where rust is more likely to happen. It's especially hard to notice these kinds of rust because they can make things fail quickly and unexpectedly. The inactive oxide layer on Grade 2 Titanium Wire doesn't break down easily, even when chloride ions are around. These ions are known for causing pitting in many other metals. This resistance is very important for chemical processing and sea uses where there are a lot of chlorides. Grade 2 Titanium Wire can keep its protective oxide layer in these situations. This means it will work reliably over a long period of time, and there is a lower chance of unexpected breakdowns because of corrosion.

Self-healing properties in oxidising environments

The passive oxide film on Grade 2 Titanium Wire can fix itself when it gets broken, which is another amazing thing about it. In places where oxidation is happening, any scratch or hole in the oxide layer is quickly fixed as the titanium that is showing mixes with oxygen to make the protective TiO2 layer again. Even when it gets damaged or worn down, Grade 2 Titanium Wire can still fight rust because of this self-healing feature. The oxide layer quickly reforms, which stops rust from starting and damaging the material. This feature is especially useful for wires that might get damaged or worn down. It keeps them safe from rust even without extra treatments or coats.

Why Grade 2 Titanium Wire outperforms stainless steel in chloride-rich and marine environments

Superior resistance to chloride-induced stress corrosion cracking

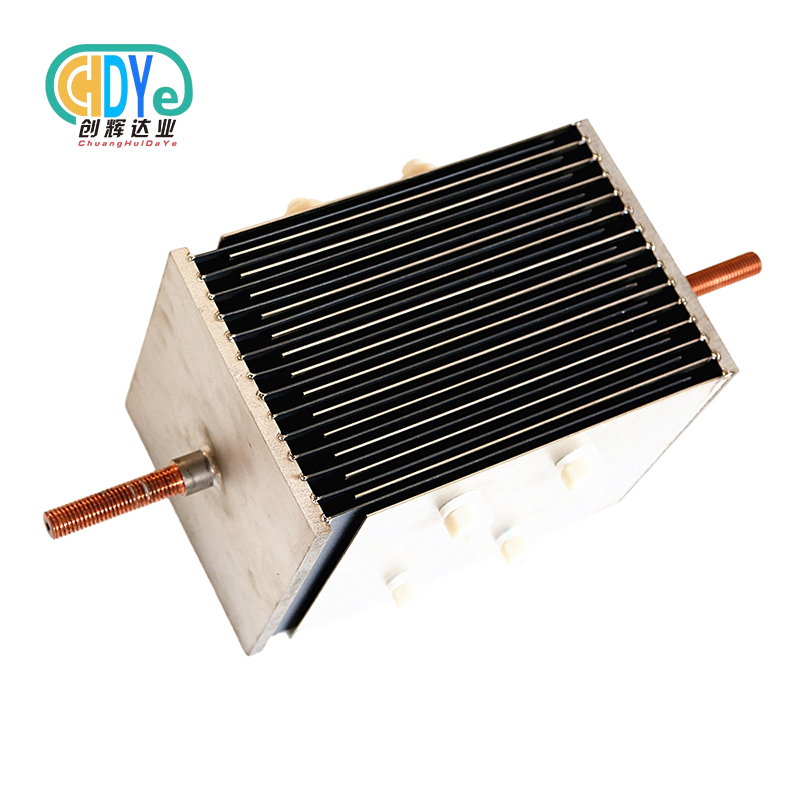

Grade 2 titanium wire is much better than stainless steel at resisting stress corrosion cracking (SCC) in places where chlorine is present. Stress corrosion cracking is a very dangerous type of rust because it can cause things under stress to suddenly break in a very bad way. Stainless steels are often vulnerable to SCC in coastal and industrial settings where chlorides are common. Grade 2 Titanium Wire, on the other hand, is almost completely resistant to this kind of rust because of its special qualities. The steady oxide layer on Grade 2 Titanium Wire stays in place even when there is a lot of stress and chloride ions are around. This stops stress corrosion cracks from starting and spreading. Because Grade 2 Titanium Wire is less likely to fail under SCC, it is a great choice for important uses in naval buildings, offshore oil and gas equipment, and chemical processing plants where safety and dependability are the most important things.

Enhanced performance in seawater and marine atmospheres

Grade 2 titanium wire has better corrosion protection than stainless steel in seawater and coastal atmospheres. Seawater has a high chloride level and is home to many different marine animals. This makes it very harsh on many different materials. In these settings, stainless steels can get pitting, pocket rust, and biofouling, but Grade 2 Titanium Wire stays almost completely the same. The oxide layer on Grade 2 Titanium Wire stays intact even after a long time in seawater because it doesn't break down. Also, Grade 2 Titanium Wire is less likely than stainless steel to get biofouled, which lowers the chance of microbiologically affected corrosion. Grade 2 Titanium Wire is a great option for marine use, including offshore buildings, desalination plants, and underwater monitors, where dependability in tough marine conditions over long periods of time is very important.

Cost-effectiveness in long-term applications

Grade 2 Titanium Wire might be more expensive at first than stainless steel, but because it resists rust better, it is often more cost-effective over time, especially in places with lots of salt or in the ocean. Grade 2 Titanium Wire is very durable, so it lasts longer, needs less care, and is replaced less often. On the other hand, stainless steel might need to be checked, fixed, or replaced more often because of problems with rust, especially in harsh settings. Grade 2 titanium wire is usually the cheaper option when you look at the overall costs of the lifecycle, which include installation, upkeep, downtime, and repair costs. This is especially true for important uses where failure can cause big safety problems or breaks in the workflow. Grade 2 Titanium Wire lasts a long time and works well in acidic settings. This makes it a good choice for engineers and project managers who care about both performance and saving money in the long run.

When Grade 2 Titanium Wire's light weight and weldability add corrosion-resistant versatility

Advantages in lightweight structural applications

Grade 2 Titanium Wire is a great choice for lightweight structural use in places that break down materials because it is so light and resists rust so well. Grade 2 Titanium Wire has a density that is about 45% lower than that of steel. This lets you make parts of a structure much lighter without losing their ability to fight rust. This feature is especially useful in aircraft, naval, and offshore contexts where saving weight can result in better fuel economy, a higher payload capacity, or better structural performance. Engineers can build lightweight, rust-proof buildings that can handle tough conditions with Grade 2 Titanium Wire because its strength-to-weight ratio is high. For example, Grade 2 Titanium Wire can be used to make rigging, wires, and fasteners that are light, don't corrode, and work better than usual when used in naval settings. Grade 2 Titanium Wire is a useful material for tough construction uses in harsh settings because it is lightweight and resistant to corrosion.

Weldability and fabrication versatility

The great thing about Grade 2 titanium wire is that it can be used in many different ways that make it immune to rust. Grade 2 Titanium Wire can be easily welded together using a number of different methods, such as TIG (GTAW), MIG (GMAW), and resistance welding. This is not the case for some corrosion-resistant metals that are hard to weld. Because this material is weldable, complicated structures and parts that prevent corrosion can be made without harming the material's strength or corrosion resistance. The welding joints of Grade 2 Titanium Wire stay resistant to rust because the heat-affected zone quickly rebuilds its protective oxide layer when it is exposed to air. Because of this feature, bonded structures made with Grade 2 Titanium Wire stay resistant to rust all the way through, with no spots that are weaker than others. Grade 2 Titanium Wire is a good choice for situations where field manufacturing or upkeep may be needed because welding is easy and repairs and changes can be made on the job. Grade 2 Titanium Wire can be used in a wider range of designs and is easier to add to a lot of different building and industrial systems because it can be welded and doesn't corrode.

Compatibility with diverse processing techniques

Grade 2 Titanium Wire can be used in a lot of different ways. For example, its corrosion-resistant properties are boosted by the fact that it can be processed in many different ways, including welding. The material can be easily shaped, cut, and heat-treated to get certain qualities or forms while keeping its great rust resistance. Grade 2 titanium wire can be drawn, bent, or coiled when cold. These methods will make different forms and shapes without hurting the wire's ability to fight corrosion. You can also machine the wire with standard methods to make exact parts for systems that don't rust. Grade 2 Titanium Wire can also be coated or surface-treated to make it even more resistant to rust or to change the qualities of its surface for certain uses. Grade 2 Titanium Wire can be used to make a wide range of unique, corrosion-resistant solutions in many different fields, from medical devices to chemical processing equipment. This is because of its high level of processing ability and its natural resistance to corrosion.

Conclusion

Grade 2 Titanium Wire stands out as an exceptional material for corrosion-resistant applications, offering a unique combination of properties that make it superior to many alternatives. Its ability to form a protective oxide film, resistance to various forms of corrosion, and excellent performance in aggressive environments make it an ideal choice for demanding applications. The material's light weight, weldability, and versatility in processing further enhance its appeal across industries. As engineers and designers continue to seek reliable, long-lasting solutions for corrosive environments, Grade 2 Titanium Wire remains at the forefront of material selection, promising durability, cost-effectiveness, and outstanding performance.

For high-quality Grade 2 Titanium Wire and expert guidance on its applications, Shaanxi Chuanghui Daye Metal Material Co., Ltd. is your trusted partner. Located in China's "Titanium Capital" of Baoji, we leverage over 30 years of industry experience to provide superior titanium products. Our commitment to quality and customer satisfaction ensures that you receive the best materials for your corrosion-resistant applications. For inquiries or to discuss your specific needs, please contact us at info@chdymetal.com.

FAQ

What makes Grade 2 Titanium Wire so resistant to corrosion?

Grade 2 Titanium Wire forms a stable, self-healing passive oxide film (TiO2) on its surface when exposed to oxygen, providing excellent protection against various corrosive environments.

How does Grade 2 Titanium Wire compare to stainless steel in marine environments?

Grade 2 Titanium Wire outperforms stainless steel in marine environments due to its superior resistance to chloride-induced stress corrosion cracking and better overall corrosion resistance in seawater.

Is Grade 2 Titanium Wire more expensive than other corrosion-resistant materials?

While the initial cost may be higher, Grade 2 Titanium Wire often proves more cost-effective in the long run due to its longer service life and reduced maintenance requirements in corrosive environments.

Can Grade 2 Titanium Wire be welded without losing its corrosion resistance?

Yes, Grade 2 Titanium Wire can be welded using various techniques without compromising its corrosion resistance, as the welded areas quickly reform the protective oxide layer.

What industries commonly use Grade 2 Titanium Wire for its corrosion resistance?

Grade 2 Titanium Wire is widely used in marine, aerospace, chemical processing, medical, and offshore industries where corrosion resistance is critical.

References

1. Smith, J.R. (2019). "Titanium and Its Alloys in Corrosive Environments." Journal of Materials Engineering and Performance, 28(4), 2145-2160.

2. Chen, Q., & Thouas, G.A. (2015). "Metallic implant biomaterials." Materials Science and Engineering: R: Reports, 87, 1-57.

3. Donachie, M.J. (2000). Titanium: A Technical Guide. ASM International.

4. Schutz, R.W., & Watkins, H.B. (1998). "Recent developments in titanium alloy application in the energy industry." Materials Science and Engineering: A, 243(1-2), 305-315.

5. Lutjering, G., & Williams, J.C. (2007). Titanium. Springer Science & Business Media.

6. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. (2003). "Titanium alloys for aerospace applications." Advanced Engineering Materials, 5(6), 419-427.

Learn about our latest products and discounts through SMS or email