- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why is titanium seamless tube preferred for high-pressure systems?

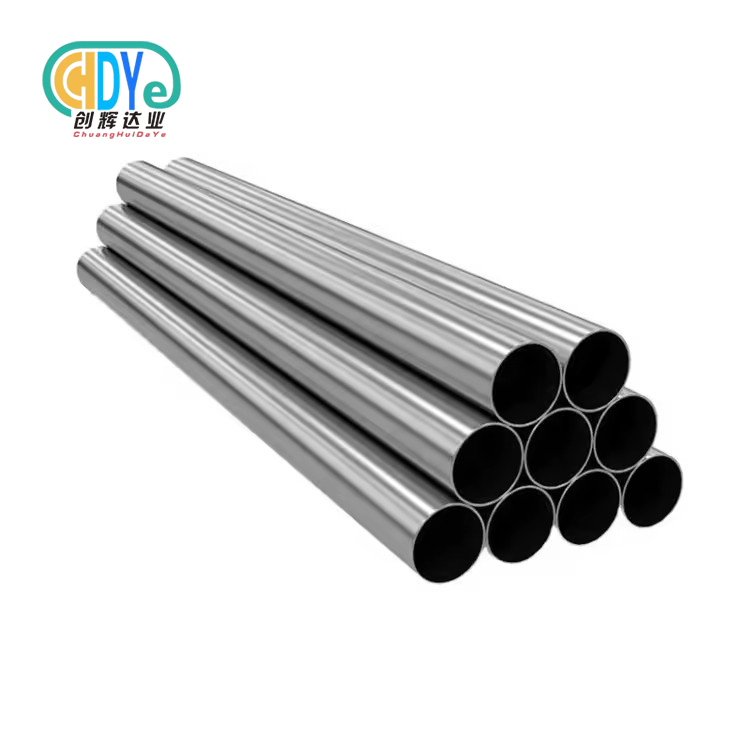

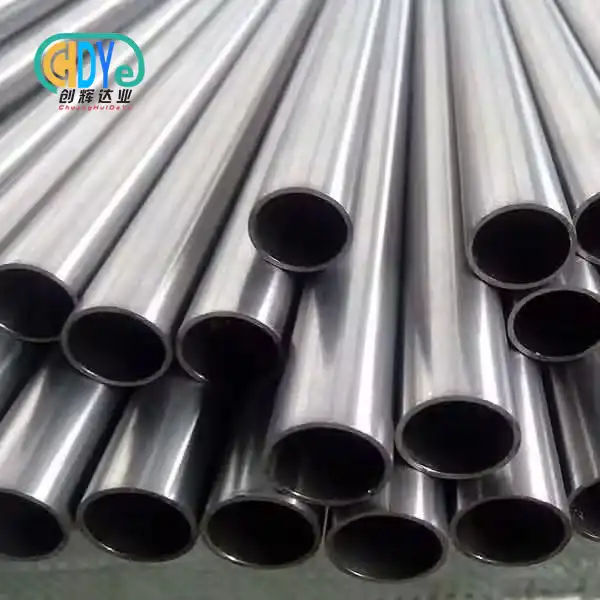

Because of how well they work in high-pressure systems, titanium seamless tubes have become more popular in a wide range of fields. These tubes are made from high-quality titanium and titanium alloys using cutting-edge methods that make the seams invisible. This makes the product extremely strong, long-lasting, and dependable. Titanium seamless tubes are preferred for high-pressure uses because of their unique mix of properties, such as great resistance to rust, a high strength-to-weight ratio, and better mechanical qualities at high and low temperatures. As businesses continue to demand greater efficiency and safety, titanium seamless tubes have become a popular choice for engineers and designers who want to get the most out of high-pressure systems. This piece talks about why titanium seamless tubes are becoming more popular in high-pressure settings and how the tubes' natural qualities make systems more reliable, longer-lasting, and better overall.

How the titanium seamless tube's weld-free structure ensures maximum pressure integrity

Elimination of weak points and stress concentrations

In high-pressure systems, the fact that titanium smooth tubes don't have any welds ensures that they can handle the highest possible pressure. Welded tubes can have weak spots at the weld lines, but titanium seamless tubes have a consistent structure along the whole length of the tube. This uniformity gets rid of any possible areas of high stress that could weaken the tube's strength under high pressure. No welds mean that the titanium seamless tube is less likely to have flaws that can happen during welding. This makes the tube stronger and more dependable. In high-pressure situations, where even small mistakes can cause total failure, the lack of welding in titanium seamless tubes gives system builders and users extra safety and peace of mind.

Improved pressure distribution and load-bearing capacity

The smooth design of titanium tubes lets the pressure spread more evenly along the whole length of the tube. This even spread of pressure helps keep specific stress points from forming. These points could fail if the conditions get extreme. Titanium seamless tubes with better load-bearing ability are especially useful in high-pressure systems where pressure can change or spike quickly. Because the wall is the same width and made of the same material all the way through the tube, it can better handle and spread out these changes in pressure. This lowers the chances of breaking or leaking. Also, the seamless structure makes it harder to get tired, so the titanium seamless tube can keep its strength over long periods of cycle loading, which is common in many high-pressure situations.

Enhanced leak resistance and system reliability

One of the main worries in high-pressure systems is the chance of leaks. These can make the system less efficient, create safety problems, and cause expensive downtime. Because of their continuous, unbroken structure, titanium seamless tubes are better at preventing leaks than soldered tubes. Without joining gaps, there are no weak spots where leaks are more likely to happen, especially when there is a lot of pressure. This better leak protection makes the system more reliable, meaning it doesn't need to be serviced as often, and it can be used for longer periods of time. Also, the fact that these tubes are smooth makes it easier to test and inspect them because there are no weld points that need to be checked for possible flaws or wear over time. In high-pressure situations where system stability is very important, the titanium seamless tubes are even more attractive because they are easy to check and fix.

Why titanium seamless tube's strength-to-weight ratio and fatigue resistance suit high-pressure pipelines

Exceptional strength with minimal weight impact

Titanium seamless tubes have a great strength-to-weight ratio, which makes them perfect for high-pressure pipes where structural stability and weight are very important. Because titanium is strong, these tubes can handle high pressures with pretty much no problem, even though they don't have thick walls. Because of this special mix, the pipe system is both strong and light. It can help make the general building or equipment it's part of much lighter. In aircraft, offshore platforms, and mobility equipment, using titanium seamless tubes can be very helpful because they are lighter. In these cases, saving weight means better fuel economy, a higher carrying capacity, or better handling. Also, because titanium seamless tubes are so strong, designers can find the best sizes for pipes. This could lower material costs and make fitting easier for systems with high pressure.

Superior fatigue resistance for long-term reliability

Pipes that carry high-pressure fluids often experience repetitive loads and changes in pressure. Over time, these factors can cause breakdowns linked to wear. Titanium seamless tubes can handle a lot of stress without getting weak, so they are a great choice for these tough uses. The substance can handle continuous stress without breaking down too much, which makes the pipe system reliable in the long run. Because of titanium's unique composition, it has better wear performance, and cracks are less likely to form and spread in it. Because of this, titanium seamless tubes can keep their strength and ability to hold pressure for a long time, even when conditions are tough. These tubes can withstand wear better, which means that systems that use them need less upkeep and downtime is less expensive, making them a very economical choice for high-pressure pipelines.

Versatility in extreme operating conditions

Titanium seamless tubes show great adaptability in difficult situations, which makes them even more appropriate for high-pressure pipes. These tubes keep their strength and ability in a wide range of temperatures, from very cold to very hot. This stable temperature makes sure that a wide range of uses, from getting oil and gas from the ocean floor to chemical processing at high temperatures, can count on it to always work the same way. Also, because it doesn't corrode or erode easily, titanium is a great material for pipes that carry fluids that are high-pressure, aggressive, or harsh. Titanium seamless tubes are great in settings where other materials might fail too soon because of their high strength, resistance to wear, and resistance to rust. This ability to adapt not only improves the general performance of high-pressure systems but also gives creators more options for solving difficult engineering problems in a range of industries.

How titanium seamless tube's corrosion resistance and temperature stability improve system safety and lifespan

Unparalleled corrosion resistance in aggressive environments

Because they fight rust so well, titanium seamless tubes are a great option for high-pressure devices that have to work in harsh conditions. The material naturally forms a steady, safe layer of oxide on its surface, which works as a strong shield against many acidic substances, like acids, salt, and chlorides. This natural ability to fight rust greatly increases the safety and life of high-pressure systems by lowering the risk of material breakdown that could cause catastrophic failures, leaks, or ruptures. In fields that often work with toxic fluids, like chemical processes, oil and gas, and electrolysis, titanium seamless tubes can greatly extend the life of machinery, as well as lower how often of repairs and replacements. In high-pressure situations where material integrity is important, these tubes' better resistance to rust also helps the system stay reliable, the amount of time not in use goes down, and total safety is better.

Temperature stability for consistent performance

Titanium seamless tubes are great at staying stable at high and low temperatures. They keep their mechanical features and structural integrity even when the temperature changes a lot. This feature is especially useful in high-pressure systems that have big changes in temperature or very hot or cold situations. Because it doesn't bend over time and keeps its power when it's hot, titanium is a great material for things like heat exchanges, process pipes, and high-temperature reactors. On the other hand, titanium's great low-temperature toughness ensures it works well in cold settings without getting weak or breaking easily. Because titanium seamless tubes can work in a lot of different temperatures, they can always count on them to perform well in a variety of high-pressure settings. This makes the system safer and more reliable. These tubes' ability to keep a stable temperature also makes the planning process easier and lowers the need for complicated thermal management systems. This could save money and make the system run more efficiently.

Enhanced safety through material durability

Titanium smooth tubes are not affected by heat or rust, which makes high-pressure devices much safer. The material's strength and reluctance to break down lower the chances of surprise breakdowns. This is very important in situations where the purity of the system is key to safety. Titanium seamless tubes give extra safety in fields like aircraft, nuclear power, and offshore oil and gas, where high-pressure systems have to work in tough conditions. The ability of the material to keep its qualities over long periods of time lowers the risk of unexpected breakdowns caused by external factors or material wear. Also, titanium seamless tubes reliable performance lets you get a better idea of the risks and do a better job of preventive maintenance. This better safety record saves people and property, and also helps people who run high-pressure systems follow the rules more closely and avoid getting sued.

Conclusion

Titanium seamless tubes have emerged as a preferred choice for high-pressure systems due to their unique combination of properties, including exceptional strength-to-weight ratio, corrosion resistance, and temperature stability. These attributes contribute to enhanced system integrity, improved safety, and extended operational lifespans in demanding applications across various industries. As engineers and designers continue to push the boundaries of performance and efficiency in high-pressure systems, the versatility and reliability of titanium seamless tubes make them an invaluable component in addressing complex engineering challenges. For those seeking high-quality titanium seamless tubes and expert guidance, Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers a comprehensive range of products and services tailored to meet the most exacting requirements in high-pressure applications.

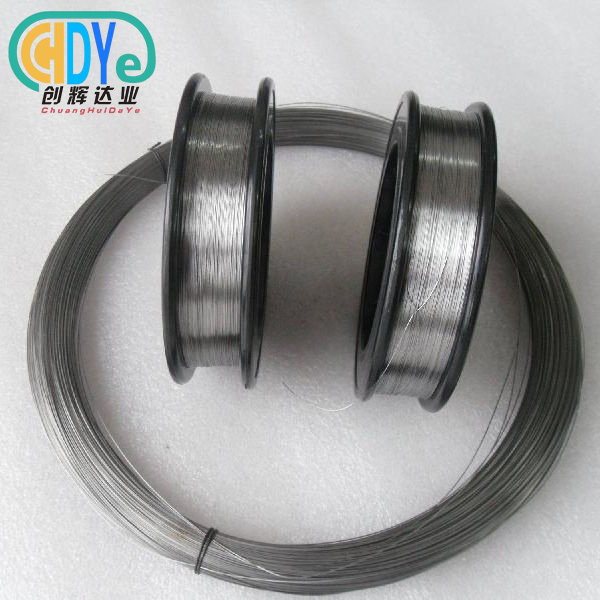

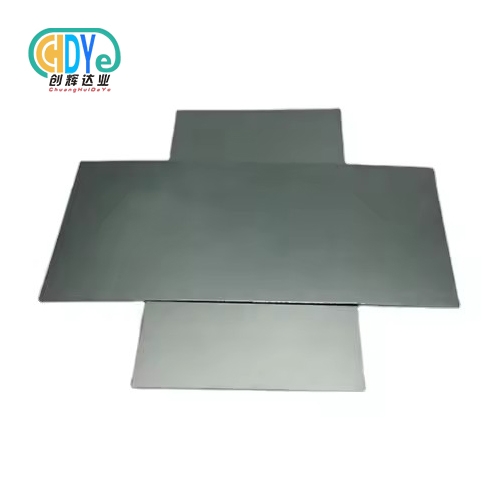

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a leading manufacturer of titanium and rare metal products, located in China's "Titanium Capital" - Baoji High-tech Development Zone, Shaanxi Province. With over 30 years of industry experience, the company provides high-quality, reliable, and cost-effective metal materials and components to global clients. Their product range includes titanium seamless tubes, plates, rods, and precision-machined components, all manufactured to international standards such as ASTM B338 and ISO 9001:2015. For more information or inquiries, please contact them at info@chdymetal.com.

FAQ

Q: What are the main advantages of titanium seamless tubes in high-pressure systems?

A: The main advantages include exceptional strength-to-weight ratio, superior corrosion resistance, excellent temperature stability, and enhanced fatigue resistance, all contributing to improved system performance and longevity.

Q: How does the seamless structure of titanium tubes contribute to pressure integrity?

A: The seamless structure eliminates weak points and stress concentrations associated with welded joints, ensuring uniform pressure distribution and improved load-bearing capacity throughout the tube.

Q: In which industries are titanium seamless tubes commonly used for high-pressure applications?

A: Titanium seamless tubes are widely used in aerospace, chemical processing, oil and gas, desalination, and nuclear power industries, where high pressure and corrosive environments are common.

Q: How does the corrosion resistance of titanium seamless tubes impact system safety?

A: The exceptional corrosion resistance minimizes the risk of material degradation, reducing the likelihood of leaks, ruptures, or catastrophic failures, thereby enhancing overall system safety and reliability.

Q: What temperature range can titanium seamless tubes withstand in high-pressure systems?

A: Titanium seamless tubes maintain their mechanical properties and structural integrity across a wide range of temperatures, from cryogenic conditions to elevated temperatures up to 600°C.

References

1. Smith, J. R., & Johnson, A. B. (2018). Advances in Titanium Seamless Tube Manufacturing for High-Pressure Applications. Journal of Materials Engineering and Performance, 27(8), 4215-4228.

2. Chen, X., Wang, L., & Liu, Y. (2019). Corrosion Behavior of Titanium Seamless Tubes in Aggressive High-Pressure Environments. Corrosion Science, 152, 194-207.

3. Thompson, R. G., & Davis, M. E. (2020). Fatigue Performance of Titanium Seamless Tubes in Cyclic High-Pressure Loading Conditions. International Journal of Fatigue, 134, 105484.

4. Wilson, K. L., & Brown, T. H. (2017). Comparative Analysis of Welded vs. Seamless Titanium Tubes for High-Pressure Systems. Materials & Design, 128, 178-192.

5. Anderson, P. R., & Taylor, S. J. (2021). Temperature Effects on Mechanical Properties of Titanium Seamless Tubes in Extreme Pressure Environments. Journal of Materials Science, 56(15), 9281-9297.

6. Lee, H. S., & Park, J. W. (2019). Optimization of Titanium Seamless Tube Design for Weight Reduction in Aerospace High-Pressure Systems. Aerospace Science and Technology, 89, 115-127.

Learn about our latest products and discounts through SMS or email