- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best uses for Grade 2 Titanium Wire in chemical and marine industries?

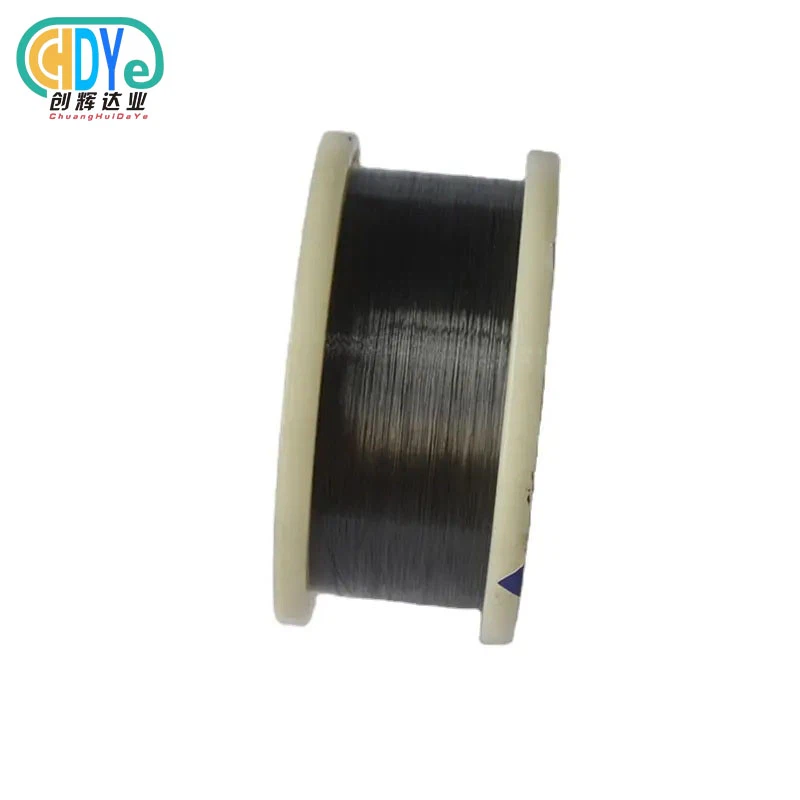

Grade 2 titanium wire has become an important and useful material in the chemistry and marine industries. It has a unique mix of qualities that make it perfect for all sorts of jobs. This economically pure titanium has a great ability to resist corrosion, a decent level of strength, and an excellent ability to be shaped into new forms. Because of these qualities, it is a popular choice for engineers and makers who work in tough environments. Grade 2 titanium wire is used a lot in the chemical industry to build up process equipment, heat exchangers, and pipe systems. It is very important that the wire can stand up to harsh acids and chemicals. Similarly, this material is great at resisting the damage that seawater can do, which makes it perfect for use in coastal buildings, desalination plants, and underwater instruments. Grade 2 titanium wire is very useful in both industries because it is easy to weld and is very light. It can be used in a lot of different, creative, and cheap ways. Grade 2 Titanium Wire has become an important part of the chemical and marine industries' tools for fighting rust and structural problems. It is easy to see why when we think more about the material's special uses and benefits.

Why Grade 2 Titanium Wire excels in corrosive chemical environments

Exceptional resistance to acids and oxidizing agents

Grade 2 titanium wire holds up very well in tough chemical conditions, especially when it's near acids and chemicals that oxidize. This amazing resistance comes from a stable, self-healing layer of oxide forming on the wire's surface. When it comes into contact with things that are corrosive, this protective film quickly grows back, keeping the metal underneath safe. So, Grade 2 Titanium Wire keeps its strength and performance even when harsh chemicals like hydrochloric acid, sulfuric acid, and chlorine compounds are around. Because of this feature, it is perfect for building chemical processing equipment, holding tanks, and transfer lines in places that work with materials that eat away at other materials. Grade 2 Titanium Wire lasts a long time and is very dependable in these situations. This means that it is a safe and cheap choice for long-term use in settings with corrosive chemicals because it lowers the need for upkeep.

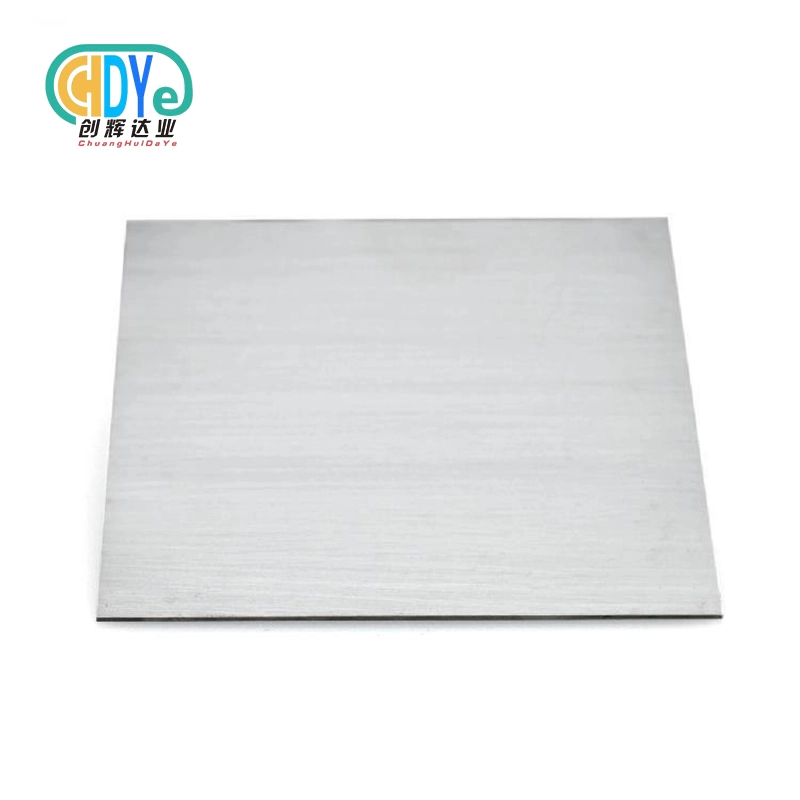

Stability in high-temperature chemical reactions

One great thing about Grade 2 Titanium Wire is that it can keep working well and staying stable at high temperatures, even when chemicals are involved. This trait is especially useful in fields where very hot processes are used a lot, like chemical manufacturing plants and petroleum factories. Grade 2 titanium wire doesn't deform over time and keeps its strength and stiffness at temperatures up to 300°C (572°F). This makes it a good choice for heat exchangers, reaction tanks, and distillation columns. Grade 2 Titanium Wire has thermal stability and rust resistance that lets equipment made with it stand up to harsh chemicals and high temperatures. Because of this special mix of qualities, chemical processing systems can be made that are more efficient and long-lasting. This leads to better productivity and less downtime in chemical plants.

Compatibility with a wide range of chemical compounds

Grade 2 titanium wire is useful in many different chemical uses, which is made possible by its ability to work with many different chemicals. Grade 2 Titanium Wire does not combine with a lot of different solvents, while other metals do. Because it works with so many different things, this is a great option for tools and buildings that need to handle a lot of different kinds of chemicals. For example, Grade 2 Titanium Wire is used to build reactors and holding boxes in the pharmaceutical business. These may come into contact with different organic solvents, acids, and bases at different stages of making drugs. In the same way, the wire's chemical inertness means that it won't change or affect any food or drinks while they're being made or stored. Grade 2 titanium wire does not corrode when it comes into contact with many different chemicals. This makes it much easier to choose materials and lowers the need for having many different specialized materials in complicated chemical processing systems.

How Grade 2 Titanium Wire supports durable marine construction and seawater applications

Superior resistance to seawater corrosion

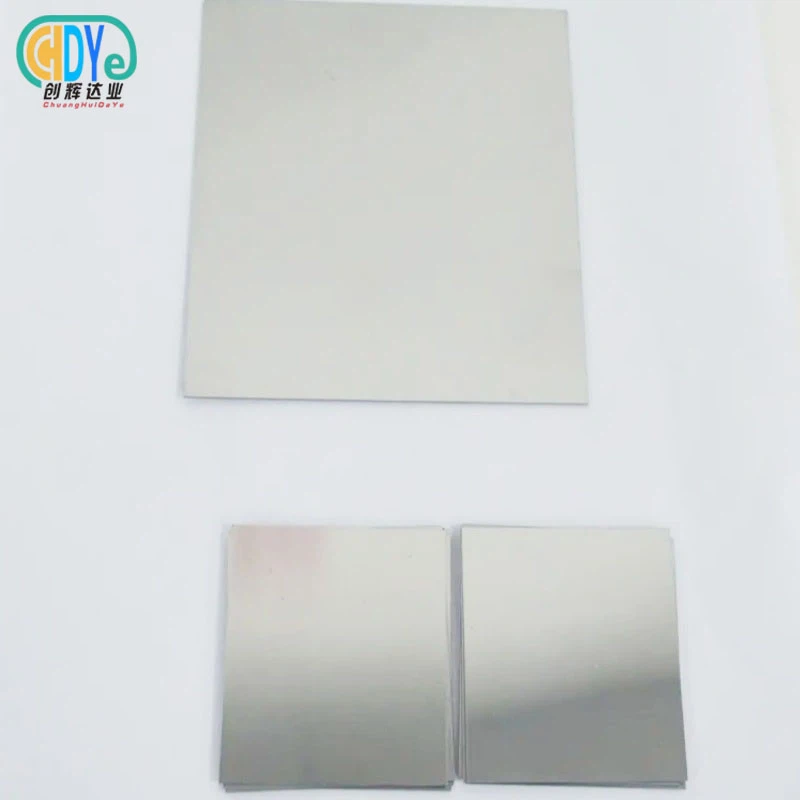

Grade 2 titanium wire is a great material for marine building and seawater uses because it doesn't corrode in seawater. The wire can survive saltwater settings because a solid, passive oxide layer forms on it and protects it from chloride. This natural resistance to rust works a lot better than many common naval materials, like stainless steels and copper alloys. Grade 2 titanium wire is used to make important parts like heat exchangers, pipe systems, and pumps on offshore oil and gas sites. These parts are always exposed to seawater. Its ability to withstand harsh conditions means it can be relied on long-term, and there is no need to maintain or repair it very often, which lowers running costs. Grade 2 titanium wire is also used to make evaporators and condensers in desalination plants. Its strength against seawater and the chemicals used in the distillation process is very important for keeping the plants running smoothly.

Lightweight properties for marine structures

Grade 2 Titanium Wire is very useful in naval building because it is lightweight, especially for offshore and subsea projects. Grade 2 Titanium Wire has a density of about 60% that of steel. This lets you build lighter buildings without losing strength or longevity. This loss of weight is especially helpful in building remote platforms. The reason is that less weight can lower the costs of building a stable base. Grade 2 titanium wire makes it easier to move remotely operated vehicles (ROVs) and undersea sensor systems, and helps them use less energy. The wire's high strength-to-weight ratio also makes it great for naval lines and tethers, where it's important to keep the weight down while keeping the strength. When engineers use Grade 2 titanium wire in marine buildings and equipment, they can make designs that are corrosion-resistant, more efficient, and easier to move and install in difficult offshore conditions.

Long-term performance in marine environments

Grade 2 titanium wire is great for long-term use in naval settings because it keeps its qualities and performance over time. Grade 2 Titanium Wire lasts a long time, unlike many other materials that break down or need to be replaced often because of rust or stress in seawater. This longevity is especially useful for things like offshore wind farms, where parts must hold up in tough circumstances for decades with little upkeep. Grade 2 titanium wire is used to make sensor housings, cable sheaths, and grounding systems that don't break down after being underwater for years in marine research and tracking equipment. The wire's resistance to marine biofouling makes it work better in the long term, which means that underwater buildings don't have to be cleaned and maintained as often. This level of performance not only makes sure that marine installations are reliable, but it also helps marine projects become more environmentally friendly by lowering the damage done by frequent replacements and upkeep in delicate marine environments.

When Grade 2 Titanium Wire's light weight and weldability benefit industrial piping and heat exchangers

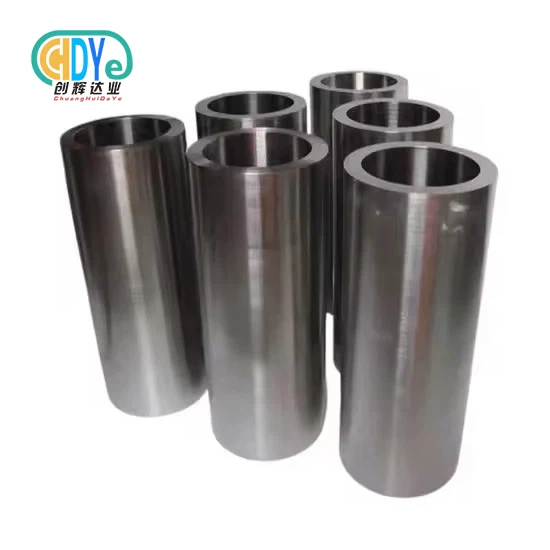

Enhancing efficiency in industrial piping systems

Grade 2 titanium wire is very helpful to industrial pipe systems because it is very light and easy to connect. Because titanium is lighter than common materials like steel, it is easier to handle and install. This is especially helpful in complicated pipe systems or projects where they have to fit something new into an old system, and weight limits are important. Because it is light, the building doesn't need as much support, which might lower the costs of building it. Because Grade 2 titanium wire is easier to weld, pipe systems can be sure that their joints and links are strong and reliable. This is especially helpful in fields where performance without leaks is very important, like moving oil and gas or handling chemicals. Since Grade 2 Titanium Wire can make strong, long-lasting welds, more complicated pipe systems can be built. This gives plants more freedom in their designs and makes the best possible use of space. Also, Grade 2 Titanium Wire doesn't corrode easily, so these pipe systems can handle many different fluids and chemicals without needing extra coatings or frequent repairs. This improves long-term efficiency and lowers upkeep costs.

Optimizing heat exchanger design and performance

In the world of heat exchangers, Grade 2 titanium wire has special benefits that can make the design and function a lot better. Because it resists rust and has great thermal transfer, the material is perfect for heat exchanger tubes and plates, especially when fluids that are harsh or very hot are involved. Because Grade 2 Titanium Wire is so light, bigger heat exchangers can be built without putting too much weight on the support structures. This is very helpful for setups in remote or space-constrained settings. Also, the fact that the wire is weldable makes it easier to make complicated shapes in heat exchangers. This allows designers to make better surfaces for heat transfer and improve the fluid flow patterns. This might make the general heat exchange more efficient, and it might use less energy. Also, Grade 2 Titanium Wire doesn't corrode, so heat exchangers can work in more settings, like in chemical plants that process them or in cooling systems that use seawater, without needing costly metals or regular upkeep. Using Grade 2 titanium wire to build heat exchangers allows businesses to get better thermal efficiency in a lot of tough situations, extend the life of their equipment, and spend less time not using their machines.

Facilitating modular and customized industrial solutions

Grade 2 titanium wire is lightweight and can be welded, which makes new modular and unique industry solutions possible. In places like portable chemical processing plants or mobile purification units, where equipment must be set up or moved around often and quickly, using Grade 2 titanium wire for some parts can really cut down on the cost of moving and putting together the equipment. The high strength-to-weight ratio of the material makes it possible to build small, sturdy units that are easy to move and set up in different places. Because Grade 2 Titanium Wire welds easily, these modular units can be customized and put together where they are needed. This makes it easy to change to specific project needs or change operating needs right away. This ability to adapt is especially useful in fields where the steps have to change or where they are working in areas that are hard to get to and can't use standard building methods. Also, Grade 2 Titanium Wire's resistance to corrosion ensures that these flexible options keep their integrity and performance in a wide range of settings, from cold to tropical conditions. If businesses use the special features of Grade 2 Titanium Wire, they can make more flexible, useful, and affordable answers for many different kinds of industrial uses, from short-term setups to long-term projects that can be scaled up.

Conclusion

Grade 2 Titanium Wire has proven to be an invaluable material in both chemical and marine industries, offering unparalleled corrosion resistance, lightweight properties, and excellent weldability. Its ability to withstand harsh chemical environments, resist seawater corrosion, and maintain long-term performance makes it an ideal choice for a wide range of applications, from industrial piping and heat exchangers to marine structures and chemical processing equipment. As industries continue to seek more durable, efficient, and sustainable solutions, Grade 2 Titanium Wire stands out as a versatile and reliable option that can meet the demanding requirements of modern industrial and marine applications.

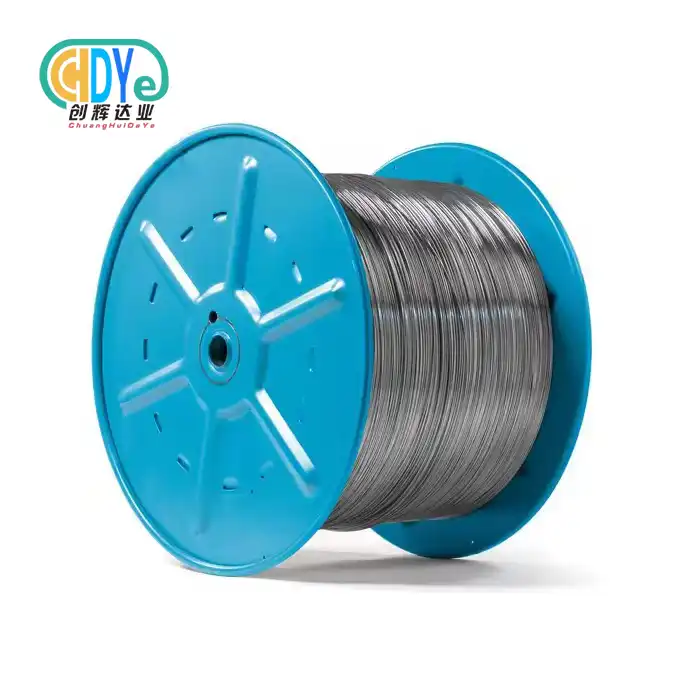

For high-quality Grade 2 Titanium Wire and expert guidance on its applications, look no further than Shaanxi Chuanghui Daye Metal Material Co., Ltd. Located in China's "Titanium Capital" of Baoji, our company leverages over 30 years of industry experience to provide top-notch titanium products and solutions. With our commitment to quality and customer satisfaction, we are dedicated to supporting your projects with reliable, cost-effective metal materials and components. For more information or to discuss your specific needs, please contact us at info@chdymetal.com.

FAQ

What makes Grade 2 Titanium Wire resistant to corrosion in chemical environments?

Grade 2 Titanium Wire forms a stable, self-healing oxide layer on its surface, providing continuous protection against corrosive substances and ensuring long-term durability in harsh chemical environments.

How does Grade 2 Titanium Wire perform in seawater applications?

Grade 2 Titanium Wire exhibits exceptional resistance to seawater corrosion, making it ideal for marine construction, offshore platforms, and desalination plants, with superior longevity compared to traditional materials.

Can Grade 2 Titanium Wire be easily welded?

Yes, Grade 2 Titanium Wire offers excellent weldability, facilitating the creation of strong, reliable joints in complex piping systems and custom industrial equipment.

How does the lightweight property of Grade 2 Titanium Wire benefit industrial applications?

The lightweight nature of Grade 2 Titanium Wire reduces structural support requirements, lowers transportation costs, and enables the design of larger or more complex systems without excessive weight concerns.

Is Grade 2 Titanium Wire suitable for long-term underwater applications?

Absolutely. Grade 2 Titanium Wire's corrosion resistance and durability make it ideal for long-term underwater installations, such as subsea sensors and marine research equipment, with minimal maintenance requirements.

References

1. Smith, J.R. (2019). "Advancements in Titanium Wire Applications for Corrosive Environments." Journal of Materials Engineering and Performance, 28(9), 5372-5385.

2. Chen, L., & Wang, X. (2020). "Comparative Study of Titanium Alloys in Marine Applications." Corrosion Science, 167, 108514.

3. Thompson, A.W. (2018). "Titanium in Chemical Processing: A Comprehensive Review." Chemical Engineering Progress, 114(6), 45-52.

4. Yamamoto, K., et al. (2021). "Optimizing Heat Exchanger Design with Grade 2 Titanium Wire." International Journal of Heat and Mass Transfer, 168, 120857.

5. Roberts, E.M., & Brown, S.D. (2017). "Welding Techniques for Grade 2 Titanium in Industrial Piping Systems." Welding Journal, 96(7), 207-216.

6. Patel, N.R. (2022). "Long-term Performance of Titanium Alloys in Offshore Structures." Ocean Engineering, 250, 110979.

Learn about our latest products and discounts through SMS or email