- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the inspection items for incoming ASTM B365 Tantalum Alloy Wire?

Hey there! As a supplier of ASTM B365 Tantalum Alloy Wire, I've been in the business long enough to know how crucial incoming inspections are. In this blog, I'll walk you through the key inspection items for ASTM B365 Tantalum Alloy Wire, so you can have a better understanding of what goes into ensuring top - notch quality.

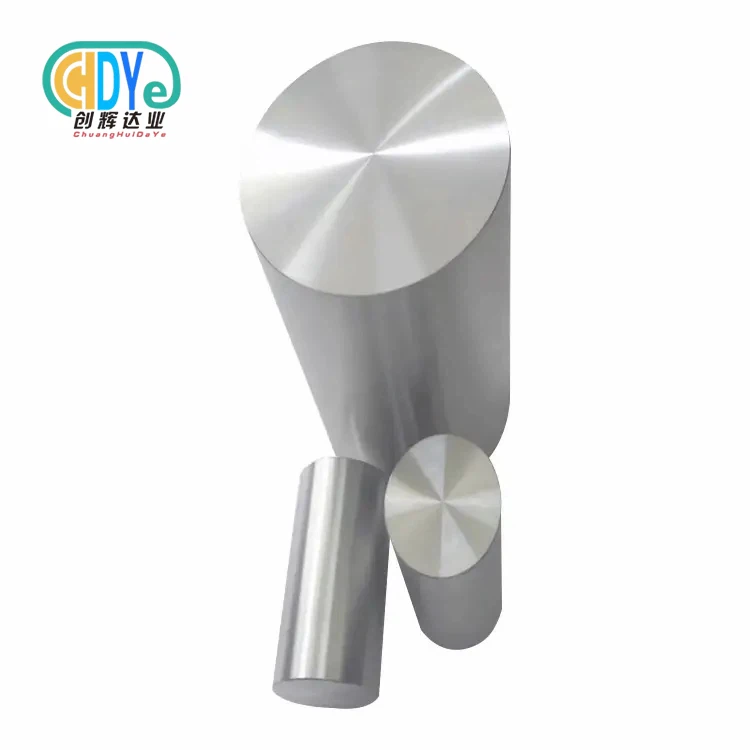

1. Dimensional Inspection

First off, we've got dimensional inspection. The diameter of the tantalum alloy wire is super important. It needs to meet the specific requirements of ASTM B365. We use precision measuring tools like micrometers to check the diameter at multiple points along the wire. Any deviation from the specified diameter can lead to problems in the end - use applications. For example, if the wire is too thick, it might not fit into the intended machinery or components. On the other hand, if it's too thin, it could lack the necessary strength.

The length of the wire is another aspect. We make sure that the wire is of the correct length as per the order. A short length can be a major issue for customers who are relying on a specific amount of wire for their projects. We measure the length using calibrated measuring tapes or other appropriate length - measuring devices.

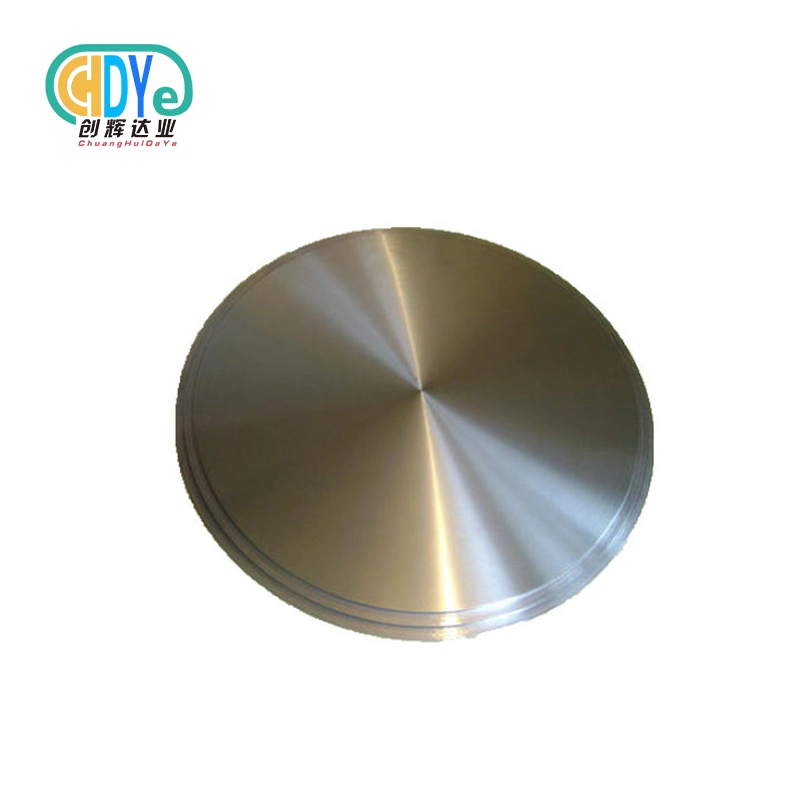

2. Surface Quality Inspection

The surface of the ASTM B365 Tantalum Alloy Wire should be smooth and free from defects. We look for scratches, cracks, pits, and other surface irregularities. Scratches can weaken the wire and make it more prone to breakage. Cracks are even more serious as they can lead to complete failure of the wire during use.

To inspect the surface, we use visual inspection methods. Sometimes, we also use magnifying glasses or microscopes for a more detailed look. Any wire with significant surface defects is rejected because it won't meet the high - quality standards that our customers expect. You can find high - quality High Purity Tantalum Wire with excellent surface quality on our website.

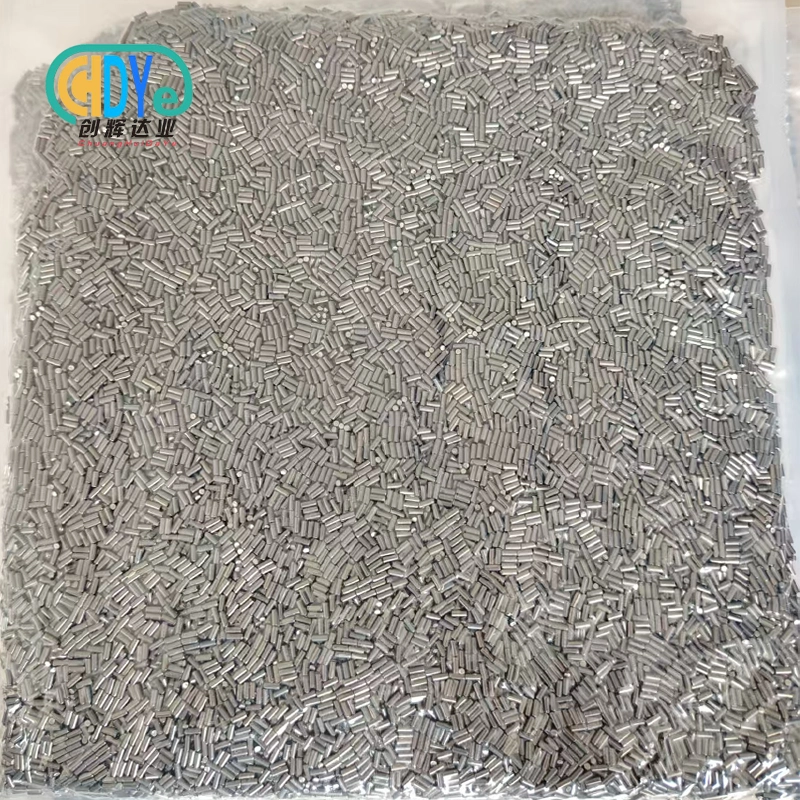

3. Chemical Composition Analysis

The chemical composition of the tantalum alloy wire is a make - or - break factor. ASTM B365 has strict requirements for the percentages of different elements in the alloy. We use advanced analytical techniques like spectroscopy to determine the chemical composition.

Tantalum is the main element, but there are also other alloying elements present in specific proportions. These alloying elements are what give the wire its unique properties, such as high strength, corrosion resistance, and heat resistance. If the chemical composition is off, the wire might not perform as expected in the end - use applications. For instance, if the percentage of a certain alloying element is too low, the wire might not have the required corrosion resistance.

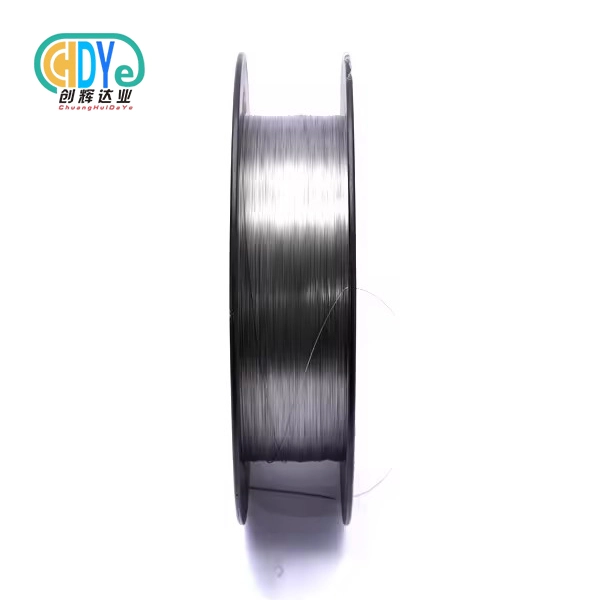

4. Mechanical Property Testing

Mechanical properties are essential for the performance of the ASTM B365 Tantalum Alloy Wire. We test for properties like tensile strength, yield strength, and elongation. Tensile strength tells us how much force the wire can withstand before it breaks. Yield strength indicates the point at which the wire starts to deform permanently. Elongation measures how much the wire can stretch before breaking.

We use tensile testing machines to perform these tests. By testing the mechanical properties, we can ensure that the wire will be able to handle the stresses and strains it will encounter in real - world applications. Whether it's being used in the electronics industry or in high - temperature environments, the wire needs to have the right mechanical properties. You can check out our Tantalum Wire For Sale which undergoes rigorous mechanical property testing.

5. Coating and Finish Inspection

If the tantalum alloy wire has a coating or a specific finish, we also inspect it carefully. The coating should be uniform and well - adhered to the wire. A non - uniform coating can lead to uneven performance, and a poorly adhered coating might peel off during use.

We check the thickness of the coating using appropriate measuring tools. We also look for any signs of coating defects, such as blisters or bubbles. A proper coating can enhance the wire's performance, for example, by providing additional corrosion resistance or improving its electrical conductivity.

6. Documentation and Traceability

Last but not least, we pay close attention to the documentation and traceability of the incoming ASTM B365 Tantalum Alloy Wire. We need to have all the necessary certificates, including the material test report (MTR). The MTR provides detailed information about the wire's chemical composition, mechanical properties, and other relevant data.

Traceability is important because it allows us to track the wire back to its source. In case there are any quality issues down the line, we can easily identify where the problem originated. This helps us in taking appropriate corrective actions and ensuring that our customers are satisfied. You can find more information about our ASTM B365 Tantalum Alloy Wire and its documentation on our website.

In conclusion, these are the main inspection items for incoming ASTM B365 Tantalum Alloy Wire. By conducting thorough inspections, we can ensure that the wire we supply meets the highest quality standards. If you're in the market for high - quality ASTM B365 Tantalum Alloy Wire, don't hesitate to reach out for a purchase negotiation. We're always ready to work with you to meet your specific needs.

References

ASTM International. ASTM B365 - Standard Specification for Tantalum - 10% Wolfram Alloy Rod, Bar, and Wire.

Various industry research papers on tantalum alloy wire quality control.

Hey there! As a supplier of ASTM B365 Tantalum Alloy Wire, I've been in the business long enough to know how crucial incoming inspections are. In this blog, I'll walk you through the key inspection items for ASTM B365 Tantalum Alloy Wire, so you can have a better understanding of what goes into ensuring top - notch quality.

1. Dimensional Inspection

First off, we've got dimensional inspection. The diameter of the tantalum alloy wire is super important. It needs to meet the specific requirements of ASTM B365. We use precision measuring tools like micrometers to check the diameter at multiple points along the wire. Any deviation from the specified diameter can lead to problems in the end - use applications. For example, if the wire is too thick, it might not fit into the intended machinery or components. On the other hand, if it's too thin, it could lack the necessary strength.

The length of the wire is another aspect. We make sure that the wire is of the correct length as per the order. A short length can be a major issue for customers who are relying on a specific amount of wire for their projects. We measure the length using calibrated measuring tapes or other appropriate length - measuring devices.

2. Surface Quality Inspection

The surface of the ASTM B365 Tantalum Alloy Wire should be smooth and free from defects. We look for scratches, cracks, pits, and other surface irregularities. Scratches can weaken the wire and make it more prone to breakage. Cracks are even more serious as they can lead to complete failure of the wire during use.

To inspect the surface, we use visual inspection methods. Sometimes, we also use magnifying glasses or microscopes for a more detailed look. Any wire with significant surface defects is rejected because it won't meet the high - quality standards that our customers expect. You can find high - quality High Purity Tantalum Wire with excellent surface quality on our website.

3. Chemical Composition Analysis

The chemical composition of the tantalum alloy wire is a make - or - break factor. ASTM B365 has strict requirements for the percentages of different elements in the alloy. We use advanced analytical techniques like spectroscopy to determine the chemical composition.

Tantalum is the main element, but there are also other alloying elements present in specific proportions. These alloying elements are what give the wire its unique properties, such as high strength, corrosion resistance, and heat resistance. If the chemical composition is off, the wire might not perform as expected in the end - use applications. For instance, if the percentage of a certain alloying element is too low, the wire might not have the required corrosion resistance.

4. Mechanical Property Testing

Mechanical properties are essential for the performance of the ASTM B365 Tantalum Alloy Wire. We test for properties like tensile strength, yield strength, and elongation. Tensile strength tells us how much force the wire can withstand before it breaks. Yield strength indicates the point at which the wire starts to deform permanently. Elongation measures how much the wire can stretch before breaking.

We use tensile testing machines to perform these tests. By testing the mechanical properties, we can ensure that the wire will be able to handle the stresses and strains it will encounter in real - world applications. Whether it's being used in the electronics industry or in high - temperature environments, the wire needs to have the right mechanical properties. You can check out our Tantalum Wire For Sale which undergoes rigorous mechanical property testing.

5. Coating and Finish Inspection

If the tantalum alloy wire has a coating or a specific finish, we also inspect it carefully. The coating should be uniform and well - adhered to the wire. A non - uniform coating can lead to uneven performance, and a poorly adhered coating might peel off during use.

We check the thickness of the coating using appropriate measuring tools. We also look for any signs of coating defects, such as blisters or bubbles. A proper coating can enhance the wire's performance, for example, by providing additional corrosion resistance or improving its electrical conductivity.

6. Documentation and Traceability

Last but not least, we pay close attention to the documentation and traceability of the incoming ASTM B365 Tantalum Alloy Wire. We need to have all the necessary certificates, including the material test report (MTR). The MTR provides detailed information about the wire's chemical composition, mechanical properties, and other relevant data.

Traceability is important because it allows us to track the wire back to its source. In case there are any quality issues down the line, we can easily identify where the problem originated. This helps us in taking appropriate corrective actions and ensuring that our customers are satisfied. You can find more information about our ASTM B365 Tantalum Alloy Wire and its documentation on our website.

In conclusion, these are the main inspection items for incoming ASTM B365 Tantalum Alloy Wire. By conducting thorough inspections, we can ensure that the wire we supply meets the highest quality standards. If you're in the market for high - quality ASTM B365 Tantalum Alloy Wire, don't hesitate to reach out for a purchase negotiation. We're always ready to work with you to meet your specific needs.

References

ASTM International. ASTM B365 - Standard Specification for Tantalum - 10% Wolfram Alloy Rod, Bar, and Wire.

Various industry research papers on tantalum alloy wire quality control.

Hey there! As a supplier of ASTM B365 Tantalum Alloy Wire, I've been in the business long enough to know how crucial incoming inspections are. In this blog, I'll walk you through the key inspection items for ASTM B365 Tantalum Alloy Wire, so you can have a better understanding of what goes into ensuring top - notch quality.

1. Dimensional Inspection

First off, we've got dimensional inspection. The diameter of the tantalum alloy wire is super important. It needs to meet the specific requirements of ASTM B365. We use precision measuring tools like micrometers to check the diameter at multiple points along the wire. Any deviation from the specified diameter can lead to problems in the end - use applications. For example, if the wire is too thick, it might not fit into the intended machinery or components. On the other hand, if it's too thin, it could lack the necessary strength.

The length of the wire is another aspect. We make sure that the wire is of the correct length as per the order. A short length can be a major issue for customers who are relying on a specific amount of wire for their projects. We measure the length using calibrated measuring tapes or other appropriate length - measuring devices.

2. Surface Quality Inspection

The surface of the ASTM B365 Tantalum Alloy Wire should be smooth and free from defects. We look for scratches, cracks, pits, and other surface irregularities. Scratches can weaken the wire and make it more prone to breakage. Cracks are even more serious as they can lead to complete failure of the wire during use.

To inspect the surface, we use visual inspection methods. Sometimes, we also use magnifying glasses or microscopes for a more detailed look. Any wire with significant surface defects is rejected because it won't meet the high - quality standards that our customers expect. You can find high - quality High Purity Tantalum Wire with excellent surface quality on our website.

3. Chemical Composition Analysis

The chemical composition of the tantalum alloy wire is a make - or - break factor. ASTM B365 has strict requirements for the percentages of different elements in the alloy. We use advanced analytical techniques like spectroscopy to determine the chemical composition.

Tantalum is the main element, but there are also other alloying elements present in specific proportions. These alloying elements are what give the wire its unique properties, such as high strength, corrosion resistance, and heat resistance. If the chemical composition is off, the wire might not perform as expected in the end - use applications. For instance, if the percentage of a certain alloying element is too low, the wire might not have the required corrosion resistance.

and its documentation on our website.

In conclusion, these are the main inspection items for incoming ASTM B365 Tantalum Alloy Wire. By conducting thorough inspections, we can ensure that the wire we supply meets the highest quality standards. If you're in the market for high - quality ASTM B365 Tantalum Alloy Wire, don't hesitate to reach out for a purchase negotiation. We're always ready to work with you to meet your specific needs. Any questions just feel free to contact at info@chdymetal.com

References

ASTM International. ASTM B365 - Standard Specification for Tantalum - 10% Wolfram Alloy Rod, Bar, and Wire.

Various industry research papers on tantalum alloy wire quality control.

Learn about our latest products and discounts through SMS or email