- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

what is mmo coated titanium anodes?

Precious metal oxide anodes are coated on titanium substrates with mixed metal oxide coatings (such as ruthenium-iridium, iridium-tantalum, platinum, etc.). They have low polarization, low consumption rate and are customized. They are suitable for a variety of environments such as seawater and soil. They are widely used in cathodic protection, electroplating and wastewater treatment. They are efficient, stable and environmentally friendly.

1. Composition and characteristics

Composition: The core of the precious metal oxide anode is a titanium substrate, and the surface is covered with a layer of metal oxide coating, such as oxides of precious metals such as iridium, tantalum and ruthenium.

Features:

Low polarization and low consumption rate: The oxide coating has extremely small polarization resistance and extremely low consumption rate, so that the anode can still maintain efficient and stable performance under long-term use.

Strong customizability: The coating type, thickness and anode specifications can be customized according to the specific needs of users to meet the current density, dielectric environment and design life requirements in different application scenarios.

2. Classification and application

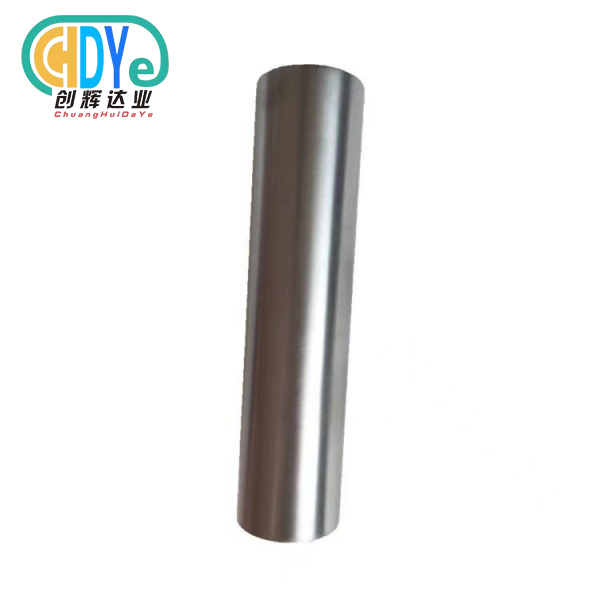

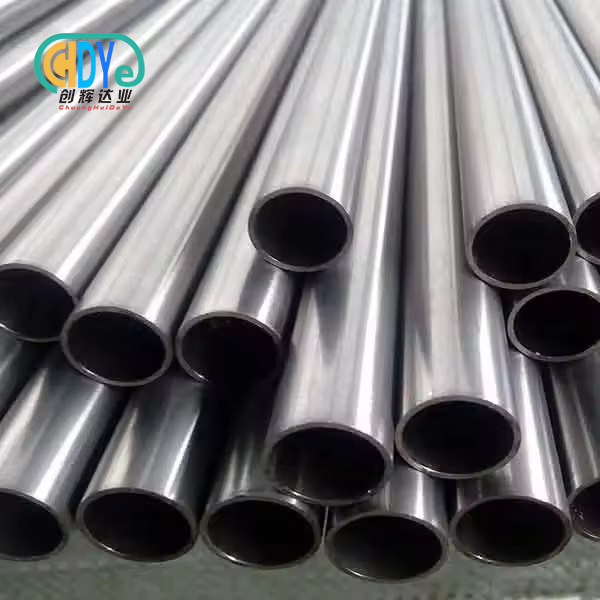

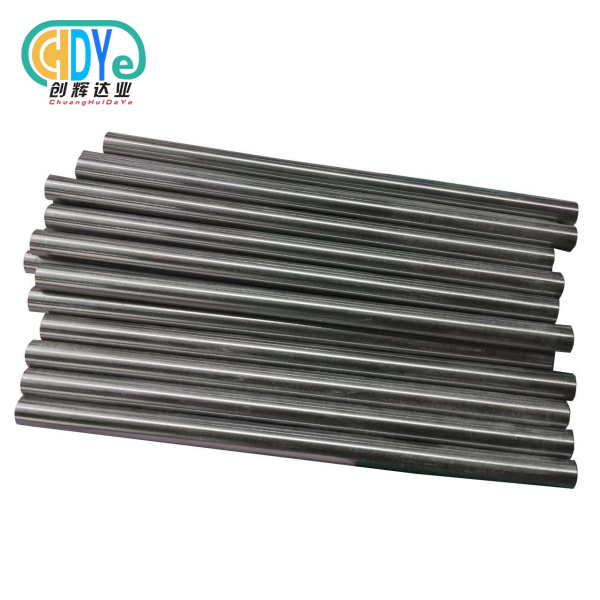

Classification: According to different shapes and uses, precious metal oxide anodes can be divided into various types such as strip anodes, tubular anodes, mesh anodes and deep well anode bodies.

Application:

Cathode protection system: Together with the constant potential instrument, test pile, reference electrode, etc., it forms a complete cathodic protection system to protect buried pipelines, storage tanks and other metal structures from corrosion.

Electroplating industry: As an anode material in the electroplating process, it improves the efficiency and quality of electroplating and reduces production costs.

Metal recycling: Using its efficient electrocatalytic performance, the valuable metal elements in scrap metals are effectively separated to achieve resource recycling.

Environmental protection field: In the process of electrochemical wastewater treatment, it is used to remove harmful substances in wastewater, such as heavy metal ions, organic matter, etc., to achieve effective treatment of wastewater.

Shaaanxi Chuanghui Daye Metal Material CO.,Ltd can provide mmo coated titanium anodes with Ru-ir, Ir-ta, platinum coating and shape can be customized like mesh, plate, rod, tube and assembly. If you have any requirements pls feel free to contact.

E-mail: info@chdymetal.com

Mob.: 86-18049386902

Learn about our latest products and discounts through SMS or email