- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the impact of impurities on the properties of tantalum round bar?

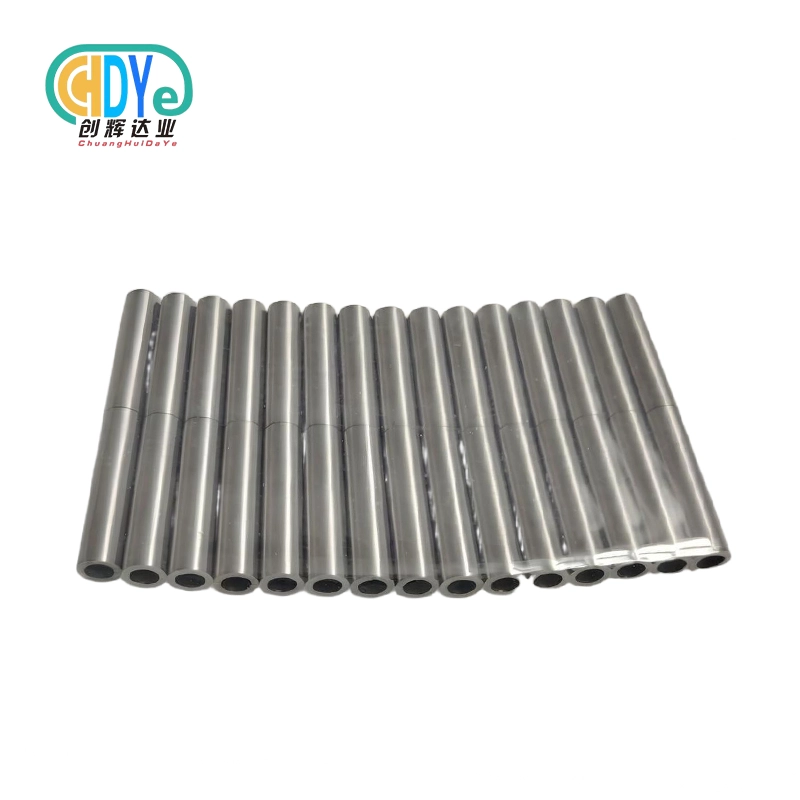

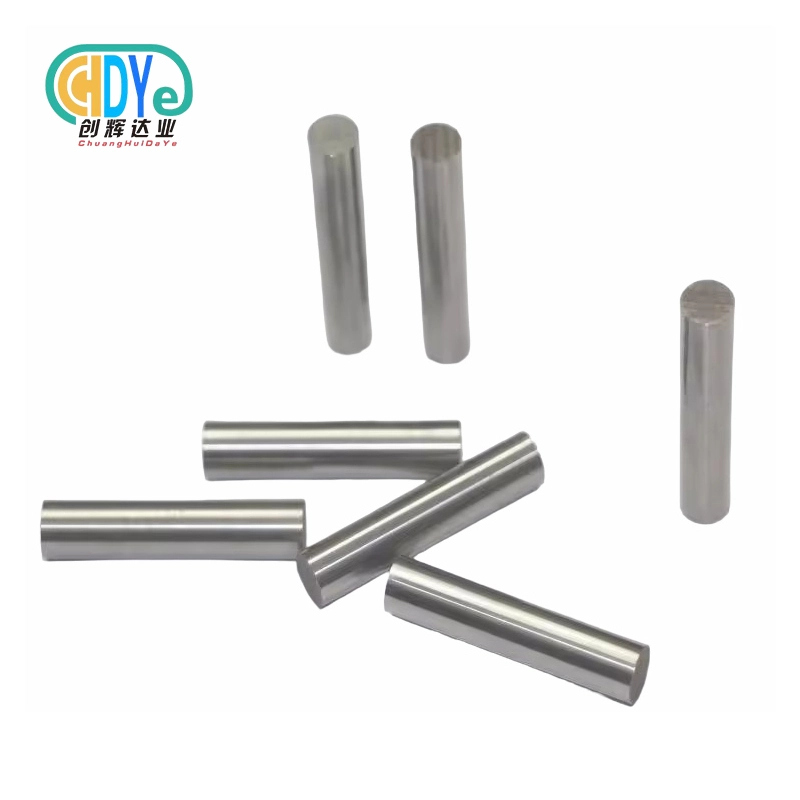

As a seasoned supplier of Tantalum Round Bars, I've witnessed firsthand the profound influence that impurities can have on the properties of these remarkable metal products. Tantalum, with its high melting point, excellent corrosion resistance, and remarkable ductility, is a highly sought-after material in various industries, including aerospace, electronics, and chemical processing. However, the presence of impurities can significantly alter its characteristics, affecting its performance and suitability for specific applications.

Understanding Tantalum and Its Properties

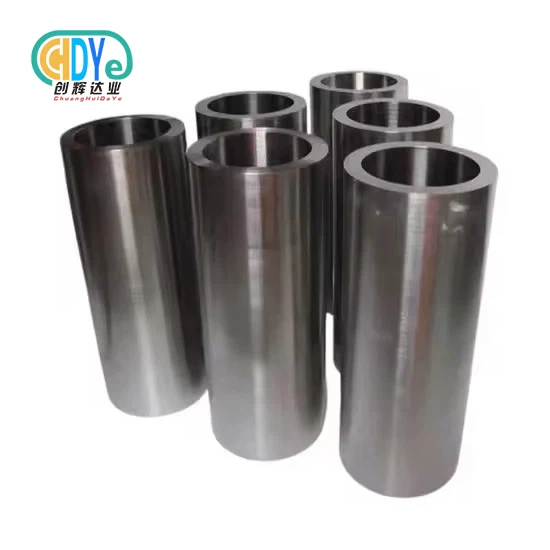

Before delving into the impact of impurities, it's essential to understand the inherent properties of tantalum. Tantalum is a transition metal with the atomic number 73 and is known for its high density, exceptional corrosion resistance, and ability to form a stable oxide layer on its surface. These properties make it an ideal material for applications where durability and reliability are crucial, such as in the production of capacitors, chemical reactors, and medical implants.

One of the most notable properties of tantalum is its high melting point, which is approximately 3,017 degrees Celsius. This makes it suitable for use in high-temperature applications, such as in the aerospace industry, where components must withstand extreme heat and pressure. Additionally, tantalum is highly resistant to corrosion, particularly in acidic environments, making it a popular choice for chemical processing equipment.

The Role of Impurities in Tantalum Round Bars

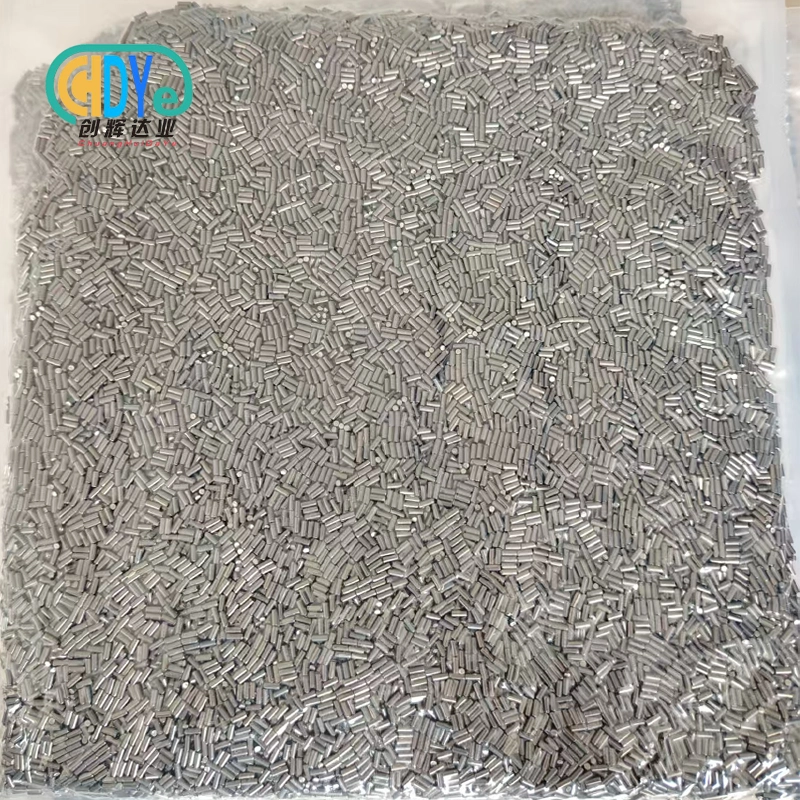

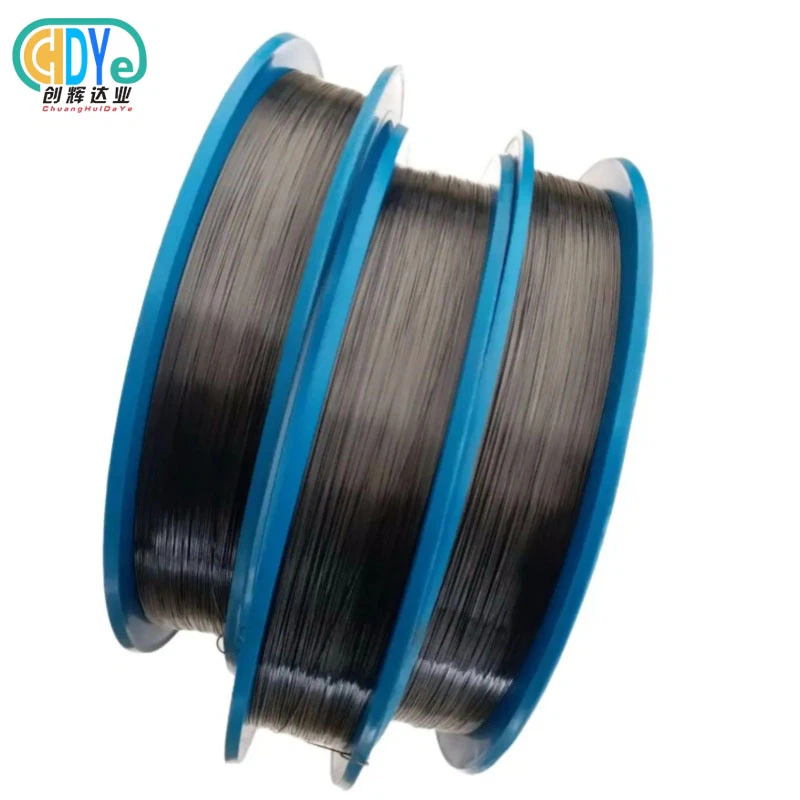

Impurities in tantalum round bars can originate from various sources, including the raw materials used in the production process, the manufacturing environment, and the handling and storage of the finished products. These impurities can include elements such as iron, nickel, chromium, and carbon, as well as non-metallic substances like oxygen, nitrogen, and hydrogen.

The presence of impurities in tantalum round bars can have a significant impact on their physical and chemical properties. For example, impurities can affect the mechanical strength, ductility, and electrical conductivity of the material. They can also alter the corrosion resistance and oxidation behavior of tantalum, making it more susceptible to degradation in certain environments.

Impact on Mechanical Properties

One of the primary ways in which impurities can affect the properties of tantalum round bars is by altering their mechanical properties. Impurities can act as stress concentrators, reducing the overall strength and ductility of the material. This can lead to premature failure of the tantalum round bars under stress, particularly in applications where they are subjected to high loads or repeated cycling.

For instance, the presence of iron impurities in tantalum can form brittle intermetallic compounds, which can significantly reduce the ductility of the material. This can make the tantalum round bars more prone to cracking and fracturing, especially during machining or forming operations. Similarly, the presence of carbon impurities can lead to the formation of carbide particles, which can also reduce the ductility and toughness of the material.

Impact on Electrical Properties

In addition to their impact on mechanical properties, impurities can also affect the electrical properties of tantalum round bars. Tantalum is a good conductor of electricity, and its electrical conductivity is an important property in many applications, such as in the production of electronic components. However, the presence of impurities can increase the electrical resistivity of the material, reducing its conductivity.

For example, the presence of oxygen impurities in tantalum can form oxide layers on the surface of the material, which can act as insulators and impede the flow of electricity. This can lead to a decrease in the electrical performance of the tantalum round bars, particularly in applications where high conductivity is required, such as in the production of capacitors.

Impact on Corrosion Resistance

Another significant impact of impurities on the properties of tantalum round bars is their effect on corrosion resistance. Tantalum is known for its excellent corrosion resistance, particularly in acidic environments. However, the presence of impurities can reduce this resistance, making the material more susceptible to corrosion.

For instance, the presence of iron and nickel impurities in tantalum can form galvanic couples with the tantalum matrix, which can accelerate the corrosion process. Additionally, the presence of non-metallic impurities such as oxygen and nitrogen can form compounds that can react with the tantalum surface, leading to the formation of corrosion products and the degradation of the material.

Controlling Impurities in Tantalum Round Bars

Given the significant impact of impurities on the properties of tantalum round bars, it is essential to control their presence during the production process. As a supplier of Tantalum Round Bars, we take several measures to ensure the purity and quality of our products.

Firstly, we carefully select the raw materials used in the production of tantalum round bars to minimize the presence of impurities. We source our tantalum from high-quality mines and suppliers, and we conduct rigorous testing to ensure that the raw materials meet our strict quality standards.

Secondly, we employ advanced manufacturing processes to minimize the introduction of impurities during the production process. Our manufacturing facilities are equipped with state-of-the-art equipment and technologies, and we follow strict quality control procedures to ensure that the tantalum round bars are produced to the highest standards of purity and quality.

Finally, we take great care in the handling and storage of our tantalum round bars to prevent contamination. We store our products in a clean and dry environment, and we use appropriate packaging materials to protect them from damage and contamination.

Importance of High-Quality Tantalum Round Bars

The importance of using high-quality tantalum round bars cannot be overstated. In industries such as aerospace, electronics, and chemical processing, the performance and reliability of components are critical to the success of the overall system. Using tantalum round bars with high levels of impurities can lead to premature failure of these components, resulting in costly downtime, repairs, and replacements.

By using high-quality tantalum round bars, manufacturers can ensure that their products meet the highest standards of performance and reliability. High-quality tantalum round bars offer superior mechanical properties, electrical conductivity, and corrosion resistance, making them suitable for a wide range of applications.

Conclusion

In conclusion, impurities can have a significant impact on the properties of tantalum round bars. They can affect the mechanical strength, ductility, electrical conductivity, and corrosion resistance of the material, making it less suitable for certain applications. As a supplier of Tantalum Round Bars, we understand the importance of controlling impurities and ensuring the purity and quality of our products.

We are committed to providing our customers with high-quality tantalum round bars that meet their specific requirements. Our products are manufactured using the latest technologies and processes, and we adhere to strict quality control standards to ensure that they are free from impurities and meet the highest levels of performance and reliability.

If you are in the market for high-quality tantalum round bars, we invite you to contact us to discuss your requirements. Our team of experts will be happy to assist you in selecting the right product for your application and to provide you with a competitive quote. We look forward to working with you to meet your tantalum round bar needs. Just feel free to contact us:

E-mail: info@chdymetal.com

Mob./what'sapp: 86-18049386902

References

"Tantalum: Properties, Applications, and Production." Encyclopedia of Materials: Science and Technology, 2001.

"The Effect of Impurities on the Properties of Tantalum." Journal of Materials Science, Vol. 35, No. 12, 2000.

"Tantalum and Tantalum Alloys." ASM Handbook, Vol. 2, 1990.

Learn about our latest products and discounts through SMS or email