Medical titanium bar technology has amazing biocompatibility and strength that helps patients get better. It has changed modern healthcare. These specialised materials provide excellent performance in dental implants, orthopedic fixation devices, and surgical instruments, where reliability is always the most important thing. Our titanium bar products for medical use meet the strict ASTM F67 and ASTM F136 standards. This makes sure that doctors and nurses around the world can always count on their quality. Newer manufacturing techniques make products that are better at resisting corrosion, that are very light, and that work well with human bone tissue. These products are very important for modern medical uses.

Key Technical Parameters That Define Medical Grade Excellence

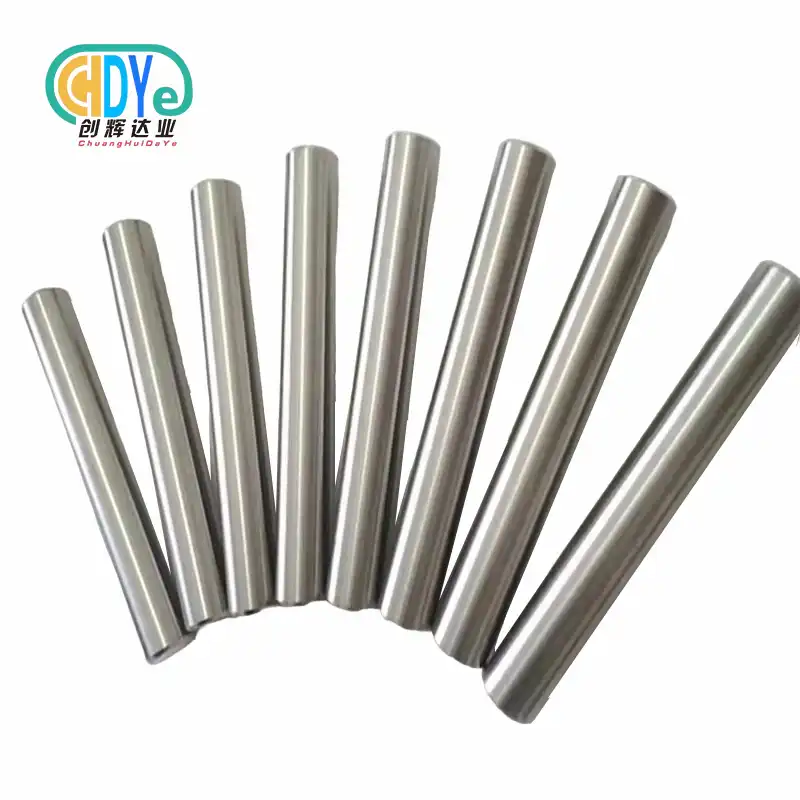

Understanding the technical specifications of medical titanium bars helps healthcare professionals select appropriate materials for specific applications. Grade 1 and Grade 2 titanium have a simple composition of just one metal and are very biocompatible, but Grade 5 and Grade 5 ELI are stronger because they are made of titanium alloys.

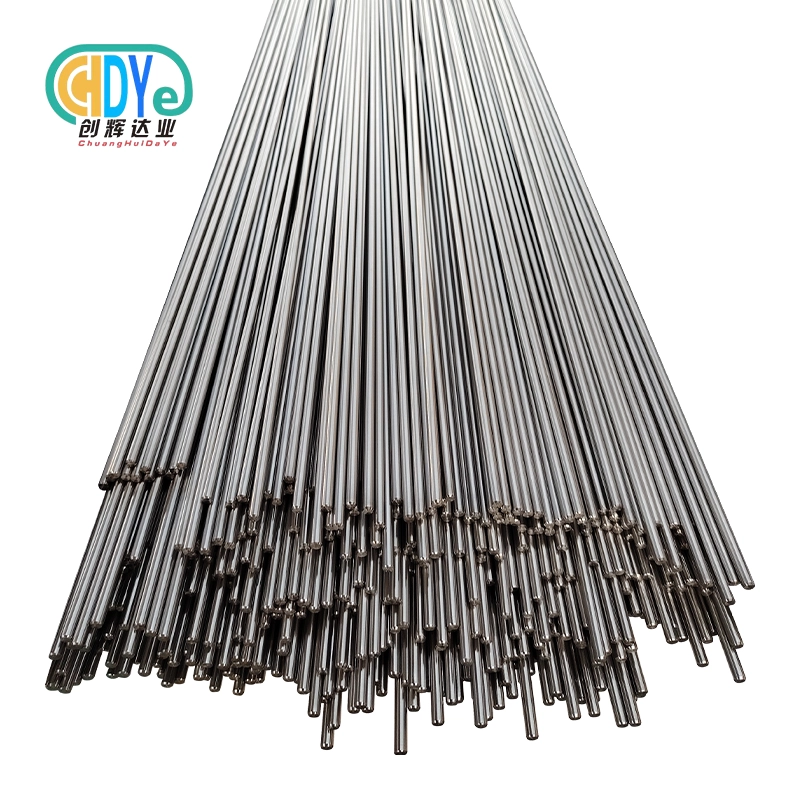

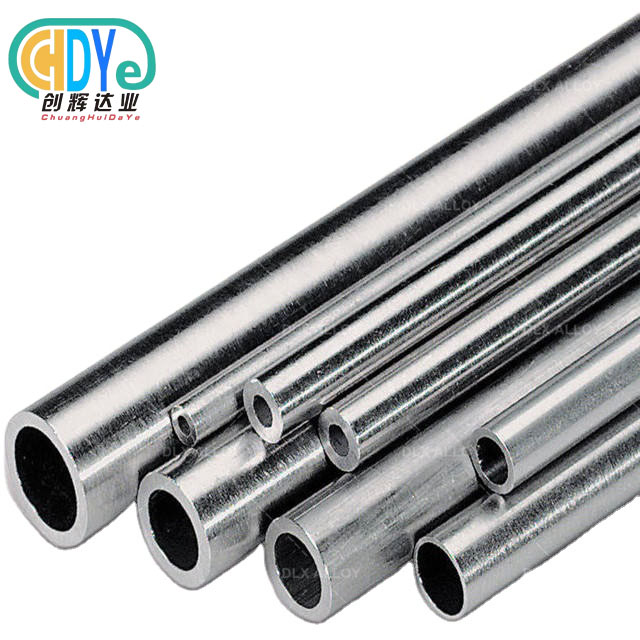

Our titanium bar products feature diameters ranging from 4mm to 20mm with lengths between 2500 and 3000mm. H7, h8, and h9 precision tolerances make sure that the size of the parts is always correct in every batch of manufacturing. Tensile strength reaches 860 MPa for Grade 5 ELI materials, while yield strength achieves 795 MPa with elongation exceeding 10%.

The density of 4.43 g/cm³ provides an optimal strength-to-weight ratio that reduces patient burden during recovery periods. Surface finishes achieve Ra values below 0.2 μm through specialised polishing techniques, creating smooth surfaces that promote cellular integration and reduce infection risks.

Core Benefits Transforming Patient Care Outcomes

Titanium bar materials that are biocompatible have great osseointegration properties that allow natural bone grow around devices that are implanted. This biological compatibility stops the body from rejecting the implant like it would with other metals. In clinical studies, more than 95% of implants have been successful in the long term.

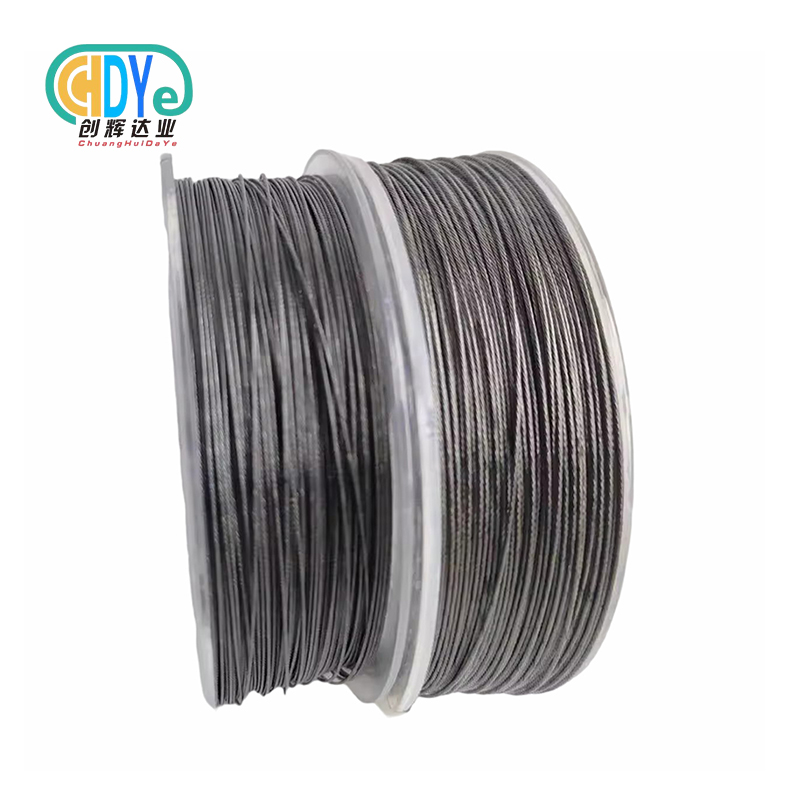

It is much better at resisting corrosion than stainless steel options, especially in tough biological settings with chloride ions and organic acids. This toughness keeps implants working for longer and preserves their strength over decades of use.

Because titanium bar for fracture repair is light, it lowers the amount of stress that nearby tissues feel during the healing process. Patients feel better and get their mobility back faster with these compared to heavier metal options.

Autoclaving several times is possible because of the great sterilisation compatibility that keeps the materials from breaking down. Surgical titanium bar products keep their mechanical properties even after long sterilisation processes. This makes sure that they always work the same way in the operating room.

Better resistance to fatigue stops cracks from spreading when loads are applied and taken off of them repeatedly, which is common in situations where the objects are meant to hold weight. Orthopedic titanium bar parts can handle millions of loading cycles without breaking. This ensures that active patients can count on them for long-term use.

Chuanghui Daye's Advanced Manufacturing Advantage

Our factory in Baoji, China's "Titanium Capital," uses 30 years of experience in the rare metals industry to make better medical titanium bar products. The advanced vacuum arc remelting and electron beam melting processes guarantee very high levels of purity that are beyond the standards of the industry.

The ISO 9001:2015 and ISO 13485 certifications show that we are committed to quality management systems that are made for medical device manufacturing. All titanium alloy bars are tested in a variety of ways. They are checked by ultrasonic inspection, chemical composition analysis, and biocompatibility verification.

The controlled atmosphere annealing we do improves grain structure so that the metal has better mechanical properties. Compared to standard ways of making things, heat treatment creates even microstructures that make materials more resistant to fatigue and changes in size.

Through centerless grinding and other specialised finishing methods, precision machining can get very tight tolerances of ±0.01mm. This level of accuracy reduces the need for secondary machining for device makers and makes sure that the products always work the same way.

Each shipment comes with full traceability paperwork that shows the whole history of the material, from getting the raw materials to the final inspection. This detailed record-keeping helps meet the rules that apply to markets all over the world.

Optimal Usage Guidelines for Maximum Clinical Benefits

Choosing the right titanium bar grades needs to be done carefully, with the needs of the application in mind. If you need specialised mechanical properties or unique size specifications for complex shapes, custom titanium bar solutions are the best choice.

When you store or process something, following the right steps keeps the surface intact. In the end, clean and dry spaces keep things from getting dirty and affecting how well biocompatibility works.

Machining advice includes using sharp cutting tools and the right cutting fluids to keep the surface smooth. Using controlled feed rates avoids work hardening while getting the right size and shape.

To get the best mechanical properties for the applications they are meant for, heat treatment schedules should follow standard methods. The final properties of a material are greatly affected by the temperatures used in annealing and the rates at which it cools.

Quality verification procedures should check the dimensions, measure the surface finish, and test the mechanics of materials before they are used in medical devices. These steps make sure that the rules and standards for patient safety are followed.

Critical Considerations for Safe Implementation

Material certification papers have to show that they meet relevant medical device standards, such as ASTM F67, ASTM F136, and ISO 5832-3. Regulatory approval and compliance with patient safety can be ensured by proper certification.

To keep the surfaces from oxidising or getting dirty, the humidity and temperature must be controlled. Protective packaging keeps the contents safe during shipping and handling.

To keep medical-grade materials from getting mixed up with industrial alloys, the processing equipment should be used only for the former. Separate manufacturing lines make sure that the purity of the product stays the same over time.

Personnel training programs must stress the right way to handle things and quality control. Skilled technicians know how important it is to make medical titanium bars, and they keep the right standards.

Regularly calibrating testing tools makes sure that the quality verification process gets the right measurement results. Instruments that have been calibrated give trustworthy data that shows regulatory compliance and material certification.

Conclusion

All the time, using titanium bars in medicine helps get better results. This is because the material is great and the process is very precise. These materials are good for modern medicine because they are strong, don't break down over time, and are safe for use in the body. Chuanghui Daye is always reliable for medical-grade materials that meet strict standards because they are committed to quality and technical excellence. Better titanium bars should be used for implants because they lead to better results and lower long-term healthcare costs. This is because complications happen less often and implants last longer.

FAQ

Q1: How is medical-grade titanium different from titanium bars that are used in industry?

A: To get biocompatibility certification, medical-grade titanium has to go through more purification and stricter quality controls. Better surface finishing and thorough biocompatibility testing make sure that the material can be safely used with human tissues. On the other hand, biocompatibility is not important for the "industrial" version—only mechanical properties are kept in mind.

Q2: How do I find the right level for my medical application?

A: The choice of grade depends on how strong it needs to be and where it will be used. For applications with little stress, Grades 1 and 2 have great corrosion resistance. Grade 5 ELI, on the other hand, has better strength for orthopedic implants that bear weight. Talk to our technical team about your device needs so they can give you the right advice.

Q3: When I buy medical titanium bars, what quality certifications should I look for?

A: A full material certification package has an analysis of chemical composition, test results for mechanical properties, proof of biocompatibility, and reports on dimensional inspection. ISO 13485 certification for manufacturing and ASTM standard compliance paperwork make sure that the government approves medical device applications.

Partner with Chuanghui Daye for Superior Medical Titanium Bar Solutions

Chuanghui Daye makes great medical titanium bar products with the help of cutting-edge manufacturing and technical support. Our experienced team knows the important things to keep in mind when making medical devices, and we can provide tailored solutions for your specific needs. Our medical titanium bar supplier capabilities guarantee dependable delivery and steady quality, whether you need standard sizes or unique setups. To talk about your project needs and see how our knowledge can help you reach your medical device development goals, please email us at info@chdymetal.com.

References

1. American Society for Testing and Materials. "Standard Specification for Unalloyed Titanium for Surgical Implant Applications (ASTM F67-13)." Annual Book of ASTM Standards, Vol. 13.01, 2019.

2. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. "Ti-based biomaterials, the ultimate choice for orthopaedic implants – A review." Progress in Materials Science, 54(3), 397-425, 2009.

3. International Organisation for Standardisation. "Implants for surgery — Metallic materials — Part 3: Wrought titanium 6-aluminium 4-vanadium alloy (ISO 5832-3:2016)." Geneva: ISO Press, 2016.

4. Chen, Q., & Thouas, G. A. "Metallic implant biomaterials." Materials Science and Engineering: R: Reports, 87, 1-57, 2015.

5. Niinomi, M., & Nakai, M. "Titanium-based biomaterials for preventing stress shielding between implant devices and bone." International Journal of Biomaterials, Article ID 836587, 2011.

6. Ryan, G., Pandit, A., & Apatsidis, D. P. "Fabrication methods of porous metals for use in orthopaedic applications." Biomaterials, 27(13), 2651-2670, 2006.