- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does tantalum alloy plate react with different acids?

As a supplier of Tantalum Alloy Plate, I've witnessed firsthand the remarkable properties and applications of this versatile material. One of the most fascinating aspects of tantalum alloy plates is their interaction with different acids. In this blog post, I'll delve into the science behind these reactions, exploring how tantalum alloy plates hold up against various acidic environments.

Understanding Tantalum Alloy Plates

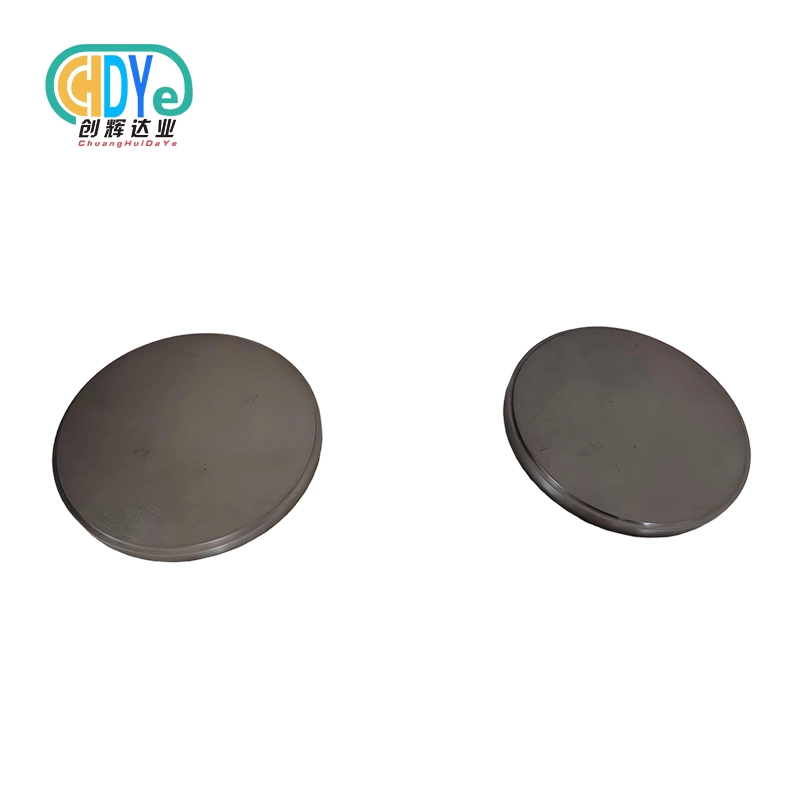

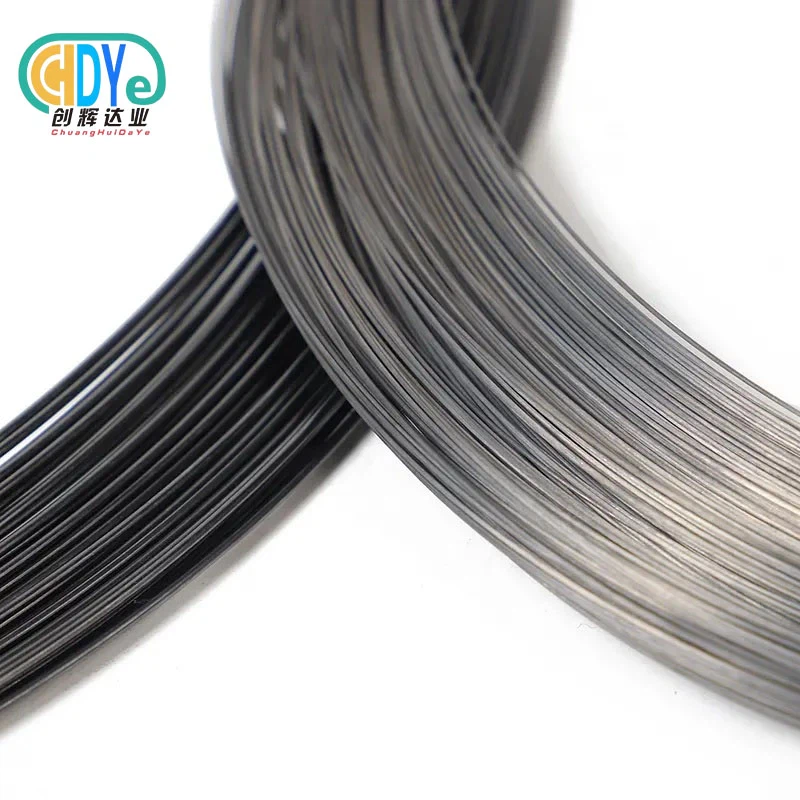

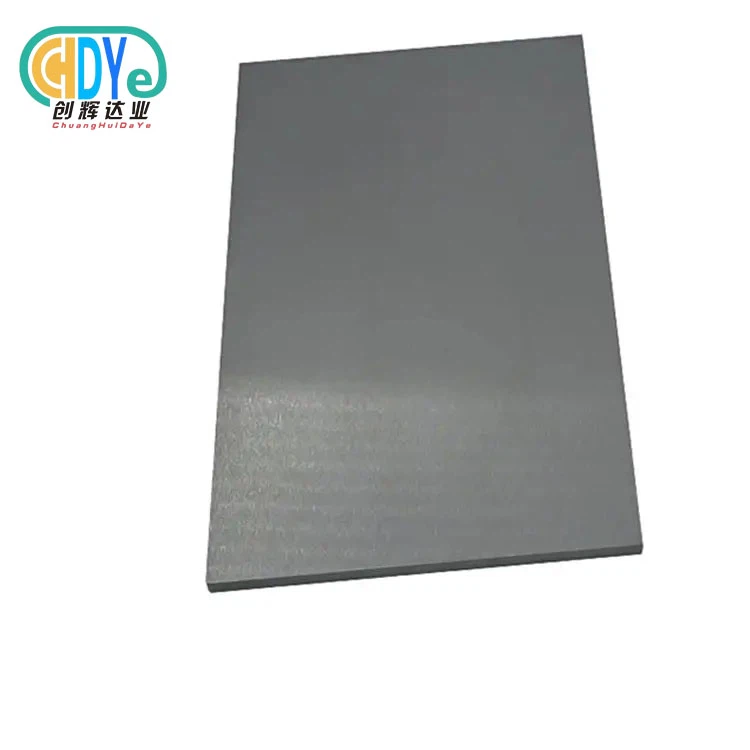

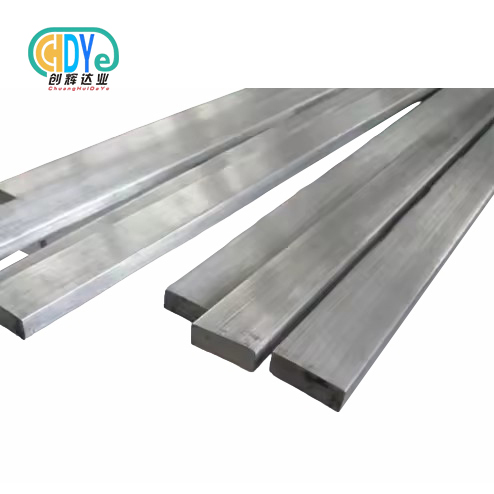

Before we dive into the reactions with acids, let's take a moment to understand what tantalum alloy plates are. Tantalum is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion-resistant. When combined with other metals to form alloys, tantalum's properties are further enhanced, making it suitable for a wide range of applications, from chemical processing to electronics.

Our Tantalum Alloy Plate products are crafted with precision, ensuring high quality and consistency. These plates come in various sizes and compositions, tailored to meet the specific needs of our customers. Whether you're looking for a Tantalum Alloy Sheet and Plates for a small-scale project or a large Pure Tantalum Plate for industrial use, we've got you covered.

Reaction with Hydrochloric Acid (HCl)

Hydrochloric acid is a strong, highly corrosive acid commonly used in industrial processes such as metal pickling and ore processing. When it comes to tantalum alloy plates, they exhibit excellent resistance to hydrochloric acid, even at high concentrations and elevated temperatures.

The reason for this resistance lies in the formation of a passive oxide layer on the surface of the tantalum alloy. This oxide layer acts as a protective barrier, preventing the acid from reacting with the underlying metal. As a result, tantalum alloy plates can be safely used in equipment that comes into contact with hydrochloric acid, such as storage tanks, pipes, and heat exchangers.

However, it's important to note that the resistance of tantalum alloy plates to hydrochloric acid can be affected by factors such as the presence of impurities in the acid, the temperature, and the duration of exposure. In some cases, prolonged exposure to concentrated hydrochloric acid at high temperatures may cause the passive oxide layer to break down, leading to corrosion. Therefore, it's crucial to carefully consider these factors when selecting tantalum alloy plates for applications involving hydrochloric acid.

Reaction with Sulfuric Acid (H₂SO₄)

Sulfuric acid is another strong acid widely used in the chemical industry. It is known for its dehydrating properties and its ability to react with a variety of metals. Tantalum alloy plates also show good resistance to sulfuric acid, especially at low to moderate concentrations and temperatures.

Similar to the reaction with hydrochloric acid, the passive oxide layer on the surface of the tantalum alloy protects it from corrosion by sulfuric acid. However, as the concentration and temperature of the acid increase, the resistance of the tantalum alloy plates may decrease. At high concentrations and temperatures, sulfuric acid can react with the tantalum alloy, causing it to dissolve slowly.

To ensure the long-term performance of tantalum alloy plates in sulfuric acid environments, it's recommended to use them in applications where the acid concentration and temperature are within the specified limits. Additionally, regular inspection and maintenance of the equipment are essential to detect any signs of corrosion early and take appropriate measures.

Reaction with Nitric Acid (HNO₃)

Nitric acid is a strong oxidizing acid commonly used in the production of fertilizers, explosives, and dyes. Tantalum alloy plates have excellent resistance to nitric acid, even at high concentrations and temperatures.

The high resistance of tantalum alloy plates to nitric acid is due to the formation of a stable passive oxide layer on the surface. This oxide layer is highly resistant to oxidation and corrosion, making tantalum alloy plates suitable for use in equipment that handles nitric acid, such as reactors, condensers, and distillation columns.

However, it's important to be aware that the presence of certain impurities in the nitric acid, such as chloride ions, can reduce the resistance of tantalum alloy plates. Chloride ions can react with the passive oxide layer, causing it to break down and leading to corrosion. Therefore, it's necessary to ensure that the nitric acid used in applications involving tantalum alloy plates is free from impurities.

Reaction with Hydrofluoric Acid (HF)

Hydrofluoric acid is a highly corrosive acid that can react with a wide range of metals, including tantalum. Unlike the other acids mentioned above, tantalum alloy plates do not have good resistance to hydrofluoric acid.

Hydrofluoric acid can react with the tantalum alloy, forming soluble fluoride compounds and causing the metal to dissolve. Even at low concentrations, hydrofluoric acid can cause significant damage to tantalum alloy plates in a relatively short period of time. Therefore, it's not recommended to use tantalum alloy plates in applications where they will come into contact with hydrofluoric acid.

Conclusion

In conclusion, tantalum alloy plates offer excellent resistance to many common acids, making them a valuable material for a variety of applications in the chemical industry. Their ability to form a passive oxide layer on the surface provides a protective barrier against corrosion, allowing them to withstand harsh acidic environments.

However, it's important to remember that the resistance of tantalum alloy plates to acids can be affected by various factors, such as the concentration and temperature of the acid, the presence of impurities, and the duration of exposure. Therefore, when selecting tantalum alloy plates for a specific application, it's crucial to carefully consider these factors and consult with a professional to ensure the best performance and longevity of the equipment.

If you're in the market for high-quality Tantalum Alloy Plate, Tantalum Alloy Sheet and Plates, or Pure Tantalum Plate, we invite you to contact us for more information. Our team of experts is ready to assist you in finding the right solution for your specific needs. Let's start a conversation about how our tantalum alloy products can benefit your projects.

Contact us with below information:

E-mail: info@chdymetal.com

Mob./What'sapp: 86-18049386902

References

"Corrosion Resistance of Tantalum and Tantalum Alloys" by The International Tantalum-Niobium Research Center.

"Handbook of Corrosion Data" by Bruce D. Craig.

"Corrosion in the Chemical Process Industries" by Milton G. Fontana.

Learn about our latest products and discounts through SMS or email