- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What makes grade 5 titanium alloy sheet the industry standard for aerospace?

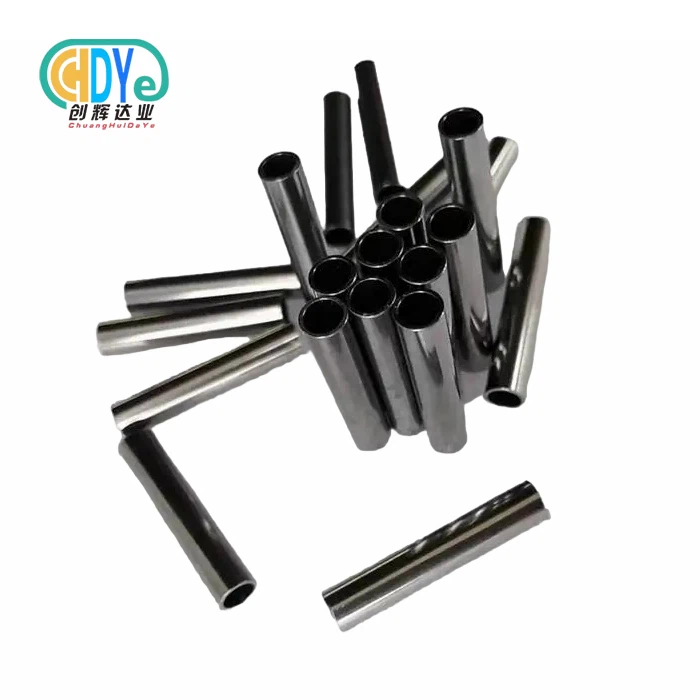

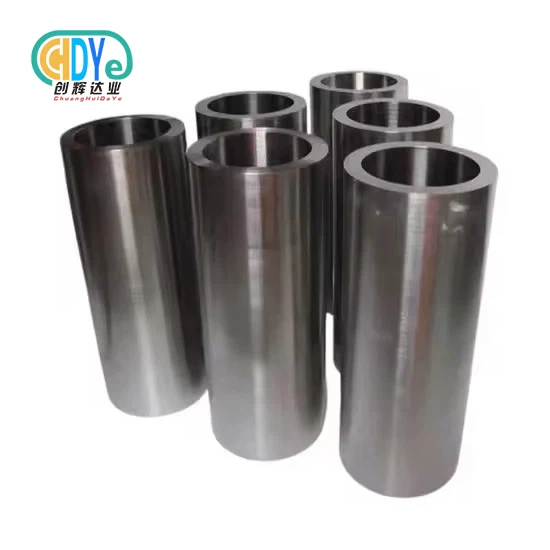

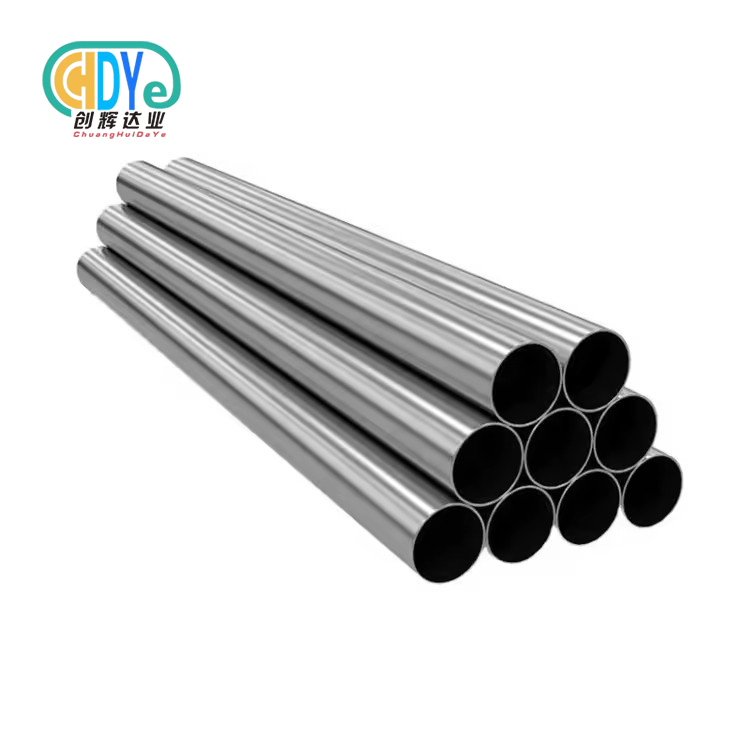

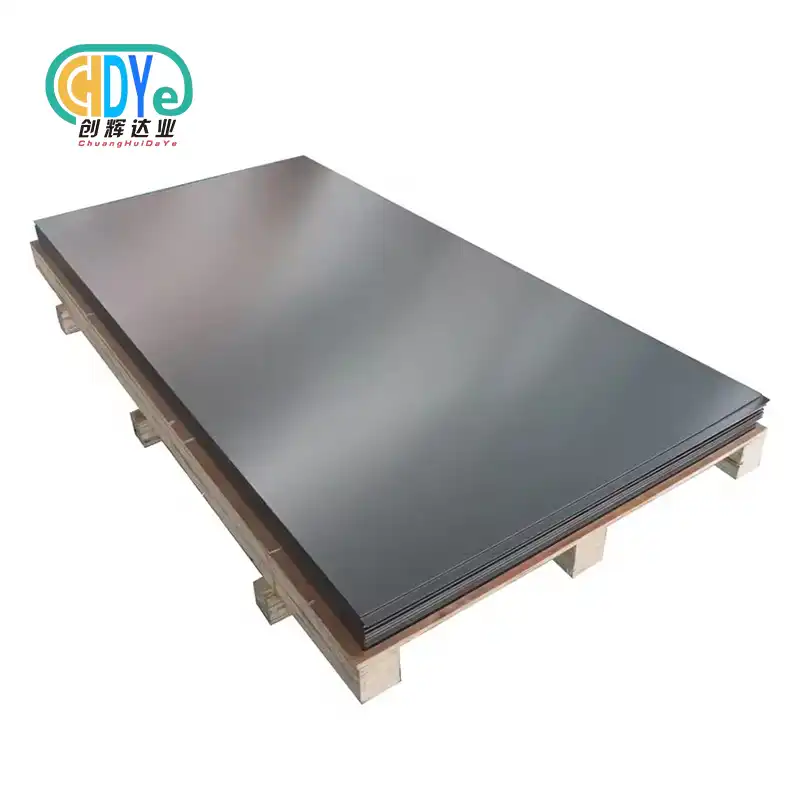

Grade 5 titanium alloy sheet, also known as Ti-6Al-4V, has established itself as the gold standard in the aerospace industry due to its exceptional combination of properties. This high-performance material has revolutionized aircraft design and manufacturing, offering an unparalleled balance of strength, weight reduction, and durability. As the aerospace sector continually pushes the boundaries of innovation, grade 5 titanium alloy sheet has become an indispensable component in the construction of modern aircraft, spacecraft, and satellites. Its ability to withstand extreme conditions while maintaining structural integrity has made it a cornerstone of aerospace engineering. In this blog, we will explore the unique characteristics that have elevated grade 5 titanium alloy sheet to its preeminent position in the aerospace industry and examine why it continues to be the material of choice for cutting-edge aerospace applications.

Why grade 5 titanium alloy sheet offers a superior strength-to-weight ratio

Exceptional tensile strength

Grade 5 titanium alloy sheet boasts an exceptional tensile strength that sets it apart in the aerospace industry. This remarkable property allows aerospace engineers to design components that can withstand tremendous stress and strain while maintaining structural integrity. The grade 5 titanium alloy sheet's high tensile strength is attributed to its unique composition of titanium, aluminum, and vanadium, which creates a microstructure that resists deformation under load. This characteristic is crucial in aerospace applications where components must endure extreme forces during takeoff, flight, and landing. The ability of grade 5 titanium alloy sheet to maintain its strength even at elevated temperatures further enhances its suitability for use in aircraft engines and other high-stress areas.

Low density for weight reduction

One of the most significant advantages of grade 5 titanium alloy sheet in aerospace applications is its low density compared to other high-strength materials. This property allows for substantial weight reduction in aircraft and spacecraft design, which is critical for improving fuel efficiency and increasing payload capacity. The grade 5 titanium alloy sheet's density is approximately 40% lower than that of steel, yet it offers comparable strength. This remarkable strength-to-weight ratio enables aerospace engineers to create lighter, more efficient structures without compromising on durability or safety. By incorporating grade 5 titanium alloy sheet into aircraft components, manufacturers can significantly reduce the overall weight of the vehicle, leading to improved performance and reduced operational costs.

High specific strength

The high specific strength of grade 5 titanium alloy sheet is another key factor that makes it the industry standard for aerospace applications. Specific strength is the ratio of a material's strength to its density, and in this regard, grade 5 titanium alloy sheet excels. This property allows aerospace engineers to design structures that are both strong and lightweight, optimizing the performance of aircraft and spacecraft. The grade 5 titanium alloy sheet's high specific strength enables the creation of thinner, lighter components that can withstand the same loads as heavier alternatives made from other materials. This characteristic is particularly valuable in applications such as aircraft fuselages, wing structures, and engine components, where weight reduction directly translates to improved fuel efficiency and increased range.

How does grade 5 titanium alloy sheet resist fatigue, heat, and corrosion

Superior fatigue resistance

Grade 5 titanium alloy sheet exhibits exceptional fatigue resistance, making it an ideal choice for aerospace applications that involve cyclic loading and repeated stress. This property ensures that components made from grade 5 titanium alloy sheet can withstand the constant vibrations, pressure changes, and stress cycles encountered during flight without developing cracks or failing prematurely. The material's high fatigue strength is attributed to its unique microstructure, which resists the initiation and propagation of fatigue cracks. This characteristic is crucial in aerospace engineering, where component failure could have catastrophic consequences. By using grade 5 titanium alloy sheet, manufacturers can design aircraft parts with longer service lives and reduced maintenance requirements, ultimately enhancing safety and reliability in the aerospace industry.

Heat resistance and thermal stability

The aerospace industry demands materials that can perform reliably under extreme temperature conditions, and grade 5 titanium alloy sheet meets this requirement with its excellent heat resistance and thermal stability. This alloy maintains its strength and structural integrity at elevated temperatures, making it suitable for use in high-temperature environments such as jet engines and supersonic aircraft components. The grade 5 titanium alloy sheet's ability to resist creep and maintain dimensional stability at high temperatures is crucial for ensuring the safety and efficiency of aerospace systems. Additionally, its low thermal expansion coefficient helps minimize stress and distortion in components subjected to temperature fluctuations, further enhancing its suitability for aerospace applications.

Exceptional corrosion resistance

Corrosion resistance is a critical property for materials used in aerospace applications, and grade 5 titanium alloy sheet excels in this aspect. The alloy forms a stable, protective oxide layer on its surface when exposed to oxygen, which provides excellent resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This inherent corrosion resistance makes grade 5 titanium alloy sheet particularly valuable in aerospace applications where exposure to harsh environments, such as saltwater or acidic conditions, is common. The material's ability to withstand corrosive attacks ensures the longevity and reliability of aircraft components, reducing maintenance costs and improving overall safety. Furthermore, the corrosion resistance of grade 5 titanium alloy sheet contributes to its long-term durability, making it an economical choice for aerospace manufacturers.

Why is grade 5 titanium alloy sheet ideal for complex aerospace parts

Excellent formability and machinability

Grade 5 titanium alloy sheet offers excellent formability and machinability, making it an ideal material for creating complex aerospace parts. These properties allow manufacturers to shape and fabricate the alloy into intricate components with high precision and consistency. The grade 5 titanium alloy sheet can be formed using various techniques, including hot and cold forming, superplastic forming, and diffusion bonding, enabling the production of complex geometries and structures that are essential in modern aerospace design. Its machinability, while not as high as some other metals, is still sufficient for producing high-quality parts with tight tolerances. This versatility in manufacturing processes allows aerospace engineers to push the boundaries of design and create innovative components that optimize performance and efficiency in aircraft and spacecraft.

Weldability and joining capabilities

The weldability and joining capabilities of grade 5 titanium alloy sheet contribute significantly to its suitability for complex aerospace parts. This alloy can be welded using various techniques, including tungsten inert gas (TIG) welding, electron beam welding, and laser beam welding, allowing for the creation of large, complex structures with minimal weight penalty. The grade 5 titanium alloy sheet's ability to form strong, reliable welds is crucial in aerospace applications where structural integrity is paramount. Additionally, its compatibility with other joining methods, such as adhesive bonding and mechanical fastening, provides engineers with a range of options for assembling complex components. These joining capabilities enable the integration of grade 5 titanium alloy sheet parts into larger aerospace systems, facilitating the construction of advanced aircraft and spacecraft designs.

Compatibility with advanced manufacturing techniques

Grade 5 titanium alloy sheet is highly compatible with advanced manufacturing techniques, making it an excellent choice for producing complex aerospace parts. The material is well-suited for additive manufacturing processes, such as 3D printing and selective laser melting, which allow for the creation of intricate, lightweight structures that would be difficult or impossible to produce using traditional manufacturing methods. This compatibility with advanced manufacturing techniques enables aerospace engineers to optimize component designs for weight reduction and performance enhancement. The grade 5 titanium alloy sheet's properties also make it suitable for other cutting-edge fabrication methods, such as near-net-shape forming and hot isostatic pressing, which can reduce material waste and improve production efficiency. As the aerospace industry continues to adopt and develop new manufacturing technologies, the versatility of grade 5 titanium alloy sheet ensures its ongoing relevance and importance in the production of complex aerospace parts.

Conclusion

Grade 5 titanium alloy sheet has firmly established itself as the industry standard for aerospace applications due to its exceptional combination of properties. Its superior strength-to-weight ratio, resistance to fatigue, heat, and corrosion, and suitability for complex part manufacturing make it an invaluable material in the aerospace sector. As the industry continues to push the boundaries of performance and efficiency, grade 5 titanium alloy sheet will undoubtedly play a crucial role in shaping the future of aerospace engineering. Its versatility and reliability ensure that it will remain at the forefront of material selection for aircraft, spacecraft, and satellite components for years to come.

For high-quality grade 5 titanium alloy sheets and other specialized metal materials, Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a leading supplier in the industry. Located in China's "Titanium Capital," the company leverages its extensive experience and advanced manufacturing capabilities to provide top-tier products for aerospace and other high-tech applications. For more information or inquiries, please contact us at info@chdymetal.com.

FAQ

1.What is a grade 5 titanium alloy sheet?

Grade 5 titanium alloy sheet, also known as Ti-6Al-4V, is a high-strength titanium alloy composed of titanium, 6% aluminum, and 4% vanadium. It offers an excellent combination of strength, light weight, and corrosion resistance.

2. Why is grade 5 titanium alloy sheet preferred in aerospace applications?

It is preferred due to its high strength-to-weight ratio, excellent fatigue resistance, heat resistance, and corrosion resistance, making it ideal for the demanding conditions in aerospace.

3. How does grade 5 titanium alloy sheet compare to other materials in terms of weight?

Grade 5 titanium alloy sheet is approximately 40% lighter than steel while offering comparable strength, allowing for significant weight reduction in aerospace structures.

4. Can a grade 5 titanium alloy sheet be welded?

Yes, grade 5 titanium alloy sheet can be welded using various techniques, including TIG welding, electron beam welding, and laser beam welding.

5. Is grade 5 titanium alloy sheet suitable for 3D printing?

Yes, grade 5 titanium alloy is compatible with additive manufacturing processes, including 3D printing and selective laser melting.

References

1. Boyer, R. R. (1996). An overview of the use of titanium in the aerospace industry. Materials Science and Engineering: A, 213(1-2), 103-114.

2. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

3. Inagaki, I., Takechi, T., Shirai, Y., & Ariyasu, N. (2014). Application and features of titanium for the aerospace industry. Nippon Steel & Sumitomo Metal Technical Report, 106, 22-27.

4. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and titanium alloys: fundamentals and applications. John Wiley & Sons.

5. Lütjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer Science & Business Media.

6. Donachie, M. J. (2000). Titanium: a technical guide. ASM International.

Learn about our latest products and discounts through SMS or email