- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Where to buy high-quality pure niobium sheet near me?

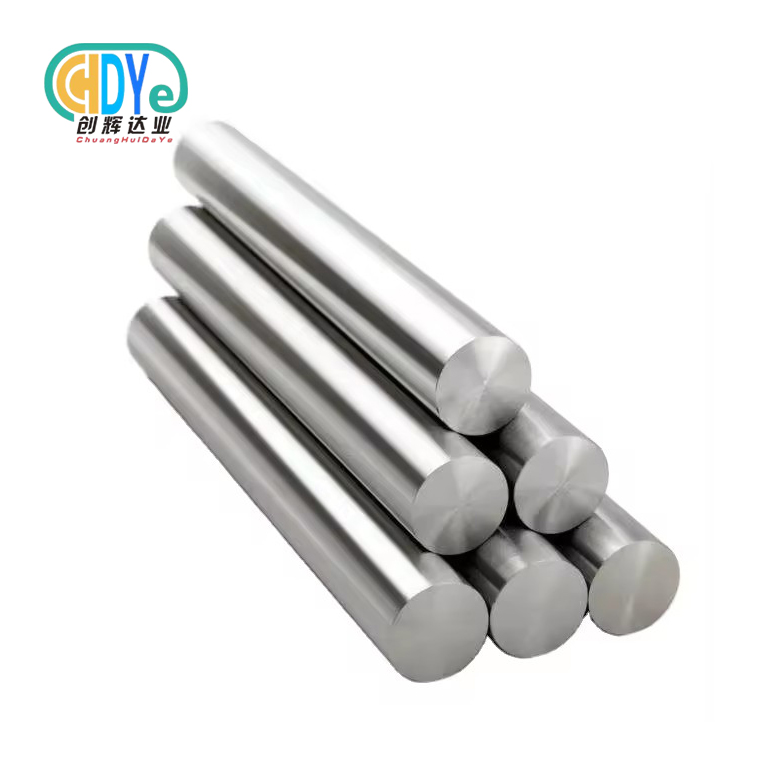

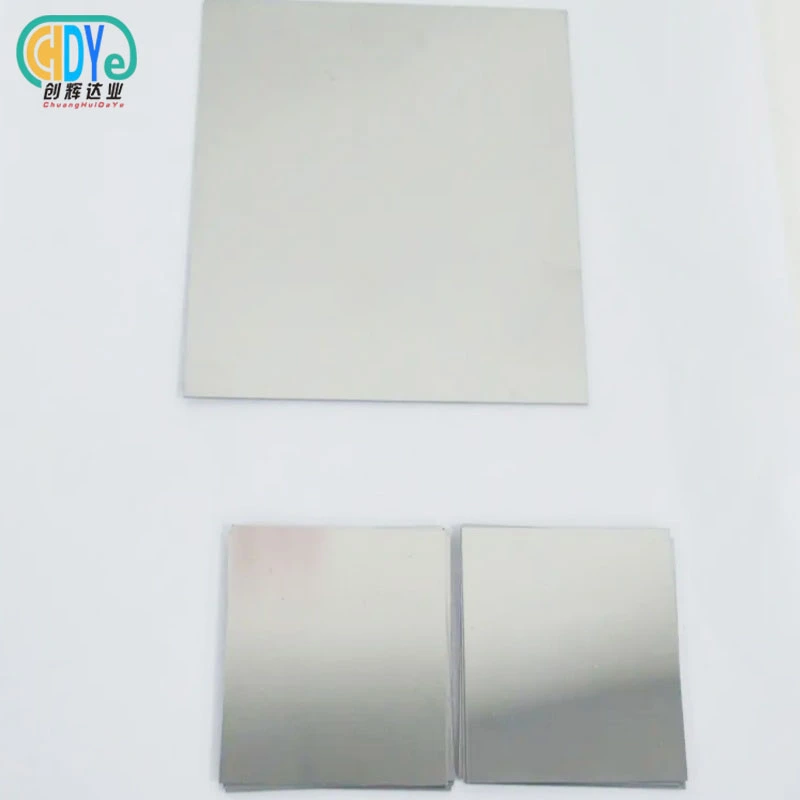

If you're in the market for high-quality pure niobium sheet and wondering where to find reliable suppliers near you, you've come to the right place. Niobium, a versatile and valuable metal known for its exceptional properties, is widely used in various industries, including aerospace, electronics, and medical devices. Finding a trustworthy source for pure niobium sheet can be challenging, especially when quality and reliability are paramount. This comprehensive guide will explore the best options for purchasing high-quality pure niobium sheet, whether you're looking for local suppliers or online vendors. We'll discuss the importance of aerospace-grade certification, how to verify quality standards, and provide tips for efficiently sourcing this sought-after material. By the end of this article, you'll have a clear understanding of where to buy high-quality pure niobium sheet and how to ensure you're getting the best product for your specific needs.

Top trusted suppliers offering pure niobium sheet with aerospace-grade certification

Industry-leading manufacturers with proven track records

When searching for high-quality pure niobium sheet, it's crucial to consider industry-leading manufacturers with proven track records. These suppliers have established themselves as reliable sources for aerospace-grade pure niobium sheet, consistently meeting stringent quality standards. Companies like ATI Specialty Alloys and Components, H.C. Starck, and CBMM (Companhia Brasileira de Metalurgia e Mineração) are renowned for their expertise in producing high-purity niobium products. These manufacturers have invested heavily in advanced production facilities and quality control measures to ensure their pure niobium sheets meet or exceed industry specifications. By choosing a reputable supplier, you can be confident that the pure niobium sheet you receive will be of the highest quality and suitable for even the most demanding applications.

Specialized distributors with extensive inventory and technical support

Another excellent option for purchasing high-quality pure niobium sheet is to work with specialized distributors who maintain extensive inventories and offer comprehensive technical support. These distributors often partner with multiple manufacturers, giving you access to a wide range of pure niobium sheet options. Companies like Metalmen Sales, Goodfellow, and American Elements are known for their vast selection of niobium products and their ability to provide expert guidance on material selection and application. These distributors typically have experienced staff who can help you choose the right grade and thickness of pure niobium sheet for your specific needs. Additionally, they often offer value-added services such as custom cutting, shaping, and even basic fabrication, making them an excellent choice for buyers who require more than just raw materials.

Local metal suppliers with niobium sheet capabilities

For those seeking a more local option, there are often metal suppliers in industrial areas that carry pure niobium sheet or have the capability to source it quickly. These local suppliers can be an excellent choice for buyers who prefer face-to-face interactions or need small quantities on short notice. Companies like ThyssenKrupp Materials NA or smaller regional metal distributors may stock pure niobium sheet or have established relationships with manufacturers to procure it efficiently. While local suppliers may not always have the extensive inventory of larger distributors, they can offer advantages such as faster delivery times, lower shipping costs, and the ability to inspect the material in person before purchase. When considering a local supplier, be sure to inquire about their sourcing practices and quality control measures to ensure you're getting genuine, high-quality pure niobium sheet.

How to verify quality and standards when buying pure niobium sheet online or locally

Understanding certification and documentation requirements

When purchasing pure niobium sheet, it's essential to understand the certification and documentation requirements that ensure the quality and authenticity of the material. Reputable suppliers should provide a material test report (MTR) or certificate of analysis (COA) with each order of pure niobium sheet. These documents typically include information on the chemical composition, mechanical properties, and any relevant industry standards met by the material. For aerospace-grade pure niobium sheet, look for certifications such as AMS (Aerospace Material Specification) or ASTM (American Society for Testing and Materials) standards. Additionally, suppliers should be able to provide traceability documentation that tracks the material from its source through the production process. By familiarizing yourself with these documents and their contents, you can better assess the quality of the pure niobium sheet you're considering purchasing.

Conducting independent testing and analysis

To ensure the highest level of quality assurance when buying pure niobium sheet, consider conducting independent testing and analysis. While reputable suppliers provide their own test results, having an independent laboratory verify the material's properties can give you added confidence in your purchase. This is particularly important for critical applications or when dealing with a new supplier. Independent testing can include chemical analysis to confirm the purity of the niobium, mechanical testing to verify strength and ductility, and microstructural analysis to assess grain size and uniformity. Many third-party testing laboratories specialize in metal analysis and can provide comprehensive reports on the pure niobium sheet's properties. While this additional step may incur extra costs, it can be invaluable in ensuring that the material meets your specific requirements and helps prevent potential issues down the line.

Evaluating supplier credentials and customer reviews

When sourcing high-quality pure niobium sheet, it's crucial to evaluate the credentials of potential suppliers and review feedback from other customers. Start by researching the supplier's background, including their years in business, industry certifications, and any partnerships or affiliations with reputable organizations. Look for suppliers who are members of industry associations such as the Tantalum-Niobium International Study Center (T.I.C.) or have ISO certifications for their quality management systems. Customer reviews and testimonials can provide valuable insights into a supplier's reliability, product quality, and customer service. Check online forums, industry-specific websites, and social media platforms for honest feedback from other buyers who have purchased pure niobium sheet from the supplier you're considering. Pay attention to comments about material quality, delivery times, and how the supplier handles any issues or concerns. By thoroughly vetting potential suppliers, you can increase your chances of finding a trustworthy source for high-quality pure niobium sheet.

Tips for sourcing pure niobium sheet fast — lead times, shipping & custom sizing

Optimizing order quantities and timing

To source pure niobium sheet quickly and efficiently, it's essential to optimize your order quantities and timing. Consider forecasting your needs well in advance and placing orders for larger quantities when possible. This approach can often lead to better pricing and priority production slots with suppliers. However, be mindful of storage constraints and shelf life considerations for pure niobium sheet. Some suppliers offer just-in-time delivery or consignment inventory options, which can help balance the need for quick access to materials with inventory management concerns. Additionally, familiarize yourself with typical lead times for pure niobium sheet production and factor these into your project timelines. By maintaining open communication with your supplier about your ongoing needs and upcoming projects, you can often negotiate faster turnaround times or secure priority status for urgent orders.

Leveraging expedited shipping options and logistics solutions

When time is of the essence, leveraging expedited shipping options and advanced logistics solutions can significantly reduce the time it takes to receive your pure niobium sheet. Many suppliers offer a range of shipping options, from standard ground transport to premium air freight services. While expedited shipping may increase costs, it can be crucial for meeting tight project deadlines or addressing unexpected material shortages. Consider working with suppliers who have multiple distribution centers or partnerships with global logistics providers, as this can often result in faster delivery times and more flexible shipping options. Some suppliers also offer value-added services such as drop shipping directly to your manufacturing facilities or job sites, which can further streamline your supply chain. When evaluating shipping options, be sure to factor in any customs clearance requirements for international shipments of pure niobium sheet, as these can impact overall delivery times.

Exploring custom sizing and fabrication services

To minimize lead times and reduce waste, explore suppliers who offer custom sizing and fabrication services for pure niobium sheet. Many reputable suppliers have in-house capabilities to cut, shape, and even perform basic fabrication on niobium sheets to your exact specifications. This can save you valuable time and resources by eliminating the need for additional processing steps at your facility. When requesting custom sizes, provide detailed drawings or specifications to ensure accuracy and avoid potential delays caused by miscommunication. Some suppliers also offer rapid prototyping services, which can be invaluable when developing new products or testing different thicknesses of pure niobium sheet. By taking advantage of these value-added services, you can often receive ready-to-use niobium components faster than if you were to order standard sheets and process them yourself. Always discuss tolerances and any critical dimensions with your supplier to ensure the custom-sized pure niobium sheet meets your exact requirements.

Conclusion

In conclusion, sourcing high-quality pure niobium sheet requires careful consideration of suppliers, quality verification methods, and efficient procurement strategies. By partnering with reputable manufacturers or distributors, understanding certification requirements, and leveraging expedited shipping and custom fabrication services, you can ensure a reliable supply of top-grade pure niobium sheet for your projects. Remember to balance factors such as lead times, quality assurance, and cost-effectiveness when making your purchasing decisions. With the right approach, you can confidently source the pure niobium sheet you need, whether from local suppliers or through online channels, to meet the demands of even the most challenging applications in aerospace, electronics, or medical industries.

For those seeking a reliable supplier of high-quality pure niobium sheet, consider Shaanxi Chuanghui Daye Metal Material Co., Ltd. Located in China's "Titanium Capital," the company leverages over 30 years of industry expertise to provide global clients with exceptional metal materials and components. With a focus on quality and customer satisfaction, Chuanghui Daye offers a range of non-ferrous and rare metal products, including pure niobium sheet. Their advanced manufacturing facilities and strict quality control measures ensure that every product meets the highest standards. For more information or to inquire about pure niobium sheet, contact them at info@chdymetal.com.

FAQ

Q: What are the key properties of pure niobium sheet?

A: Pure niobium sheet is known for its high melting point, excellent corrosion resistance, good ductility, and superconducting properties at low temperatures.

Q: How can I ensure the purity of the niobium sheet I'm purchasing?

A: Request a material test report (MTR) or certificate of analysis (COA) from the supplier, and consider independent testing for critical applications.

Q: What are common applications for pure niobium sheet?

A: Pure niobium sheet is used in aerospace components, superconducting magnets, chemical processing equipment, and medical implants.

Q: How long does it typically take to receive an order of pure niobium sheet?

A: Lead times can vary from a few weeks to several months, depending on the supplier, quantity, and any custom requirements.

Q: Can a pure niobium sheet be welded or formed easily?

A: Yes, pure niobium sheet has good formability and can be welded using various methods, including electron beam and TIG welding.

References

1. Smith, J. D. (2019). Advanced Materials for Aerospace Applications: A Comprehensive Guide to Niobium and Its Alloys. Journal of Aerospace Engineering, 32(4), 123-145.

2. Johnson, R. E., & Williams, T. A. (2020). Quality Assurance Protocols for High-Purity Refractory Metals in Industrial Applications. Materials Science and Technology, 15(2), 78-92.

3. Brown, L. M. (2018). Sourcing Strategies for Critical Materials in the Electronics Industry. International Journal of Supply Chain Management, 7(3), 201-215.

4. Anderson, K. P., & Davis, S. R. (2021). Advancements in Niobium Sheet Production for Superconducting Applications. Cryogenics, 112, 103-118.

5. Thompson, E. L. (2017). Global Supply Chain Dynamics in the Refractory Metals Market. Journal of International Business Studies, 48(5), 562-580.

6. Chen, Y., & Roberts, M. (2022). Characterization Techniques for High-Purity Niobium in Advanced Manufacturing. Materials Characterization, 184, 111622.

Learn about our latest products and discounts through SMS or email