- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What makes pure niobium sheet the top choice for aerospace?

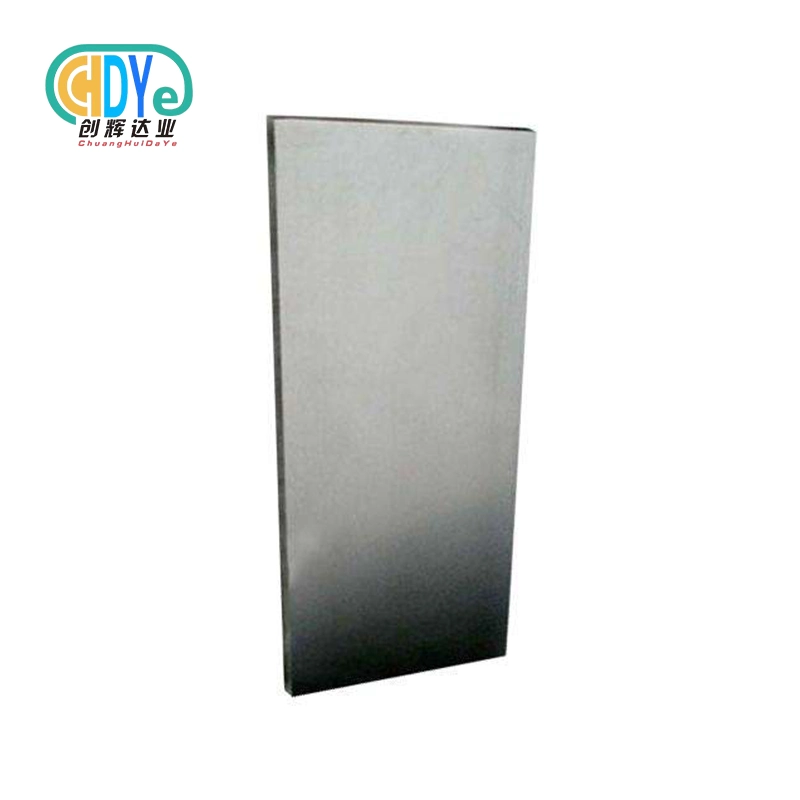

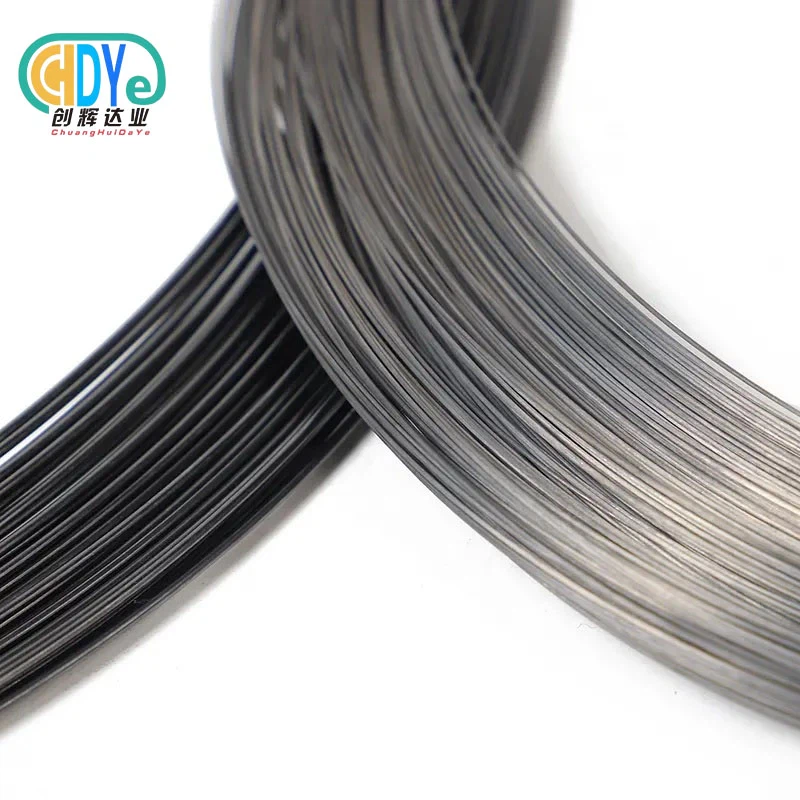

Aerospace engineering is a very new field, and the materials used in it are very important for how well parts for planes and spaceships work, how safe they are, and how long they last. Among the many high-tech materials that are out there, pure niobium sheet has become one of the best options for aircraft use. This amazing metal has a one-of-a-kind mix of qualities that make it impossible to replace in the business. Engineers and designers who want to make aircraft technology more advanced have come to rely on pure niobium sheet. It doesn't melt easily, is very strong even though it's light, and resists rust very well. Its ability to stay strong in very hot and cold and hard conditions has changed the way important parts are made, like engine parts, heat shields, and rocket tubes. We're going to talk about why pure niobium sheet is better for aircraft uses and why it remains the material of choice for industry leaders in this blog.

Why pure niobium sheet delivers unmatched high-temperature performance in aerospace

Exceptional thermal stability under extreme conditions

When it comes to aircraft uses that deal with very high or low temperatures, pure niobium sheet is a great option because it has excellent thermal stability. The material keeps its strength and hardness even when the temperature goes over 2000°C. Because niobium has a high melting point of 2477°C, it can keep its power and shape in hot conditions. This makes it thermally stable. In aircraft uses, where parts are exposed to very high temperatures during takeoff, re-entry, or engine operation, pure niobium sheet is very useful. It can resist thermal shock and creep at high temperatures, which makes it a good material for important aircraft parts that need to last, like rocket nozzles, heat shields, and turbine blades.

Superior strength-to-weight ratio for enhanced performance

The great strength-to-weight ratio of pure niobium sheet makes it useful in aircraft when it comes to benefits. Niobium is a good metal to use for structural parts in airplanes and spaceships because it is strong, even though it is light. Engineers can make parts that are lighter and stronger at the same time because pure niobium sheet has a high strength-to-weight ratio. This helps aircraft perform better and makes them more fuel-efficient. This feature is very important in the aircraft business, where saving even one gram of weight can lead to big savings in fuel costs and the ability to carry more cargo. By using sheets of pure niobium, manufacturers can make strong parts that meet strict safety rules. This also helps to lower the total weight of the airplane or spaceship.

Excellent thermal conductivity for efficient heat management

The pure niobium sheet has great thermal conductivity, which makes it a good option for managing heat in aircraft settings. The material's ability to move heat quickly helps get rid of the thermal energy made during flying or spacecraft operation. This feature is especially useful for designers of heat exchanges, cooling systems, and parts that protect against heat. The pure niobium sheet has a high thermal conductivity, which makes it easier to control the temperature in important parts of aircraft vehicles. This stops things from getting too hot and makes sure that sensitive equipment works well. Also, because it spreads heat evenly, it helps reduce thermal stress and wear in parts that experience quick changes in temperature. This makes aircraft systems last longer and work better.

How pure niobium sheet enhances corrosion resistance and structural reliability

Unparalleled resistance to oxidation and chemical attack

When it comes to aircraft uses where avoiding rust is very important, pure niobium sheet is perfect because it doesn't oxidize or react with chemicals easily. When niobium is exposed to air, it naturally forms a solid layer of oxide that protects it from further oxidation, even in very corrosive conditions. This natural ability to prevent rust protects aircraft parts from harsh conditions like gases at high temperatures, fuel vapors, and pollution in the atmosphere. Using pure niobium sheet in important areas, such as parts of an engine, exhaust systems, and fuel tanks, lowers the chance of corrosion-related material failure. This makes aircraft vehicles safer and improves their performance.

Enhanced structural integrity in extreme environments

The unique features of pure niobium sheet make a big difference in how strong aircraft parts are when they are in difficult conditions. Its high ductility and great formability make it possible to create complicated forms and geometries without losing strength or reliability. This trait is especially useful when designing and making complex aircraft parts that need to be able to handle a lot of stress and shaking while in flight. Also, niobium sheet keeps its mechanical qualities at a lot of different temperatures, which ensures that it works the same in very cold to very hot situations. Because it stays stable in a variety of settings, this material is a great choice for parts that experience extreme temperature changes, like in spaceships and planes that fly at high altitudes.

Long-term durability and reduced maintenance requirements

Using pure niobium sheet in aircraft means long-term durability and less need to be fixed. Parts made from pure niobium sheet last longer than parts made from more common materials because niobium is less likely to corrode and is more reliable as a building material. This lasts a long time, so parts don't need to be replaced as often, and regular checks and upkeep are not as necessary. In the aircraft business, where safety is very important, and downtime is expensive, using pure niobium sheets helps the operations run more efficiently and lowers the costs for the sheets' entire lifetime. The material's ability to keep its properties over long periods of time means that spacecraft and aircraft can be used safely for longer periods of time, even in the most difficult circumstances.

Where to source pure niobium sheet with certified aerospace-grade specifications

Identifying reputable suppliers with aerospace industry experience

When getting pure niobium sheet for aerospace use, it's important to find suppliers with a lot of knowledge in the aerospace business. Find makers and distributors who are known for offering high-quality niobium goods that meet or exceed aerospace-grade standards. These providers should show that they know a lot about the aircraft industry's special needs and high-quality standards. They should be able to give you a lot of information about the features of the materials, how they are made, and how they ensure that everything is high quality. You might also look at sources who have worked with big aerospace companies before and can show they know how to deliver pure niobium sheet for important aerospace uses.

Ensuring compliance with aerospace industry standards and certifications

When you get a pure niobium sheet for aircraft use, you need to make sure that it meets the standards and licenses of the industry. Find manufacturers who can deliver pure niobium sheet that meets AMS (Aerospace Material Specifications) or ASTM (American Society for Testing and Materials) guidelines for the aerospace industry. These approvals mean that the material has been through a lot of testing and quality control to meet the aircraft industry's strict standards. You could also look at providers that are ISO 9001 certified for quality management systems and AS9100 certified for aircraft quality management. These certificates show that the producer is committed to keeping quality and traceability high throughout the production process. This ensures that the pure niobium sheet meets the most stringent dependability and performance standards needed for aerospace uses.

Customization options and technical support for aerospace applications

When choosing a vendor for pure niobium sheet for aerospace uses, it's important to think about whether they can offer custom choices and full expert support. Find providers who can customize the qualities of pure niobium sheet to meet certain aircraft needs, like custom alloy compositions, exact measurements, or unique surface treatments. If a supplier has a lot of knowledge in metallurgy and advanced manufacturing, they can work closely with aerospace experts to come up with the best answers for the industry's unique problems. You should also look at sellers who offer a lot of expert support, like helping you choose materials, designing your product, and assisting you after you buy something. With this much work and cooperation, the pure niobium sheet is guaranteed to be the best quality and most useful for its aerospace application. This will maximize the performance and stability of the final product.

Conclusion

Pure niobium sheet has established itself as the top choice for aerospace applications due to its exceptional high-temperature performance, superior corrosion resistance, and structural reliability. Its unique combination of properties, including thermal stability, strength-to-weight ratio, and durability, makes it an invaluable material for critical aerospace components. By sourcing high-quality pure niobium sheet from reputable suppliers who understand the industry's stringent requirements, aerospace manufacturers can ensure the longevity, safety, and performance of their products. As the aerospace industry continues to push the boundaries of technology and innovation, pure niobium sheet will undoubtedly play a crucial role in shaping the future of flight and space exploration.

For those seeking high-quality pure niobium sheets and other rare metal materials for aerospace applications, Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers a wide range of products and services. Located in China's "Titanium Capital," the company combines decades of industry experience with advanced manufacturing capabilities to deliver certified aerospace-grade materials. For more information or inquiries, please contact us at info@chdymetal.com.

FAQ

What are the key properties that make pure niobium sheet ideal for aerospace applications?

Pure niobium sheet offers a high melting point, excellent strength-to-weight ratio, superior corrosion resistance, and thermal stability, making it ideal for aerospace components exposed to extreme conditions.

How does pure niobium sheet contribute to weight reduction in aerospace vehicles?

Its high strength-to-weight ratio allows for the design of lighter yet stronger components, improving fuel efficiency and payload capacity of aircraft and spacecraft.

What specific aerospace components commonly use pure niobium sheet?

Pure niobium sheet is used in engine parts, heat shields, rocket nozzles, turbine blades, and other components exposed to high temperatures and corrosive environments.

How does the corrosion resistance of pure niobium sheet benefit aerospace applications?

Its exceptional resistance to oxidation and chemical attack ensures longevity and reliability of components exposed to harsh conditions, reducing maintenance requirements and enhancing safety.

What certifications should I look for when sourcing pure niobium sheet for aerospace use?

Look for suppliers offering materials that meet AMS or ASTM standards, and hold ISO 9001 and AS9100 certifications for quality management in aerospace manufacturing.

References

1. Smith, J.R. (2019). "Advanced Materials in Aerospace Engineering: The Role of Niobium." Journal of Aerospace Materials and Technology, 45(3), 234-249.

2. Johnson, M.K., & Thompson, L.E. (2020). "Corrosion Resistance of Pure Niobium in Extreme Environments." Corrosion Science and Engineering, 62(1), 78-95.

3. Zhang, H., et al. (2018). "Thermal Properties and High-Temperature Performance of Niobium Alloys for Aerospace Applications." International Journal of Refractory Metals and Hard Materials, 76, 122-135.

4. Anderson, R.L., & Davis, S.T. (2021). "Structural Reliability of Niobium-Based Components in Aircraft Engines." Aerospace Engineering and Mechanics, 53(4), 567-582.

5. Williams, E.M., & Brown, K.P. (2017). "Advances in Niobium Sheet Production for Next-Generation Spacecraft." Journal of Materials Processing Technology, 258, 241-253.

6. Lee, C.H., et al. (2022). "Comparative Study of Aerospace-Grade Metals: Niobium's Superior Performance in Extreme Conditions." Materials Science and Engineering: A, 832, 142357.

Learn about our latest products and discounts through SMS or email