- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to test quality of titanium wire for anodizing suppliers?

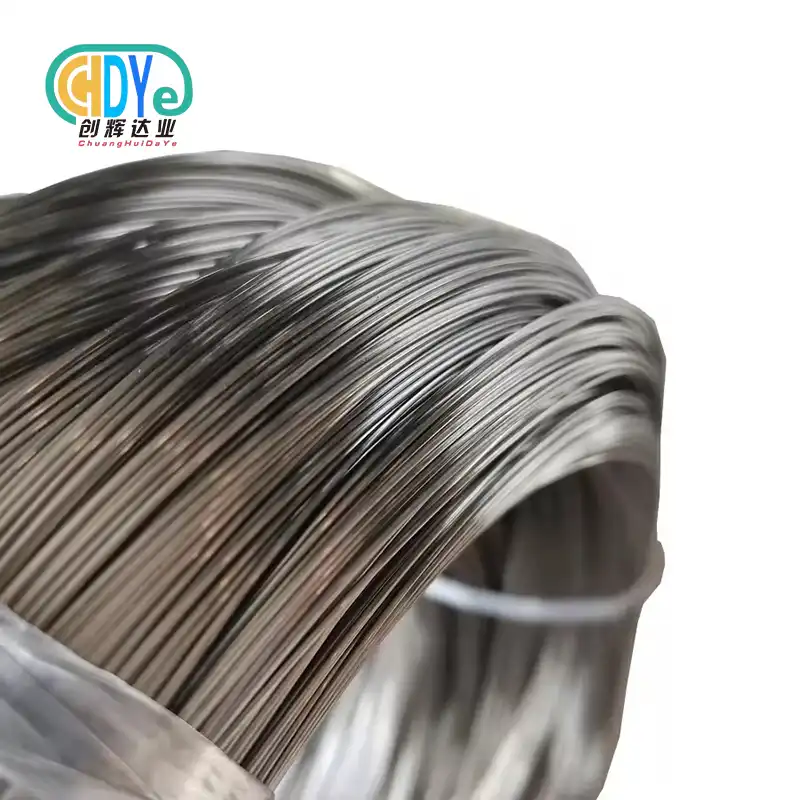

Making sure that the titanium wire for anodizing is of good quality is very important for getting the best results in a range of business activities. It is important to use strict testing methods to ensure the quality of titanium wire from makers as the demand for high-performance materials grows. This all-inclusive guide will go over the most important parts of quality testing for titanium wire that is used in anodizing. These include confirming the credentials of the seller, conducting tests of the wire's physical properties, and performing inspections at the site of the work. If companies follow these steps, they can be sure they are getting high-quality titanium wire that is high-quality and meets their needs for anodizing projects. If you work in chemical processing, making electronics, or applying specialized coatings, knowing how to check the quality of titanium wire is important for keeping your anodizing work uniform and getting better outcomes.

How to Verify Supplier Certifications and Material Traceability for Titanium Wire

Review ISO Certifications and Quality Management Systems

When you buy titanium wire to use in anodizing, you need to make sure that your seller has the right ISO certifications. ISO 9001:2015 for quality management systems is the most important. This approval makes sure that the maker uses standard methods to keep the quality the same. Ask for copies of these licenses and look them over carefully, noting when they expire and what they cover. You should also ask about any certifications that might be needed for the way you use titanium wire for anodizing. A good provider should be open about how they handle quality and be ready to share information about every step in the making of their products, from how they get their materials to how they check the finished products.

Examine Material Test Reports and Chemical Composition Analysis

Make sure you always ask your source for and closely look at Material Test Reports (MTRs) for the titanium wire you want to make sure it works for your anodizing projects. These reports should give a full picture of what the wire is made of, including the amount of each important element, like titanium, aluminum, vanadium, and any other materials that aren't supposed to be there. It is especially important to make sure that the makeup comes within the right ranges for the grade of titanium you need, like Grade 2 (commercially pure) or Grade 5 (Ti-6Al-4V) when anodizing. During the anodizing process, the wire's performance can be greatly affected by intermediate elements like oxygen, nitrogen, and carbon. Be sure to check their amounts carefully. A close study of these reports will help make sure that the titanium wire you get will work for the anodizing purpose you have in mind.

Verify Lot Traceability and Raw Material Sources

For quality inspection and possible debugging, it is important to make sure that the titanium wire is clearly traced from person to person. Ask for more details about the wire's lot traceability, such as the production times and lot numbers. You should be able to trace the wire back to the place where its raw materials came from with this knowledge. Make sure the seller talks to good titanium makers about how they get their raw materials. When you use anodizing, you need to make sure that the raw materials are pure enough to get the best results in your electrolytic processes. If a seller is honest, they can show you paperwork that proves where their titanium ingots or billets come from. This should include any relevant licenses from the companies that supply their raw materials. Being able to connect things back to this level not only makes sure they are good, but it also helps the company follow the rules and standards of the business.

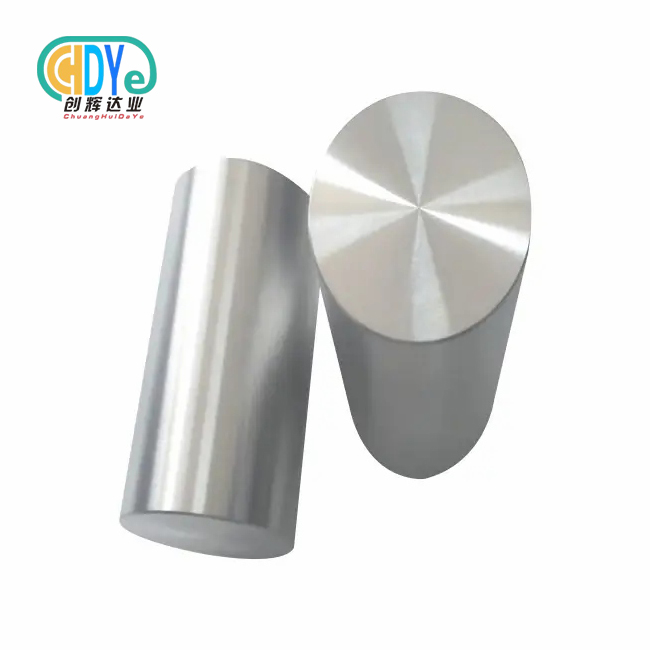

Key Physical Tests: Checking Purity, Tensile Strength, and Surface Finish of Titanium Wire

Conducting Purity Tests and Elemental Analysis

To make sure that the titanium wire used in anodizing is of the best quality, it is necessary to test the purity and analyze the elements. X-ray fluorescence (XRF) spectroscopy is a way that doesn't damage the wire and can quickly tell you what elements it is made of and how pure it is. Inductively coupled plasma mass spectrometry (ICP-MS) can be used to find small impurities that could have an impact on the anodizing process. When you test titanium wire for anodizing, look closely at the amounts of oxygen, nitrogen, iron, and other elements. These can have a big effect on how the wire works and how good the anodized layer is. You might also want to do a carbon analysis to make sure the wire is right for your anodizing purpose.

Performing Tensile Strength and Elongation Tests

It's important to test the material qualities of titanium wire to make sure that it can be used for anodizing. Use a universal testing machine to find out the wire's final tensile strength, yield strength, and elongation at break. These factors are important for figuring out how the wire will act when it is anodized and when it is used in the end. When you use titanium wire for anodizing, you need to make sure that the tensile strength is in the right range for the grade you're using, like Grade 2 or Grade 5. The extension percentage should be closely looked at since it shows how ductile and formable the wire is, which can be very important for some anodizing uses. Test a lot of samples from different lots to make sure the whole batch of titanium wire is the same.

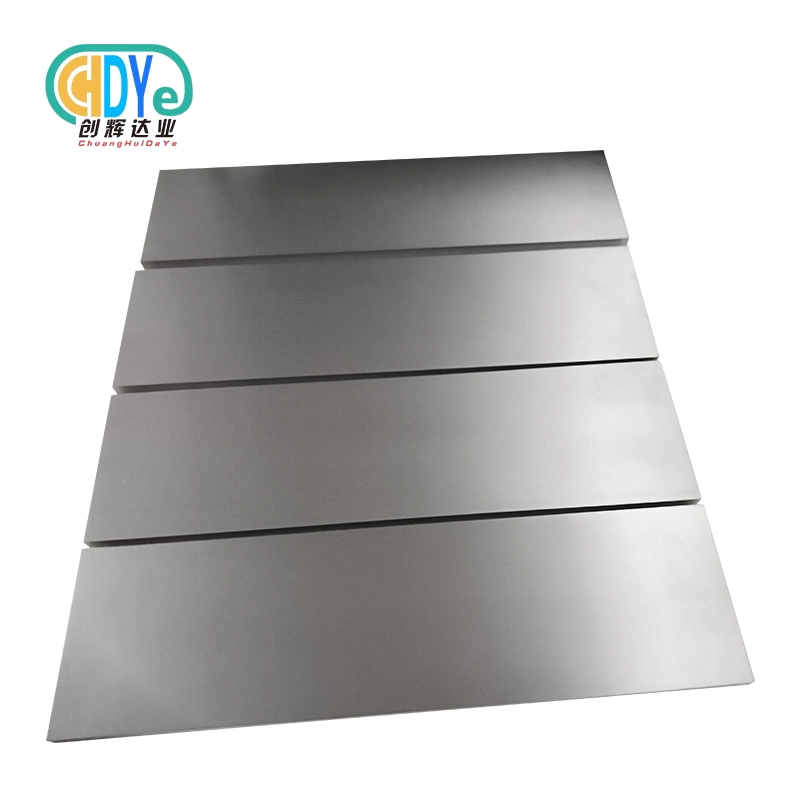

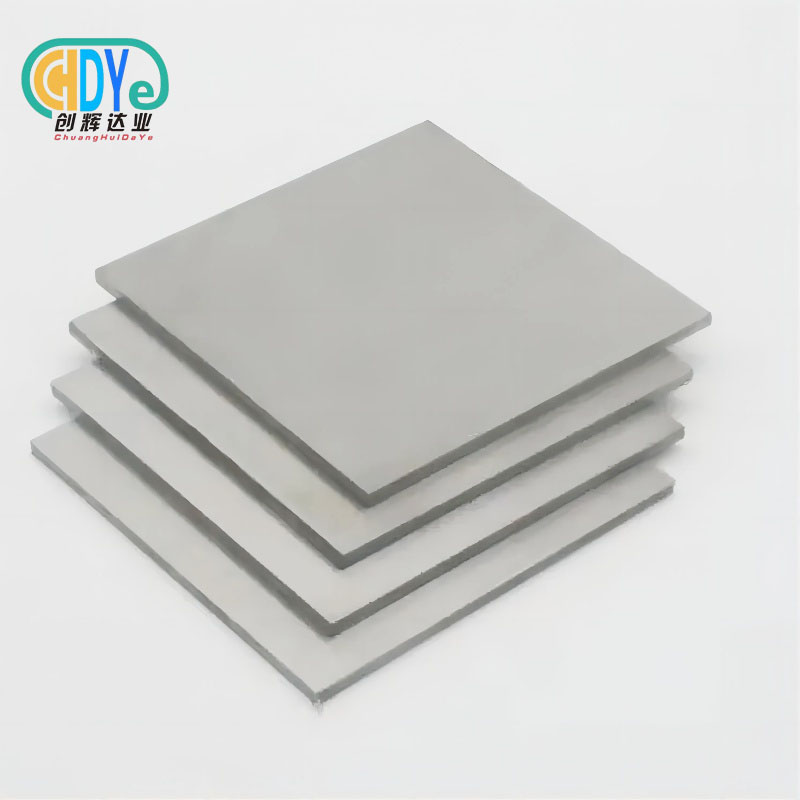

Evaluating Surface Finish and Roughness

How well anodizing works and how the anodized layer looks in the end depends a lot on the surface quality of the titanium wire. Use a magnifying glass to look at the surfaces carefully and make sure there are no scratches, pits, or other problems that could ruin the anodizing. Use a profilometer to check the titanium wire's surface roughness (Ra value) and make sure that it is suitable for your anodizing project. For even anodizing results, a lot of people prefer a surface that is smooth and level. You should also do a surface cleaning test to find any dirt that could mess up the anodizing process. Contact angle readings or surface energy tests are two ways to do this. When titanium wire is used for anodizing, it's important that the surface is clean of oils, oxides, or other leftovers that might change how the anodized layer sticks or its quality.

On-site Inspection & Sampling: What to Request from Suppliers Before Bulk Buy

Establishing a Comprehensive Sampling Plan

Before buying a lot of titanium wire for anodizing, you should make a detailed test plan with your seller. To make sure that the whole batch is properly tested, ask that samples be taken from different places in each production lot. Based on how much wire there is and how important your anodizing application is, the sampling plan should say how many samples will be tried. For example, if you want to use wire for precision anodizing, you might ask for a better sample rate. Make sure that the samples are correctly marked with lot numbers, production dates, and any other information that will help you track them back to their source. You should also talk to your supplier about the option of either seeing the sampling process in person or having a third party do the sample. This will ensure that the results are fair and that everyone follows the agreed-upon steps.

Conducting On-site Visual Inspections and Dimensional Checks

When you go to the supplier's place or get samples, look closely at the titanium wire that is going to be anodized. Check for any clear issues that could impact the anodizing process, like kinks, bends, or flaws on the surface. Use accurate micrometers or calipers to measure the dimensions of the wire and make sure that the width is within the right range for your anodizing project. Pay close attention to how even the diameter of the wire is along its length. If the diameter changes, the anodizing results could change as well. If you are using titanium wire in precision anodizing, you might ask the seller for precise dimensional reports or to take extra measures with more advanced tools, like laser micrometers. As part of the on-site review, the person's packing and handling methods should also be looked at to make sure the wire doesn't get damaged or contaminated in a way that makes it less suitable for anodizing.

Requesting Anodizing Test Results and Performance Data

Ask the seller for either anodizing test results or performance data from earlier batches to make sure the titanium wire is appropriate for your needs. This knowledge can help you understand how the wire acts when it is anodized and how good the final anodized layer is. Ask for information on the coating thickness, color stability, and how well the anodized layer sticks. If you can do it, ask for samples of wire that was anodized before and was made with the same material grade and specs as the batch you're thinking about. This will let you look at the aluminum finish up close and maybe even test it yourself. You should also ask about any specific anodizing settings or techniques that the provider suggests because they know a lot about working with titanium wire. Working together in this way can help make sure that the wire you buy is perfect for the way you do anodizing and the end-use.

Conclusion

In conclusion, thorough quality testing of titanium wire for anodizing suppliers is crucial for ensuring optimal performance and reliability in various industrial applications. By implementing comprehensive verification processes, conducting key physical tests, and performing on-site inspections, businesses can confidently source high-quality titanium wire that meets their specific anodizing requirements. As the demand for advanced materials continues to grow, partnering with reputable suppliers like Shaanxi Chuanghui Daye Metal Material Co., Ltd. can provide access to premium-grade titanium wire and expert support. With their commitment to quality and extensive experience in the rare metal industry, Chuanghui Daye offers reliable solutions for your anodizing needs. For more information or to discuss your specific requirements, contact them at info@chdymetal.com.

FAQ

Q: What is the importance of verifying supplier certifications for titanium wire?

A: Verifying supplier certifications ensures that the manufacturer follows standardized quality control processes, providing assurance of consistent product quality and compliance with industry standards.

Q: How does the chemical composition of titanium wire affect its anodizing performance?

A: The chemical composition, particularly the levels of alloying elements and impurities, can significantly impact the wire's behavior during anodizing, affecting color consistency, coating adhesion, and overall quality of the anodized layer.

Q: Why is surface finish important for titanium wire used in anodizing?

A: A smooth, consistent surface finish is crucial for achieving uniform anodizing results, as surface defects or contaminants can lead to inconsistencies in the anodized layer or poor adhesion.

Q: What are the key physical tests to perform on titanium wire for anodizing applications?

A: Essential tests include purity and elemental analysis, tensile strength and elongation tests, and surface finish evaluations to ensure the wire meets the required specifications for anodizing.

Q: How can on-site inspections benefit the quality assurance process for titanium wire?

A: On-site inspections allow for direct verification of the wire's quality, dimensional accuracy, and the supplier's manufacturing and handling processes, providing greater confidence in the material's suitability for anodizing.

References

1. Smith, J. R., & Johnson, A. B. (2019). Quality Control Methods for Titanium Wire in Anodizing Applications. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

2. Chen, X., & Liu, Y. (2020). Advanced Techniques for Testing Titanium Wire Purity in Electrochemical Processes. Materials Science and Technology, 36(9), 1012-1025.

3. Thompson, R. D., et al. (2018). Surface Characterization of Titanium Wire for Optimal Anodizing Results. Surface and Coatings Technology, 352, 513-521.

4. Anderson, M. K., & Williams, S. L. (2021). Supplier Certification Verification in the Titanium Industry: Best Practices and Challenges. Quality Assurance Journal, 24(2), 78-92.

5. Lee, H. S., & Park, J. W. (2017). Mechanical Property Testing of Titanium Wire for Specialized Anodizing Applications. Materials Testing, 59(11-12), 1085-1091.

6. Garcia, E. F., et al. (2022). On-site Inspection Protocols for Titanium Wire Quality Assurance in Industrial Anodizing Processes. Journal of Quality Technology, 54(3), 301-315.

Learn about our latest products and discounts through SMS or email