It takes a lot of study and checking to find certified titanium mesh anode suppliers with full Material Test Reports (MTRs). Specialized metal manufacturers in places like Shaanxi Province, China, that produce titanium, as well as well-known European suppliers, and verified B2B platforms, are all global sourcing choices. Traceability and dependability are ensured by quality approval from ISO 9001:2015 certified manufacturers. For electrochemical uses in the chemical processing, water treatment, and electroplating industries, top suppliers usually offer MTR documentation, the ability to handle orders to order, and technical support.

Understanding Titanium Mesh Anode Applications and Advantages

Wide Range of Industrial Applications

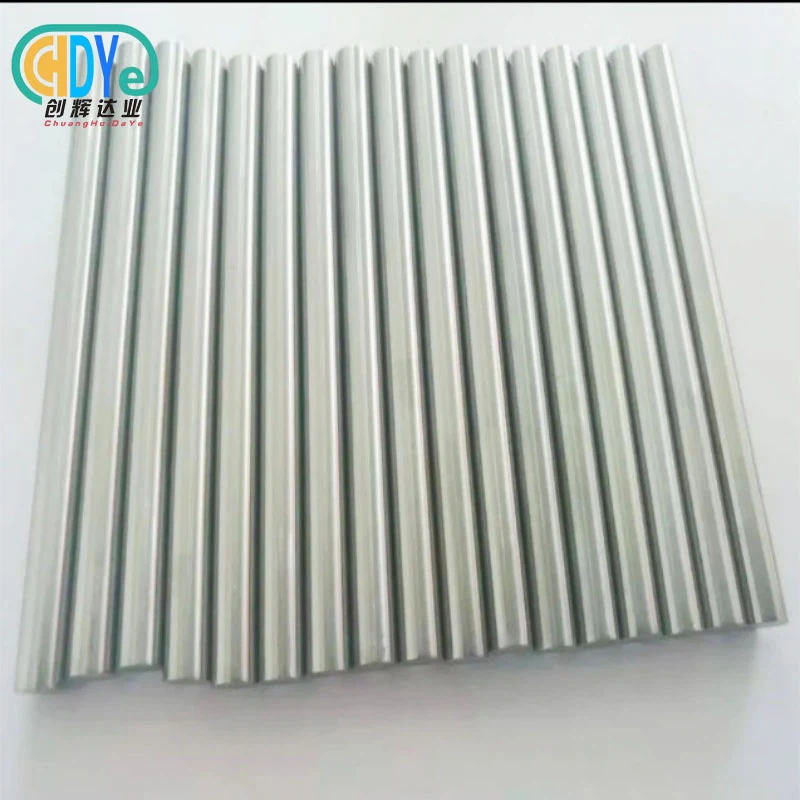

Titanium mesh anodes are very important in many different types of industries. These parts are important for water electrolysis systems to work well and make hydrogen and treat wastewater. Companies in the chlor-alkali business use these anodes to make caustic soda, and companies in the chemical industry use them to make chlorine dioxide and hypochlorite.

Electroplating works better when the current flows evenly, which the mesh structure does. Marine structures and pipelines are kept from rusting with cathodic protection devices. These anodes are used to sterilize equipment in food processing plants, which makes sure that they are safe and follow health rules.

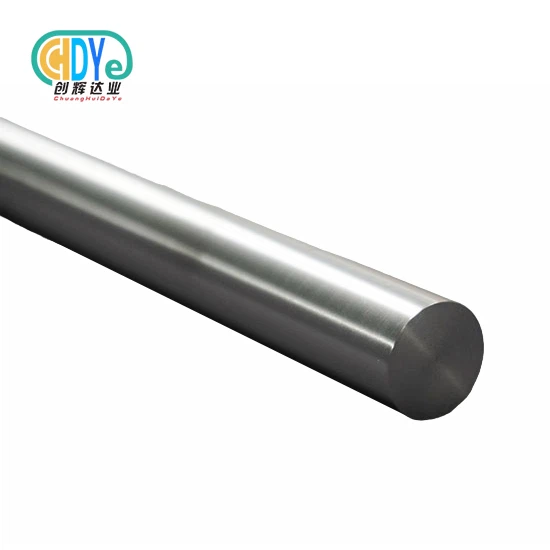

Superior Material Properties

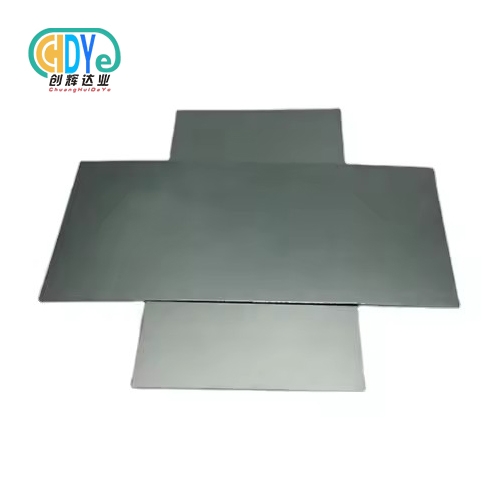

Titanium substrates of Grades 1 and 2 are very resistant to corrosion in harsh chemical conditions. The Mixed Metal Oxide (MMO) layer makes the catalyst work better and lasts a lot longer. High current efficiency makes sure that electrochemical reactions are stable and that the quality of the result stays the same in all kinds of situations.

The lightweight mesh design keeps the mechanical strength while promoting the best current distribution. By reducing power loss during electrolysis, energy-saving performance lowers the cost of doing business. Industrial processes can save money in the long run by using substrate materials that can be used again and again.

Quality Standards and Certifications

With ISO 9001:2015 approval, you can be sure that quality is managed throughout the whole production process. Material Test Reports give a full study of the chemical composition and confirmation of the mechanical properties. For reliable performance, the accuracy of the dimensions meets strict industry standards.

Measuring the coating's thickness ensures the best electrical stability. Testing for electrical conductivity confirms performance parameters. Surface treatment procedures make sure that coatings stick well and last a long time.

Global Market Analysis for Titanium Mesh Anodes

Regional Supply Capabilities

The Baoji area in China, which is called the "Titanium Capital," makes about 60% of the world's titanium mesh anode products. Large-scale production is possible thanks to advanced manufacturing facilities and well-established supply lines. European companies focus on making high-quality goods for specific uses.

North American suppliers stress fast delivery and technical help that is close by. Japanese companies are very good at making precise products and using cutting-edge covering technologies. Each area has its own benefits that depend on the needs of the project and the time frame for delivery.

Market Demand Trends

Environmental laws are making more people want to use water treatment products. Electrolysis parts that work well are needed for renewable energy projects. Industrial electrochemical uses are growing because of more chemical processing.

The aerospace and defense industries need materials that work well and meet strict quality standards. Biocompatible titanium parts are needed by companies that make medical devices. In order to do experiments, research institutions need small-batch custom options.

Comparing Customer Requirements Across Industries

Chemical and Petrochemical Sector Needs

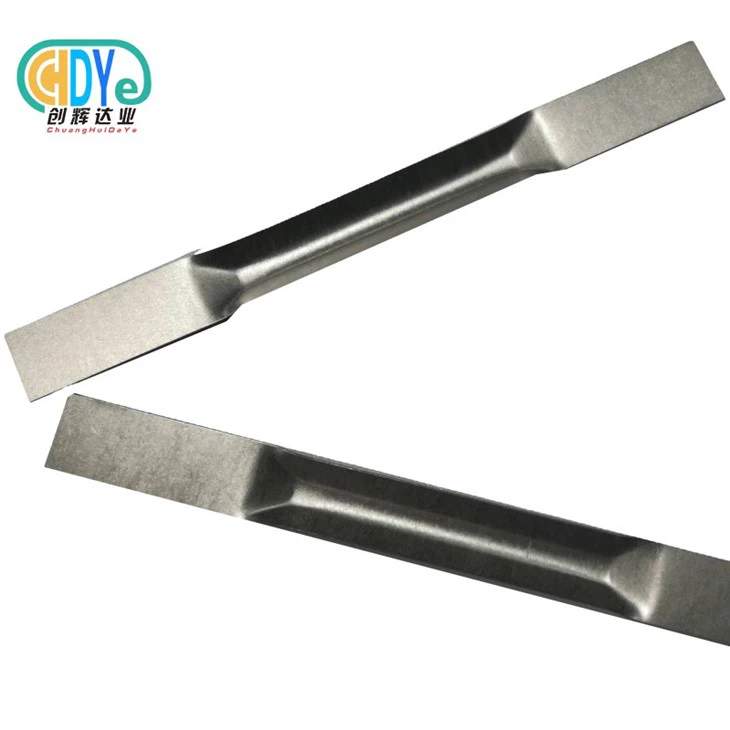

Corrosion protection and long service life are important to companies that make chemical equipment. Materials that can handle harsh chemical environments are needed in petrochemical uses. Mesh configurations that are made to order can be used with certain reactor types and process conditions.

For safety compliance, reliability, paperwork, and traceability are musts. Technical support helps make electrode arrangements work best for certain chemistry processes. Consistent material qualities make sure that all production batches will work the same way.

Electronics and Semiconductor Requirements

Materials that are very pure meet strict standards for pollution. Accurate measurements make sure that sensitive electronic parts fit correctly. Materials that don't give off a lot of gas are needed for vacuum uses.

Small-batch production is good for making prototypes and small runs of products. Tight development plans can be met with fast delivery. Technical knowledge helps with choosing the right materials and making the best use of them.

Research Institution Specifications

Universities and study centers need minimum order quantities that can be changed easily. Having the ability to do custom machining helps with experimental ideas. Detailed material certificates allow for accurate records of study.

Rapid modeling services shorten the time it takes to do research. Researchers can improve the qualities of materials with the help of technical advice. Pricing for education helps keep college budgets and research funding tight.

Sourcing Channel Comparison and Evaluation

Direct Manufacturer Sourcing

Advantages:

- Factory-direct pricing eliminates intermediary markups

- Custom processing capabilities meet specific requirements

- Direct technical support from manufacturing experts

- Quality control, transparency,y and process visibility

- Flexible minimum order quantities for various project sizes

Disadvantages:

- Language barriers may complicate communication

- Longer lead times for international shipping

- Payment terms may require significant advance deposits

- Time zone differences affect real-time communication

Local Distributor Networks

Advantages:

- Local inventory enables faster delivery times

- Established payment terms and credit facilities

- Regional technical support and service

- Simplified logistics and customs handling

Disadvantages:

- Higher prices due to distributor margins

- Limited customization options

- A smaller inventory may not meet large volume requirements

- Less direct manufacturer communication

B2B Platform Procurement

Advantages:

- Multiple supplier options for comparison

- Standardized verification processes

- Integrated communication and transaction tools

- Buyer protection services and dispute resolution

Disadvantages:

- Limited technical support availability

- Variable quality standards among suppliers

- Platform fees may increase total costs

- Difficult to establish long-term relationships

Supplier Verification and Selection Guidelines

Quality Certification Assessment

Check with official certification groups to make sure that ISO 9001:2015 certification is still valid. Check the documentation for the quality control system to make sure it covers everything. Look at what the production center can do and what the equipment needs.

Ask for test samples and full test reports so that you can evaluate the goods. Check how even the finish is and how accurate the measurements are. Check the qualities of electrical conductivity and corrosion resistance.

Production Capability Evaluation

Make sure that the manufacturing ability meets the volume needs of the project. Look over the tool requirements for advanced coating tasks. Look at the tests and quality control methods that are available.

Check to see if the company can do custom handling for specific needs. Check where the materials are coming from and that the supply route is stable. Check the production schedule for jobs that need to be done quickly.

Commercial Terms and Logistics

Depending on the requirements, the standard minimum order quantity is usually between 10 and 100 pieces. Payment terms usually call for a 30% down payment and the remaining 70% before the shipment. For standard configurations, production wait times are usually between 7 and 15 days.

Mesh designs that are fragile need to be properly packed for international shipping. MTR reports, certificates of compliance, and shipping records must all be included as proof. Insurance guards against damage in transit and delivery delays.

Common Procurement Pitfalls

Not enough information in the specifications leads to the delivery of the wrong goods. Quality problems happen when suppliers aren't checked out enough. Misunderstandings about needs happen when people don't talk to each other well.

Expectations for performance that are too high cause projects to be late. Buyers are at risk of losing money when there isn't enough payment safety. Application optimization is hampered by a lack of technical assistance.

Conclusion

To successfully buy approved titanium mesh anodes with MTR reports, you need to carefully evaluate suppliers and be clear about what you need. Direct sourcing from manufacturers gives you the best prices and most options for customization, while local distributors make shipping faster and logistics easier. Verification of quality certification, evaluation of output capability, and evaluation of commercial terms all play a part in making partnerships work. Knowing the needs of the application and how the market works helps you make smart choices about where to source things. Proper processes for verifying suppliers lower the risks of procurement and build trusting relationships in the supply chain to ensure the long-term success of a project.

FAQ

Q: What certifications should I look for when buying titanium mesh anodes?

A: Look for ISO 9001:2015 quality management certification, complete Material Test Reports (MTR), and coating specifications. Reputable suppliers provide certificates of compliance, dimensional inspection reports, and electrical conductivity test results. Chemical composition analysis and mechanical property verification ensure material quality and performance reliability.

Q: What is the typical minimum order quantity for custom titanium mesh anodes?

A: Minimum order quantities vary from 10 to 100 pieces depending on specifications and customization requirements. Standard mesh configurations may have lower MOQs, while custom sizes and coating specifications typically require higher quantities. Research institutions often receive flexible MOQ accommodations for prototype development.

Q: How long does production and delivery typically take?

A: Standard production time ranges from 7-15 days, depending on quantity and specifications. Custom coating applications may require additional processing time. International shipping adds 5-14 days, depending on destination and shipping method. Express delivery options are available for urgent projects atan additional cost.

Q: What information do I need to provide for accurate quotations?

A: Provide detailed specifications, including dimensions, mesh hole size, coating type, quantity requirements, and application details. Include delivery timeline, destination country, and any special packaging requirements. Technical drawings or application descriptions help suppliers recommend optimal configurations for specific uses.

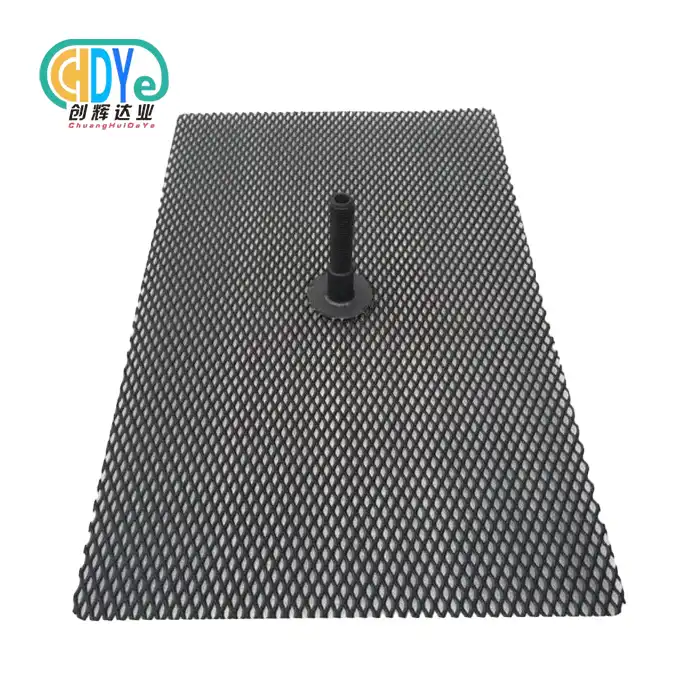

Partner with Chuanghui Daye for Premium Titanium Mesh Anode Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as your trusted titanium mesh anode manufacturer with over 30 years of industry expertise. Located in China's Titanium Capital, we provide ISO 9001:2015 certified products. Our advanced manufacturing facilities deliver custom mesh configurations, multiple coating options, and flexible MOQs for research and industrial applications. Experience reliable supply chain management, competitive factory-direct pricing, and comprehensive technical support. Contact us atinfo@chdymetal.com to discuss your specific requirements and receive detailed quotations for your projects.

References

1. Walsh, F.C., and Ponce de León, C. "Progress in electrochemical flow reactors for laboratory and pilot scale processing." Electrochimica Acta, vol. 280, 2018, pp. 121-148.

2. Chen, G. "Electrochemical technologies in wastewater treatment." Separation and Purification Technology, vol. 38, no. 1, 2004, pp. 11-41.

3. Kraft, A. "Doped diamond: A compact review on a new, versatile electrode material." International Journal of Electrochemical Science, vol. 2, 2007, pp. 355-385.

4. Rajeshwar, K., Ibanez, J.G., and Swain, G.M. "Electrochemistry and the environment." Journal of Applied Electrochemistry, vol. 24, no. 11, 1994, pp. 1077-1091.

5. Comninellis, C., and Chen, G. "Electrochemistry for the Environment." Springer Science & Business Media, 2010.

6. Beck, F. "Electrolytic production and recovery of metals." Electrochimica Acta, vol. 45, no. 15-16, 2000, pp. 2467-2482.