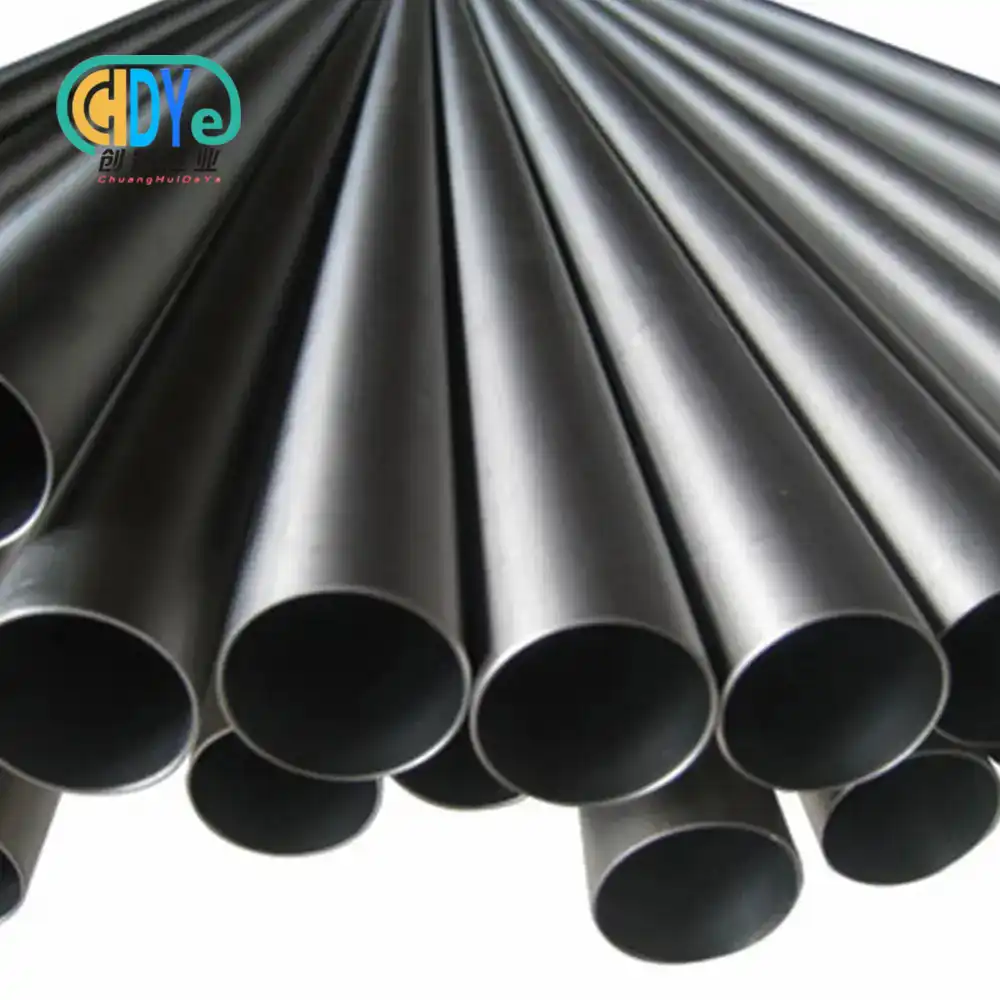

Tantalum tube and pipe uses in semiconductor and vacuum systems underpin modern high-tech manufacturing. These specialty components enable chip fabrication, vacuum metallurgy, and precise production using tantalum's corrosion resistance, ultra-high melting point of 2996°C, and purity. Tantalum tubing is essential for meeting today's strict semiconductor and vacuum technology performance standards in chemical vapor deposition chambers and ion implantation systems.

Why Tantalum Dominates Semiconductor and Vacuum Applications?

Over three decades in the rare metal market, I've seen tantalum go from a curiosity to a semiconductor manufacturing requirement. Tantalum seamless pipe and tubing are irreplaceable due to their atomic structure and qualities.

Tantalum can survive difficult semiconductor manufacturing chemicals due to its chemical inertness. Tantalum resists hydrofluoric acid, phosphoric acid, and other corrosives that damage stainless steel and aluminum. This resistance extends equipment life and reduces contamination.

Equally important is the material's high-temperature stability. Many metals oxidize or lose structural integrity at temperatures above 1000°C, where semiconductor processes occur. The mechanical qualities and dimensional stability of tantalum alloy tubes remain unchanged under these high conditions, maintaining process performance.

Due to its negligible outgassing, tantalum is good for vacuum systems. In semiconductor manufacturing, even trace impurities might lower product quality, so the material doesn't leak contaminants into ultra-high vacuum settings.

Chemical Vapor Deposition (CVD) System Components

One of the most demanding semiconductor production applications for tantalum heat exchanger tubes is chemical vapor deposition. CVD decomposes gaseous precursors at high temperatures to generate thin films, requiring materials that can tolerate thermal and chemical stress.

CVD systems use tantalum tubes and pipes in several ways. Tantalum pipe fittings produce reactive precursor gases without contamination or degradation. Tantalum's inertness precludes reactions that could change gas compositions or introduce contaminants during deposition.

Tantalum's characteristics assist reaction chamber components. Tantalum custom-sized chamber walls, heating elements, and gas distributors withstand thousands of heating and cooling cycles. Durability lowers maintenance and enhances process consistency.

CVD applications require temperature consistency because even slight differences can affect layer thickness. Tantalum's low thermal expansion coefficient and high thermal conductivity distribute heat uniformly and reduce dimensional changes during temperature cycling.

Epitaxial reactors using silicon wafers above 1200°C use tantalum susceptors. Susceptors support wafers during growth and preserve flatness and surface quality for consistent film deposition.

Ion Implantation and Plasma Processing Equipment

Tantalum tube characteristics are crucial for current semiconductor device ion implantation systems. Before embedding ions into semiconductor substrates, these technologies accelerate them to high energies, providing precise doping patterns.

Tantalum tubing is mostly used in beam transfer components. Evacuated tubes carry ion beams in ultra-high vacuum and resist high-energy particle sputtering. Tantalum tube corrosion resistance is useful here because it resists physical and chemical attack from reactive ion species.

Ion generation source chambers benefit from tantalum's thermal characteristics. These chambers generate ion beams using corrosive gases at high temperatures. These systems use tantalum pipe gas intake tubes, extraction electrodes, and chamber liners to withstand extreme operating conditions.

Materials for plasma processing equipment must also withstand harsh conditions. Plasma etching removes semiconductor chip material nanometer-by-nanometer using reactive gases. Tantalum components resist plasma degradation and preserve process repeatability and critical dimensional stability.

Ion implantation system end-station components use tantalum tube annealing to reduce manufacturing stress. Stress-relieved components maintain shape and dimensions throughout years of operation, assuring ion beam placement and dose homogeneity.

Vacuum Furnace and Heat Treatment Systems

Tantalum producers' vacuum metallurgy and heat treatment solutions for harsh conditions are demonstrated. These devices use ultra-high vacuum and temperatures that would kill conventional materials.

Tantalum tube thickness is designed for thermal cycle resistance in heating element support systems. Tantalum may expand without cracking or failing at high temperatures, unlike molybdenum or tungsten.

Vacuum furnace gas circulation systems move process gases at high temperatures using tantalum tubing. Gas purity is maintained during processing cycles due to the material's carburization, nitriding, and oxidation resistance. This purity is crucial for titanium alloy heat treatment, where contamination can damage material characteristics.

In harsh conditions, tantalum thermocouple protection tubes measure temperature accurately. These tubes provide rapid temperature responsiveness while protecting thermocouples from reactive atmospheres. Tantalum is appropriate for this essential application due to its chemical resistance and thermal conductivity.

Tantalum's low vapor pressure and outgassing help vacuum chamber components. Chamber walls, flanges, and feedthrough assemblies resist heat cycling and chemical exposure to maintain vacuum integrity.

Sputtering Targets and Thin Film Deposition

Physical vapor deposition systems are another important application where tantalum seamless pipe technology boosts manufacturing. Sputtering techniques produce thin coatings on substrates with fine thickness control using energetic particles to expel material from solid targets.

Sputtering targets use tantalum backing plates for thermal management. These plates retain flatness and transfer heat away from target materials for uniform film deposition. Tantalum is better than backing plates due to its heat conductivity and dimensional stability.

Sputtering chambers are severe, hence magnetron assemblies use tantalum. Magnetic field confinement generates high-density plasmas that destroy weaker materials quickly. Tantalum's sputtering resistance extends component lives more than alternatives.

Shielding components direct sputtered material to substrates and prevent chamber wall deposition. Tantalum shields remain geometrically intact after thousands of deposition cycles and produce minimal film contamination.

Process gas distribution systems use tantalum tube and pipe welding to make leak-tight, thermally and chemically resistant assemblies. In reactive plasma conditions, these systems must maintain exact gas flow patterns.

Analytical and Measurement Equipment

Advanced analytical equipment requires the purest and most stable materials for semiconductor production. Mass spectrometers, electron beam systems, and surface analysis instruments use tantalum for process control sensitivity and precision.

Mass spectrometer ion source components use tantalum's chemical inertness to avoid analytical influence. Tantalum's low background signal and contamination resistance improve sample introduction systems, ion guides, and detector assemblies.

Electron beam lithography systems use tantalum in electron optical columns for ultra-high vacuum and thermal stability. After years of use, tantalum beam-defining apertures, deflection systems, and chamber components remain precise.

Surface analysis equipment employs tantalum to reduce measurement artifacts. X-ray photoelectron spectroscopy, Auger electron, and secondary ion mass spectrometers use tantalum to minimize background signals and increase detection limits.

High-purity tantalum calibration standards supply analytical equipment reference materials. These standards must withstand handling and environmental contamination and retain compositional and dimensional stability over time.

Specialized Vacuum System Applications

Tantalum tubes aid aircraft and scientific instruments' vacuum systems beyond semiconductor manufacture. Custom solutions using tantalum's specific properties are typically needed for these demanding applications.

Ultra-high vacuum chambers for surface science research use tantalum components to achieve base pressures below 10^-11 Torr. The material's low outgassing and hydrogen embrittlement resistance make it perfect for these demanding applications.

Tantalum tubing is used in thermal management systems in space simulation chambers to work at severe temperatures. The material's thermal cycling resistance and dimensional stability guarantee reliable operation from cold to several hundred degrees Celsius.

In effusion cells and beam shutters, molecular beam epitaxy systems use tantalum for temperature control and contamination-free operation. These techniques create single-crystal films atomically, requiring impurity-free and thermally stable materials.

Accelerators and particle physics experiments use tantalum beam conveyance and detector assemblies. These specialised applications benefit from the material's radiation resistance and particle bombardment stability.

Quality Standards and Performance Verification

To make tantalum tubes and pipes for vacuum and semiconductor uses, strict quality standards must be followed. These standards make sure that the products work the same way in all kinds of operating situations. Dimensional and compositional standards are based on ASTM B521, but even tighter tolerances are often needed for semiconductor uses.

Purity standards usually go above and beyond 99.95% for semiconductor uses, with limits on intermediate elements like carbon, nitrogen, and oxygen. These impurities can have a big effect on electrical qualities and resistance to corrosion, so they need to be carefully controlled at every stage of the manufacturing process.

Specifications for the surface finish make sure that it works with ultra-high vacuums and stops particles from forming that could damage sensitive processes. When surfaces are electropolished, they get hardness values below 0.1 micrometers and get rid of surface contaminants that could give off gases in vacuum settings.

Checking the mechanical properties of parts by tension testing, measuring hardness, and analyzing grain size makes sure that the parts can handle the temperature changes and mechanical stress that they will face in service. These tests prove that heat treatment works and that all finished goods are made of the same material.

Ultrasonic screening and eddy current testing are two examples of non-destructive testing methods that can find problems inside a product that might affect its performance or cause it to fail too soon. These quality control steps give users confidence in the dependability of parts for important uses.

Conclusion

As technology needs get better, tantalum tubes and pipes are being used in more and more semiconductor and vacuum systems. Tantalum's special qualities make it possible for big steps forward in many fields, from CVD chambers that work at over 1000°C to ion implantation systems that need an ultra-high vacuum. Because it doesn't rust, stays stable at high temperatures, and doesn't react with chemicals, the material is unbeatable in situations where dependability and cleanliness are essential. As semiconductor devices get smarter and vacuum processing methods get better, tantalum tubing will continue to be at the forefront of technologies that make electronics, research, and manufacturing move forward.

FAQ

Q: What makes tantalum superior to stainless steel for vacuum applications?

A: Tantalum offers significantly lower outgassing rates, better chemical resistance, and higher temperature capability compared to stainless steel. These properties enable ultra-high vacuum achievement and longer service life in aggressive environments.

Q: How does tantalum tube welding differ from conventional materials?

A: Tantalum welding requires inert atmosphere protection and specialized techniques due to its high melting point and reactivity with oxygen at elevated temperatures. Proper welding produces joints with strength matching the base material.

Q: What purity levels are available for semiconductor-grade tantalum tubing?

A: Semiconductor applications typically require 99.95% minimum purity, with some critical applications demanding 99.99% or higher. Trace element content must meet strict specifications to prevent contamination of sensitive processes.

Partner with Chuanghui Daye for Premium Tantalum Solutions

Shaanxi Chuanghui Daye stands as your trusted tantalum tube and pipe manufacturer, delivering ISO 9001:2015 certified quality from China's titanium capital. Our three decades of expertise in rare metal processing ensure your semiconductor and vacuum system requirements receive the precision and reliability your applications demand. Contact us atinfo@chdymetal.com to discuss your specific tantalum tubing needs and discover how our advanced manufacturing capabilities can support your next project.

References

1. Materials Research Society Symposium Proceedings, "Tantalum in Semiconductor Manufacturing: Properties and Applications," Vol. 1245, pp. 156-167, 2020.

2. Journal of Vacuum Science and Technology, "Ultra-High Vacuum Performance of Refractory Metal Components in Semiconductor Processing Equipment," 38(4), pp. 041203-1 to 041203-12, 2019.

3. IEEE Transactions on Semiconductor Manufacturing, "Chemical Vapor Deposition System Design Using Tantalum Components for Advanced Node Processing," 32(3), pp. 298-305, 2019.

4. Surface and Coatings Technology, "Plasma-Surface Interactions with Tantalum Components in Semiconductor Etching Systems," 401, pp. 126234-126241, 2020.

5. Applied Physics Reviews, "Refractory Metals in Ion Implantation Equipment: Performance and Reliability Analysis," 7(2), pp. 021306-1 to 021306-18, 2020.

6. Vacuum Technology Handbook, "Tantalum Applications in Ultra-High Vacuum Systems," 4th Edition, Chapter 12, pp. 445-478, Academic Press, 2021.