- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why ASTM B 265 Titanium Sheet Is the Preferred Corrosion-Resistant Metal?

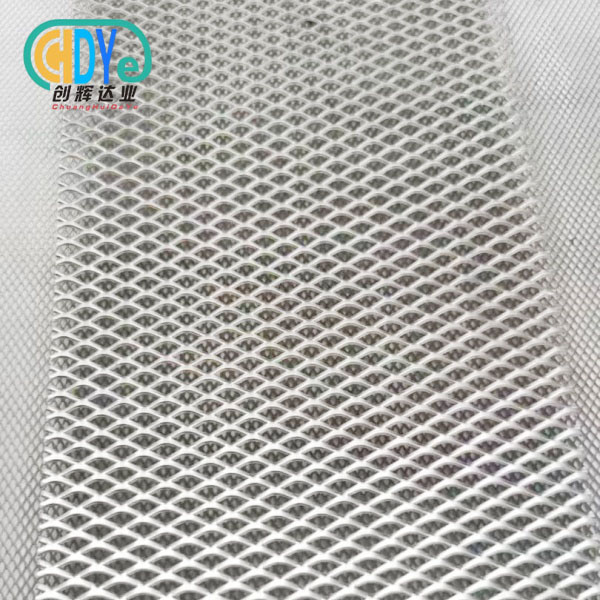

When it comes to materials that don't rust, ASTM B 265 titanium sheet is the best option for many commercial uses. The exceptional strength of this high-performance metal in harsh environments while keeping structural integrity has earned it a lot of praise. The unique mix of strength, durability, and resistance to corrosion in ASTM B 265 titanium sheet makes it the preferred material for many fields, from aircraft to chemical processing. The American Society for Testing and Materials (ASTM) sets very strict rules for the manufacturing process, which is what gives it its amazing qualities. As we learn more about the features and benefits of ASTM B 265 titanium sheet, it becomes clear why this material has become the first choice for engineers and makers who need reliable, long-lasting solutions in harsh conditions.

Superior Corrosion Resistance and Protective Oxide Layer of ASTM B 265 Titanium Sheet

Formation of Protective Oxide Layer

ASTM B 265 titanium sheet's uncommon erosion resistance is basically credited to its capacity to frame a steady, ceaseless, and profoundly disciple defensive oxide layer. When uncovered to discuss or other oxidizing situations, titanium quickly creates a lean, straightforward film of titanium dioxide (TiO2) on its surface. This normally happening oxide layer acts as a boundary, viably protecting the fundamental metal from encourage erosion. The oxide film on ASTM B 265 titanium sheet is surprisingly relentless and self-healing, meaning that if it's scratched or harmed, it rapidly changes to keep up its defensive properties. This interesting characteristic permits ASTM B 265 titanium sheet to keep up its erosion resistance indeed in challenging conditions where other metals might fall flat.

Resistance to Various Corrosive Media

It is very resistant to a lot of different corrosive substances, which makes ASTM B 265 titanium sheet a great choice for many industry uses. It can withstand corrosion in chloride-containing environments, which are known to be very bad for many other metals. ASTM B 265 titanium sheet works really well in ocean and marine environments because it doesn't get pitted or corrode in cracks like other materials do in these conditions. It is also very resistant to most acids, alkalis, salt solutions, and organic and artificial acids. ASTM B 265 titanium sheet can be used in chemical processing equipment, desalination plants, and offshore oil and gas sites that are constantly and severely exposed to corrosive substances because it is resistant to a wide range of corrosion types.

Long-Term Performance in Corrosive Environments

One big reason why engineers and makers like ASTM B 265 titanium sheet so much is that it works well in corrosive environments for a long time. Some materials may break down over time when they are exposed to harsh conditions, but ASTM B 265 titanium sheet keeps its shape and look for a long time. Because they last longer, they need less upkeep, need to be replaced less often, and are more reliable overall. The consistent performance of ASTM B 265 titanium sheet in corrosive environments also helps to improve safety in important settings, like in the aircraft industry or chemical processing plants, where a failure of the material could have terrible results. ASTM B 265 titanium sheet has been used for many years and has been shown to be strong against chemical attacks. This makes it a reliable choice for projects that need to last.

Strength-to-Weight Benefits and Industry Applications of ASTM B 265 Titanium Sheet

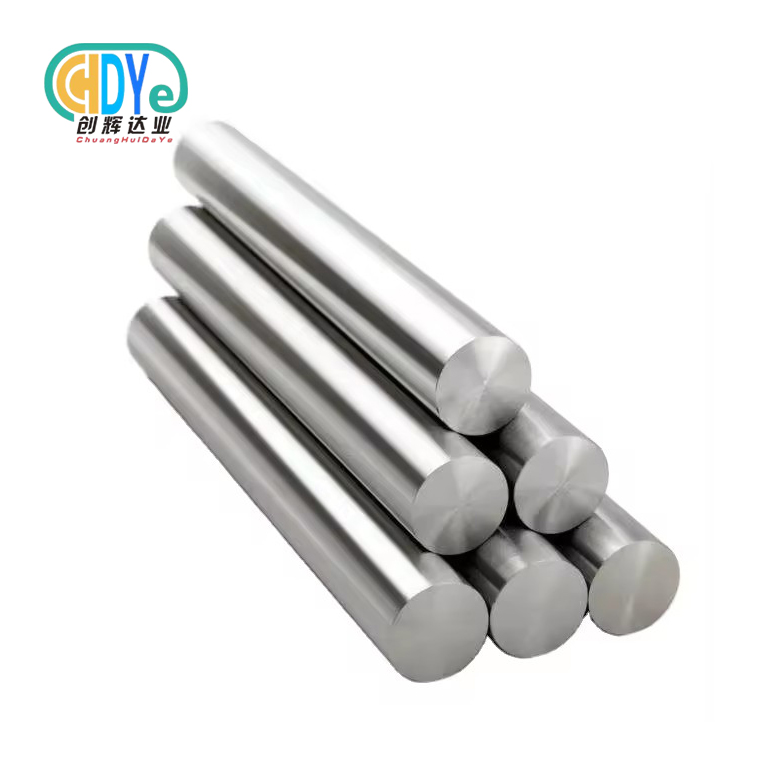

High Strength-to-Weight Ratio Advantages

One of the most critical preferences of ASTM B 265 titanium sheet is its uncommon strength-to-weight proportion. This property makes it an perfect fabric for applications where weight lessening is pivotal without compromising auxiliary judgment. ASTM B 265 titanium sheet offers quality comparable to steel but at generally half the weight, giving considerable benefits in terms of fuel productivity and execution in aviation and car businesses. The tall strength-to-weight proportion of ASTM B 265 titanium sheet moreover permits for the plan of lighter, more effective structures in building applications and mechanical gear. This characteristic is especially profitable in the development of large-scale structures or versatile apparatus, where weight decrease can lead to critical enhancements in operational proficiency and cost-effectiveness.

Aerospace and Aviation Applications

ASTM B 265 titanium sheet is exceptionally critical to the aviation trade since it has a uncommon set of properties. When building airplanes, ASTM B 265 titanium sheet is utilized a part in the fuselage, wing areas, and motor parts. Airplanes can be made littler since of its tall strength-to-weight proportion. This spares fuel and makes it conceivable to carry more cargo. The capacity of ASTM B 265 titanium sheet to anticipate erosion is particularly valuable in this field since it makes a difference secure vital parts from the unforgiving conditions that happen amid flight, such as changing temperatures, weights, and barometrical erosion. ASTM B 265 titanium sheet is moreover exceptionally great at standing up to weakness, which makes it culminate for parts that are stacked and emptied over and over once more, like landing equip parts and motor mounts. This makes beyond any doubt that the portion will be dependable and secure for a long time in flying machine applications.

Chemical and Marine Industry Uses

ASTM B 265 titanium sheet is broadly utilized in the marine and chemical businesses since it doesn't rust and keeps going a long time in unforgiving conditions. Astm B 265 titanium sheet is utilized to make reactors, warm trades, and capacity tanks that bargain with chemicals that are destructive to living things. Since it doesn't respond with numerous acids, bases, or chlorides, it's a incredible fabric for these employments since it will final for a long time and require small upkeep. ASTM B 265 titanium sheet is utilized in the marine industry to construct desalination plants, oil and gas bases at ocean, and parts for submarines. It is way better than standard materials like stainless steel since it can handle the destructive impacts of seawater and marine environments. When utilized in these areas, ASTM B 265 titanium sheet not as it were makes hardware final longer, but it moreover makes strides security and working proficiency in intense conditions.

How ASTM B 265 Standards Ensure Performance and Durability in Harsh Environments?

Rigorous Testing and Quality Control Measures

The ASTM B 265 standard sets forward thorough testing and quality control measures to guarantee the reliable execution and solidness of titanium sheet in cruel situations. These guidelines include a comprehensive run of tests, counting chemical composition examination, mechanical property assessments, and erosion resistance appraisals. For ASTM B 265 titanium sheet, producers must follow to strict resiliences in natural composition, which straightforwardly impacts the material's erosion resistance and mechanical properties. Pliable quality, abdicate quality, and prolongation tests are conducted to confirm that the titanium sheet meets the indicated mechanical prerequisites. Moreover, particular erosion tests may be performed to survey the material's resistance to different natural conditions. This thorough testing administration guarantees that each bunch of ASTM B 265 titanium sheet meets the tall guidelines required for basic applications in destructive and requesting situations.

Specification of Grades and Their Properties

The ASTM B 265 standard gives specific details for various grades of titanium sheet, each made to meet particular performance needs. Among these grades are Grades 1-4, which are commercially pure titanium, and Grade 5, which is also known as Ti-6Al-4V. Each grade is described by its chemical make-up and mechanical properties, which lets engineers choose the material that will work best for their needs. For example, Grade 2 ASTM B 265 titanium sheet is very easy to shape and weld, which means it can be used for a wide range of tasks in harsh settings. On the other hand, Grade 5 ASTM B 265 titanium sheet is stronger and is often used in high-performance and aerospace uses. By making these grades and their properties clear, the ASTM B 265 standard helps makers and end users make smart choices. This way, they can be sure that the titanium sheet they choose will work as expected in its intended setting.

Traceability and Documentation Requirements

Traceability and paperwork are very important parts of the ASTM B 265 standard. This condition makes sure that each sheet of ASTM B 265 titanium can be linked to the batch that it came from, as well as its original heat treatment and testing results. Manufacturers must keep thorough records of the whole production process, such as where the raw materials come from, how they are melted, how they are shaped, and how they are heated. A unique identification number is given to each batch of ASTM B 265 titanium sheet. This number is used to keep track of the material throughout its entire lifecycle. This tracking is important for making sure the quality of the product and can be very important in situations where a failed material could have very bad results. In addition, the standard calls for detailed records of all test results, proving that the material meets the required chemical, mechanical, and physical standards. End users can be sure that the ASTM B 265 titanium sheet they are using will work successfully in harsh environments and meet the strict needs of their applications thanks to this strong system of tracking and documentation.

Conclusion

Because it has great properties and works well in harsh environments, ASTM B 265 titanium sheet has become the chosen corrosion-resistant metal in many fields. Because it doesn't rust, is strong for its weight, and can be used in many ways, it is very useful in aircraft, chemical processing, and marine settings. ASTM B 265 sets strict standards for quality, performance, and traceability. These standards make sure that engineers and makers have a reliable material for their most difficult projects. ASTM B 265 titanium sheet is still the best choice for industries looking for new ways to make things that don't rust because it is so durable and lasts a long time even in the worst circumstances.

For high-quality ASTM B 265 titanium sheet and expert guidance on its applications, consider Shaanxi Chuanghui Daye Metal Material Co., Ltd. Located in China's "Titanium Capital," our company combines decades of industry experience with state-of-the-art production facilities to deliver superior titanium products. We are committed to providing global clients with reliable, cost-effective metal materials that meet the highest standards of quality and performance. For more information or to discuss your specific requirements, please contact us at info@chdymetal.com.

FAQ

Q: What makes ASTM B 265 titanium sheet superior to other corrosion-resistant metals?

A: ASTM B 265 titanium sheet offers a unique combination of excellent corrosion resistance, high strength-to-weight ratio, and durability in harsh environments, outperforming many other metals in diverse applications.

Q: How does the protective oxide layer on ASTM B 265 titanium sheet form?

A: The protective oxide layer forms naturally when titanium is exposed to air or oxidizing environments, creating a thin, transparent film of titanium dioxide that shields the metal from corrosion.

Q: What industries commonly use ASTM B 265 titanium sheet?

A: ASTM B 265 titanium sheet is widely used in aerospace, chemical processing, marine, and medical industries due to its corrosion resistance and strength properties.

Q: How does the ASTM B 265 standard ensure the quality of titanium sheet?

A: The ASTM B 265 standard sets rigorous testing requirements, specifies grades and properties, and mandates traceability and documentation to ensure consistent quality and performance.

Q: Can ASTM B 265 titanium sheet be welded or formed easily?

A: Yes, many grades of ASTM B 265 titanium sheet offer excellent formability and weldability, making them suitable for various manufacturing processes.

Q: Is ASTM B 265 titanium sheet more expensive than other corrosion-resistant materials?

A: While the initial cost may be higher, the long-term benefits of ASTM B 265 titanium sheet, including reduced maintenance and longer lifespan, often make it a cost-effective choice for corrosion-resistant applications.

References

1. American Society for Testing and Materials. (2020). ASTM B265 - Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate. ASTM International.

2. Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International.

3. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. John Wiley & Sons.

4. Peters, M., Hemptenmacher, J., Kumpfert, J., & Leyens, C. (2003). Structure and Properties of Titanium and Titanium Alloys. In Titanium and Titanium Alloys: Fundamentals and Applications (pp. 1-36). Wiley-VCH.

5. Schutz, R. W., & Thomas, D. E. (1987). Corrosion of titanium and titanium alloys. ASM Handbook, 13, 669-706.

6. Boyer, R., Welsch, G., & Collings, E. W. (Eds.). (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

Learn about our latest products and discounts through SMS or email