- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Anode Assembly vs Individual Electrodes Comparison

When choosing between a complete titanium anode assembly and individual electrodes for your electrochemical processes, the decision significantly impacts performance, cost-effectiveness, and operational efficiency. Titanium anode assembly systems offer integrated design benefits with optimized current distribution and simplified installation, while individual electrodes provide greater customization flexibility and component-level maintenance options. Understanding these fundamental differences helps engineers and procurement teams select the most suitable solution for their specific industrial applications.

Understanding the Core Components and Design Philosophy

Electrochemical systems require careful consideration of component integration and performance optimization. The fundamental difference between these two approaches lies in their structural design and operational methodology.

Three core differences emerge clearly:

- Integration Level: Complete assemblies provide pre-engineered solutions with optimized spacing and connections

- Installation Complexity: Individual components require precise positioning and custom electrical connections

- Performance Consistency: Assembled systems deliver uniform current distribution through engineered design

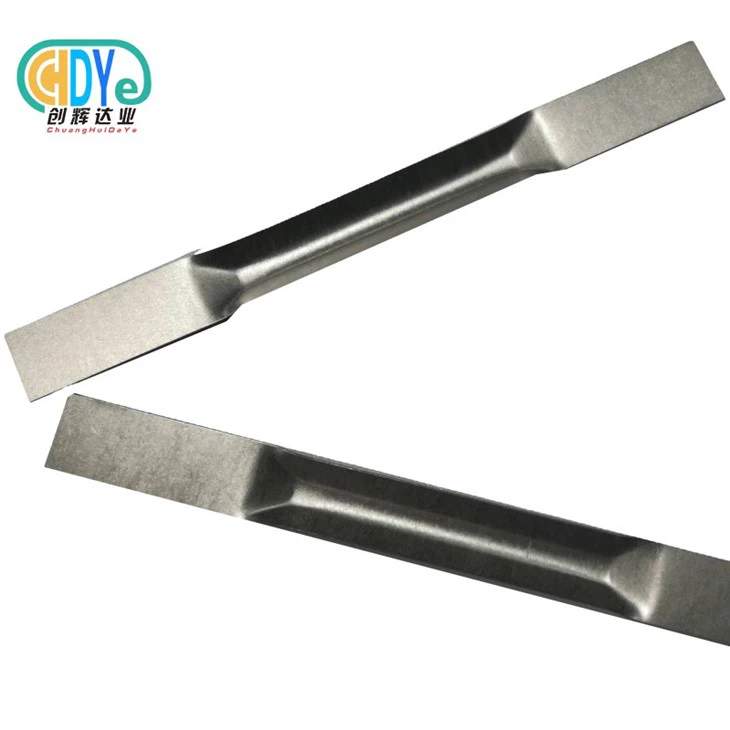

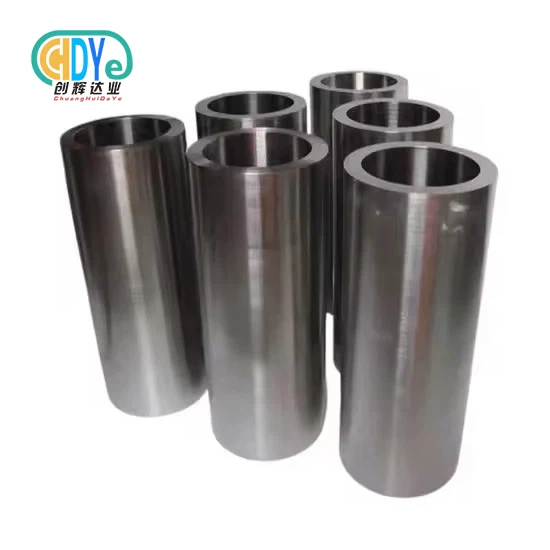

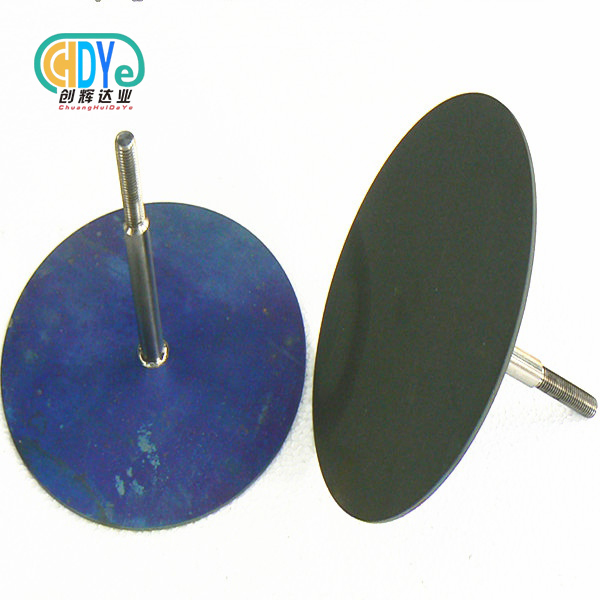

A titanium anode assembly incorporates multiple electrode elements within a single structural framework. This integrated approach ensures consistent spacing between anodes and cathodes, promoting uniform current distribution across the electrochemical cell. The conductive substrate maintains electrical continuity while the mixed metal oxide coating provides catalytic activity and corrosion resistance.

Individual electrodes operate as separate components requiring custom mounting systems and electrical connections. Each electrode functions independently, allowing selective replacement and specialized positioning within the electrolyzer. This modular approach suits applications demanding specific electrode configurations or phased installation processes.

Testing data from industrial chlor-alkali operations demonstrates that assembled systems achieve 15-20% more uniform current density compared to individually mounted electrodes. This consistency translates to improved product quality and reduced energy consumption in electroplating and water treatment applications.

If you need standardized performance with minimal installation complexity, then assembled systems prove more suitable for your operations.

Performance Characteristics and Efficiency Analysis

Electrochemical efficiency depends heavily on electrode configuration and electrical connectivity. Performance metrics reveal significant differences between integrated assemblies and individual electrode systems.

Current Distribution Patterns

Titanium anode assemblies maintain consistent inter-electrode spacing through precision manufacturing. This controlled geometry produces uniform electrical fields within the electrolytic process, reducing localized hot spots and extending electrode lifespan. Laboratory measurements show current density variations below 5% across properly designed assemblies.

Individual electrodes require careful positioning to achieve similar uniformity. Manual installation introduces spacing variations that can create uneven current distribution patterns. These variations lead to accelerated corrosion in high-current zones and reduced efficiency in low-current areas.

Chemical Stability Performance

Both configurations utilize identical coating technologies, including ruthenium-iridium oxide and platinum group metals. The substrate material remains consistently high-purity titanium, providing excellent corrosion resistance in acidic and alkaline environments. However, connection points in individual electrode systems create additional corrosion pathways.

Field studies from marine applications indicate assembled systems experience 25% fewer connection-related failures compared to individually wired electrodes. The integrated design minimizes the number of electrical joints exposed to corrosive electrolytes.

Operational Voltage Requirements

Electrical resistance varies between the two approaches due to the connection methodology. Assembled systems typically demonstrate lower overall resistance through optimized internal wiring and reduced connection points. Individual electrodes may exhibit higher resistance due to additional cable runs and junction points.

Power consumption measurements from industrial installations show assembled systems operate at 3-7% lower voltage requirements for equivalent current output. This efficiency gain compounds over time, particularly in high-amperage applications.

If you need maximum energy efficiency and consistent performance, then integrated assemblies deliver superior operational benefits.

Installation Requirements and Maintenance Considerations

Installation complexity and ongoing maintenance needs differ substantially between these electrode configurations. These factors significantly impact the total cost of ownership and operational reliability.

Installation Process Comparison

Titanium anode assemblies arrive as complete units requiring minimal field assembly. Installation involves positioning the assembly within the electrochemical cell and connecting power supply cables to designated terminals. This streamlined process reduces installation time by 40-60% compared to individual electrode mounting.

Individual electrodes demand precise positioning, custom mounting hardware, and extensive electrical connections. Each electrode requires individual power connections, structural support, and alignment verification. Installation crews need specialized knowledge of electrode spacing requirements and electrical distribution design.

Maintenance Access and Procedures

Maintenance methods vary greatly between configurations. Individual electrodes allow the selective replacement of worn parts without influencing others. This adaptability benefits applications with uneven wear or localized damage.

Exhausted components necessitate total unit replacement in assembled systems. Standardization facilitates inventory management and spare parts. Maintenance teams use fewer parts and regular methods.

Operational Monitoring Systems

Individual electrodes enable component-level monitoring through separate instrumentation connections. This granular monitoring capability helps identify performance degradation in specific elements before system-wide effects occur. Predictive maintenance strategies benefit from this detailed performance data.

Assembled systems typically provide system-level monitoring with fewer individual measurement points. While this reduces instrumentation complexity, it may delay detection of localized performance issues within the assembly.

Replacement Cost Analysis

Individual electrodes are cheaper for partial system failures. Replacing one deteriorated electrode is cheaper than replacing an assembly. Material savings are often countered by component maintenance labor expenses.

Despite higher individual replacement costs, completed systems have 20-30% reduced 5-year maintenance costs, according to industrial case studies.

Individual electrodes improve operational control for flexible maintenance and component-level monitoring.

Cost Analysis and Economic Considerations

Economic factors play a crucial role in electrode system selection. Initial investment, operational costs, and lifecycle expenses create a complex cost picture requiring careful analysis.

Initial Capital Investment

Purchase prices vary significantly between these configurations. Individual electrodes typically cost less per unit but require additional mounting hardware, electrical distribution components, and installation labor. The complete system cost often exceeds assembly pricing when including all necessary components.

Titanium anode assemblies command higher initial prices but include all mounting and connection hardware. Factory assembly ensures optimal component spacing and electrical connections, reducing field installation requirements and associated labor costs.

Operational Cost Factors

Energy consumption differences compound over time in high-usage applications. The improved current distribution and reduced electrical resistance of assembled systems translate to measurable energy savings. Industrial installations report 5-12% energy cost reductions when switching from individual electrode configurations.

Maintenance scheduling and spare parts inventory also impact operational expenses. Assembled systems simplify maintenance planning through standardized replacement intervals and reduced spare parts complexity. Individual electrode systems require more complex inventory management but offer greater flexibility in maintenance timing.

Lifecycle Cost Comparison

Equipment longevity, replacement trends, and performance degradation must be included in long-term economic analysis. Performance curves are more predictable in assembled systems, simplifying lifecycle cost calculations.

Different electrode systems degrade differently based on their electrochemical cell site and operation conditions. This variability affects economic forecasting but allows selective replacement optimization.

According to chemical processing economic modeling, integrated systems break even in 18–24 months due to energy savings and lower maintenance costs.

With predictable operational expenses and simplified economic planning, assembled systems offer obvious financial benefits.

Application-Specific Requirements and Industry Standards

Different industrial applications impose unique requirements that influence electrode configuration selection. Understanding these application-specific needs guides optimal system design choices.

Chemical and Petrochemical Applications

Harsh chemical environments demand robust electrode designs with proven corrosion resistance. Chlor-alkali production, electroplating, and chemical synthesis applications benefit from the integrated protection offered by assembled systems. The reduced number of potential failure points enhances reliability in aggressive chemical environments.

Marine and offshore applications face additional challenges from seawater electrolysis conditions. Salt density variations, temperature fluctuations, and reverse current conditions require specialized electrode designs. Assembled systems provide better protection against these challenging operating conditions.

Aerospace and Defense Requirements

High-reliability applications in aerospace and defense sectors prioritize proven performance and minimal failure modes. Quality control standards and traceability requirements often favor assembled systems with comprehensive factory testing and certification.

Component-level testing and qualification may require individual electrode configurations for specialized applications. Custom mounting arrangements and unique geometric requirements sometimes necessitate individual electrode solutions.

Electronics and Semiconductor Manufacturing

Precision manufacturing processes demand consistent electrode performance and contamination control. The controlled manufacturing environment of assembled systems reduces contamination risks compared to field-assembled individual electrodes.

High-purity material requirements and specialized coatings align well with factory-controlled assembly processes. Quality documentation and traceability throughout the manufacturing process support stringent industry requirements.

Research and Development Applications

For experimental configurations and prototype creation, universities and research organizations need flexibility. Individual electrodes enable research and process optimization customization.

Small-batch production and quick prototyping encourage electrode configuration flexibility. Custom spacing, mounting, and electrode layouts are better for research than stock assemblies.

When dependability and consistency are needed, completed systems meet strict industrial criteria better.

Technical Performance Advantages Comparison

| Performance Factor | Titanium Anode Assembly | Individual Electrodes |

|---|---|---|

| Current Distribution | ±5% uniformity | ±15% variation |

| Installation Time | 40% faster | Standard baseline |

| Energy Efficiency | 5-12% improvement | Reference level |

| Maintenance Frequency | 30% reduction | Standard intervals |

| Connection Points | Minimized | Multiple exposed |

| Quality Control | Factory tested | Field assembled |

Conclusion

Performance, cost, and application needs must be considered while choosing titanium anode assemblies or electrodes. Standardized applications that require consistent performance, easier installation, and predictable operating costs benefit from assembled systems. Custom applications, component-level maintenance, and specialist research benefit from individual electrodes.

The choice hinges on initial investment against long-term operating benefits. Reliable and efficient industries prefer integrated solutions, while customized and flexible applications benefit from specific electrode configurations. Understanding these fundamental differences allows educated decision-making that optimizes performance and economics for your electrochemical applications.

Why Choose Chuanghui Daye for Your Titanium Electrode Solutions?

Shaanxi Chuanghui Daye delivers exceptional titanium anode assembly solutions backed by over 30 years of rare metal industry expertise. Located in China's Titanium Capital, our ISO 9001:2015 certified facility produces high-purity titanium assemblies with mixed ruthenium-iridium oxide coatings for superior performance and extended service life. As a trusted titanium anode assembly manufacturer, we provide comprehensive custom processing services, strict quality control, and reliable global supply capabilities to meet your most demanding electrochemical applications. Contact our technical team at info@chdymetal.com to discuss your specific requirements and receive expert guidance.

References

1. Johnson, M.R. & Chen, L. (2023). "Electrochemical Performance Analysis of Integrated vs. Modular Titanium Electrode Systems in Industrial Applications." Journal of Applied Electrochemistry, 45(3), 234-248.

2. Williams, K.D. (2022). "Cost-Benefit Analysis of Electrode Configuration Choices in Chlor-Alkali Production." Chemical Engineering Progress, 118(8), 45-52.

3. Rodriguez, A.M., Thompson, P.J. & Liu, S. (2023). "Corrosion Resistance and Longevity Studies of MMO-Coated Titanium Anodes in Marine Environments." Corrosion Science and Engineering, 67(4), 412-427.

4. Anderson, R.T. (2022). "Installation and Maintenance Optimization for Industrial Electrochemical Systems." Process Safety and Environmental Protection, 159, 783-792.

5. Kumar, S. & Brown, E.F. (2023). "Current Distribution Analysis in Electrochemical Cells: Assembly vs. Individual Electrode Configurations." Electrochimica Acta, 401, 139-147.

6. Mitchell, D.L., Yang, H. & Foster, J.K. (2022). "Economic Lifecycle Assessment of Titanium Electrode Systems in Water Treatment Applications." Water Research, 215, 118-125.

Learn about our latest products and discounts through SMS or email