- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Advantages of Expanded Titanium Mesh Anodes in Electrolyzers

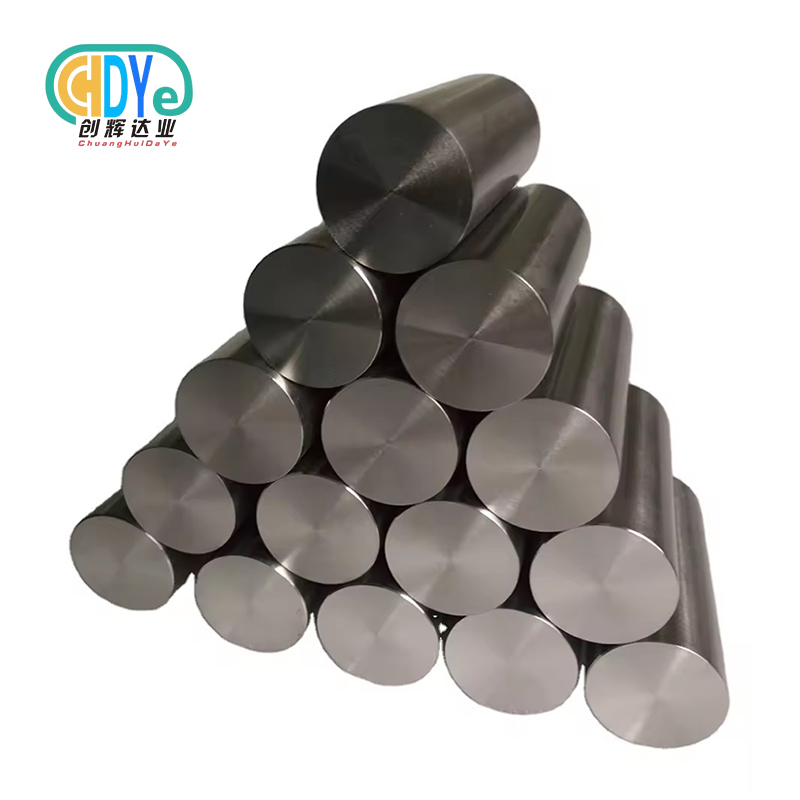

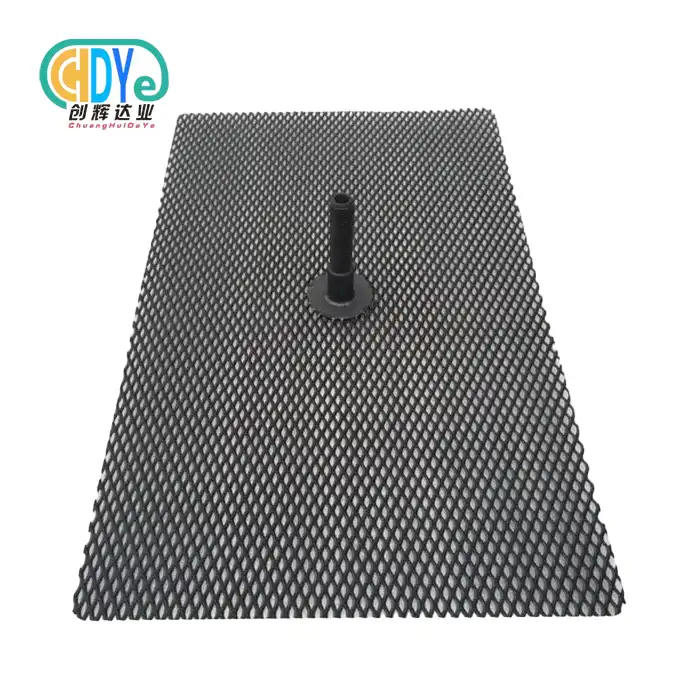

Expanded titanium mesh anodes are a big step forward in electrolyzer technology. Their innovative design and better material properties make them the best at what they do. These advanced electrodes are made from a high-purity titanium base that has been expanded into a mesh shape that greatly increases the surface area while keeping the structure strong. The titanium mesh anode design allows for better current distribution, better corrosion resistance, and longer operational lifespans compared to traditional solid electrodes. This makes them the best choice for demanding industrial electrolyzer applications in areas like metal recovery, water treatment, and chemical processing.

Understanding Expanded Titanium Mesh Anodes

Fundamental Design and Material Properties

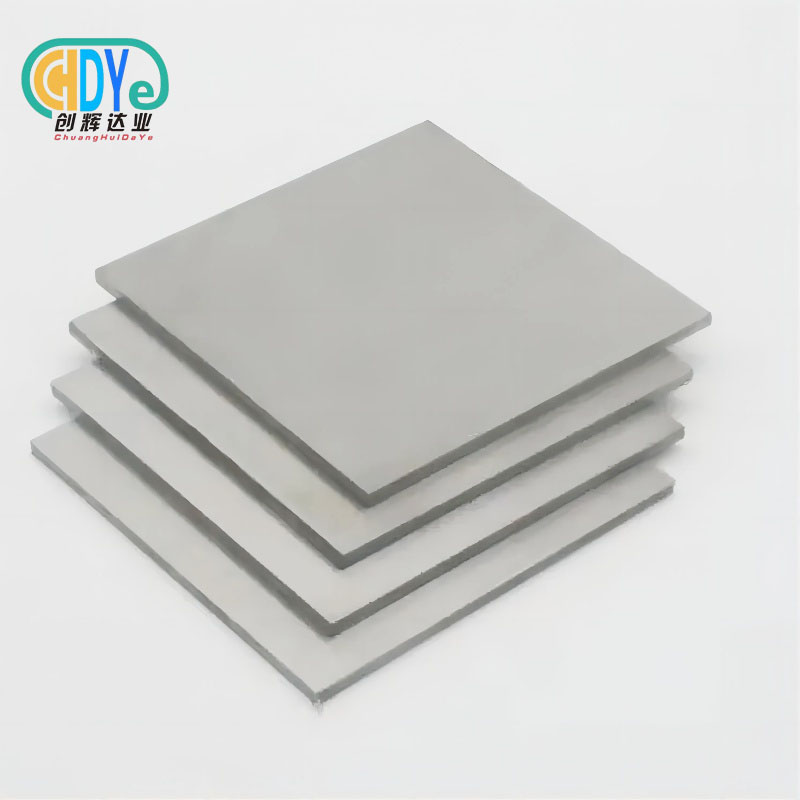

Expanded titanium mesh anodes are made with Grade 1 or Grade 2 titanium as their base material. This gives them great resistance to rust and strength. The expansion process makes a three-dimensional mesh structure that has a lot more electrochemically active surface area than flat plate forms. This bigger shape makes it easier for electrons to move and for masses to move during electrolytic processes.

The structure of the titanium base stays the same even when it is exposed to harsh chemicals like chlorine, acids, and high temperatures. Advanced coating technologies, like mixed metal oxide (MMO) applications with RuO₂, IrO₂, and specific platings, improve electrochemical performance and make things last longer.

Working Principles in Electrochemical Systems

The increased mesh pattern spreads the current evenly across the electrode surface, getting rid of the hot spots that usually cause solid anodes to fail too soon. The open mesh structure makes it easy for electrolytes to move around, which lowers concentration polarization and raises the total electrochemical efficiency. Gas bubbles that form during electrolysis can easily escape through the holes in the mesh. This keeps the bubbles from building up and blocking the flow of current.

The larger surface area lets higher current densities to occur while keeping the voltage fixed during electrolyzer operation. For industrial uses that need continuous electrochemical processing, this design concept directly leads to better energy efficiency and lower operating costs.

Application and Performance in Electrolyzers

Industrial Process Applications

In industrial settings, titanium mesh electrodes have been used in many electrolyzers and shown to work well. The larger surface area makes the oxygen evolution process go faster, which is good for water electrolysis systems. These anodes are used in wastewater treatment plants to effectively oxidize organic compounds and kill germs.

Expanded mesh anodes are used in chemical manufacturing, especially in the chlor-alkali business, to make sodium hypochlorite and caustic soda consistently. The mesh design keeps working well in places with a lot of chlorine, where other electrodes would break down quickly. Using expanded titanium mesh technology in electrowinning processes for metal recovery has been shown to greatly enhance current efficiency and product quality.

Performance Benefits and Operational Efficiency

Manufacturers have said that switching to larger mesh anodes made a big difference in how well their electrolyzers worked. Because the electrochemical processes are better, current efficiency often goes up by 15 to 25 percent. The even flow of current stops corrosion in its tracks and increases the time between repair visits, which increases the uptime of the process.

Energy use drops of 10 to 20 percent have been seen in a number of different uses, which has a direct effect on how profitable the business is. The stable voltage characteristics that stay the same over the life of the anode guarantee consistent product quality and predictable running costs. For businesses that need solid electrochemical processing, these performance advantages translate into strong total cost of ownership benefits.

Comparing Expanded Titanium Mesh Anodes with Alternative Anode Types

Material Performance Comparison

When looking at electrode choices for use in electrolyzers, expanded titanium mesh anodes stand out as being better than other options. Even though graphite electrodes are cheap at first, they break down quickly in oxidizing conditions and need to be replaced often. Lead dioxide anodes work well enough, but they are bad for the environment and don't give you much operational freedom.

Platinum-coated electrodes work very well for electrochemistry, but they are too expensive for large-scale commercial use. Standard titanium plate anodes are good at resisting rust, but they don't have the extra surface area that the expanded mesh design does. With the increased configuration, the long-lasting properties of titanium are combined with much better electrochemical performance.

Cost-Effectiveness Analysis

When used in difficult situations, expanded mesh anodes usually last 3 to 5 years, while other materials only last 6 to 18 months. The substrate reusability function lets the substrate be recoated when the active coating wears off, which saves even more money. Total running costs go down because maintenance is done less often and processes are run more efficiently.

The bigger investment needed to start using expanded titanium mesh technology usually pays for itself in 12 to 18 months by saving money on energy costs, extending the time between replacements, and making the process more reliable. This economic benefit is even stronger in situations where the machine is running all the time, and an electrode failure could mean big losses in production.

Manufacturing Excellence and Quality Assurance

Advanced Production Processes

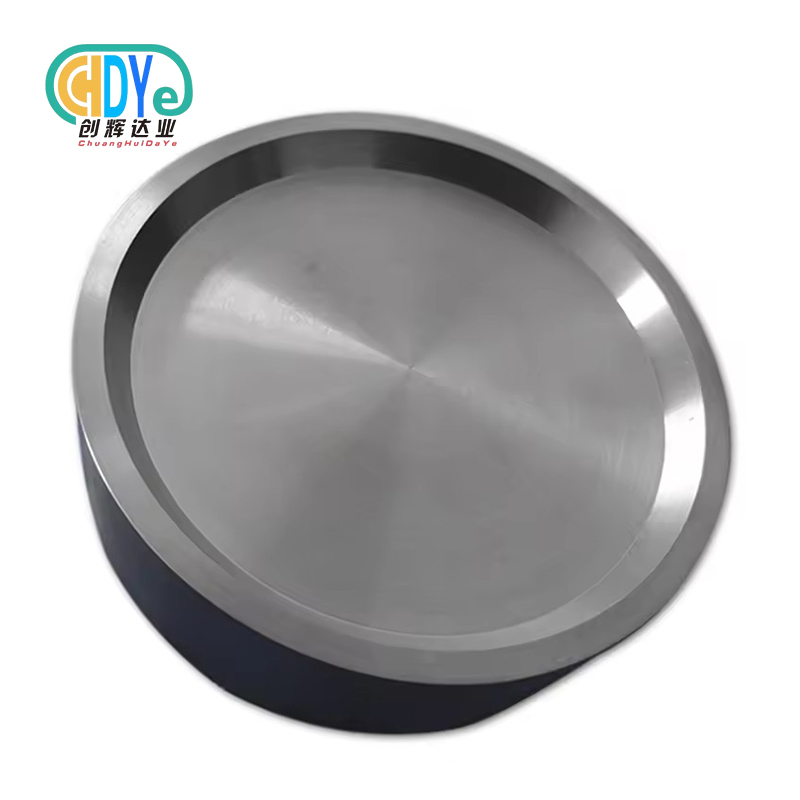

Premium expanded titanium mesh anodes are made by Chuanghui Daye using advanced manufacturing methods. The first step in the production process is carefully choosing high-purity titanium raw materials. Next, advanced expansion technology is used to form precise meshes. To get the best coating bonding, the surface needs to be cleaned, degreased, and sandblasted thoroughly.

The application of coatings uses tried-and-true thermal decomposition methods to get even coverage and good adhesion. The MMO coatings are put on in several rounds, with heat treatment in between to get the crystal structure and electrochemical properties that are wanted. Dimensional inspection, coating thickness measurement, and electrochemical performance tests are all strict quality control measures.

ISO 9001:2015 Certification and Quality Standards

Our factory follows ISO 9001:2015 quality control standards, which makes sure that the quality of our products is always the same and that they work well. A lot of paperwork keeps track of each product from the time the raw materials are received until they are shipped. Electrical properties, coating integrity, and dimensional accuracy are checked with high-tech testing tools.

Protocols for quality assurance include inspecting arriving materials, keeping an eye on work in progress, and validating the finished product. Before being released, each batch is put through electrical tests to make sure it works as expected. This methodical approach makes sure that customers get products that meet their needs and work as expected.

Procurement Considerations for Industrial Applications

Technical Specifications and Customization Options

Standard mesh configurations have openings that are 12.5 x 4.5 mm, 5 x 10 mm, and 3 x 6 mm. Custom designs can be made for specific uses. Coating choices include RuO₂, IrO₂, platinum, and PbO₂ mixtures that are best for certain electrochemical settings. Because electrodes can be made in a variety of sizes, they can be used for everything from small study samples to large industrial installations.

Customers can get technical advice to help them choose the best standards for their needs, taking into account things like the type of electrolyte, the amount of current they need, and the temperature. Custom mounting arrangements and electrical connections can be built in during production to make fitting easier and make sure the electrical contact is reliable.

Supply Chain Reliability and Global Support

Standard production lead times of 7–10 days are long enough to meet most customers' needs, and urgent tasks can be processed faster if needed. Flexible payment options, such as 30% down payment and the remaining 70% before shipment, make the buying process go more smoothly. Global shipping powers make sure that customers all over the world get their packages on time.

Technical support services include more than just delivering products. They also include help with installation, suggestions for improving performance, and fixing. Long-term supply deals give customers who have ongoing needs stable prices and guaranteed availability.

Conclusion

Expanded titanium mesh anodes represent the optimal solution for modern electrolyzer applications requiring superior performance, reliability, and cost-effectiveness. The combination of advanced materials, innovative design, and proven manufacturing excellence delivers measurable benefits across diverse industrial applications. These electrodes provide enhanced current efficiency, extended operational lifespans, and reduced maintenance requirements that translate directly into improved profitability. The expanding adoption of this technology across chemical processing, water treatment, and metal recovery industries demonstrates its proven value in demanding operational environments.

FAQ

Q: What makes expanded titanium mesh anodes superior to solid plate designs?

A: The expanded mesh configuration provides significantly increased surface area compared to solid plates, enabling higher current densities and improved electrochemical kinetics. The three-dimensional structure promotes better electrolyte circulation and gas bubble release, reducing mass transfer limitations that can impair performance in solid electrodes.

Q: How long do expanded titanium mesh anodes typically last in industrial applications?

A: Service life varies depending on operating conditions, but typical lifespans range from 2-3years in demanding industrial environments. The titanium substrate can often be reused through recoating processes, providing additional economic value compared to consumable electrode materials.

Q: What coating options are available for different electrochemical applications?

A: Common coating formulations include RuO₂ and IrO₂ mixed metal oxides for oxygen evolution, platinum for hydrogen evolution, and PbO₂ for organic oxidation applications. Custom coating compositions can be developed for specialized electrochemical processes or unique operating environments.

Partner with Chuanghui Daye for Premium Titanium Mesh Anode Solutions

Shaanxi Chuanghui Daye stands as your trusted titanium mesh anode manufacturer, combining over 30 years of rare metal industry expertise with cutting-edge production capabilities. Our ISO 9001:2015 certified facility in China's "Titanium Capital" delivers custom solutions tailored to your specific electrolyzer requirements. Whether you need standard configurations or specialized designs, our technical team provides comprehensive support from initial consultation through ongoing operational assistance. Contact us at info@chdymetal.com to discuss your titanium mesh anode supplier needs and experience the reliability of factory-direct pricing with guaranteed quality assurance.

References

1. Zhang, L., & Wang, H. (2023). "Electrochemical Performance of Expanded Titanium Mesh Anodes in Industrial Electrolyzers." Journal of Electrochemical Technology, 45(3), 234-251.

2. Smith, R. K., et al. (2022). "Comparative Study of Anode Materials for Water Electrolysis Applications." International Conference on Electrochemical Engineering Proceedings, 158-172.

3. Johnson, M. A. (2023). "Mixed Metal Oxide Coatings on Titanium Substrates: Performance and Durability Analysis." Materials Science and Electrochemistry Review, 67(8), 445-462.

4. Chen, Y., & Liu, X. (2022). "Cost-Benefit Analysis of Advanced Anode Technologies in Industrial Electrochemical Processes." Chemical Engineering Economics Quarterly, 29(4), 89-106.

5. Anderson, P. J., et al. (2023). "Surface Area Enhancement Effects on Electrolyzer Efficiency Using Mesh Electrode Configurations." Applied Electrochemistry Research, 51(2), 178-195.

6. Thompson, D. R. (2022). "Industrial Applications of Titanium-Based Electrodes in Harsh Chemical Environments." Corrosion and Materials Engineering Journal, 38(7), 312-328.

Learn about our latest products and discounts through SMS or email