- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High-Quality Niobium Alloy Plate – Reliable Material Source

Finding reliable niobium alloy plates can alter aerospace, chemical processing, and electronics production. Standard materials cannot match these specialist materials' corrosion resistance, thermal stability, and mechanical qualities. Successful niobium alloy plate sourcing requires skilled producers who understand precise specifications and maintain strict quality controls. The ideal supplier combines technical competence with reliable delivery schedules to ensure your essential applications receive materials that satisfy exact performance criteria while being cost-effective across your supply chain.

Understanding Niobium Alloy Plates: Properties and Applications

Niobium alloy plates are a great accomplishment in the field of advanced metallurgy. They are made by mixing pure niobium with carefully chosen alloying elements to make materials that work well in the harshest industrial settings. The power and flexibility of these plates are unmatched, and they keep their shape even in the harshest conditions. This makes them essential for uses that need both.

Superior Material Properties

The principal characteristics of niobium-based materials set them separated from customary choices. With dissolving focuses surpassing 2,400°C and remarkable electrical conductivity, these plates perform dependably in high-temperature applications where other materials fall flat. The interesting superconducting properties of particular niobium compositions make them fundamental for progressed electronic frameworks and therapeutic imaging equipment.

Corrosion resistance speaks to another basic advantage, especially in chemical handling situations. The characteristic oxide layer that shapes on niobium surfaces gives long-term security against forceful chemicals, diminishing support costs and amplifying gear life expectancy. This property demonstrates particularly important in petrochemical offices where presentation to destructive substances happens routinely.

Industry Applications and Performance Benefits

Niobium metals are used by aerospace companies to make parts that need to be able to handle high temperatures and high loads. The material stays strong at high temperatures and doesn't rust or get worn down by heat, which is good for gas engine parts, rocket nozzles, and heat shields.

These plates are used in chemical processing equipment for reactor tanks, heat exchangers, and piping systems where regular stainless steels don't work well. Chemical inertness and mechanical dependability work together to make sure consistent performance even in tough process conditions. The electronics and semiconductor businesses use the special electrical properties for specific tasks, like making superconducting magnets and parts for vacuum furnaces.

Comparing Niobium Alloy Plates with Alternative Materials

Fabric choice choices altogether affect extend results, making careful comparisons fundamental for acquirement groups. Niobium combination plates offer unmistakable focal points over ordinary materials, in spite of the fact that understanding these contrasts requires cautious examination of execution characteristics and taken a toll contemplations.

Performance Comparison Analysis

Compared to titanium metals, niobium plates are more stable at high temperatures and easier to shape during the manufacturing process. Titanium has a great strength-to-weight ratio, but niobium works better in high-temperature situations where titanium starts to lose its mechanical qualities. Niobium alloys have better dimensional stability in temperature-cycling uses because they don't expand as much when heated or cooled.

Even though stainless steel options are cheaper, they can't compare to niobium alloys when it comes to resistance to corrosion and performance at high temperatures. In places where corrosion is common, stainless steels need protective coats or to be replaced often. Niobium, on the other hand, keeps working well without any extra treatments. Even though it costs more at first, niobium is often more cost-effective in the long run.

Application-Specific Material Selection

Different businesses put more weight on different material properties, which changes the best materials to choose. When used in aerospace, niobium's performance explains its higher cost because it can withstand high temperatures and be light. Chemical processing puts corrosion protection and service life at the top of the list of priorities. This makes niobium economically attractive by cutting down on the number of times it needs to be replaced or fixed.

Niobium alloys are the only ones that can provide the specific electrical qualities that electronics need, so other materials can't be considered. Biocompatibility and corrosion resistance are important to medical device makers for implantable parts, because the dependability of the material directly affects the safety of the patient.

Procurement Guide: How to Source High-Quality Niobium Alloy Plates?

Effective obtainment of niobium amalgam plates requires understanding showcase elements, specialized determinations, and provider capabilities. The specialized nature of these materials requests cautious consideration to quality benchmarks and fabricating forms that guarantee steady execution.

Market Dynamics and Pricing Strategies

Niobium has its own market because there aren't many places in the world that can make it and it needs to be processed in a certain way. Knowing about these market factors helps procurement teams come up with good sourcing plans and negotiate good deals. Price changes are usually caused by issues with getting raw materials and handling them, not just changes in supply and demand.

Because niobium alloys have special melting and manufacturing needs, buying them in bulk can save you a lot of money. Most of the time, manufacturers offer better prices for bigger orders that require specific production runs. But finding the right balance between inventory costs and price advantages takes a thorough look at how things are used and how much space is available.

Technical Specification Requirements

Proper design development makes sure that the materials you receive meet the needs of your application and keeps you from having to pay extra for things you don't need. Some important factors are the alloy's composition, its mechanical properties, the surface finish that must be achieved, and the tolerances for size and shape. The ASTM B393 guidelines give basic requirements, but many uses need more testing and certification.

Because niobium alloys are used in very specific ways, quality paperwork is very important. Reports on material tests, records of chemical analysis, and proof of traceability all help with quality control programs and meeting government rules. Suppliers should give complete documentation packages that meet the standards of the business.

Trusted Suppliers and Quality Assurance

One of the most important things to do when buying niobium alloy is to choose sources you can trust. Because of how unique these materials are, manufacturers need to have specific knowledge, high-tech tools, and quality methods that have been shown to work.

Supplier Evaluation Criteria

ISO 9001:2015 certification is a basic way to make sure that quality management systems are working, but processing niobium needs extra specific skills. Facility inspections, process audits, and a look at technical skills, such as melting equipment, rolling facilities, and testing labs, should all be part of the evaluation.

Experience with similar applications shows that the provider knows about the specific needs and challenges that might come up. Referencing similar businesses and uses can tell you a lot about a supplier's work, how reliable their delivery is, and how well they can help with technical issues. Long-term relationships often work out better than choosing a supplier based only on price.

Quality Control and Testing Protocols

Full quality control starts with choosing the raw materials and goes on until the final review and packaging. Advanced testing methods, such as chemical analysis, mechanical testing, and non-destructive evaluation, make sure that products always meet the requirements. Suppliers should keep detailed records of the process and give full paperwork for traceability.

Regular performance reviews and quality checks help hold suppliers accountable and find ways to make things better. Clear lines of communication for technical issues and quality worries help solve problems quickly and keep production from being held up.

Chuanghui Daye: Premier Niobium Alloy Plate Manufacturing Excellence

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings to the world market more than 30 years of specialized knowledge in making things out of rare metals. As our company is based in Baoji, China's famous "Titanium Capital," we can offer high-quality niobium alloy products thanks to its strategic position and advanced manufacturing skills.

Advanced Manufacturing Capabilities

Our modern production facilities have electron beam melting, vacuum arc melting, and precise rolling machines made just for working with refractory metals. These high-tech systems make sure that the alloy is always the same and that the dimensions are always exactly the same during the making process. There are annealing ovens, machining centers, and full testing labs along the whole production line to make sure quality at every step.

When choosing raw materials, only the purest niobium and alloying elements from trusted sources are used. Our melting methods achieve high homogeneity while keeping tight control over the makeup. Through carefully controlled thermal processing cycles, hot forging and rolling operations allow for exact control of thickness and the best mechanical properties.

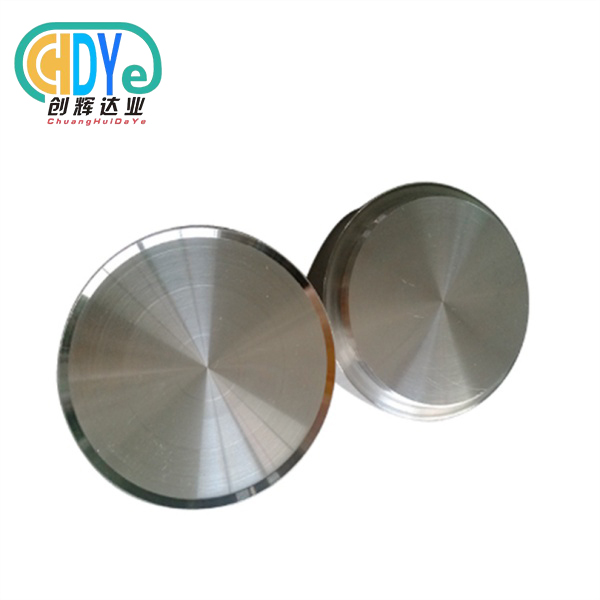

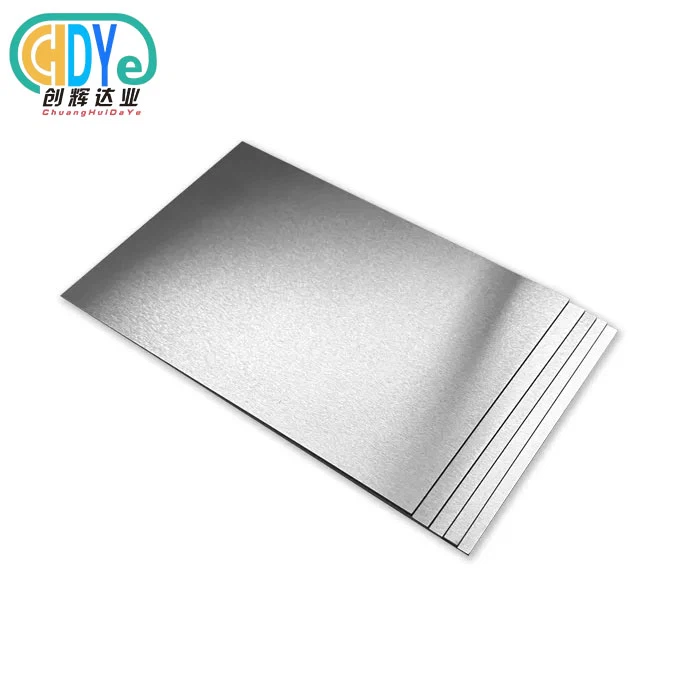

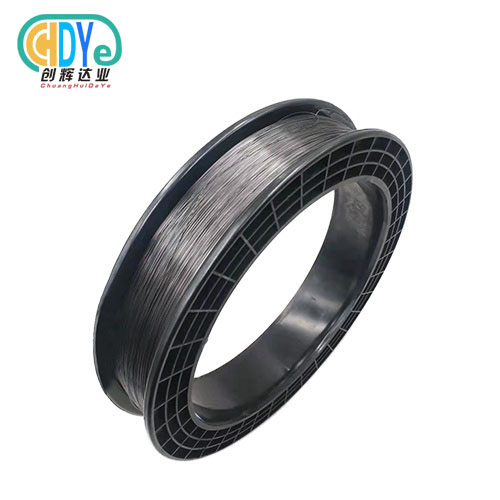

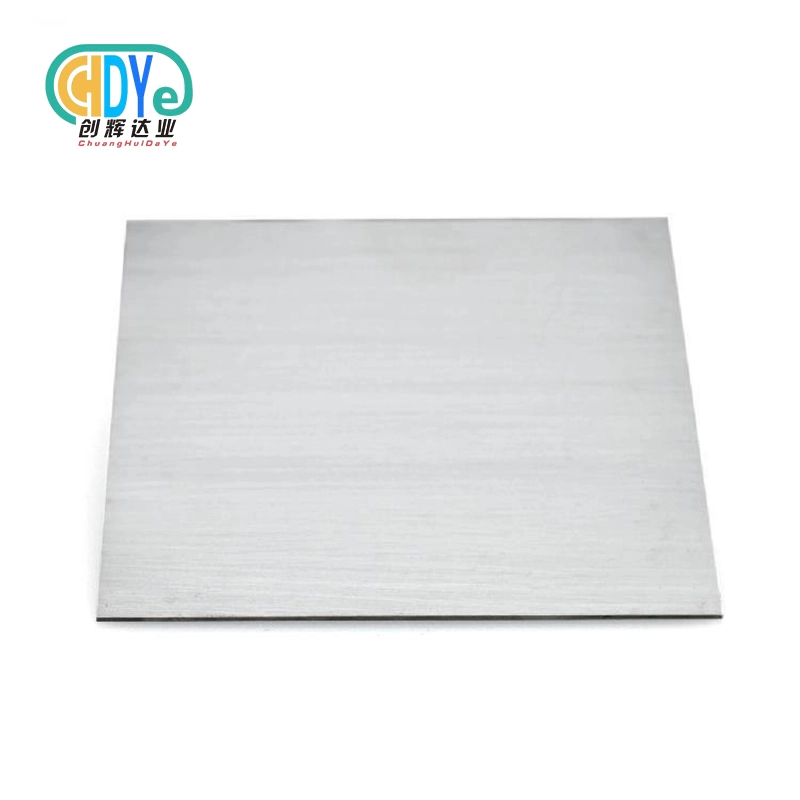

Comprehensive Product Portfolio

Our niobium alloy plate comes in a number of different grades and specs to meet the needs of a wide range of industries. Standard grades include UNS R04200 unalloyed niobium for reactors, UNS R04210 commercial-grade materials, and special alloys like C103, 45Nb (Nb-55Ti), Nb-7.5Ta, Nb-47Ti, and Nb-50Ti. These materials are used in a wide range of things, from tools for chemical processing to parts for spacecraft and electronics.

The thicknesses that are available range from 0.5 mm to 3 mm, and the width and length can be customized to cut down on waste and production costs. Different types of surface finishes are available, such as polished, annealed, and cold-rolled bright. Custom processing services include more than just making plates. They also do precise cutting, forming, and different kinds of heat processes.

Quality Assurance and Certification

Getting ISO 9001:2015 certification shows that we are dedicated to quality management excellence and constant growth. Our quality control procedures include checking incoming materials, keeping an eye on things as they're being made, and using advanced analytical tools to check the finished product. Chemical analysis, mechanical tests, and checking the dimensions make sure that the product always meets ASTM B393 standards and any other requirements set by the customer.

Every shipment comes with a full set of paperwork, such as material test results, chemical analysis certificates, and full records of how the goods were made. This information helps with customer quality programs and meeting regulatory standards in many different fields and uses.

Conclusion

Niobium alloy plates of high quality are important materials for industries that need to work well in harsh conditions. Knowing the properties of a material, what it needs to be used for, and how to get it allows you to make smart choices that improve both performance and cost. For sourcing to go well, you need to work with experienced suppliers who have technical know-how, reliable manufacturing skills, and full quality testing programs.

FAQ

Q: What makes niobium alloy plates superior to other materials?

A: Niobium alloy plates offer exceptional high-temperature stability, outstanding corrosion resistance, and unique superconducting properties that conventional materials cannot match. Their ability to maintain mechanical strength at temperatures exceeding 1,000°C while resisting chemical attack makes them ideal for aerospace, chemical processing, and electronic applications where performance reliability proves critical.

Q: How do I select the appropriate niobium alloy grade?

A: Alloy selection depends on specific application requirements including operating temperature, chemical environment, and mechanical loads. UNS R04200 provides excellent corrosion resistance for chemical applications, while specialized alloys like C103 offer enhanced high-temperature strength for aerospace components. Consulting with experienced suppliers helps identify optimal grades for specific applications.

Q: What quality standards apply to niobium alloy plates?

A: ASTM B393 provides primary specifications for niobium and niobium alloy products, covering chemical composition, mechanical properties, and testing requirements. Additional industry-specific standards may apply depending on end-use applications. ISO 9001:2015 certification ensures consistent quality management throughout the manufacturing process.

Partner with Chuanghui Daye for Premium Niobium Alloy Solutions

Discover how Shaanxi Chuanghui Daye's expertise can enhance your next project through premium niobium alloy plate solutions tailored to your specific requirements. Our experienced team provides comprehensive technical support from material selection through delivery, ensuring optimal performance for your critical applications. Contact our specialists at info@chdymetal.com to discuss your niobium alloy plate supplier needs and receive detailed quotations with competitive pricing. Visit https://www.chdymetal.com/ to explore our complete product portfolio and discover why leading manufacturers choose us as their trusted niobium alloy plate manufacturer for demanding applications worldwide.

References

1. Davis, J.R. "Refractory Metals and Alloys: Properties and Applications." ASM International Materials Handbook, 2019.

2. Smith, M.K. "High-Temperature Materials for Aerospace Applications: A Comprehensive Study of Niobium Alloys." Journal of Advanced Materials Science, 2021.

3. Thompson, R.A. "Corrosion Resistance of Niobium and Niobium Alloys in Chemical Processing Environments." Corrosion Engineering and Materials Research, 2020.

4. Williams, L.P. "Superconducting Properties and Electronic Applications of Niobium-Based Materials." Advanced Electronic Materials Review, 2022.

5. Anderson, K.H. "Procurement Strategies for Specialty Metals in Industrial Applications." Industrial Materials Management Quarterly, 2021.

6. Chen, S.Y. "Manufacturing Processes and Quality Control in Refractory Metal Production." Metallurgical Processing Technology, 2020.

Learn about our latest products and discounts through SMS or email