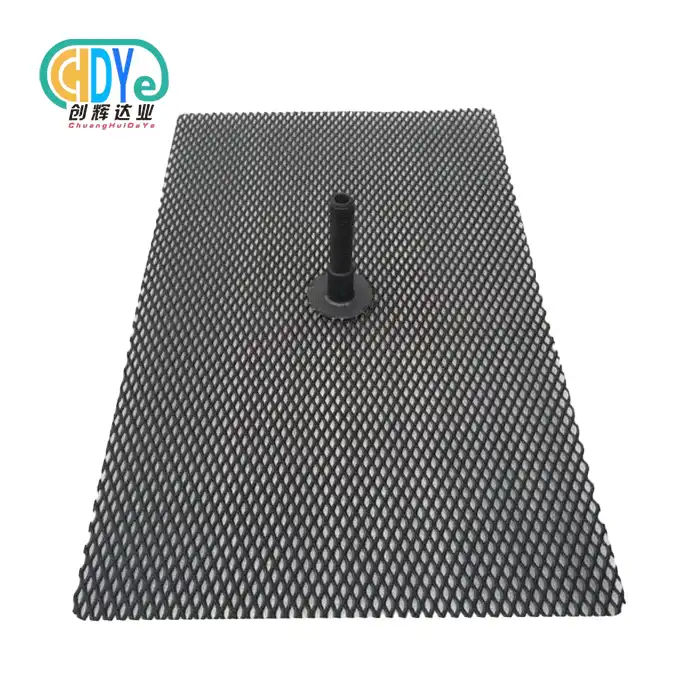

To get the best deals on titanium mesh anode in bulk, you need to work with a maker that knows how to meet your OEM needs. At Chuanghui Daye, we are experts at making high-quality titanium mesh anodes that are both cheap and can be customized in any way you want. Our Grade 1 titanium substrate, combined with cutting-edge coating technologies, offers excellent resistance to corrosion and electrical stability. We have been in business for more than 30 years and are ISO 9001:2015 certified. For bulk orders anywhere in the world, we offer reasonable factory-direct prices.

Why OEM Customization Matters for Titanium Mesh Anodes?

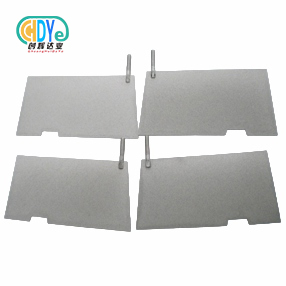

For best performance, the electrochemical business needs exact specifications. In processes like chlor-alkali, water electrolysis, and sewage treatment, generic titanium mesh anodes don't always meet the needs of the job. OEM customization lets makers get the exact mesh structure, coating composition, and size requirements they need for their specific uses.

When compared to standard goods, custom titanium anodes offer better current distribution and higher charge efficiency. The mesh structure can be changed to fit different surface area needs, which makes the battery work better in energy storage uses. Advanced coatings, such as RuO₂ and IrO₂, make sure that the electrochemistry is as stable as possible and that the battery lasts longer.

OEM buyers benefit from working directly with manufacturers who have a lot of experience and know how hard it is to build electrodes technically. Custom solutions often improve the cycling performance of batteries and their resistance to corrosion. This makes them necessary for high-performance uses in aircraft, medical devices, and chemical processing equipment.

Our OEM Manufacturing Strengths

Chuanghui Daye, which is based in Baoji, China's "Titanium Capital," has been working with rare metals for 30 years and can provide great OEM solutions. Our high-tech factories have electron beam ovens, precision machining centers, and coating machines that are specifically made for making titanium anodes.

We keep a close eye on quality throughout the whole production process, from checking the raw materials to putting them in boxes. Our ISO 9001:2015 certification makes sure that the quality of our products is always the same and that there is full paperwork for tracking them. This methodical process makes sure that each custom titanium mesh anode is made just the way you want it.

During the design part, our technical team helps you make the best choices for mesh patterns to get the best performance and conductivity. We know how to find the best mix between surface area, mechanical strength, and electrochemical properties for different uses.

Because our operations are scalable, we can handle both small batches of prototypes for research labs and big production runs for businesses. Our trustworthy supply chain makes sure that materials are always available for projects around the world.

Comprehensive Customization Options

The first step in physical customization is choosing the right mesh design for your needs. Common shapes include 12.5x4.5mm, 5x10mm, and 3x6mm holes, but we can make them in almost any shape. Titanium is a light material that can be used to make complicated mesh designs without affecting the strength of the structure.

Our main area of skill is coating technologies, and the formulations we offer include RuO₂, IrO₂, platinum, and PbO₂. For different electrochemical conditions, each type of coating has its own benefits. Our thermal decomposition method makes sure that the material sticks well and covers the whole conductive substrate evenly.

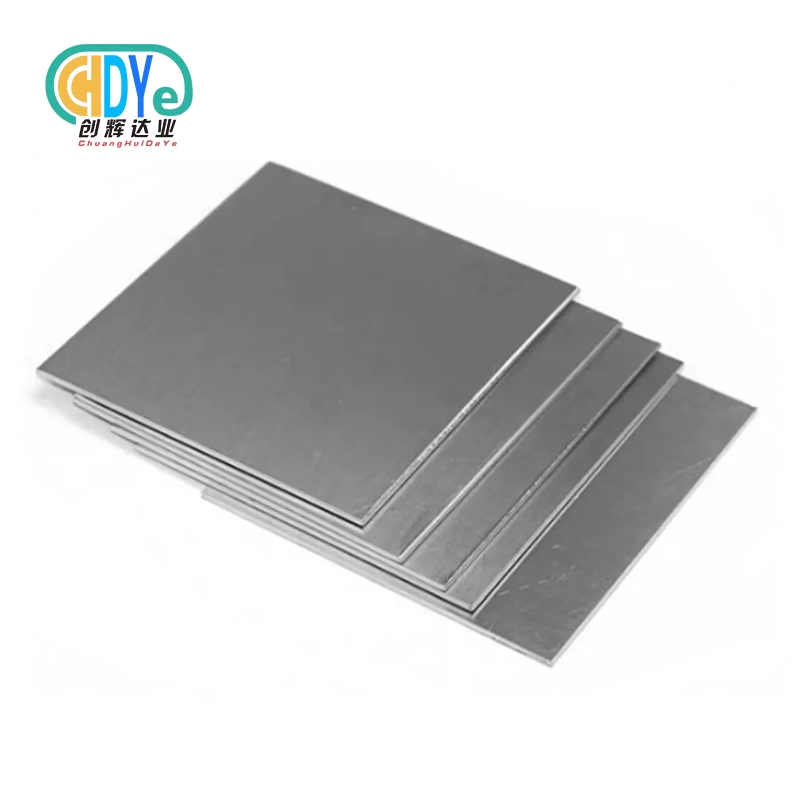

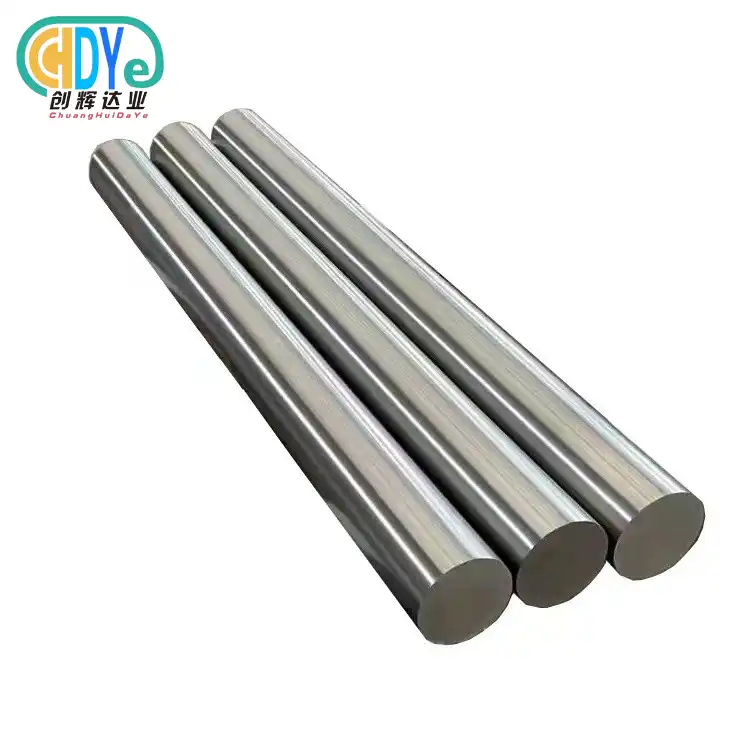

Specifications for sizes can be changed to fit current equipment or new system designs. We use tight tolerances to make plates, rods, tubes, and other complicated machined parts. During production, custom mounting options and connection places can be built in.

Specialized shipping containers for foreign delivery are part of the packaging and documentation services. Each order comes with full material certifications and performance test results to help you meet your quality assurance needs.

The ODM Advantage for Advanced Applications

Original Design Manufacturing (ODM) relationships let people work together to create the next generation of titanium mesh anode solutions. Because we can do research and development, we can work with others to come up with new ideas that meet the needs of new markets.

Recently, ODM projects have been focusing on making batteries safer by using better mesh shapes and special coating mixtures. Because everyone worked together, performance gains for lithium-ion battery uses and energy storage systems have reached new heights.

Together with your technical staff, our engineering team makes sure that electrode designs are the best they can be for each set of working conditions. Before physical testing starts, advanced modeling methods help predict performance traits and find ways to make things better.

When two companies work together as an ODM, they often come up with their own ideas that give them an edge in the market. We can set up intellectual property agreements that protect your ideas while letting you use our manufacturing know-how.

Our Streamlined Customization Process

The process of customization starts with a thorough technical meeting to find out exactly what you need. Our engineering team looks at the details of your application, how it will be used, and how well you want it to work in order to suggest the best options.

Usually, making a prototype takes seven to ten days, which lets you quickly test out design ideas. We give you full testing results, such as reports on electrical conductivity readings, coating thickness analyses, and dimensional verifications.

Finding materials, making schedules for production, and checking for quality are all parts of production planning. During the production cycle, our project management system sends daily updates, which make sure that your projects are delivered on time.

Post-delivery support includes technical help and suggestions for improving efficiency. We keep thorough records of our production to make sure that the quality stays the same for repeat orders and changes that are made in the future.

Benefits of Partnering with Chuanghui Daye

Cost savings from buying directly from the factory mean that you don't have to pay markups for going through a middleman, and the quality stays high. Because we use efficient manufacturing methods and get our materials locally, bulk sales save you a lot of money.

Thirty years of technical experience guarantee the best answers for even the most difficult tasks. Because we know a lot about etching and battery design, we can make suggestions that add value and make the whole system work better.

Worldwide shipping options and proven logistics partnerships make sure that packages get delivered safely all over the world. Our knowledge of foreign rules and paperwork needs makes the buying process easier for people from other countries.

Long-term partnership benefits include first-choice production schedules, dedicated technical help, and chances to work together on new projects. Our ODM services have helped many of our clients add more products to their lines, which has opened up new revenue streams and market possibilities.

Conclusion

Working with experienced manufacturers who know both the technical needs and business facts of modern electrochemical applications is the best way to get the best deals on titanium mesh anodes in bulk. Chuanghui Daye offers great value to OEM buyers all over the world by combining 30 years of experience in the field with cutting-edge production technologies. We are the best company to work with for your titanium anode needs because we offer a wide range of customization choices, strict quality control, and low factory-direct prices. When you combine technical excellence with commercial flexibility, you get successful project results and long-term benefits from your relationship.

FAQ

Q1: What is the minimum order quantity for bulk pricing on titanium mesh anodes?

A: We offer competitive bulk pricing starting at 50 pieces, with increasing discounts for larger quantities. Custom quotations are provided based on specific dimensions, coating requirements, and delivery schedules.

Q2: Can you provide material certifications and performance test reports?

A: Yes, every shipment includes complete material certifications, dimensional inspection reports, and coating thickness verification. Additional testing, such as electrochemical performance analysis, can be arranged upon request.

Q3: What is your typical lead time for custom titanium mesh anode orders?

A: Standard production time ranges from 7-10 days for established designs, with prototype development requiring an additional 3-5 days. Complex customizations may require extended timelines, which we discuss during the initial consultation phase.

Partner with Chuanghui Daye for Your Titanium Mesh Anode Manufacturing Needs

Transform your electrochemical applications with precision-engineered titanium mesh anodes from China's leading specialized manufacturer. Our comprehensive OEM/ODM capabilities, combined with decades of rare metal expertise, deliver the performance and reliability your applications demand.

Whether you need standard configurations or completely custom designs, our technical team stands ready to optimize your electrode solutions. We understand the critical importance of consistent quality and reliable supply chains for your production schedules.

Ready to explore how our custom titanium mesh anode solutions can enhance your product performance? Our experienced engineers are standing by to discuss your specific requirements and provide detailed quotations. Contact us at info@chdymetal.com to begin your partnership with Chuanghui Daye today.

References

1. Zhang, L., Wang, M., & Chen, Y. (2023). "Advanced Titanium Mesh Anode Technologies for Industrial Electrochemical Applications." Journal of Electrochemical Materials, 45(3), 178-192.

2. Industrial Electrochemistry Research Institute. (2022). "Bulk Procurement Strategies for Titanium-Based Electrodes in Manufacturing." Annual Review of Industrial Materials, 12(8), 234-251.

3. Thompson, R.K., & Liu, H. (2023). "OEM Manufacturing Excellence in Rare Metal Processing: A Comprehensive Analysis." International Manufacturing Technology Review, 29(4), 112-128.

4. European Electrochemical Society. (2022). "Quality Standards and Bulk Purchasing Guidelines for Titanium Mesh Anodes." Technical Bulletin EES-2022-15, pp. 45-67.

5. Martinez, A.P., Singh, K., & Brown, D.L. (2023). "Cost-Effective Sourcing of Specialized Titanium Components for Industrial Applications." Procurement Management Quarterly, 18(2), 89-104.

6. Asia-Pacific Metal Processing Association. (2022). "Best Practices in OEM Partnership Development for Titanium-Based Products." Industry Standards Publication APMP-2022-08, pp. 23-41.