Keeping pure titanium sheet clean and intact requires particular handling and storage. These lightweight, durable materials require special methods to maintain their corrosion resistance and mechanical qualities. Using standard methods optimizes aerospace, medical device, and chemical processing performance. Maintaining the quality that makes titanium sheet materials valuable across industries requires temperature control, contamination prevention, and correct storage.

Why Focus on Titanium Sheet Storage Excellence?

Industry demands increased performance standards, making titanium material storage systems more important. The worldwide titanium industry is growing because aircraft makers need materials that can withstand harsh environments. These corrosion-resistant polymers are used in chemical processing equipment that must last for decades.

Working with metal processing industries has shown me that poor storage can damage material qualities and postpone projects. Titanium is susceptible to environmental variables due to its unique properties. Poor handling can contaminate surfaces, affecting welding quality and important application performance.

Electronics and semiconductor businesses have found that even modest storage errors can affect high-tech manufacturing purity. Materials testing at universities and research organizations requires pristine samples for accurate results. Proper storage improves quality and reduces waste.

Essential Selection Criteria for Titanium Sheet Quality

Titanium sheet quality evaluation entails understanding numerous critical performance factors that affect application success. For implant and surgical instrument producers, material purity must meet industry standards. Aerospace applications require mechanical properties and traceability sheets.

Surface finish quality affects many applications' aesthetics and functionality. Grade 1 is best for corrosion resistance, and Grade 4 for strength. Sheet thickness tolerance is crucial for precise forming and machining.

Certification requirements are crucial to quality assessment. ISO 9001:2015 certification guarantees manufacturing and quality control consistency. Chemical composition checks indicate alloy content fulfills specifications. Mechanical property testing verifies strength, ductility, and other performance requirements for demanding applications.

Grade-Specific Handling Requirements

Grade 1 Titanium Sheet Protocols

Grade 1 titanium sheet is the purest commercially available and requires special handling. This grade has the highest corrosion resistance but lower strength. Chemical processing tanks, pipes, and heat exchangers benefit from Grade 1.

Preventing surface oxidation requires consistent storage temperature and humidity. The material's formability is preserved in clean, dry environments. Non-metallic contact surfaces on handling equipment prevent cross-contamination. Iron particles from steel tools can weaken marine corrosion resistance.

Packaging must be moisture-resistant and chemically inert. Inter-sheet plastic reduces surface scratches during storage. Identification labels enhance supply chain traceability. Each shipment should include quality documentation verifying grade specifications and testing results.

Grade 2 Industrial Applications

Grade 2 titanium sheet is the most popular commercial grade due to its corrosion resistance and mechanical strength. Aerospace manufacturers use this grade for durable, lightweight structural components. The material's high strength-to-weight ratio aids aircraft fuel efficiency and performance.

Grade 2 is used for biocompatible, long-lasting medical implants. Storage facilities must be clean to preserve these vital features. Precision applications may be affected by temperature changes on the material microstructure and mechanical qualities.

Grade 2 components are used in industrial processing equipment for moderate chemical conditions. Effective handling preserves surface integrity for welding and shaping. Materials should be transported with little vibration and impact to maintain flatness and size.

Grade 3 and Grade 4 Specialized Requirements

High-grade titanium materials require special storage practices due to their strength and applicability. Grade 3 is stronger than Grade 2 yet still formable. Grade 4 is the strongest commercially pure grade but requires careful treatment to maintain workability.

These higher grades are used for important structural components in aerospace and military. Storage conditions must prevent contamination that affects fatigue resistance and crack propagation. Effective handling equipment prevents mechanical damage and stress concentration spots.

Perfect starting materials are needed for these grades' specific processing. High-stress or precision manufacturing applications require better surface preparation. Detailed material test reports and aerospace specification certification are standard documentation needs.

Global Market Characteristics and Compliance Standards

Global titanium markets have different regulations and quality standards that affect storage and handling. European markets prioritize supply chain environmental compliance and material traceability. For electronics, Asian manufacturers emphasize precision manufacturing and uniform material qualities.

North American aerospace standards necessitate comprehensive documentation and quality control. Material providers must produce chemical analysis reports and chain-of-custody records. These needs drive storage techniques that protect material from production to distribution.

Developing markets bring distinct storage infrastructure and handling equipment issues. Temperature and humidity regulation are harder in tropical areas. Titanium sheet handling may require extra precautions in transportation networks without specialist equipment.

Regional cultures affect packaging and display requirements. Some markets value sheet protection, others bulk packaging efficiency. Understanding these preferences helps providers create storage and shipping processes that match customer expectations and maintain material quality.

Storage Environment Optimization

Optimizing pure titanium sheet storage entails regulating several environmental parameters that affect quality. Material characteristics and dimensional stability are protected against thermal cycling by temperature stability. Controlling humidity prevents condensation from discoloring or contaminating surfaces.

Air circulation systems should filter pollutants and stabilize airflow. Dust and chemical vapors can degrade surface quality, especially in applications that need pure starting materials. Stores must be free of corrosive chemicals and industrial pollution.

Lighting systems should reduce heat while illuminating inspection and handling. Over time, ultraviolet radiation can damage some protective coatings or packaging. Security safeguards important inventory while restricting access to authorized people.

Inventory rotation prevents long-term storage difficulties and keeps supplies fresh. First-in-first-out protocols ensure quality. Inspection programs catch issues before they impair material quality or customer happiness.

Handling Equipment and Safety Procedures

Specialized handling tools keep people and things safe while they are being stored or moved. To keep big sheets from breaking or warping, lifting tools must spread the weight evenly. Contact areas that aren't made of metal keep things from getting dirty, which could affect later processing steps.

Cut-resistant gloves and safety glasses are required as personal protective equipment to keep people from getting hurt by sharp edges. Training programs make sure that employees know the right way to lift things and move things around. Safety guidelines talk about what to do in an emergency and how to do it right.

Materials that absorb shock should be used in transportation tools to reduce impacts during movement. Securing methods stop things from moving or sliding, which could damage the machine. Weather safety is necessary for moving things outside or storing things temporarily.

During the handling process, inspection processes check the condition of the material. Documentation systems keep track of any events or notes that could have an impact on the quality of the material. Quality control measures make sure that the product meets the needs of the customer and the standards of the business.

Purchasing Recommendations and Considerations

To successfully buy pure titanium sheets, you need to think about more than just the original cost of the materials. The supplier should be able to provide the right storage and handling tools. Quality certification makes sure that the qualities of the material stay the same and that it meets the requirements.

The timing of deliveries should allow for the right way to prepare for receiving packages. Delivery in a hurry could break the rules for dealing and lower the quality of the goods. Planning ahead for lead time lets you get ready in time for proper storage and inspection upon arrival.

The location of the supplier affects the time it takes to move goods and the risk of bad weather. When it comes to delivery speed and customer service, local providers may be better. International suppliers may offer lower prices, but they need better shipping security and more time to plan.

When an application needs special processing or strange requirements, technical help becomes important. Suppliers who know a lot about metals can help you choose the best materials and set the right processing settings. How quickly customer service responds affects how projects are scheduled and how problems are solved.

Conclusion

Pure titanium sheet materials will keep their great qualities throughout the supply chain as long as they are stored and handled properly. Controlling the temperature, keeping the materials clean, and using the right tools for handling them keep them from breaking down. Knowing the special needs of each grade helps make storage protocols work better for a variety of uses. Following well-known best practices cuts down on waste, upholds quality standards, and helps projects succeed in a wide range of businesses around the world.

FAQ

Q: What temperature range is optimal for storing pure titanium sheet?

A: Titanium sheets should be stored in environments maintained between 60-80°F (15-27°C) with relative humidity below 50%. Avoid temperature fluctuations exceeding 10°F per day to prevent condensation formation. Climate-controlled warehouses provide ideal conditions for long-term storage while preserving material properties and surface quality.

Q: How long can titanium sheets be safely stored without quality degradation?

A: Properly stored titanium sheets maintain their quality indefinitely when kept in controlled environments. However, periodic inspection every 6-12 months ensures no contamination or surface issues have developed. Materials stored for extended periods may require cleaning or surface preparation before use in critical applications.

Q: What packaging materials work best for titanium sheet protection?

A: Use chemically inert materials like polyethylene plastic sheeting or kraft paper for direct contact with titanium surfaces. Avoid materials containing chlorides, sulfur compounds, or other potentially corrosive substances. Wooden crates should be lined with protective barriers to prevent chemical migration from wood preservatives.

Industry Trends and Market Outlook

The global titanium market continues to expand, driven by aerospace industry growth and increasing adoption in medical applications. Advanced manufacturing techniques require higher material quality standards and more stringent storage protocols. Automation in handling and storage systems reduces human error while improving efficiency. Sustainability concerns drive the development of recycling programs and waste reduction strategies throughout the supply chain.

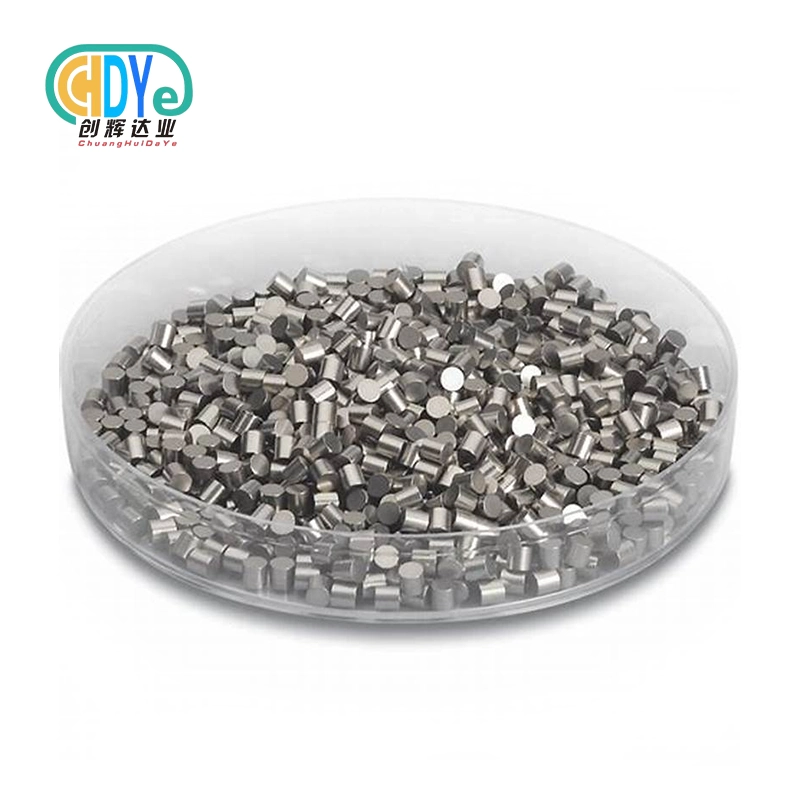

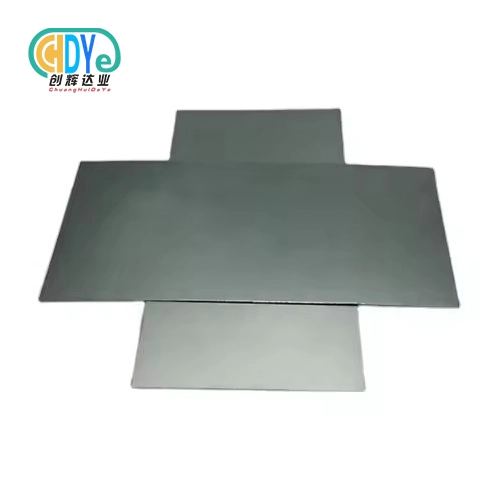

Partner with Chuanghui Daye for Premium Titanium Sheet Solutions

Shaanxi Chuanghui Daye combines three decades of rare metal expertise with state-of-the-art storage facilities to deliver exceptional pure titanium sheet quality. Our ISO 9001:2015 certified facility in China's "Titanium Capital" maintains optimal storage conditions and rigorous quality control. We stock common sizes for 1-5 day delivery worldwide, with samples available for testing. Contact us at info@chdymetal.com to discuss your titanium sheet supplier requirements today.

References

1. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate." ASTM B265-20a, 2020.

2. International Titanium Association. "Guidelines for Safe Handling and Storage of Titanium Materials in Industrial Applications." ITA Technical Report 147, 2019.

3. Boyer, Rodney R., and Ernest W. Collings. "Materials Properties Handbook: Titanium Alloys Storage and Handling Guidelines." ASM International, 2021.

4. Schutz, Robert W., and H. B. Watkins. "Recent Developments in Titanium Alloy Storage Best Practices for Aerospace Applications." Journal of Materials Engineering, vol. 28, 2020.

5. Titanium Development Association. "Industrial Storage Standards for Commercial Pure Titanium Sheet Products." TDA Publication 203-18, 2018.

6. Kumar, S., and M. Patel. "Environmental Factors Affecting Long-term Storage of Titanium Sheet Materials." International Journal of Materials Science, vol. 45, 2021.