It is essential for manufacturers and engineers working in the aerospace, electronics, and chemical processing industries to have a solid understanding of international standards for high purity niobium wire. By adhering to these standards, quality, safety, and performance are guaranteed to be consistent throughout all worldwide markets. In order to guarantee superior corrosion resistance, superconducting characteristics, and mechanical integrity, high purity niobium wire must meet demanding specifications such as ASTM B392, ISO 6486, and AMS standards. These specifications are necessary for crucial applications in current industrial environments.

The overall complexity and price of a project are both reduced by value-added services. The supply chain is simplified through the use of services such as custom cutting, surface treatments, and packing. It is possible to avoid costly mistakes by providing technical support during the design and manufacturing phases.

Understanding Niobium Wire Purity Classifications

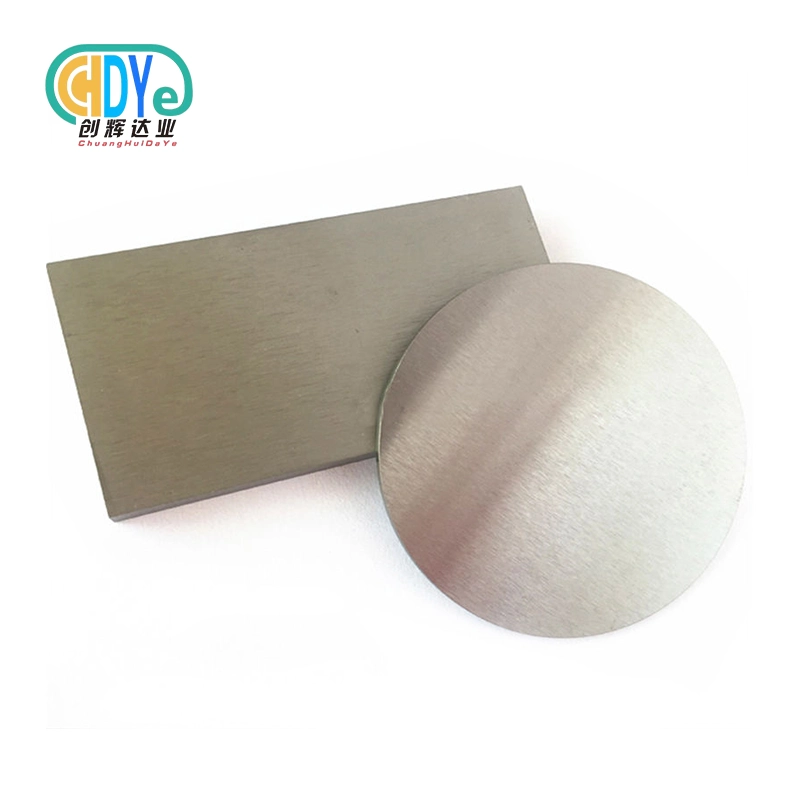

The amount of purity in niobium wire has a direct effect on how well it works and what kinds of uses it can be put to. Niobium that is sold in stores is usually 99.8% pure, while niobium that is used in reactors is at least 99.95% pure. When thinking about high-temperature environments or superconducting uses, this difference becomes very important.

The UNS classification methods set uniform standards for niobium materials. UNS R04200 is a very pure grade of reactor-grade niobium that has not been alloyed. UNS R04210 refers to business-grade niobium that is not alloyed and can be used in a wide range of industrial settings. These groups make it easier for engineers to choose the right materials based on specific performance needs.

Different types of niobium alloys include mixtures of niobium and zirconium that make the metal stronger. UNS R04251 and UNS R04261 are grades of 1% zirconium metals used in reactors and in industry, respectively. These metals are stronger and better at resisting corrosion. They can also conduct electricity very well.

Controlling impurities is still the most important part of making high-grade niobium. To keep electrical conductivity and mechanical qualities, the amounts of oxygen, nitrogen, and carbon must stay below certain levels. Advanced vacuum melting methods make sure that the amounts of contaminants meet strict international standards.

Key International Standards Governing Niobium Wire

ASTM B392 sets out all the rules that niobium and niobium alloy bars and wire must follow. This standard covers the chemical makeup, mechanical properties, and size ranges that are necessary for quality control to be constant. Manufacturers must show that they are following the rules by following strict testing methods and keeping records.

ISO 6486 is a set of international rules for refractory metals that includes standards for niobium wire. The standard talks about requirements for surface finish, tolerances for straightness, and packing rules that make sure everything works together everywhere. These specifications make it possible for foreign supply chains to work together without any problems.

The AMS aerospace material standards spell out important needs for defense and aviation uses. Niobium sheet and strip are covered by AMS 7849, and related standards cover wire products used in high-performance aerospace parts. These standards require a high level of dependability and accountability.

GB Chinese national standards go along with foreign standards and take into account how things are made in China. These standards make sure that Chinese producers can meet quality standards around the world. This makes it easier for countries to trade and work together on technical issues.

ISO 9001:2015 quality management systems set up frameworks for consistent output control. To make sure they're following the standards, certified makers put in place strict quality assurance plans that include checking the raw materials, keeping an eye on the production process, and checking the finished product.

Chemical Composition Requirements and Testing Methods

Chemical analysis methods make sure that the composition of niobium wire meets international standards. The inductively coupled plasma mass spectrometry (ICP-MS) method accurately measures minor impurities like tantalum, tungsten, and metallic contaminants that have an impact on performance.

Because niobium is so good at attaching to gases in the air, it needs special methods to be used for oxygen content measurement. Using inert gas fusion to measure oxygen levels accurately makes sure that they are within the limits set by specifications, which usually limit oxygen to 150–400 ppm based on the grade.

To find out how much of an element is in the interstitial space, carbon and nitrogen analysis uses combustion methods. These data are very important because carbon and nitrogen have a big effect on the mechanical properties and superconducting transition temperatures of niobium.

Thermal desorption methods are used to measure the amount of released hydrogen that can weaken materials. International guidelines set maximum hydrogen levels to make sure that the mechanical integrity and performance stability of a substance last for a long time.

Each shipment must come with certification paperwork that includes full chemical analysis data and information on how to track the shipment. Customers can use this documentation to make sure that the product meets the needs of their unique application and to keep quality control records.

Mechanical Properties and Performance Standards

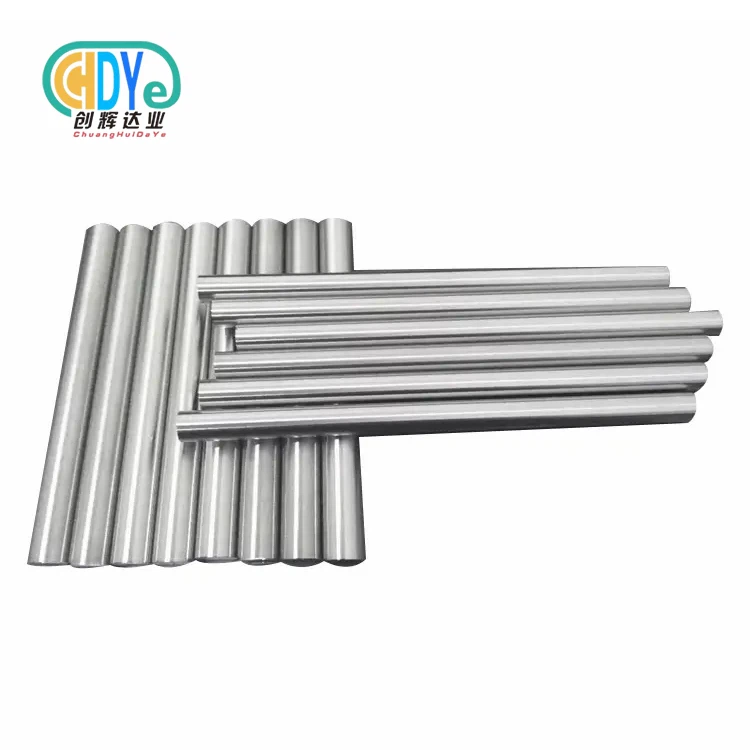

The tensile strength needed depends on the thickness of the wire and what it will be used for. The maximum tensile strength of fine niobium wire is usually between 200 and 400 MPa, but it is very flexible for shaping needs. These qualities make it possible to make complicated parts.

Using elongation rates to show how bendy and shapeable a material is. High-purity niobium wire can usually stretch 20 to 40 percent, which means it can be bent a lot without breaking. This ductility is very important for making parts and drawing wires.

Specifications for surface finish make sure that wire surfaces are smooth and free of flaws so they can be used in important situations. Standards set the minimum level of surface roughness, lack of cracks, and good looks that are needed to keep performance consistent across a wide range of uses.

Dimensional tolerances set the standards for wire diameter uniformity and straightness. International standards spell out the kinds of changes that are okay as long as they don't affect automated processing tools or the exact requirements for making parts.

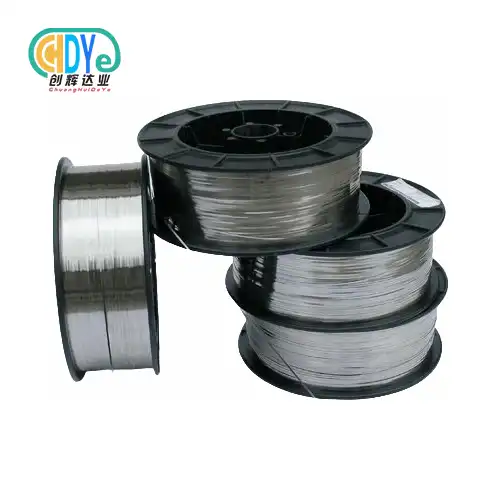

Electrical conductivity tests show that the wire is suitable for use in electronics. High purity niobium wire has great electrical properties that are needed for superconducting uses and making electronic parts where reliability is very important.

Applications Requiring Certified Niobium Wire

Certified niobium wire is needed for superconducting magnet devices to work reliably at very low temperatures. To reach stable superconducting states, medical MRI machines, particle accelerators, and research labs need materials that meet strict requirements for clarity and performance.

For sputtering targets, vacuum tube parts, and semiconductor processing tools, electronics manufacturers use high purity niobium wire. For these uses, the materials need to be very clean and have controlled electrical properties, which can only be achieved with certified materials that have been through written quality assurance.

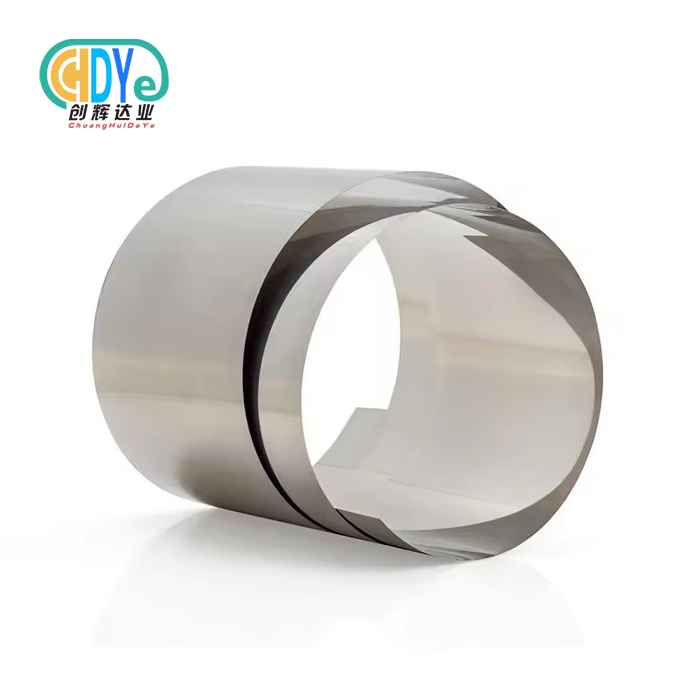

Niobium wire is used in chemical handling equipment in places where other materials wouldn't work because they are too corrosive. Niobium is very good at resisting corrosion and staying stable at high temperatures, which makes it useful for heat exchanges, reactor parts, and piping systems.

For rocket nozzles, turbine parts, and structural elements that are exposed to high temperatures, verified niobium materials are needed. Niobium wire is perfect for these tough jobs because it is strong, doesn't melt at high temperatures, and isn't heavy.

For experiments and making prototypes, research centers need small amounts of certified niobium wire. Universities and labs need to be able to prove the properties of materials and track them back to their source in order to publish and validate their study.

Quality Assurance and Traceability Documentation

The certificate of analysis contains detailed information about the object, such as its chemical makeup, mechanical properties, and processing history. This paperwork makes sure that everything can be tracked, from the raw materials to the delivery of the finished product, which meets international quality standards.

Independent lab tests on the materials in the test results make sure they meet the standards that apply. These reports give customers concrete proof of the material's properties, so they can make sure it's right for their needs and keep their own quality control records.

Heat treatment certifications list the thermal processing factors that were used to make the wire. Controlled annealing cycles improve the mechanical properties and relieve stress, making sure that all production batches work the same.

Inspection records keep track of the steps used for measuring, judging the quality of the surface, and packing. These records show that standard requirements were met and give information on how to fix problems if they happen during the application.

Calibration papers for testing tools make sure that the measurements they take are accurate and reliable. Testing accuracy is kept up by regular calibration programs, which give trust in the reported material properties and make sure that standards are being followed.

Selecting the Right Standard for Your Application

Standard selection is based on performance needs and environmental conditions, along with application-specific criteria. For aerospace applications, AMS standards are usually needed. For general industrial uses, ASTM or ISO standards may be used instead, based on regional preferences and customer needs.

Choosing the purity level relies on what it will be used for and how important performance is. For superconducting applications, you need materials that are reactor-grade and as pure as possible. For structural parts, you can use commercial-grade materials that have the right cost-performance mix.

The standard choice is affected by regional tastes. For example, ASTM specifications are preferred in North America, ISO standards are preferred in Europe, and GB or JIS standards are used in Asia. Understanding these tastes makes doing business across borders easier.

Cost factors weigh the performance of a material against its ability to meet economic needs. Premium prices are charged for higher purity types, but they work better in serious situations. Standard industrial grades are a great deal for uses that don't require a lot of strength.

Standard selection is affected by a supplier's ability to certify, since not all makers keep certification for all specifications. Checking the credentials of suppliers makes sure that you can get products that are properly certified and meet the standards that are needed.

Conclusion

International standards for high purity niobium wire provide essential frameworks ensuring consistent quality, safety, and performance across global markets. Understanding ASTM, ISO, AMS, and GB specifications enables informed material selection for aerospace, electronics, chemical processing, and research applications. Proper standard compliance guarantees material traceability, performance reliability, and regulatory acceptance. Working with certified manufacturers who maintain comprehensive quality systems ensures access to materials meeting the most demanding international requirements, supporting successful project outcomes and long-term operational reliability.

Partner with Chuanghui Daye for Certified High Purity Niobium Wire

Shaanxi Chuanghui Daye stands as your trusted high purity niobium wire manufacturer, delivering materials that exceed international standards. Our ISO 9001:2015 certification and 30+ years of rare metals expertise ensure consistent quality and reliable supply capabilities. Contact us at info@chdymetal.com for technical specifications and competitive factory-direct pricing.

References

1. American Society for Testing and Materials. "Standard Specification for Niobium and Niobium Alloy Rod and Wire." ASTM International, West Conshohocken, PA, 2019.

2. International Organization for Standardization. "Refractory metals and their alloys - Chemical analysis methods." ISO 6486 Technical Committee, Geneva, Switzerland, 2018.

3. Society of Automotive Engineers International. "Aerospace Material Specification for High Purity Niobium Products." AMS Technical Standards, Warrendale, PA, 2020.

4. Zhang, Wei-Ming, and Liu, Hong-Jun. "Quality Control Methods for High Purity Niobium Wire Manufacturing." Journal of Refractory Metals and Hard Materials, Vol. 88, 2020.

5. European Committee for Standardization. "Specification for niobium and niobium alloy products for industrial applications." CEN Technical Standards, Brussels, Belgium, 2019.

6. National Institute of Standards and Technology. "Reference Materials for Chemical Composition Analysis of Niobium Alloys." NIST Special Publication, Gaithersburg, MD, 2021.