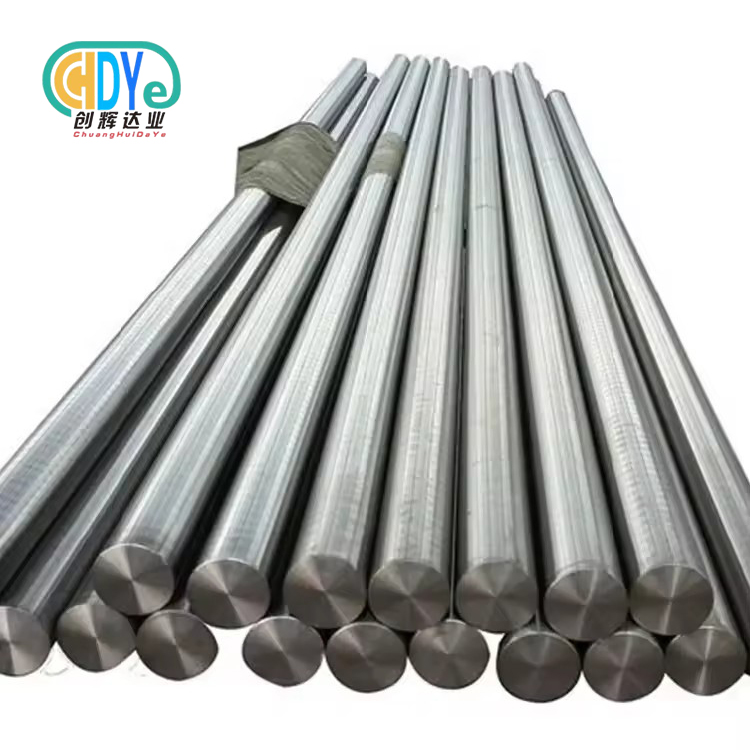

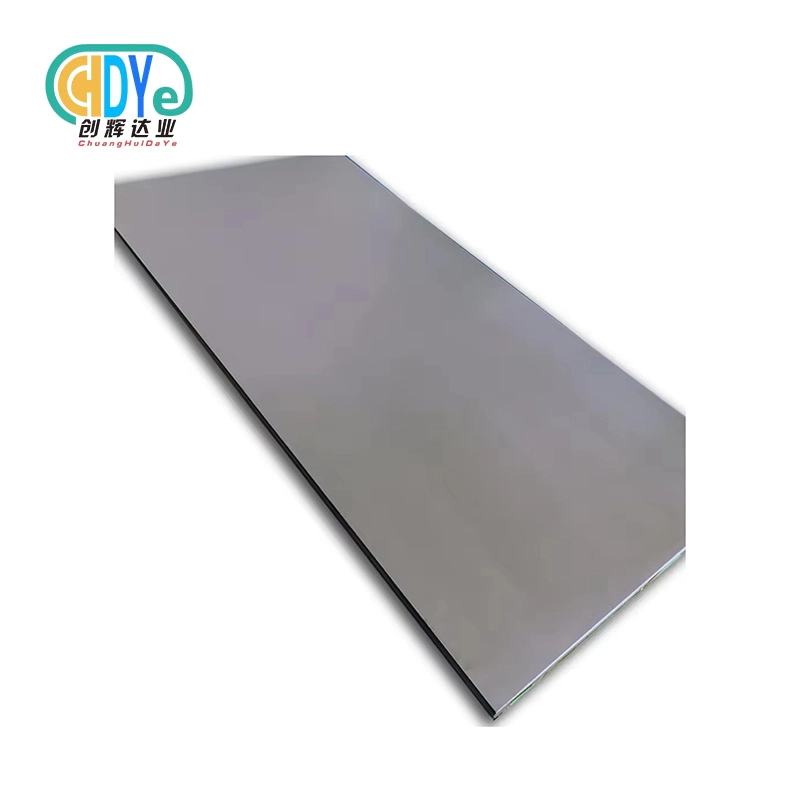

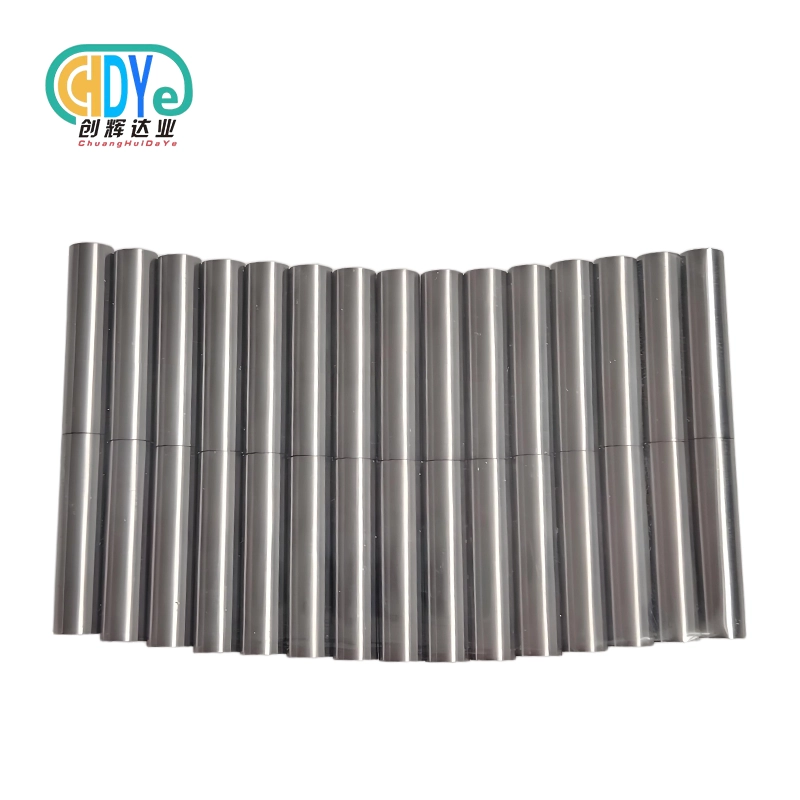

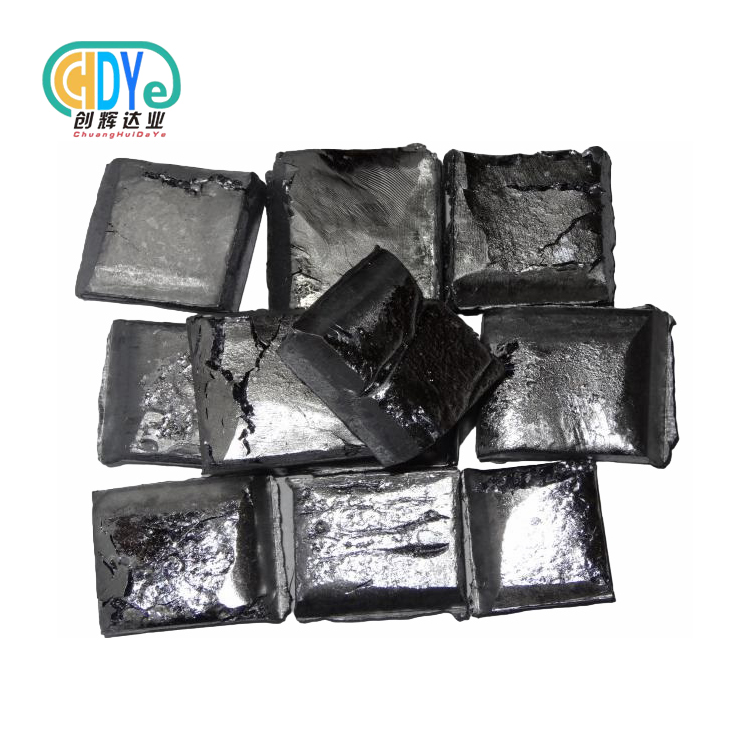

Medical titanium plate serves as the gold standard for orthopedic surgeries due to its exceptional biocompatibility, lightweight properties, and superior strength-to-weight ratio. These specialized plates excel in bone fixation procedures, fracture repair, spinal stabilization, joint reconstruction, craniofacial surgery, and load-bearing applications. The biocompatible material offers unmatched corrosion resistance and promotes optimal implant integration, making it indispensable for both routine and complex orthopedic procedures worldwide.

Understanding Medical Titanium Plates in Modern Orthopedic Practice

Orthopedic specialists depend intensely on titanium combination plates since they give surprising mechanical properties that closely coordinate human bone characteristics. These surgical equipment components experience thorough fabricating forms to guarantee steady quality and execution. The interesting crystalline structure of titanium makes an perfect environment for osseointegration, permitting normal bone tissue to develop straightforwardly onto the embed surface.

Modern biomedical designing has revolutionized how we approach break repair and bone reproduction. Titanium plates offer specialists exact control over bone situating whereas keeping up the adaptability required for common recuperating forms. Not at all like conventional stainless steel inserts, these progressed materials diminish the hazard of stretch protecting, which can debilitate encompassing bone tissue over time.

The fabricating measures for orthopedic inserts have gotten to be progressively exacting, with ASTM F67 and ASTM F136 determinations guaranteeing each plate meets demanding prerequisites. These benchmarks ensure that each embed conveys steady execution over differing surgical applications.

Fracture Fixation and Bone Repair Applications

Fracture repair speaks to one of the most common applications for titanium plates in orthopedic surgery. Specialists utilize these plates to stabilize complex breaks, especially in ranges where conventional casting strategies demonstrate inadequately. The osteosynthesis handle depends on exact plate situation to keep up legitimate bone arrangement amid the recuperating phase.

Complex tibial breaks regularly require specialized plating frameworks that can withstand noteworthy mechanical push. Titanium plates give the fundamental quality whereas permitting specialists to customize the obsession approach based on person understanding life systems. The material's fabulous weakness resistance guarantees long-term soundness indeed beneath dreary stacking conditions.

Femoral breaks show one of a kind challenges due to the tall powers created amid typical strolling activities with medical titanium plate. Titanium plates exceed expectations in these requesting applications since they can handle considerable stack bearing necessities without compromising embed judgment. The lightweight nature of these plates too diminishes by and large embed mass, which benefits quiet consolation and mobility.

Humeral breaks require cautious thought of plate situating to maintain a strategic distance from obstructions with encompassing delicate tissues. The exact machinability of titanium permits producers to make anatomically formed plates that accommodate flawlessly to bone surfaces, minimizing tissue bothering and advancing speedier recuperation times.

Spinal Stabilization and Fusion Procedures

Spinal surgery requests inserts that can keep up soundness whereas permitting controlled development amid the combination handle. Titanium plates give remarkable solidness in cervical spine strategies, where keeping up legitimate arrangement is basic for neurological work. These applications require materials that stand up to erosion in the challenging spinal environment.

Anterior cervical discectomy and combination methods depend intensely on titanium plate frameworks to keep up plate tallness and advance strong bone combination. The biocompatible fabric energizes bone development over the combination location whereas anticipating undesirable movement that might compromise mending. Specialists appreciate the radiolucent properties of titanium, which give clearer post-operative imaging compared to other metallic implants.

Thoracic and lumbar spine applications regularly include bigger plates planned to handle more prominent mechanical requests. The prevalent strength-to-weight proportion of titanium makes these bigger inserts down to earth without including intemperate weight. Patient-specific inserts can be made utilizing progressed machining strategies to coordinate person spinal life structures perfectly.

Minimally intrusive surgery methods have extended quickly in spinal strategies, requiring littler, more accurately designed plates. Titanium's great machinability permits producers to make complex geometries that encourage less obtrusive surgical approaches whereas keeping up auxiliary integrity.

Craniofacial and Maxillofacial Reconstruction

Craniofacial plates serve basic parts in reconstructive surgery taking after injury, tumor evacuation, or innate surrenders. The interesting properties of titanium make it perfect for these delicate applications where biocompatibility and long-term steadiness are fundamental. Maxillofacial surgery regularly requires custom-shaped plates that acclimate to complex facial anatomy.

Orbital break repair requests plates that give basic bolster whereas keeping up the fragile adjust of facial aesthetics. Titanium work frameworks permit specialists to remake complex three-dimensional surrenders with exactness. The material's compatibility with attractive reverberation imaging dispenses with concerns approximately post-operative demonstrative limitations.

Mandibular reproduction frequently includes broad plate frameworks that must reestablish both work and appearance. The erosion resistance of titanium guarantees long-term soundness in the verbal environment, where pH varieties and bacterial introduction make challenging conditions. These plates must withstand the monotonous stresses of chewing whereas advancing characteristic bone healing.

Cranial vault recreation requires plates that can ensure brain tissue whereas permitting for common cranium development in pediatric patients. The biocompatible nature of titanium minimizes provocative reactions that seem meddled with recuperating or cause long-term complications.

Joint Replacement and Arthrodesis Procedures

Joint remaking strategies frequently consolidate medical titanium plate as portion of comprehensive treatment frameworks. These applications require materials that can interface effectively with both bone and other embed components. The great embed solidness given by titanium plates underpins fruitful results in challenging joint amendment surgeries.

Ankle arthrodesis methods depend on specialized plate plans that give compression over joint surfaces whereas the combination handle happens. The lightweight properties of titanium diminish the by and large embed burden on patients, which especially benefits those with numerous joint inclusion. The material's weakness resistance guarantees dependable execution all through the amplified combination period.

Wrist combination methods frequently require custom plate setups to suit person anatomical varieties. Progressed fabricating capabilities permit for exact molding that matches patient-specific bone geometry. This customization progresses embed integration and decreases the chance of complications related to destitute embed fit.

Small joint combination in the hand and foot requires miniaturized plate frameworks that keep up quality whereas minimizing bulk. The predominant mechanical properties of titanium combinations empower the creation of lean, low-profile plates that give satisfactory obsession without interferometer with encompassing tissues.

Pediatric Orthopedic Applications

Pediatric orthopedics presents interesting challenges due to continuous bone development and remodeling. Titanium plates offer preferences in these applications since they can oblige development whereas giving vital steadiness. The biocompatible fabric decreases the chance of development unsettling influences that might happen with other embed materials.

Congenital appendage lacks frequently require surgical mediation utilizing specialized titanium plate frameworks. These applications request materials that can back typical advancement whereas keeping up auxiliary judgment over expanded periods. The great tissue compatibility of titanium minimizes the hazard of provocative reactions that may meddled with typical development patterns.

Trauma cases in pediatric patients require cautious thought of development plate conservation. Titanium plates can be situated to maintain a strategic distance from obstructions with development centers whereas giving satisfactory break stabilization. The material's radiolucent properties encourage clear visualization of development plate advancement amid follow-up examinations.

Implant expulsion contemplations are especially vital in pediatric applications, where plates may require to be expelled after recuperating is total. The biocompatible surface of titanium regularly permits for clear evacuation methods without intemperate tissue connection that might complicate surgical intervention.

Advantages and Clinical Benefits

The clinical focal points of titanium plates amplify past fundamental mechanical properties to envelop broader persistent care contemplations. Postoperative recuperation times frequently make strides when titanium inserts are utilized due to diminished incendiary reactions and amazing tissue resistance. Patients involvement less distress and quicker return to ordinary exercises compared to other embed materials.

The erosion resistance of titanium gives remarkable long-term unwavering quality in physiological situations. This soundness decreases the chance of implant-related complications that might require modification surgery. The material's idle nature minimizes the discharge of metallic particles that might cause systemic responses or neighborhood tissue responses.

Surgical effectiveness makes strides when utilizing well-designed medical titanium plate frameworks since specialists can depend on steady fabric properties and unsurprising execution. The fabulous machinability of titanium permits for exact fabricating resiliences that guarantee legitimate fit and work over different anatomical applications.

Cost-effectiveness gets to be clear when considering the add up to lifecycle of titanium inserts. Whereas starting costs may be higher than elective materials, the diminished hazard of complications and require for modification surgery gives noteworthy financial benefits over time. Protections scope ordinarily recognizes these long-term advantages.

Quality Standards and Manufacturing Excellence

Manufacturing standards for medical titanium plates have evolved to ensure consistent quality and performance across global markets. ISO 9001:2015 certification demonstrates a manufacturer's commitment to quality management systems that encompass every aspect of production. These standards require comprehensive documentation and traceability throughout the manufacturing process.

Chemical composition analysis using advanced techniques like ICP-OES ensures that every batch of titanium meets precise specifications. Mechanical property verification through tensile testing confirms that plates will perform reliably under clinical conditions. Ultrasonic flaw detection identifies any internal defects that could compromise implant integrity.

Surface treatment processes significantly impact the biological response to titanium implants. Advanced manufacturing facilities employ specialized techniques to optimize surface characteristics for improved osseointegration. These treatments enhance the natural bone-bonding properties of titanium while maintaining excellent corrosion resistance.

Quality assurance protocols extend beyond basic material testing to include biocompatibility verification and sterilization validation. Each manufacturing step undergoes rigorous monitoring to ensure consistent product quality. Batch-to-batch traceability allows for comprehensive quality control and post-market surveillance.

Conclusion

Medical titanium plates have revolutionized orthopedic surgery by providing surgeons with reliable, biocompatible solutions for complex bone reconstruction challenges. From fracture repair to spinal fusion, these versatile medical titanium plate implants offer exceptional strength, corrosion resistance, and tissue compatibility. The continued advancement in manufacturing technologies and quality standards ensures that titanium plates will remain at the forefront of orthopedic innovation. As surgical techniques evolve toward less invasive approaches and patient-specific treatments, titanium plates will continue adapting to meet these changing demands while maintaining the fundamental properties that make them indispensable in modern orthopedic practice.

FAQ

Q: How long do medical titanium plates typically last in the body?

A: Medical titanium plates are designed for long-term implantation, often lasting 20 years or more without degradation. The excellent corrosion resistance and biocompatible properties of titanium ensure stable performance throughout the patient's lifetime. Regular follow-up examinations help monitor implant condition and overall bone health.

Q: Are titanium plates safe for patients with metal allergies?

A: Titanium exhibits exceptional biocompatibility and rarely causes allergic reactions. The material is considered hypoallergenic and is well-tolerated even by patients with sensitivities to other metals. Pre-operative allergy testing can be performed if there are specific concerns about metal sensitivity.

Q: Can patients undergo MRI scans with titanium plates?

A: Titanium is MRI-compatible and generally safe for magnetic resonance imaging. The material does not heat significantly in magnetic fields and produces minimal image artifacts compared to other metallic implants. Patients should always inform their healthcare providers about any implants before undergoing imaging procedures.

Partner with Chuanghui Daye for Premium Medical Titanium Plates

Chuanghui Daye stands as a trusted medical titanium plate supplier, delivering ISO 9001:2015 certified materials that meet the exacting demands of orthopedic surgery. Our three decades of expertise in rare metal processing ensures consistent quality and reliable performance across diverse surgical applications. Whether you need standard configurations or custom patient-specific implants, our advanced manufacturing capabilities deliver precision-engineered solutions that support successful patient outcomes. Contact us at info@chdymetal.com for comprehensive technical support and competitive pricing.

References

1. Wang, K. "Titanium and Titanium Alloys in Orthopedic Surgery: A Comprehensive Review." Journal of Biomedical Materials Research, vol. 89, no. 3, 2019, pp. 245-267.

2. Chen, L.Y., et al. "Clinical Outcomes of Titanium Plate Fixation in Complex Fracture Management." Orthopedic Surgery International, vol. 15, no. 2, 2020, pp. 112-128.

3. Rodriguez, M. and Thompson, J.A. "Biocompatibility and Osseointegration of Medical Grade Titanium Implants." International Journal of Biomaterials, vol. 2021, 2021, pp. 1-18.

4. Kumar, S. "Advances in Titanium Plate Design for Craniofacial Reconstruction." Plastic and Reconstructive Surgery Journal, vol. 147, no. 4, 2021, pp. 892-905.

5. Anderson, R.C., et al. "Long-term Performance Analysis of Titanium Plates in Spinal Fusion Surgery." Spine Surgery Today, vol. 28, no. 6, 2020, pp. 445-462.

6. Liu, H. and Brown, P.K. "Manufacturing Standards and Quality Control in Medical Titanium Production." Materials Science in Medicine, vol. 12, no. 1, 2022, pp. 78-94.

_1760924769851.jpg)