When choosing materials for medical implants and surgical instruments, the decision between medical titanium bar and stainless steel significantly impacts patient outcomes and device longevity. Medical titanium bar emerges as the superior choice for biomedical applications due to its exceptional biocompatibility, corrosion resistance, and strength-to-weight ratio. Unlike stainless steel, which contains nickel and other potentially allergenic elements, titanium alloy bars offer seamless integration with human tissue while maintaining structural integrity over decades of use.

Understanding Medical Grade Materials: The Foundation of Modern Healthcare

The determination of suitable materials for restorative applications expands past fundamental mechanical properties. Healthcare producers require materials that illustrate steady execution beneath physiological conditions.

Medical titanium bar items fabricated agreeing to ASTM F136 and ASTM F67 guidelines give the unwavering quality required for basic applications. These determinations guarantee each titanium bar meets rigid necessities for:

- Chemical composition control with debasement levels underneath 0.5%

- Grain structure consistency through controlled warm treatment

- Surface wrap up details keeping up Ra values beneath 0.2 μm

- Dimensional resistance accomplishing h7-h9 accuracy levels

Stainless steel grades like 316L, whereas reasonable for certain applications, contain 8-12% nickel substance. This composition can trigger safe reactions in delicate patients, restricting their utilize in lasting embed applications.

If you require materials for brief surgical rebellious, stainless steel offers cost-effective arrangements. In any case, for changeless inserts requiring long-term biocompatibility, therapeutic titanium bar items give unmatched performance.

Biocompatibility Comparison: Safety Meets Performance

The human body's acknowledgment of embedded materials decides surgical victory rates and persistent quality of life. Broad clinical investigate illustrates titanium's predominant natural reaction compared to stainless steel alternatives.

Titanium Biocompatibility Advantages:

- Osseointegration capability permitting coordinate bone-to-implant contact

- Non-cytotoxic properties anticipating cellular damage

- Allergic response rates underneath 0.6% in clinical studies

- Stable oxide layer arrangement anticipating particle release

Clinical information from orthopedic thinks about appear that titanium bar embed frameworks accomplish 98.5% victory rates over 10-year periods. Comparable stainless steel inserts illustrate 89.2% victory rates due to corrosion-related complications.

The titanium oxide layer, measuring 2-5 nanometers thick, shapes suddenly upon presentation to oxygen. This defensive obstruction anticipates metal particle filtering into encompassing tissues, a common concern with stainless steel inserts containing chromium and nickel.

If you require inserts for elderly patients with compromised safe frameworks, biocompatible titanium bar materials minimize dismissal dangers. Stainless steel remains appropriate for short-term applications where fetched contemplations exceed biocompatibility requirements.

Mechanical Properties Analysis: Strength Where It Matters

The mechanical execution of embed materials specifically influences gadget solidness and persistent versatility. Understanding the particular points of interest each fabric offers makes a difference producers select ideal arrangements for diverse applications.

Titanium Review 5 ELI (Ti-6Al-4V) Execution Data:

- Tensile Quality: 860-1000 MPa

- Yield Quality: 795-875 MPa

- Elastic Modulus: 110 GPa

- Density: 4.43 g/cm³

- Fatigue Quality: 600 MPa (10⁷ cycles)

- 316L Stainless Steel Comparison:

- Tensile Quality: 515-620 MPa

- Yield Quality: 205-310 MPa

- Elastic Modulus: 200 GPa

- Density: 8.0 g/cm³

- Fatigue Quality: 280 MPa (10⁷ cycles)

The versatile modulus contrast demonstrates especially noteworthy in orthopedic titanium bar applications. Titanium's 110 GPa modulus closely matches cortical bone (15-30 GPa) superior than stainless steel's 200 GPa, diminishing stretch protecting impacts that can lead to bone resorption.

Weight contemplations ended up significant in spinal and appendage remaking strategies. Lightweight titanium bar restorative gadgets decrease understanding burden by 45% compared to comparable stainless steel develops, progressing consolation and portability outcomes.

If you require high-strength applications requiring most extreme solidness, titanium combination bar restorative review materials convey prevalent execution. Stainless steel works well for applications where higher solidness gives preferences, such as certain orthopedic obsession devices.

Corrosion Resistance: Long-term Reliability in Biological Environments

The harsh environment within the human body, characterized by chloride ions, proteins, and varying pH levels, challenges implant material stability. Corrosion resistance determines both implant longevity and patient safety.

Electrochemical testing in simulated body fluid demonstrates titanium's exceptional stability. Medical titanium bar samples show corrosion rates of 0.002 mm/year under physiological conditions, compared to 0.015 mm/year for 316L stainless steel.

The corrosion mechanism differs significantly between materials:

- Titanium Protection: Passive oxide layer regenerates automatically if damaged

- Stainless Steel Vulnerability: Pitting corrosion occurs at chloride concentrations above 150 ppm

- Ion Release: Titanium releases negligible quantities, while stainless steel releases detectable nickel and chromium

Long-term studies tracking implant performance over 20+ years reveal that titanium bar for implants maintains structural integrity without significant degradation. Stainless steel implants often require revision due to corrosion-induced loosening or tissue discoloration.

Sterilization processes using gamma radiation, electron beam, or autoclave methods affect material properties differently. Sterilizable titanium bar products maintain mechanical properties unchanged through multiple sterilization cycles, while stainless steel may experience slight property degradation.

If you need implants for high-chloride environments like cardiovascular applications, titanium provides unmatched protection. Stainless steel suffices for external fixation devices where replacement remains feasible.

Cost-Benefit Analysis: Investment vs. Long-term Value

Material selection involves balancing initial costs against lifetime value, including potential revision procedures, patient outcomes, and regulatory compliance expenses.

Initial material costs show stainless steel at $8-12 per kilogram compared to $35-50 per kilogram for medical titanium bar stock. However, this comparison overlooks total cost of ownership factors:

| Factor | Titanium | Stainless Steel |

|---|---|---|

| Material Cost (per kg) | $35-50 | $8-12 |

| Machining Complexity | Moderate | Low |

| Revision Rate (10-year) | 1.5% | 10.8% |

| Biocompatibility Testing | Standard | Enhanced Required |

| Expected Service Life | 25+ years | 15-20 years |

Manufacturing considerations affect overall project costs. Custom titanium bar implant production requires specialized equipment but offers design flexibility impossible with standard stainless steel grades.

Regulatory approval processes favor established titanium grades with extensive biocompatibility data. New stainless steel formulations require comprehensive testing, increasing development timelines and costs.

If you need rapid prototyping for research applications, stainless steel enables faster iteration cycles. For commercial implant production targeting regulatory approval, surgical titanium bar materials provide established pathways to market.

Manufacturing and Processing Considerations

The production requirements for medical-grade materials influence supplier selection and quality outcomes. Understanding manufacturing complexities helps optimize supply chain decisions.

Titanium Processing Requirements:

- Vacuum arc remelting (VAR) for impurity control

- Controlled atmosphere forging to prevent contamination

- Precise heat treatment for microstructure optimization

- Specialized machining techniques for dimensional accuracy

Quality control protocols for medical titanium bar production involve 100% ultrasonic testing, chemical composition verification, and mechanical property validation. These procedures ensure each bar meets ASTM F136 or ASTM F67 specifications.

Surface finishing achieves critical importance in medical applications. Titanium bar dental applications require mirror finishes with Ra values below 0.1 μm to prevent bacterial adhesion and promote tissue integration.

Processing capabilities vary significantly among suppliers. Established manufacturers with ISO 13485 certification demonstrate the quality systems necessary for medical device component production.

If you need high-volume production with consistent quality, partnering with experienced titanium bar strength medical grade suppliers ensures reliable supply chains. Stainless steel processing remains more widely available but may lack specialized medical device expertise.

Application-Specific Recommendations

Different medical applications demand specific material characteristics. Understanding these requirements guides optimal material selection for each use case.

Orthopedic Applications:

Titanium bar for bone fixation applications benefit from titanium's modulus matching and osseointegration properties. Hip replacement stems, spinal rods, and fracture plates perform optimally with Grade 5 ELI titanium alloys.

Clinical outcomes in titanium bar spinal fixation procedures show 96% fusion rates compared to 84% with stainless steel constructs. The reduced stiffness allows natural load distribution, promoting bone healing and preventing stress shielding.

Dental and Maxillofacial Applications:

Titanium bar maxillofacial reconstruction requires materials compatible with oral environments. Titanium's resistance to acidic conditions and bacterial colonization makes it ideal for dental implant abutments and facial reconstruction plates.

Aesthetic considerations favor titanium's natural silver appearance over stainless steel's tendency toward discoloration in tissue contact applications.

Cardiovascular Applications:

Blood contact applications demand exceptional corrosion resistance and thromboresistance. Titanium bar prosthetics for heart valve frameworks demonstrate superior performance in high-flow, high-stress cardiovascular environments.

If you need materials for temporary surgical instruments, stainless steel provides adequate performance at lower costs. For permanent implant applications requiring decades of service, titanium bar joint replacement materials offer unmatched reliability.

Conclusion

Medical titanium bar materials clearly outperform stainless steel across critical parameters including biocompatibility, corrosion resistance, and mechanical performance matching physiological requirements. While stainless steel offers initial cost advantages for temporary applications, titanium provides superior long-term value through reduced revision rates, enhanced patient outcomes, and extended service life.

The choice between materials depends on specific application requirements, regulatory considerations, and total cost of ownership analysis. For permanent implant applications demanding maximum biocompatibility and durability, titanium represents the optimal investment in patient care and device reliability.

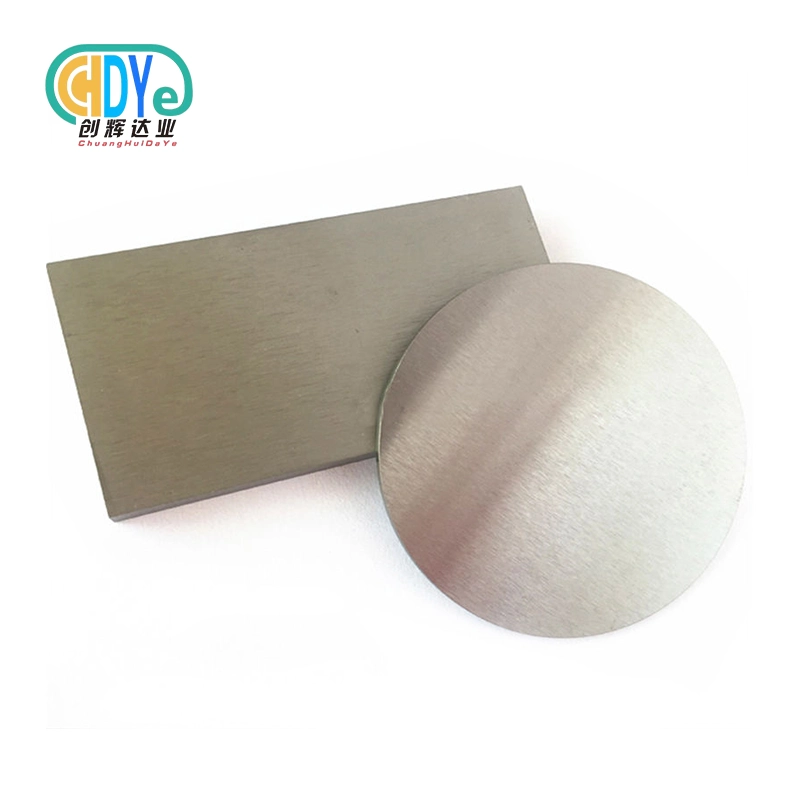

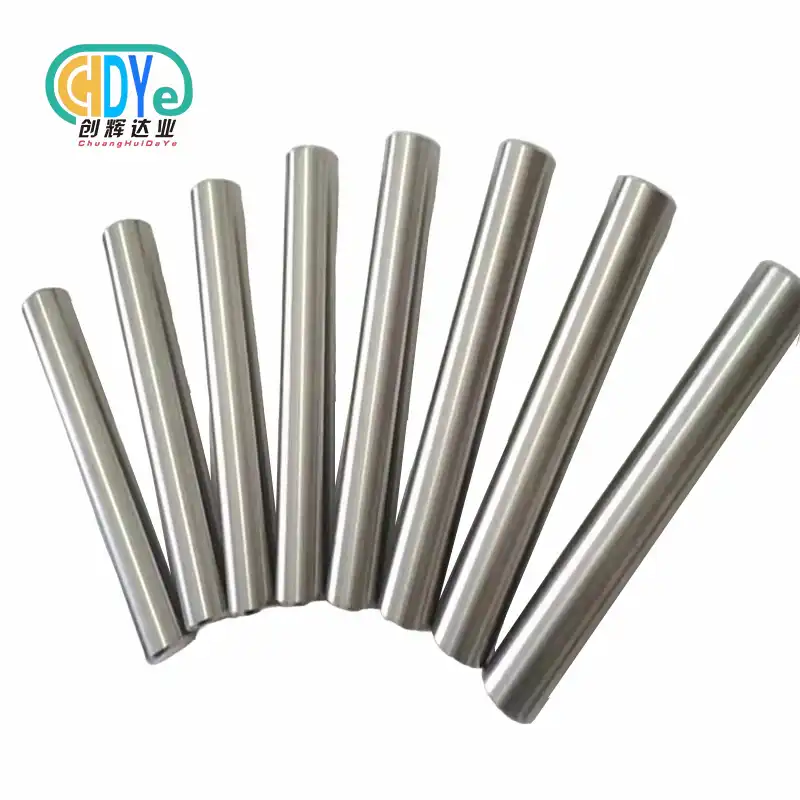

Why Choose Chuanghui Daye Medical Titanium Bar Solutions?

Chuanghui Daye stands out as a leading medical titanium bar manufacturer combining advanced production capabilities with decades of rare metal expertise. Our facility in Shaanxi Province's "Titanium Capital" provides access to premium raw materials and specialized processing equipment designed specifically for medical-grade applications.

Our comprehensive quality management system, certified to ISO 9001:2015 and ISO 13485 standards, ensures every medical titanium bar meets the stringent requirements of global medical device manufacturers. With complete traceability from raw material sourcing through final delivery, you receive documented quality assurance supporting regulatory compliance worldwide.

Whether you need standard dimensions or custom titanium bar implant solutions, our experienced technical team provides rapid prototyping and flexible production capabilities. Ready to elevate your medical device projects with premium titanium solutions? Contact us at info@chdymetal.com for expert consultation and competitive pricing on your specific requirements.

References

1. Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications. Brunette, D.M., et al. Springer-Verlag Berlin Heidelberg, 2001.

2. Biocompatibility of Clinical Implant Materials Volume II. Williams, D.F. CRC Press, 1981.

3. Metals as Biomaterials. Helsen, J.A. and Breme, H.J. John Wiley & Sons, 1998.

4. Titanium Alloys: Properties, Processing and Applications. Peters, M. and Leyens, C. Wiley-VCH, 2003.

5. Medical Device Materials: Proceedings from the Materials and Processes for Medical Devices Conference. ASM International, 2004.

6. Corrosion and Biocompatibility of Metallic Biomaterials. Ryhanen, J. University of Oulu Press, 1999.