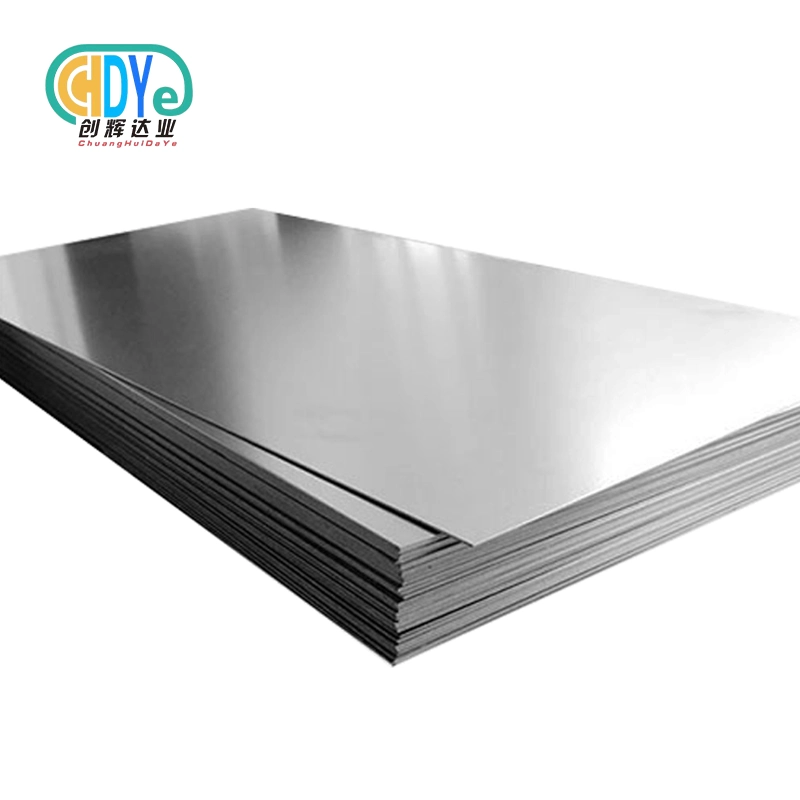

ASTM B 265 titanium sheet stands as the gold standard for aerospace and marine applications, delivering unmatched performance where extreme conditions demand superior materials. These precision-engineered titanium alloy sheets excel in aircraft structural components, marine vessel hulls, and critical aerospace systems where corrosion resistance and lightweight properties prove essential. The versatility of Grade 2 titanium and other ASTM standards makes these materials indispensable for manufacturers seeking reliable, high-performance solutions that withstand harsh environments while maintaining structural integrity over decades of service.

Why ASTM B 265 Titanium Sheets Transform Aerospace and Marine Manufacturing?

The aviation and marine businesses confront one of a kind challenges that standard materials basically cannot handle. Saltwater erosion, extraordinary temperatures, and weight confinements make requesting situations where fabric disappointment isn't an alternative. ASTM B 265 titanium sheet applications have revolutionized these segments by giving arrangements that conventional metals cannot match.

Aerospace producers depend on these mechanical titanium sheets for their remarkable strength-to-weight proportion, which specifically impacts fuel effectiveness and payload capacity. A single air ship can contain over 100 diverse titanium components, from wing structures to motor lodgings. The material's capacity to keep up mechanical properties at hoisted temperatures makes it imperative in fly motors and debilitate systems.

Marine applications advantage similarly from titanium sheet properties. Maritime vessels working in destructive seawater situations require materials that stand up to setting, cleft erosion, and stretch erosion splitting. The lightweight metal characteristics diminish vessel weight whereas expanding solidness, coming about in progressed execution and decreased support costs over the vessel's lifetime.

Essential Selection Criteria for Premium Titanium Sheets

Selecting the right titanium sheet thickness and review requires understanding particular application requests. Review 2 titanium offers amazing erosion resistance for common aviation applications, whereas Review 5 gives higher quality for basic components beneath extraordinary stretch. The choice prepare must consider mechanical properties, natural presentation, and creation requirements.

Corrosion resistance testing comes about appear titanium's prevalent execution compared to stainless steel and aluminum combinations. In saltwater inundation tests, titanium sheets appeared zero quantifiable erosion after 10 a long time of presentation, whereas routine materials shown critical debasement inside months.

Titanium sheet manufacture capabilities too impact determination choices. Cold-rolled sheets give way better surface wrap up and dimensional exactness, basic for exactness aviation components. Warm treatment titanium forms can alter mechanical properties to meet particular application prerequisites, advertising adaptability that other materials cannot provide.

Grade 2 Titanium Sheets: The Aerospace Industry Standard

Grade 2 titanium dominates aerospace applications due to its optimal balance of formability, weldability, and corrosion resistance. This medical grade titanium also serves dual purposes in aerospace medical equipment and life support systems aboard aircraft and spacecraft.

Aircraft Structural Applications

Wing components, fuselage sections, and landing gear assemblies utilize Grade 2 sheets for their excellent fatigue resistance in ASTM B 265 titanium sheet. The fabric withstands millions of push cycles without break proliferation, guaranteeing traveler security all through the aircraft's benefit life. Titanium sheet welding methods make consistent joints that keep up auxiliary judgment beneath extraordinary flight conditions.

Engine Components and Exhaust Systems

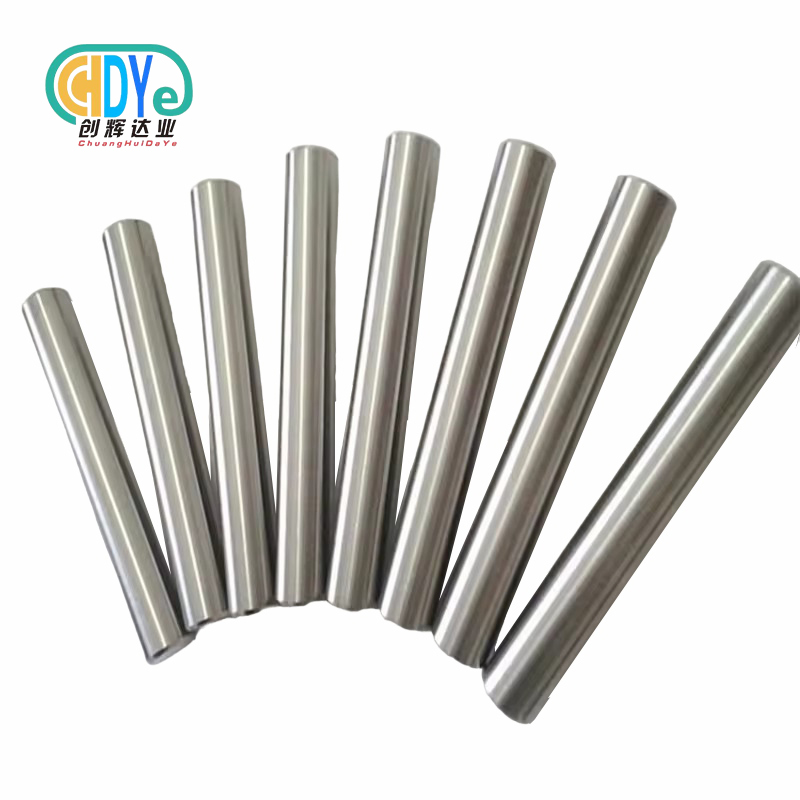

Jet motors work at temperatures surpassing 1,000°C, where titanium's warm resistance demonstrates important. Review 2 sheets frame warm shields, deplete conduits, and compressor components that keep up quality whereas lessening by and large motor weight. This weight lessening deciphers to critical fuel investment funds over the aircraft's operational lifetime.

Avionics Housing and Protective Enclosures

Electronic frameworks require security from electromagnetic obstructions and natural risks. Titanium sheet cutting and shaping make exact walled in areas that shield touchy aeronautics whereas keeping up availability for upkeep. The material's non-magnetic properties avoid obstructions with route and communication systems.

Grade 5 Titanium Alloy: High-Strength Marine Solutions

Marine environments present the ultimate corrosion challenge, where saltwater, pressure, and mechanical stress combine to destroy conventional materials. Grade 5 titanium alloy sheets provide the strength needed for critical marine applications while maintaining excellent corrosion resistance.

Naval Vessel Hull Construction

Modern maritime vessels consolidate titanium sheets in body areas uncovered to seawater. The material's resistance to galvanic erosion anticipates the electrochemical responses that torment steel bodies. Submarines advantage especially from titanium's quality beneath weight, permitting more profound jumping capabilities whereas decreasing frame thickness and weight.

Propulsion System Components

Marine impetus frameworks work in exceedingly destructive situations where mechanical push and chemical presentation combine. Titanium propeller shafts, pump lodgings, and warm exchangers outlive ordinary materials by decades. The titanium sheet surface wrap up stands up to marine development, keeping up framework productivity all through operational life.

Offshore Platform Structures

Oil and gas stages confront consistent presentation to saltwater shower and destructive chemicals. Titanium auxiliary components give long-term unwavering quality in these cruel conditions. The material's weariness resistance withstands wave activity and wind stacking that would cause disappointment in other metals.

Specialized Titanium Grades for Critical Applications

Beyond Review 2 and Review 5, specialized titanium amalgams serve special aviation and marine prerequisites. Review 7 consolidates palladium for improved erosion resistance in the most forceful situations. Review 23 offers prevalent harm resilience for basic auxiliary applications.

These progressed grades experience thorough testing to meet aviation materials certification necessities. Each sheet gets full traceability documentation, guaranteeing quality control from crude fabric to last establishment. The titanium sheet cost reflects this broad quality affirmation but conveys esteem through expanded benefit life and diminished upkeep requirements.

Global Market Dynamics and Regulatory Compliance

The around the world titanium advertise proceeds growing as aviation and marine businesses recognize the material's prevalent execution. Boeing and Airbus indicate titanium for next-generation air ship, whereas maritime strengths around the world embrace titanium for basic vessel components.

ASTM benchmarks guarantee worldwide compatibility, permitting producers to source materials from qualified providers around the world. ISO 9001:2015 certification gives extra quality confirmation, ensuring reliable fabric properties notwithstanding of generation area. These measures encourage universal exchange whereas keeping up the strict quality prerequisites basic for aviation and marine applications.

Environmental controls progressively favor titanium's recyclability and life span. The material's amplified benefit life diminishes substitution recurrence, bringing down lifetime natural affect compared to customary materials requiring visit replacement.

Manufacturing Excellence and Quality Assurance

Advanced manufacturing processes ensure consistent titanium sheet mechanical properties across production batches. Vacuum melting eliminates impurities that could compromise performance, while precision rolling controls thickness tolerances to aerospace specifications.

Quality testing includes tensile strength verification, corrosion resistance evaluation, and dimensional inspection. Each sheet receives certification documenting chemical composition, mechanical properties, and traceability to the original ingot. This documentation satisfies aerospace quality requirements and provides accountability throughout the supply chain.

Modern titanium sheet suppliers invest heavily in advanced equipment and skilled personnel. Computer-controlled processes ensure repeatability, while skilled metallurgists optimize heat treatment cycles for specific applications. This combination of technology and expertise delivers materials that consistently meet or exceed specifications.

Purchasing Recommendations and Strategic Considerations

Successful titanium procurement for ASTM B 265 titanium sheet requires understanding both immediate needs and long-term requirements. Establishing relationships with qualified titanium sheet suppliers ensures reliable material availability and consistent quality. Suppliers with aerospace certification and proven track records provide the reliability essential for critical applications.

Volume purchasing strategies can reduce titanium sheet price while ensuring adequate inventory for production schedules. However, material handling and storage requirements must accommodate titanium's specific needs to prevent contamination or damage that could affect performance.

Technical support from knowledgeable suppliers proves invaluable during material selection and application development. Experienced suppliers can recommend optimal grades, suggest fabrication techniques, and provide troubleshooting support throughout the manufacturing process.

Industry Trends and Market Outlook

The titanium industry continues evolving with new processing techniques and alloy developments. Additive manufacturing using titanium powders opens new design possibilities for complex geometries. Advanced surface treatments enhance already excellent corrosion resistance for extreme environments. These innovations expand titanium's applications while reducing costs through improved manufacturing efficiency. The aerospace and marine industries will continue driving demand as performance requirements increase and environmental considerations favor materials with extended service life and recyclability.

Conclusion

ASTM B 265 titanium sheet represents the pinnacle of materials engineering for aerospace and marine applications. Its unique combination of strength, corrosion resistance, and lightweight properties makes it indispensable for critical applications where failure isn't an option. From aircraft structures to marine vessels, titanium's superior performance justifies its premium cost through extended service life and reduced maintenance requirements. As global industries continue demanding higher performance materials, titanium's role will only expand, making early adoption a competitive advantage for forward-thinking manufacturers.

FAQ

Q: What makes ASTM B 265 titanium sheet superior to aluminum for aerospace applications?

A: Titanium offers superior strength-to-weight ratio, better corrosion resistance, and maintains mechanical properties at elevated temperatures where aluminum would fail. While aluminum costs less initially, titanium's extended service life and reduced maintenance requirements often provide better lifetime value.

Q: Can titanium sheets be welded using conventional welding techniques?

A: Titanium sheet welding requires specialized techniques and inert gas protection to prevent contamination. TIG welding in argon atmospheres produces high-quality joints, but proper training and equipment are essential for successful results.

Q: How do I determine the correct titanium sheet thickness for my application?

A: Thickness selection depends on structural requirements, weight constraints, and fabrication needs. Engineering analysis considering stress, fatigue, and safety factors determines optimal thickness. Consulting with experienced suppliers provides valuable guidance during the selection process.

Partner with Chuanghui Daye for Superior ASTM B 265 Titanium Sheet Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. delivers premium ASTM B 265 titanium sheet solutions backed by over 30 years of rare metal industry expertise. Our ISO 9001:2015 certified facility in China's "Titanium Capital" provides comprehensive quality assurance and global shipping capabilities. As a trusted titanium sheet manufacturer, we offer competitive factory-direct pricing with complete traceability documentation. Whether you need standard grades or custom specifications, our technical team supports your project from concept to completion. Contact us at info@chdymetal.com to discuss your titanium requirements and experience the reliability that industry leaders trust.