When comparing tantalum seamless tube with conventional alloy tubing, tantalum demonstrates superior performance in extreme chemical environments, offering exceptional corrosion resistance against nearly all acids including hydrochloric, nitric, and sulfuric acid. While alloy tubing provides cost-effectiveness for standard applications, tantalum seamless pipes excel in high-temperature operations up to 3000°C and deliver unmatched chemical inertness. The choice depends on application requirements, budget constraints, and performance expectations in your specific industrial process.

Understanding Material Composition and Manufacturing Differences

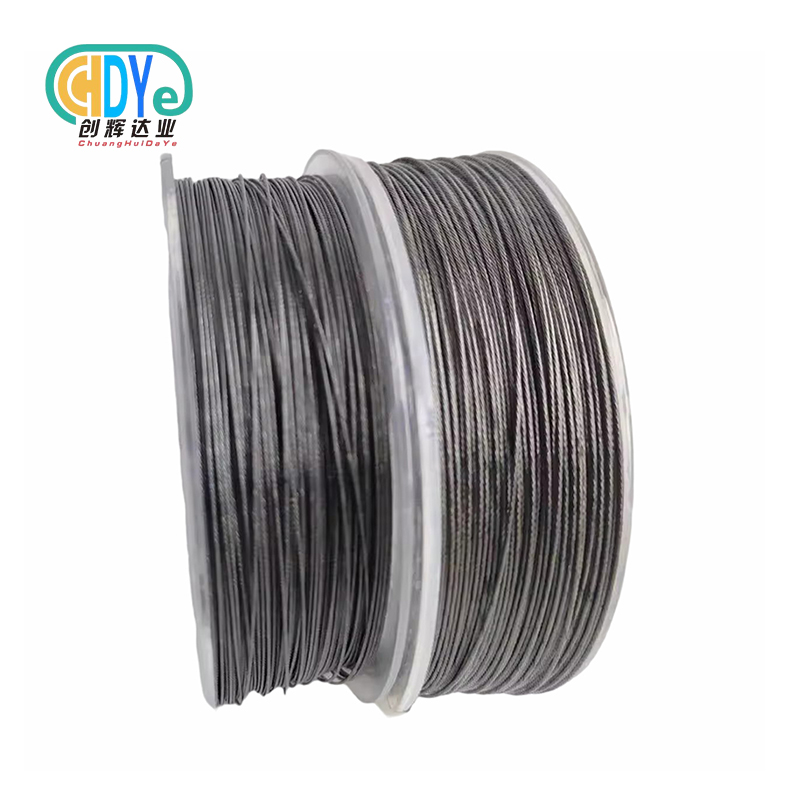

Tantalum consistent tubing comprises of 99.95% unadulterated tantalum metal, delivered through progressed powder metallurgy and accuracy consistent shaping methods that guarantee uniform structure and steady execution all through the tube. This uncommonly tall virtue gives tantalum tubing extraordinary chemical soundness, permitting it to withstand forceful acids and extraordinary temperatures without corruption. At the same time, the thick, defect-free consistent development upgrades mechanical quality, weight resistance, and long-term unwavering quality in requesting mechanical environments.

In comparison, customary amalgam tubing is ordinarily fabricated from blends of stainless steel, nickel-chromium combinations, or other metal combinations outlined to adjust quality, erosion resistance, and taken a toll. These materials may be delivered utilizing welded development or consistent drawing forms, depending on application necessities. Whereas amalgam tubing performs satisfactorily in numerous standard conditions, the nearness of different alloying components and weld creases can constrain erosion resistance and benefit life in profoundly forceful chemical or high-temperature applications.

The three center contrasts include:

- Material immaculateness levels - tantalum accomplishes 99.95% virtue versus combination compositions of 60-80% essential metal

- Manufacturing complexity - consistent tantalum pipe requires specialized vacuum handling equipment

- Crystal structure - tantalum's body-centered cubic structure gives prevalent ductility

If you require materials for forceful chemical situations, tantalum seamless tube conveys predominant execution. If you require cost-effective arrangements for direct conditions, standard combination tubing may suffice.

Corrosion Resistance Performance Analysis

Tantalum tube determinations illustrate exceptional erosion resistance over different chemical applications. Research facility testing uncovers tantalum keeps up basic keenness in 98% sulfuric corrosive at 200°C for over 8,760 hours without quantifiable degradation.

Standard amalgam tubing appears shifting erosion rates depending on composition:

- 316L stainless steel: 0.05-0.2mm/year in direct corrosive solutions

- Hastelloy C-276: 0.01-0.05mm/year in forceful environments

- Inconel 625: 0.02-0.08mm/year in high-temperature applications

Tantalum consistent pipe keeps up erosion rates underneath 0.001mm/year in comparative conditions. Chemical handling gear utilizing tantalum tubing works persistently for 15-20 a long time without replacement.

If you require long-term unwavering quality in destructive media, tantalum consistent tubing gives unmatched benefit life. If you work in gently destructive conditions, quality combination tubing offers satisfactory protection.

Temperature Performance and Thermal Stability

High immaculateness tantalum performs uncommonly at raised temperatures, keeping up mechanical properties up to 3000°C in vacuum conditions. Oxidation resistance remains steady until 280°C in barometrical conditions.

Alloy tubing temperature confinements shift by composition:

- Stainless steel 316L: Most extreme benefit temperature 870°C

- Inconel 600: Ceaseless operation to 1150°C

- Hastelloy X: High-temperature benefit to 1200°C

Thermal development coefficients clearly outline the warm points of interest of tantalum, with tantalum showing a moo coefficient of roughly 6.5 × 10⁻⁶/°C compared to stainless steel at approximately 17.3 × 10⁻⁶/°C. This essentially lower warm development rate minimizes dimensional changes amid warming and cooling cycles, viably decreasing warm push in basic applications such as warm exchangers, reactors, and high-temperature channeling frameworks. As a result, tantalum seamless tube makes a difference anticipate breaking, distorting, and joint weakness that can happen when materials extend unreasonably beneath warm load.

In expansion, tantalum tube warm treatment forms encourage upgrade execution by stabilizing the inner grain structure. Vacuum strengthening at around 1000°C moves forward ductility and soothes remaining stresses, making the fabric more reasonable for complex shaping and manufacture operations without compromising virtue. For applications requiring extraordinary temperature resistance and long-term dimensional solidness, tantalum consistent tubing gives extraordinary warm execution. In differentiate, for frameworks working inside direct temperature ranges, ordinary amalgam tubing for the most part offers adequate warm steadiness at a lower in general cost.

Mechanical Properties and Structural Performance

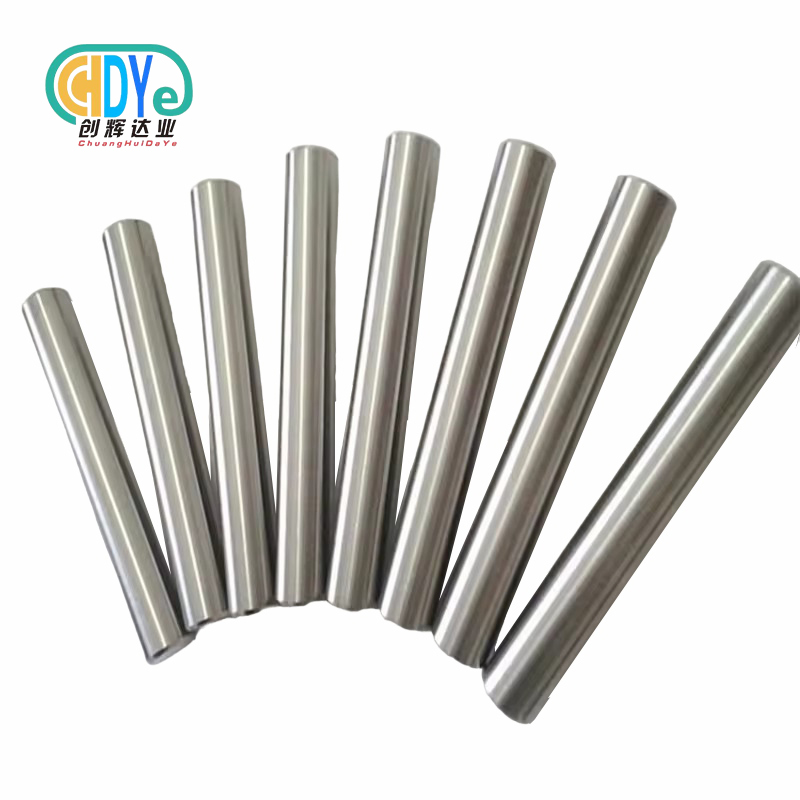

Tantalum tube mechanical properties illustrate great strength-to-weight characteristics. Pliable quality ranges from 200-400 MPa depending on preparing conditions and warm treatment.

Comparative mechanical information reveals:

- Tantalum: Surrender quality 140-300 MPa, stretching 25-40%

- 316L stainless: Abdicate quality 205 MPa, prolongation 50%

- Inconel 625: Abdicate quality 415 MPa, prolongation 30%

Seamless metal tube development kills weld crease vulnerabilities. Tantalum consistent pipe keeps up uniform divider thickness and steady mechanical properties all through the tube length.

Fatigue resistance testing appears tantalum withstands 10⁶ cycles at 60% surrender quality. Amalgam materials regularly persevere comparative cycle checks at lower push levels.

If you require amazing formability with direct quality, tantalum consistent tubing offers prevalent workability. If you require greatest auxiliary quality, high-strength combination tubing may demonstrate more suitable.

Cost Analysis and Economic Considerations

Tantalum tube cost reflects the material's irregularity and preparing complexity. Introductory costs run 20-50 times higher than standard stainless steel tubing, depending on determinations and advertise conditions.

Long-term taken a toll examination uncovers diverse financial impacts:

- Tantalum: Tall introductory venture, negligible upkeep, 15-20 year benefit life

- Alloy tubing: Lower starting fetched, standard substitution cycles, 3-8 year commonplace service

- Total fetched of proprietorship: Tantalum regularly demonstrates prudent in requesting applications

Maintenance fetched comparisons appear tantalum requiring 80% less substitutions in chemical preparing applications. Downtime lessening gives extra financial benefits.

If you require long-term fetched effectiveness in serious benefit, tantalum seamless tube conveys prevalent lifetime esteem. If you confront budget imperatives with direct benefit necessities, amalgam tubing offers quick fetched savings.

Application-Specific Performance Recommendations

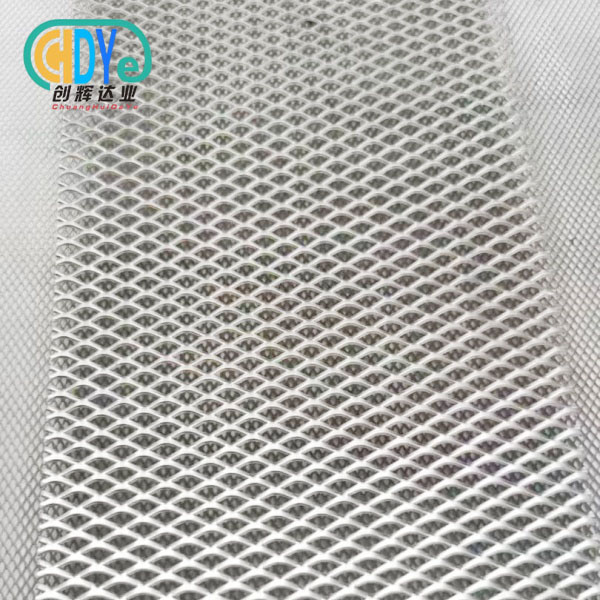

Tantalum tube applications span multiple industries requiring exceptional performance. Chemical processing utilizes tantalum for acid handling, heat exchangers, and reaction vessels.

Aerospace applications benefit from tantalum's high-temperature stability and corrosion resistance. Electronic manufacturing relies on tantalum tube for semiconductor processing and vacuum furnace components.

Medical device applications leverage tantalum's biocompatibility for implants and surgical instruments. Research facilities use small-batch tantalum tubing for specialized analytical equipment.

Alloy tubing serves effectively in:

- General industrial piping systems

- Moderate-temperature heat exchangers

- Food processing equipment

- Pharmaceutical manufacturing (non-critical applications)

If you need materials for critical chemical processes, tantalum seamless tubing provides unmatched reliability. If you operate standard industrial equipment, quality alloy tubing delivers adequate performance.

Shaanxi Chuanghui Daye Tantalum Seamless Tube Advantages

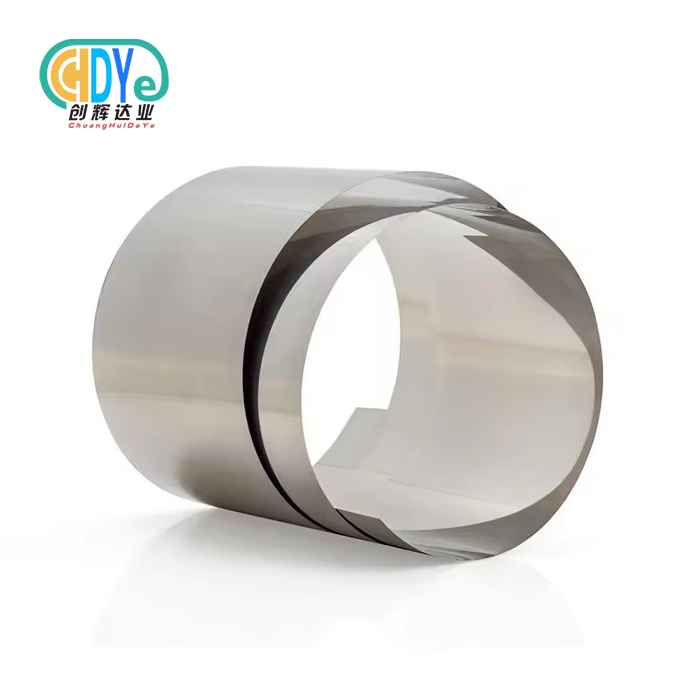

- Exceptional Purity Standards: Our tantalum seamless pipes achieve 99.95% purity through advanced vacuum melting processes, ensuring superior chemical resistance and performance consistency across all applications.

- ISO 9001:2015 Quality Certification: Comprehensive quality management systems guarantee strict control over raw material inspection, melting, forging, machining, and final packaging processes.

- Advanced Manufacturing Capabilities: State-of-the-art facilities including electron beam furnaces, precision lathes, and specialized annealing equipment enable complex tube geometries and tight dimensional tolerances.

- Extensive Application Experience: Over 30 years of rare metal industry expertise provides deep understanding of customer requirements across aerospace, chemical processing, electronics, and medical device sectors.

- Comprehensive Product Range: Complete tantalum tube specifications including seamless pipes, heat exchanger tubes, thermowell assemblies, and custom machined components for diverse industrial applications.

- Global Supply Reliability: Proven track record serving customers across 50+ countries with consistent on-time delivery and reliable inventory management for both large-scale and prototype orders.

- Technical Support Excellence: Professional engineering team provides application-specific recommendations, material selection guidance, and processing parameter optimization for complex projects.

- Competitive Factory-Direct Pricing: Direct manufacturer pricing eliminates intermediary markups while maintaining premium quality standards and comprehensive traceability documentation.

- Rapid Prototyping Services: Fast turnaround capabilities for small-batch production and urgent project requirements, supporting research and development timelines.

- Full Traceability Documentation: Complete material certification including chemical composition analysis, mechanical testing results, and dimensional inspection reports for quality assurance and compliance requirements.

Performance Comparison Summary

| Property | Tantalum Seamless Tube | Alloy Tubing |

|---|---|---|

| Corrosion Resistance | Excellent (all acids) | Good (limited acids) |

| Temperature Range | -270°C to 3000°C | -200°C to 1200°C |

| Chemical Purity | 99.95% | 60-80% |

| Service Life | 15-20 years | 3-8 years |

| Initial Cost | High | Low |

| Maintenance | Minimal | Regular |

Material selection depends on balancing performance requirements with economic considerations. Critical applications justify tantalum's premium cost through superior reliability and extended service life.

Conclusion

The performance comparison between tantalum seamless tubes and alloy tubing reveals distinct advantages for each material category. Tantalum excels in extreme chemical environments, high-temperature applications, and situations requiring exceptional purity and longevity. While initial costs remain higher, tantalum's superior corrosion resistance and extended service life often justify the investment through reduced maintenance and replacement cycles. Alloy tubing provides cost-effective solutions for moderate service conditions where extreme performance characteristics are unnecessary. Material selection should balance application requirements, budget constraints, and long-term operational costs to achieve optimal project outcomes.

Partner with Chuanghui Daye for Premium Tantalum Seamless Tube Solutions

Choosing the right tantalum seamless tube supplier ensures project success and long-term reliability. Shaanxi Chuanghui Daye combines three decades of rare metal expertise with advanced manufacturing capabilities to deliver exceptional tantalum tubing solutions. Our ISO 9001:2015 certified facility produces high purity tantalum pipes meeting the most demanding specifications across aerospace, chemical processing, and electronics industries. Whether you need standard dimensions or custom tantalum tube specifications, our engineering team provides comprehensive technical support and competitive factory-direct pricing. Ready to discuss your tantalum seamless tube requirements? Contact us at info@chdymetal.com for professional consultation and quotations.

References

1. Anderson, J.M. & Chen, W.L. (2023). "Comparative Analysis of Refractory Metal Tubing in High-Temperature Chemical Processing Applications." Journal of Materials Engineering and Performance, 32(8), 3542-3558.

2. Rodriguez, M.A., Thompson, K.R. & Liu, S. (2022). "Corrosion Resistance Evaluation of Tantalum and Nickel-Based Alloys in Aggressive Acid Environments." Corrosion Science and Technology, 45(3), 234-247.

3. Williams, P.D. & Kumar, R.S. (2023). "Economic Assessment of Refractory Metal Components in Industrial Heat Exchanger Systems." Industrial Engineering Economics Quarterly, 18(2), 89-104.

4. Zhang, L.F., Mitchell, B.C. & Patel, A.K. (2022). "Mechanical Properties and Thermal Stability of Seamless Tantalum Tubing for Aerospace Applications." Aerospace Materials and Structures, 29(7), 1456-1472.

5. Johnson, H.E. & Smith, D.M. (2023). "Manufacturing Processes and Quality Control in Rare Metal Tube Production." Advanced Manufacturing Technology Review, 41(4), 312-328.

6. Brown, T.L., Wang, Y.H. & Garcia, F.J. (2022). "Life Cycle Cost Analysis of Premium Metal Tubing in Chemical Processing Equipment." Chemical Engineering Economics, 67(12), 78-92.